FC-BGA Substrates: Revolutionizing Semiconductor Packaging

Ball Grid Array (BGA) substrates serve as pivotal components in modern semiconductor packaging, facilitating the interconnection of integrated circuits (ICs) to printed circuit boards (PCBs). These substrates provide a stable platform for mounting ICs and transferring electrical signals efficiently. Amidst the landscape of semiconductor packaging, FC-BGA substrates emerge as a notable advancement. FC-BGA, or Flip Chip Ball Grid Array, represents a cutting-edge approach in semiconductor packaging technology. It integrates flip chip technology with the traditional BGA architecture, offering enhanced performance, reliability, and compactness. In this comprehensive guide, we delve into the intricacies of FC-BGA substrates, elucidating their composition, manufacturing process, advantages, and applications in the semiconductor industry.

What is an FC-BGA Substrate?

An FC-BGA Substrate (Flip-Chip Ball Grid Array Substrate) is a high-density interconnect substrate used in advanced semiconductor packaging. It serves as a critical component in Flip-Chip BGA packaging, providing mechanical support, electrical connections, and thermal management for flip-chip-mounted devices. The substrate allows the chip to be directly flipped and attached via solder balls, making it a key technology for high-performance computing and consumer electronics.

Structure and Features of FC-BGA Substrates

Structure

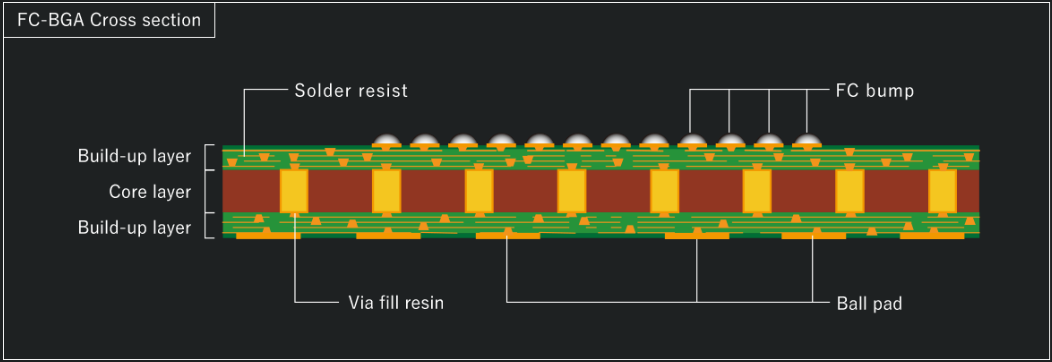

FC-BGA substrates typically consist of the following multilayer structure:

-

Conductive Layers:

- Enable electrical signal transmission and power distribution.

- Typically made of copper with complex interconnect patterns.

-

Insulating Layers:

- Separate conductive layers to prevent short circuits.

- Often made of BT (Bismaleimide-Triazine) resin or ABF (Ajinomoto Build-up Film).

-

Thermal Layers:

- Enhance heat dissipation to manage chip thermal loads.

- Include metallic layers or thermally conductive materials.

-

Solder Ball Array:

- Located on the bottom side to connect the substrate to the PCB (Printed Circuit Board).

- Typically made of tin-alloy materials.

Key Features

-

High-Density Interconnects:

Supports greater signal line density, ideal for high-performance applications. -

Efficient Thermal Management:

Incorporates heat-conductive materials to dissipate heat effectively. -

Optimized Electrical Performance:

Flip-chip technology shortens signal pathways, improving signal integrity and reducing latency. -

Reliable Mechanical Strength:

The multilayer structure ensures robust and stable connections between the chip and substrate.

Functions of the Multilayer Structure

-

Conductive Layers:

- Responsible for transmitting electrical signals and distributing power.

- Short signal paths reduce parasitic effects and signal delays.

-

Insulating Layers:

- Ensure electrical isolation between conductive layers.

- Support high-frequency signal transmission and minimize interference.

-

Thermal Layers:

- Transfer heat from the chip to external cooling systems to prevent overheating.

-

Solder Ball Array:

- Establish physical and electrical connections between the substrate and PCB.

- Provide multiple channels for power, data, and ground signals.

Role of the Solder Ball Array

The solder ball array is a critical component of FC-BGA packaging, with the following functions:

-

Electrical Connections:

Facilitates signal transmission and power distribution between the chip and external circuits. -

Mechanical Support:

Stabilizes the chip-substrate connection, reducing stress and vibration impacts. -

Signal Integrity:

Reduces signal loss and interference compared to traditional wire bonding.

Comparison with Other Packaging Technologies

FC-BGA vs. BGA (Ball Grid Array)

| Feature | FC-BGA | BGA |

|---|---|---|

| Chip Mounting Method | Flip-Chip | Wire Bonding |

| Signal Path Length | Short (improved performance) | Long (higher delay) |

| Packaging Density | High | Medium |

| Thermal Performance | Superior | Moderate |

Get a quotation for fc bga substrates manufacturing nowGet a Quote Now

FC-BGA vs. CSP (Chip Scale Package)

| Feature | FC-BGA | CSP |

|---|---|---|

| Package Size | Larger | Almost chip-size |

| Application | High-performance computing (CPU, GPU) | Mobile devices (smartphones, tablets) |

| Manufacturing Cost | Higher | Lower |

Understanding FC-BGA Substrates

Definition of FC-BGA (Flip Chip Ball Grid Array)

FC-BGA, or Flip Chip Ball Grid Array, represents a sophisticated iteration of traditional BGA technology. In FC-BGA packages, the integrated circuits (ICs) are flipped upside down, allowing the active area of the IC to be directly connected to the substrate through solder bumps or balls. These solder connections replace the wire bonding used in conventional BGA packages, offering several advantages such as reduced parasitic capacitance, improved electrical performance, and enhanced thermal dissipation.

Evolution and Advancements in FC-BGA Technology

The development of FC-BGA technology has been driven by the need for higher performance, miniaturization, and reliability in semiconductor packaging. Over the years, significant advancements have been made in FC-BGA design, materials, and manufacturing processes. For instance, improvements in solder bumping techniques, substrate materials, and assembly processes have enabled the widespread adoption of FC-BGA in various applications, including high-performance computing, telecommunications, and consumer electronics.

Moreover, the evolution of FC-BGA substrates has been closely intertwined with the broader advancements in semiconductor packaging technology. Innovations such as fine-pitch interconnects, multi-layer substrates, and embed

ded passive components have further enhanced the performance and functionality of FC-BGA packages. These developments underscore the continuous evolution and refinement of FC-BGA substrates to meet the evolving demands of modern electronic devices.

Get a quotation for fc bga substrates manufacturing nowGet a Quote Now

Difference Between BGA and FC-BGA

Overview of Traditional BGA Technology

Traditional Ball Grid Array (BGA) technology has been a staple in semiconductor packaging, offering a robust solution for mounting integrated circuits (ICs) onto printed circuit boards (PCBs). In BGA packages, solder balls are arranged in a grid pattern beneath the IC, providing electrical connections to the PCB.

Contrasting Features and Benefits of FC-BGA over BGA

FC-BGA (Flip Chip Ball Grid Array) represents a significant evolution from traditional BGA technology, introducing several key features and benefits:

- Interconnection Method: While BGA packages rely on wire bonding or flip chip interconnects, FC-BGA utilizes flip chip technology, where the IC is directly connected to the substrate using solder bumps or balls. This direct connection reduces signal path lengths, minimizing parasitic capacitance and inductance, thus improving electrical performance.

- Thermal Performance: FC-BGA substrates offer superior thermal dissipation compared to traditional BGA substrates. The direct attachment of the IC to the substrate enables efficient heat transfer, enhancing thermal management capabilities and reducing the risk of overheating in high-power applications.

- Miniaturization: FC-BGA packages typically feature smaller footprints and finer pitch interconnects compared to traditional BGA packages. This miniaturization allows for higher integration densities, enabling the development of compact and lightweight electronic devices.

- Reliability: The flip chip interconnects used in FC-BGA packages offer enhanced mechanical robustness and reliability compared to wire bonding. This improves the overall durability of the package, making FC-BGA substrates suitable for demanding applications where reliability is paramount.

- Performance: Due to reduced parasitic effects and improved thermal management, FC-BGA substrates offer enhanced electrical performance, including lower signal propagation delays, reduced power consumption, and increased bandwidth, making them ideal for high-speed and high-frequency applications.

Overall, FC-BGA substrates represent a significant advancement over traditional BGA technology, offering improved performance, reliability, and miniaturization capabilities for semiconductor packaging.

Composition of BGA Balls

Explanation of Materials Used in BGA Balls

BGA balls, also known as solder balls, play a crucial role in providing electr ical connections between the integrated circuits (ICs) and the substrate or printed circuit board (PCB). These solder balls are typically composed of tin (Sn) or tin-lead (Sn-Pb) alloys, chosen for their excellent solderability, mechanical properties, and thermal conductivity. Additionally, various fluxes and surface finishes may be applied to the solder balls to improve wetting and adhesion during the soldering process.

Considerations for Ball Composition in FC-BGA

In FC-BGA substrates, the composition of solder balls is of paramount importance due to the direct connection between the IC and the substrate. Several key considerations must be taken into account when selecting the material for FC-BGA solder balls:

- Thermal Conductivity: The solder balls should possess high thermal conductivity to facilitate efficient heat dissipation from the IC to the substrate and ultimately to the PCB. This is crucial for maintaining optimal operating temperatures and preventing thermal-induced failures in high-power applications.

- Reliability: The solder balls must exhibit excellent mechanical properties, including high tensile strength and fatigue resistance, to ensure long-term reliability and durability of the FC-BGA package. This is particularly important in applications subjected to mechanical stress, temperature cycling, and vibration.

- Compatibility: The solder material chosen for FC-BGA solder balls should be compatible with the materials used in the package assembly process, including the substrate, IC, and PCB. Compatibility issues can lead to solder joint failures and compromise the integrity of the FC-BGA package.

- Solderability: The solder balls should demonstrate good wetting and solderability properties to ensure reliable bonding between the IC and the substrate during the assembly process. Proper fluxes and surface finishes may be employed to enhance solder wetting and reduce the risk of solder defects.

By carefully considering these factors, manufacturers can select appropriate solder ball compositions for FC-BGA substrates, ensuring optimal performance, reliability, and manufacturability of semiconductor packages.

FC-BGA Substrate Manufacturing Process

Detailed Steps Involved in Manufacturing FC-BGA Substrates

- Substrate Preparation: The manufacturing process begins with the preparation of the substrate material, which can be composed of materials such as FR-4, polyimide, or ceramic composites. The substrate is typically fabricated into thin sheets or panels of the desired size and thickness.

- Surface Treatment: The substrate surface undergoes various surface treatment processes to enhance solderability and adhesion. This may include processes such as surface roughening, chemical cleaning, and application of adhesion promoters.

- Circuit Patterning: Next, the substrate is coated with a conductive material such as copper using techniques like sputtering or electroplating. The copper layer is then patterned using photolithography and etching processes to create the desired circuitry and interconnects.

- Dielectric Layer Deposition: Following circuit patterning, dielectric layers are deposited onto the substrate surface to insulate the conductive traces and provide electrical isolation between circuit layers. These dielectric layers may be deposited using methods such as chemical vapor deposition (CVD) or spin coating.

- Via Formation: Vias are created in the substrate to allow for vertical interconnects between different circuit layers. This is typically achieved through processes such as laser drilling or mechanical drilling followed by metallization to ensure electrical continuity.

- Surface Finish Application: The substrate surface is coated with a surface finish to protect the exposed copper traces and facilitate soldering during the assembly process. Common surface finishes include electroless nickel immersion gold (ENIG), organic solderability preservatives (OSP), and immersion tin or silver.

- Solder Ball Attachment: In the final step of the manufacturing process, solder balls are attached to the substrate surface using techniques such as solder paste stencil printing, pick-and-place, and reflow soldering. The solder balls provide electrical connections between the FC-BGA package and the printed circuit board (PCB).

Key Technologies and Methodologies Utilized in the Process

- Photolithography: Photolithography is a crucial technology used for patterning the conductive traces and creating intricate circuit patterns on the substrate surface.

- Chemical Vapor Deposition (CVD): CVD is employed for depositing thin films of dielectric materials onto the substrate surface, providing electrical insulation between circuit layers.

- Laser Drilling: Laser drilling is utilized for creating precise vias in the substrate material, allowing for vertical interconnects between different layers of the FC-BGA substrate.

- Surface Mount Technology (SMT): Surface mount technology is employed for attaching solder balls to the substrate surface, ensuring precise alignment and uniform solder joints for optimal electrical performance.

By leveraging these advanced technologies and methodologies, manufacturers can produce high-quality FC-BGA substrates with excellent electrical performance, reliability, and manufacturability.

Advantages of FC-BGA Substrates

FC-BGA substrates offer a range of advantages over traditional BGA technology, revolutionizing semiconductor packaging in terms of both technical capabilities and practical benefits.

Highlighting the Advantages of FC-BGA Substrates over Traditional BGA

- Enhanced Electrical Performance: FC-BGA substrates feature shorter signal paths and reduced parasitic capacitance and inductance compared to traditional BGA packages. This results in improved signal integrity, reduced crosstalk, and higher data transmission speeds, making FC-BGA ideal for high-speed and high-frequency applications.

- Superior Thermal Management: The direct attachment of the integrated circuits (ICs) to the substrate in FC-BGA packages allows for more efficient heat dissipation. This results in lower operating temperatures and improved thermal stability, reducing the risk of thermal-induced failures and prolonging the lifespan of electronic devices.

- Increased Miniaturization: FC-BGA substrates enable higher integration densities and finer pitch interconnects compared to traditional BGA packages. This allows for the development of smaller and more compact electronic devices without compromising performance, making FC-BGA ideal for space-constrained applications such as mobile devices and wearables.

- Enhanced Reliability: The flip chip interconnects used in FC-BGA substrates offer superior mechanical robustness and reliability compared to wire bonding used in traditional BGA packages. This results in fewer solder joint failures, improved shock and vibration resistance, and enhanced long-term reliability of electronic devices.

Technical and Practical Benefits for Semiconductor Packaging

- Improved Signal Integrity: FC-BGA substrates minimize signal degradation and distortion, ensuring reliable communication between ICs and the printed circuit board (PCB). This is critical for high-performance applications where data accuracy and integrity are paramount.

- Streamlined Manufacturing Process: FC-BGA substrates simplify the assembly process by eliminating the need for wire bonding and reducing the number of assembly steps. This results in faster production cycles, lower manufacturing costs, and increased throughput, making FC-BGA a cost-effective solution for semiconductor packaging.

- Compatibility with Advanced Technologies: FC-BGA substrates are compatible with a wide range of advanced technologies, including flip chip packaging, system-in-package (SiP), and 3D integration. This versatility allows for the integration of multiple functions and components into a single package, enhancing design flexibility and enabling innovative product development.

Overall, FC-BGA substrates offer a compelling combination of technical performance, reliability, and practical advantages, making them an attractive choice for semiconductor packaging in various industries and applications.

Applications of FC-BGA

Exploration of Industries and Applications where FC-BGA Technology Excels

- Telecommunications: FC-BGA technology finds extensive use in telecommunications equipment, where high-speed data processing and reliable connectivity are essential. FC-BGA substrates enable the development of compact and power-efficient networking devices, such as routers, switches, and base stations, facilitating seamless communication in both wired and wireless networks.

- Consumer Electronics: FC-BGA substrates are widely employed in consumer electronics devices, including smartphones, tablets, and gaming consoles. The miniaturization and enhanced performance capabilities of FC-BGA enable manufacturers to design sleek and feature-rich products that meet the demands of modern consumers for high-speed data processing, multimedia capabilities, and connectivity.

- Automotive Electronics: In the automotive industry, FC-BGA technology is utilized in a variety of applications, including infotainment systems, advanced driver assistance systems (ADAS), and engine control units (ECUs). FC-BGA substrates offer robustness, reliability, and resistance to harsh operating conditions, making them well-suited for automotive electronics applications where reliability and performance are critical.

- Industrial Automation: FC-BGA substrates play a vital role in industrial automation systems, providing the processing power and connectivity required for real-time control, monitoring, and data analysis. FC-BGA technology enables the development of high-performance controllers, sensors, and actuators that enhance productivity, efficiency, and safety in industrial environments.

Real-World Examples of FC-BGA Implementation

- Mobile Devices: Smartphones and tablets often utilize FC-BGA technology for their main processors, memory chips, and wireless communication modules. FC-BGA substrates allow for compact designs and efficient heat dissipation, enabling manufacturers to pack powerful components into slim and lightweight devices without compromising performance.

- Network Infrastructure: Networking equipment such as routers, switches, and access points leverage FC-BGA technology for their high-speed processors, memory modules, and network interfaces. FC-BGA substrates enable reliable data transmission, low-latency communication, and scalability, supporting the growing demands of modern networks for bandwidth, reliability, and security.

- Automotive Control Systems: Automotive electronic control units (ECUs), including engine control modules (ECMs), transmission control modules (TCMs), and body control modules (BCMs), rely on FC-BGA technology for their microcontrollers, sensors, and communication interfaces. FC-BGA substrates offer ruggedness, temperature resistance, and high reliability, ensuring consistent performance in challenging automotive environments.

- Industrial Controllers: Industrial automation systems, including programmable logic controllers (PLCs), distributed control systems (DCSs), and motion control systems, utilize FC-BGA technology for their processing units, input/output modules, and communication interfaces. FC-BGA substrates enable real-time control, precise motion control, and seamless integration with industrial networks, enhancing productivity and flexibility in manufacturing and process industries.

Overall, FC-BGA technology demonstrates versatility and adaptability across a wide range of industries and applications, providing the performance, reliability, and efficiency required for the development of next-generation electronic devices and systems.

Future Trends in FC-BGA Substrates

Discussion on Ongoing Research and Developments in FC-BGA Technology

- Advanced Materials: Ongoing research focuses on developing new substrate materials with enhanced electrical, thermal, and mechanical properties to further improve the performance and reliability of FC-BGA packages. Advanced materials such as liquid crystal polymers (LCPs), silicones, and metal matrix composites are being explored for their potential in FC-BGA applications.

- Embedded Components: Future trends in FC-BGA technology involve the integration of passive and active components directly into the substrate, enabling more compact and integrated semiconductor packages. Embedded components such as capacitors, resistors, and inductors can improve signal integrity, reduce footprint, and simplify assembly processes in FC-BGA packages.

- High-Density Interconnects: Ongoing developments focus on increasing the density of interconnects in FC-BGA substrates to accommodate the growing demand for higher bandwidth and data transmission speeds. Advanced fabrication techniques such as microvia drilling, laser ablation, and thin-film deposition enable the creation of finer pitch interconnects and higher routing densities in FC-BGA packages.

- 3D Integration: Future trends in FC-BGA technology include the adoption of 3D integration techniques to stack multiple ICs vertically within a single package. Through-silicon vias (TSVs) and microbump bonding enable dense stacking of chips, offering increased functionality, reduced footprint, and improved performance in FC-BGA packages.

Predictions for the Future of FC-BGA in Semiconductor Packaging

- Increased Adoption in High-Performance Applications: FC-BGA technology is expected to see increased adoption in high-performance computing, networking, and data center applications, where the demand for faster data processing, higher bandwidth, and lower latency continues to grow. FC-BGA substrates offer the performance, reliability, and scalability required for these demanding applications.

- Expansion into Emerging Technologies: FC-BGA technology is poised to expand into emerging technologies such as artificial intelligence (AI), Internet of Things (IoT), and automotive electrification, where compact and efficient semiconductor packages are essential. FC-BGA substrates enable the integration of advanced functionalities and sensors into compact and energy-efficient devices, driving innovation in these rapidly evolving fields.

- Integration with Advanced Packaging Technologies: FC-BGA technology is expected to integrate with advanced packaging technologies such as fan-out wafer-level packaging (FOWLP), system-in-package (SiP), and heterogeneous integration, enabling the development of highly integrated and multifunctional semiconductor packages. FC-BGA substrates will play a key role in enabling the seamless integration of diverse components and functionalities within a single package, further advancing the capabilities of electronic devices.

FC-BGA technology is poised to continue evolving and expanding its presence in semiconductor packaging, driven by ongoing research and developments in materials, interconnects, and integration techniques. With its versatility, performance, and scalability, FC-BGA substrates are poised to play a crucial role in shaping the future of electronic devices and systems.

Contact Us NOW

FAQs About FC-BGA Substrates

The substrate in BGA (Ball Grid Array) is a base material upon which integrated circuits are mounted, facilitating electrical connections to a printed circuit board (PCB).

FC-BGA (Flip Chip Ball Grid Array) is a type of BGA package where the integrated circuits (ICs) are mounted upside down, allowing the active area of the IC to be directly connected to the substrate through solder bumps or balls.

The main difference between BGA and FBGA (Fine Ball Grid Array) lies in the pitch or spacing between the solder balls. FBGA typically has a smaller pitch, allowing for higher density and finer pitch interconnections compared to traditional BGA packages.

BGA balls, also known as solder balls, are typically made of tin (Sn) or tin-lead (Sn-Pb) alloys. These alloys offer excellent solderability, mechanical properties, and thermal conductivity, making them suitable for providing electrical connections in BGA packages.

发表评论

Want to join the discussion?Feel free to contribute!