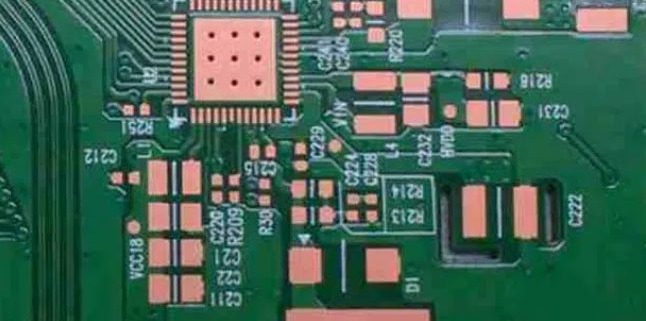

In PCB (Printed Circuit Board) manufacturing, the choice of surface finish plays a crucial role in ensuring the performance and reliability of the final product. One such widely used surface finish is OSP (Organic Solderability Preservative), which has gained popularity due to its excellent soldering properties and cost-effectiveness. OSP substrate provides a thin organic coating on the copper surface, which prevents oxidation and preserves the solderability of the PCB during the manufacturing process. This eco-friendly surface treatment is not only free from toxic materials but also helps in maintaining the integrity of the soldering process. By offering superior protection against oxidation, OSP ensures that the PCB remains easy to solder even after long storage periods, thus enhancing the overall reliability of the final product. As a result, OSP substrate is increasingly favored by manufacturers seeking to deliver high-quality, environmentally conscious PCB solutions.

OLED (Organic Light Emitting Diode) technology has revolutionized the display industry, offering vibrant colors, high contrast, and ultra-thin designs. OLED displays are widely used in various consumer electronics, including smartphones, televisions, and wearable devices. One of the key factors driving the success of OLED technology is its reliance on OLED glass substrates. These substrates serve as the foundation for OLED displays, providing both structural integrity and essential optical properties. The glass substrate ensures the display’s transparency, while also offering excellent thermal stability and mechanical strength to support the delicate OLED layers. Without a high-quality OLED glass substrate, the performance, longevity, and overall durability of OLED displays would be significantly compromised. As OLED technology continues to evolve, the role of OLED glass substrates becomes even more critical, enabling innovations in flexible, transparent, and ultra-thin display designs.

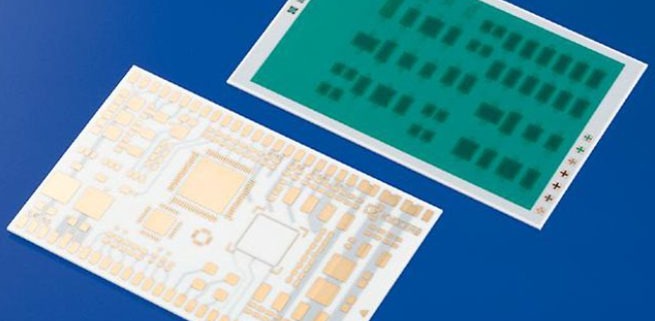

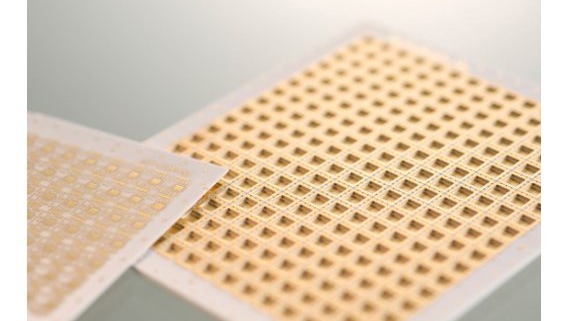

A multilayer substrate is a type of material used in electronic components and systems, consisting of multiple layers of insulating and conductive materials. These layers are stacked and bonded together to form a substrate that can support complex circuits. Multilayer substrates are essential in modern electronics and PCB (Printed Circuit Board) technology, enabling the creation of high-performance, compact devices.

In the electronics industry, substrates come in various types, including ceramic, metal, and organic materials. Ceramic substrates, such as alumina and ALN, are used for high-frequency and high-power applications. Metal substrates, like aluminum and copper, are often used in power electronics for heat dissipation. Organic substrates, such as FR4, are common in general consumer electronics.

The use of multilayer substrates is critical in enhancing the performance, miniaturization, and functionality of electronic devices. They allow for denser circuits, better thermal management, and improved overall reliability, making them indispensable in today’s advanced electronics.

A material substrate is a fundamental component used across various industries, providing the necessary support and foundation for other materials or components. In electronics, for instance, substrates are used in printed circuit boards (PCBs) to support the electrical components, while in construction, they form the structural basis of walls and floors. In the textile industry, substrates serve as the base for printing and coating processes. The significance of material substrates cannot be overstated, as they are essential for ensuring stability, durability, and functionality in many applications. In this article, we will explore the different types of material substrates, including PCB substrates, ceramic substrates, and textile substrates. Additionally, we will delve into their diverse applications in electronics, construction, and textiles, showcasing their importance in modern manufacturing and design. Understanding the various material substrates will offer insights into their crucial role in innovation and industry development.

LTCC (Low-Temperature Co-fired Ceramic) substrates have become a key material in modern electronic technologies due to their unique ability to integrate high-performance circuits into compact, reliable solutions. The LTCC multilayer substrate offers significant advantages, particularly in RF (Radio Frequency) and high-frequency applications, where minimizing signal loss and ensuring high-performance conductivity are crucial. By utilizing ceramic materials that are co-fired at lower temperatures, LTCC technology enables the creation of multi-layered circuits with embedded components, reducing both size and complexity while enhancing electrical performance.

This article will explore the essential aspects of LTCC technology, including the materials used in its construction, the differences between LTCC and HTCC (High-Temperature Co-fired Ceramic), and how LTCC substrates are manufactured. We will also highlight the critical role of LTCC multilayer substrate in RF applications, demonstrating how this technology is transforming the way high-frequency circuits are designed and integrated into modern electronic devices.

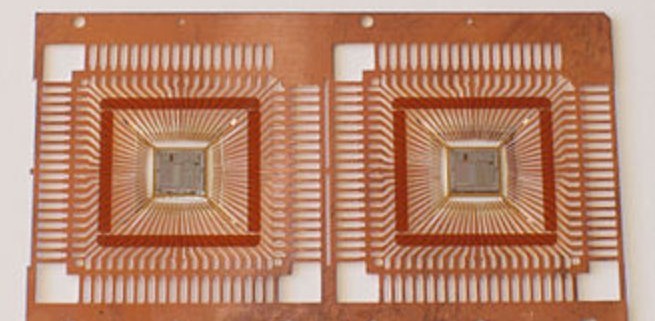

As semiconductor devices become smaller, faster, and more energy-efficient, packaging technology has quietly undergone a transformation. The shift from leadframe-based IC packaging to substrate-based packaging represents one of the most critical shifts in semiconductor packaging.

This article will delve into leadframe and substrate packaging—what they are, how they are manufactured, and the advantages they offer in modern semiconductor manufacturing.

Intel glass substrates represent a groundbreaking innovation in semiconductor packaging technology, playing a pivotal role in the development of next-generation processors. Traditional organic substrates have long been used for chip packaging, but Intel glass substrates are set to revolutionize the industry by offering superior performance, higher density, and greater scalability. The key advantage of glass substrates lies in their ability to improve chip performance, reduce power consumption, and enhance thermal management, which are critical factors for advanced semiconductor applications. As part of Intel’s 2030 roadmap, the company plans to transition from conventional organic materials to Intel glass substrates, pushing the boundaries of chip performance and enabling the integration of up to 1 trillion transistors per chip. This shift marks a significant milestone in Intel’s ongoing efforts to lead the way in semiconductor technology, shaping the future of high-performance computing and driving the next wave of innovation in the industry.

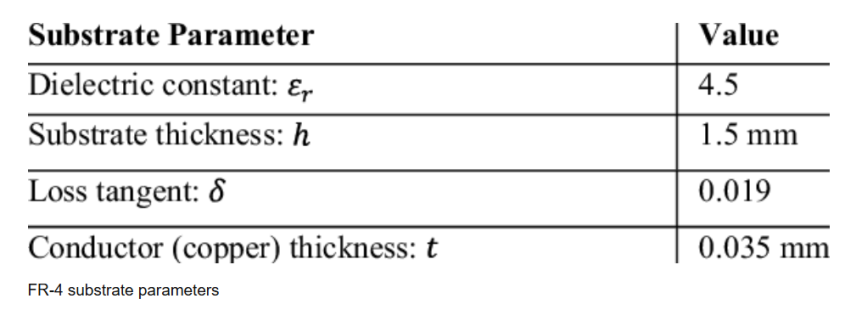

FR4 is one of the most widely used materials in the printed circuit board (PCB) industry due to its excellent properties and versatility. Commonly recognized for its reliability, FR4 serves as the backbone of many electronic devices, providing mechanical support and electrical insulation for PCB components. The FR4 substrate full form is “Flame Retardant 4,” which highlights its flame-resistant nature. This property makes it an ideal choice for electronic applications requiring high safety standards and thermal stability.

In this article, we will explore the origins of the name FR4, its material composition, and the technical specifications that make it a preferred choice for PCB manufacturing. Additionally, we will delve into its role in various applications, from consumer electronics to industrial control systems, showcasing why it remains an indispensable material in modern electronics. Through this guide, you’ll gain a comprehensive understanding of the FR4 substrate.

FR4 material is widely used in the electronics industry for its cost-effectiveness, mechanical strength, and excellent electrical insulating properties. It is a composite of epoxy resin and woven glass fiber, offering durability and thermal stability, making it ideal for a wide range of electronic applications. An FR4 epoxy substrate is a specific type of FR4 material commonly used in PCB (Printed Circuit Board) manufacturing, providing a stable foundation for electronic circuits. It ensures reliable performance across various temperatures and electrical conditions, making it essential in high-demand applications such as consumer electronics, telecommunications, and automotive industries. The unique properties of FR4 epoxy substrates, including thermal resistance, electrical insulation, and mechanical strength, enable them to meet the rigorous demands of these industries, ensuring both reliability and performance in complex electronic systems.

FR4 is one of the most widely used materials in printed circuit board (PCB) manufacturing due to its excellent mechanical strength, cost-effectiveness, and electrical insulation properties. It is a composite material consisting of woven glass fiber and epoxy resin, making it ideal for a variety of electronic applications. However, understanding the dielectric constant of FR4 is crucial for achieving optimal PCB performance, particularly in high-speed and high-frequency designs. The dielectric constant directly influences signal propagation speed and impedance control, making it a key factor in ensuring signal integrity. Variations in the dielectric constant of FR4 substrate across different frequencies can lead to signal loss and degraded performance, especially in advanced applications. This article will focus on explaining the dielectric constant of FR4, its behavior over varying frequencies, and its impact on PCB design, helping designers make informed material selections for their electronic projects.

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午