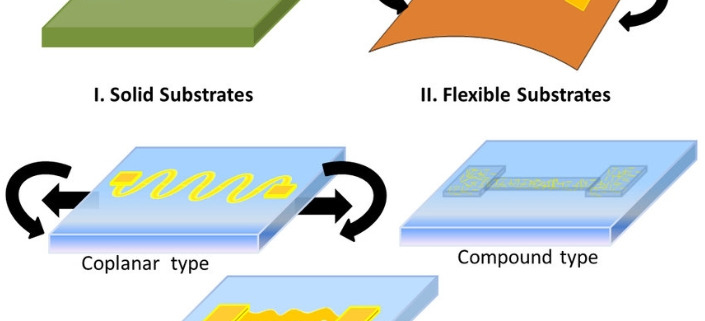

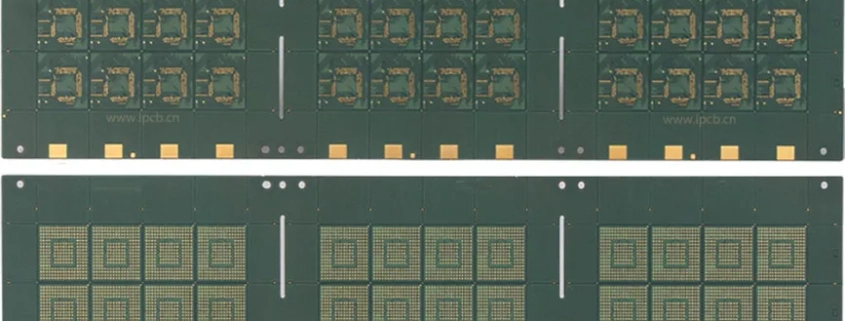

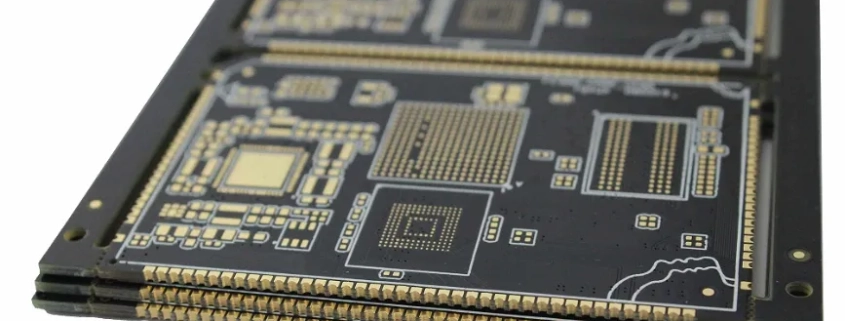

Printed Circuit Board (PCB) design and manufacturing are critical processes in the electronics industry, forming the backbone of almost all electronic devices. PCBs serve as the foundation for mounting and interconnecting various electronic components, from simple resistors to complex microprocessors. The design phase involves creating a layout that ensures optimal performance and reliability, while manufacturing transforms this layout into a physical board through precise fabrication techniques.

Understanding design rules and specifications is paramount for producing high-quality PCBs. These rules, such as trace width, spacing, and via size, dictate the electrical and physical properties of the board. Adhering to these specifications ensures signal integrity, minimizes electromagnetic interference (EMI), and enhances overall device performance. Moreover, compliance with manufacturing capabilities prevents defects, reduces production costs, and accelerates time-to-market. As the electronics industry advances, mastering these design principles is essential for innovation and maintaining competitive edge in the market.

阅读更多