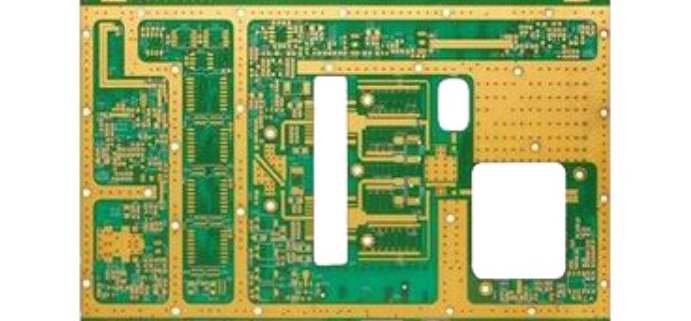

In the world of electronics, PCB materials play a crucial role in determining the performance, durability, and cost-effectiveness of electronic devices. Printed Circuit Boards (PCBs) are the backbone of nearly all modern electronics, connecting components and ensuring proper signal flow. Among the various PCB materials available, FR4 PCB, Rogers PCB, and Aluminum PCB are three of the most commonly used. Each of these materials has unique properties that make them suitable for different applications. FR4 PCB is widely used due to its affordability and reliable performance in general electronics. Rogers PCB, on the other hand, is known for its superior high-frequency performance, making it ideal for specialized applications like RF circuits and telecommunications. Lastly, Aluminum PCB offers excellent thermal management, making it perfect for high-power applications such as LED lighting. This article will compare the differences between these materials and explore their respective applications in various industries.

In PCB (Printed Circuit Board) manufacturing, the choice of substrate material is crucial as it directly affects the performance and application of the circuit board. Substrate materials determine the mechanical strength, electrical performance, heat dissipation, and manufacturing cost of the PCB. Common substrate materials include organic substrates and ceramic substrates, with the debate of “ceramic vs organic substrate” being widely discussed in the industry. Ceramic substrates are favored in high-power and high-frequency applications due to their excellent thermal conductivity, high-temperature resistance, and signal integrity. On the other hand, organic substrates, such as FR-4, are more cost-effective and easier to manufacture, making them suitable for a wide range of consumer electronics. Understanding the key differences in “ceramic vs organic substrate” helps designers make informed decisions, ensuring optimal stability and performance of the PCB in specific applications.

Arlon is a renowned brand in the electronics industry, recognized for its high-performance substrates used in a wide range of applications. With decades of expertise, Arlon has established itself as a leader in the development of advanced materials designed for printed circuit boards (PCBs). The company’s substrates, known for their exceptional electrical, thermal, and mechanical properties, are widely used in industries such as telecommunications, aerospace, medical electronics, and more. As the demand for higher performance and reliability in electronic devices grows, these materials continue to play a critical role in meeting these challenges. This article aims to explore the different types of Arlon substrate, delve into their key features, and examine their applications in various sectors. Whether you’re working with flexible circuits, thermal management systems, or high-frequency designs, understanding Arlon’s materials is essential for making informed material choices in modern PCB design.

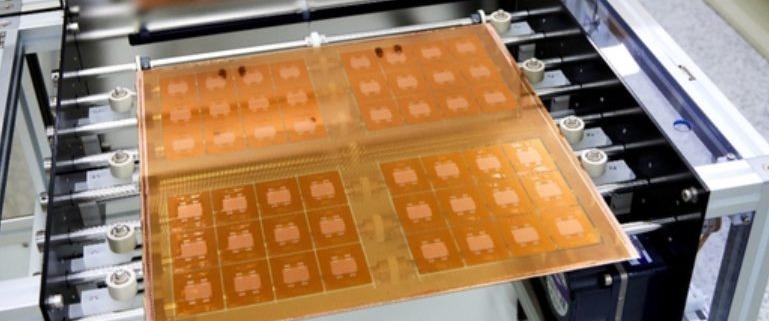

Aluminum substrates are essential materials used in various industries due to their unique properties. These thin, flat aluminum layers serve as a reliable base in applications ranging from electronics to construction and signage. Known for their lightweight nature, high thermal and electrical conductivity, and corrosion resistance, they play a critical role in many sectors.

In electronics, they are used for heat dissipation in devices like LEDs and power modules. In construction, aluminum substrates are utilized in cladding and roofing, while in signage, their durability makes them ideal for advertising boards.

This blog delves into the features, types, advantages, and challenges associated with aluminum substrates, providing a comprehensive understanding of their significance and potential in modern industries.

In the semiconductor industry, glass substrates are emerging as a next-generation material for advanced packaging and interconnects, offering advantages over traditional materials like silicon and ceramics. With superior properties such as higher thermal conductivity, better electrical insulation, and enhanced dimensional stability, glass substrates are ideal for high-performance applications, particularly in miniaturized and complex IC designs driven by chiplet technologies. Absolics stands at the forefront of this innovation, pioneering the development and manufacturing of glass substrates that enable improved performance and scalability in semiconductor packaging. Through cutting-edge technology and strategic collaborations, Absolics has established itself as a leader in the field, making Absolics glass substrate a crucial component in the next generation of electronic devices and systems.

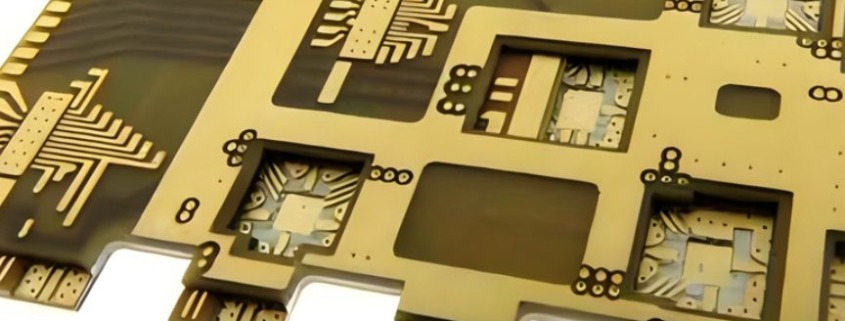

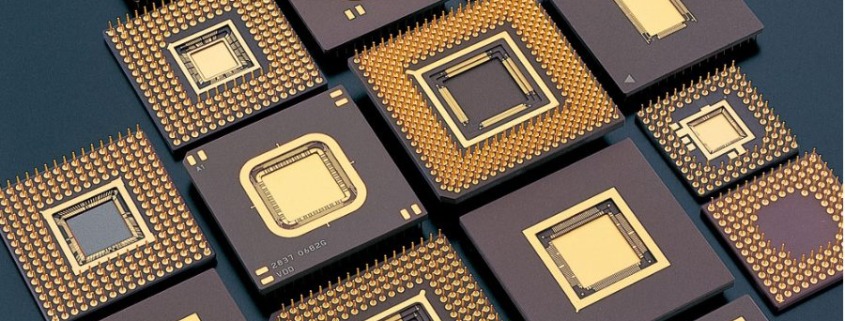

Ceramic substrates are essential components in a wide range of electronic applications, including power electronics, high-frequency circuits, and IC packaging. These substrates, typically made from materials like alumina and RF ceramics, provide a stable platform for mounting electronic components while offering excellent thermal and electrical properties. The ceramic substrate thickness plays a crucial role in the overall performance and durability of these electronic devices. It directly impacts heat dissipation, mechanical strength, and electrical insulation. In applications where high heat resistance is needed, thicker ceramic substrates are often used to ensure efficient heat management. On the other hand, thinner ceramic substrates are favored in high-frequency applications where signal integrity and miniaturization are key. Understanding the ceramic substrate thickness is essential for optimizing both the performance and longevity of electronic devices, as it affects not only the physical robustness but also the efficiency of thermal and electrical functions in these systems.

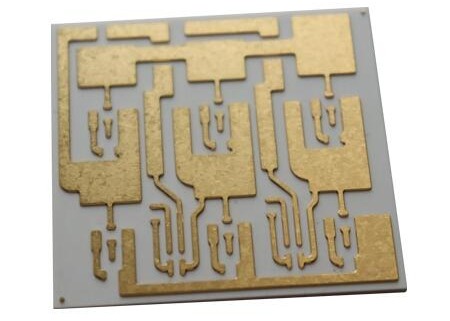

LTCC (Low-Temperature Co-Fired Ceramic) technology is a cutting-edge manufacturing process used to create high-performance ceramic substrates. This technology has evolved over the years, enabling the production of multi-layered ceramic packages that meet the demanding requirements of modern electronics. LTCC substrates are essential in semiconductor packaging due to their excellent thermal conductivity, low dielectric loss, and ability to support high-frequency applications. These qualities make LTCC an ideal material for advanced electronic devices, ensuring efficient performance in various sectors. The ceramic substrate LTCC group has found significant use in RF (Radio Frequency) applications, where high-frequency performance is crucial. Additionally, LTCC substrates are widely utilized in power electronics, automotive systems, and communications, where reliability and performance are key. With its versatility and high reliability, LTCC technology continues to be a cornerstone in the development of next-generation electronic devices and systems.

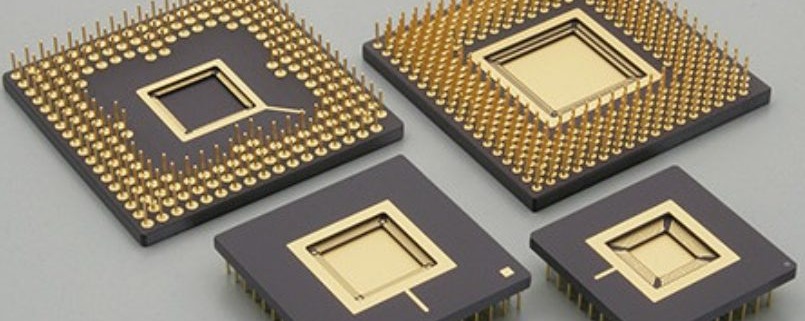

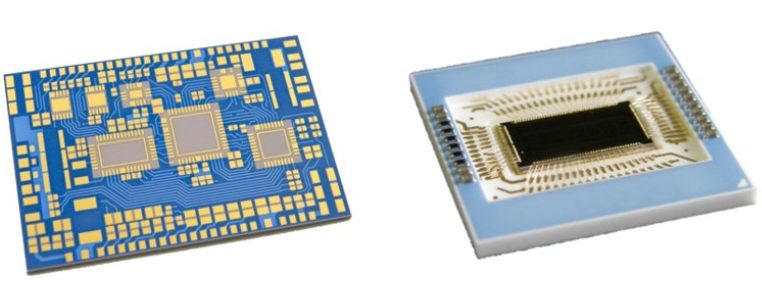

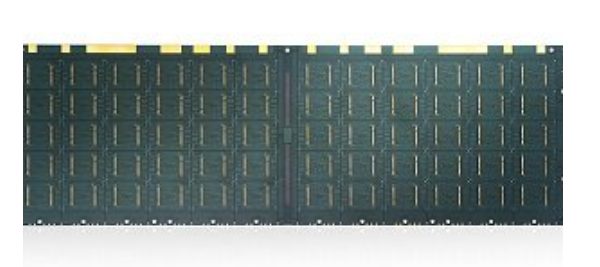

IC substrates are critical components in modern electronic devices, serving as the foundation for integrated circuits (ICs). These substrates provide essential support for chips, enabling electrical connections and facilitating heat dissipation. As electronic devices become smaller, faster, and more powerful, the role of IC substrate material has become even more significant. It ensures reliable performance by maintaining the mechanical stability and electrical integrity of the chip. Moreover, the IC substrate material plays a crucial role in heat management, preventing overheating, which is vital for the longevity and efficiency of devices. Additionally, IC substrates support advanced packaging technologies such as 3D stacking and high-density interconnects (HDI), which are essential for next-generation microelectronics. As technology evolves, the demand for more advanced IC substrate materials grows, making them an integral part of cutting-edge electronic applications in fields like telecommunications, automotive electronics, and consumer gadgets.

An IC substrate is a crucial material that supports and connects the components of an integrated circuit (IC), ensuring proper electrical connectivity and efficient heat dissipation. Its role is vital in determining the performance, reliability, and durability of an IC. Without a high-quality substrate, an IC would face challenges such as poor thermal management and signal integrity issues. The process of how IC substrates are made involves selecting materials like ceramics, metals, and organic laminates, followed by a multi-step manufacturing procedure that includes material preparation, lamination, etching, and testing. These steps are designed to create a substrate that can support the IC while meeting strict electrical and mechanical requirements. Ultimately, the quality of the substrate plays a significant role in enhancing the overall performance and longevity of the integrated circuit in various applications.

IC substrates, or integrated circuit substrates, are vital components in the semiconductor industry, providing mechanical support, electrical connections, and thermal management for integrated circuits (ICs) in electronic devices. These substrates play a crucial role in integrated circuit packaging by ensuring the secure mounting of IC chips and facilitating their seamless interaction with other electronic components. China plays a significant role in the global IC substrate market, driven by its robust manufacturing capabilities and increasing expertise. As the demand for advanced electronics continues to grow, China’s manufacturers, such as EFPCB and RayPCB, have become key contributors to the global supply of China IC substrates, supporting industries ranging from consumer electronics to telecommunications and automotive. Their contributions are vital in meeting the growing global need for high-quality IC substrates.

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Understanding the Benefits of Polyimide Flexible PCB Technology2025-06-03 - 3:17 上午

Understanding the Benefits of Polyimide Flexible PCB Technology2025-06-03 - 3:17 上午 Building a Custom Keyboard with a Keyboard Flexible PCB2025-05-30 - 3:22 上午

Building a Custom Keyboard with a Keyboard Flexible PCB2025-05-30 - 3:22 上午 Advantages of Using FPC Flexible PCB in Modern Electronics2025-05-29 - 4:20 上午

Advantages of Using FPC Flexible PCB in Modern Electronics2025-05-29 - 4:20 上午 Essential Design Guidelines for Flexible Rigid PCB Success2025-05-28 - 3:28 上午

Essential Design Guidelines for Flexible Rigid PCB Success2025-05-28 - 3:28 上午