What is ABF Substrate? Key to Semiconductor Advancements

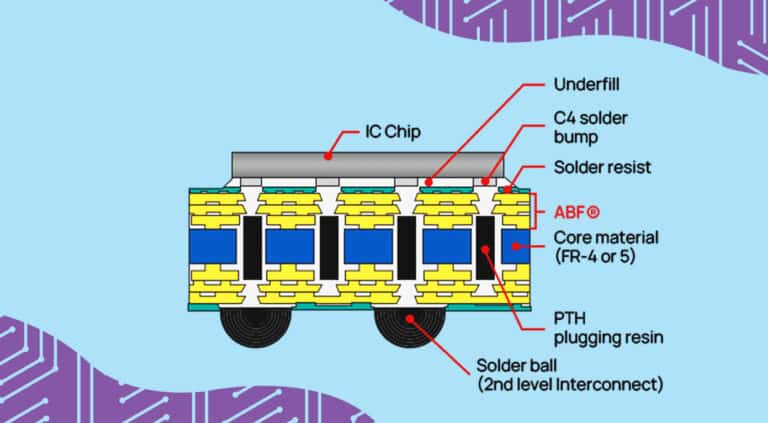

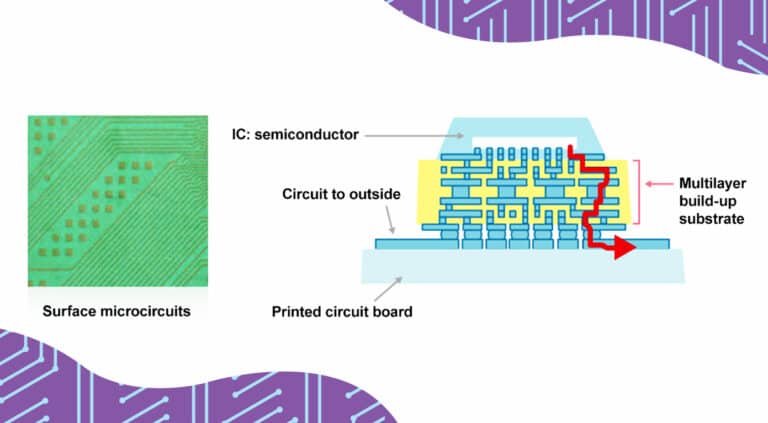

What is ABF substrate? ABF substrate, short for Ajinomoto Build-Up Film substrate, is a crucial component in the semiconductor industry. Essentially, ABF substrate refers to a specialized material utilized in semiconductor packaging and interconnection processes. Its significance lies in its ability to provide high-density interconnects, enabling efficient communication between semiconductor components. ABF substrate plays a pivotal role in the development of advanced electronic devices, such as microprocessors and memory chips. Its unique properties make it suitable for various applications, including flip-chip packaging, multi-chip modules, and high-speed data transmission systems. Understanding what ABF substrate is and its applications is essential for grasping the complexities of modern semiconductor technology.

What is ABF Substrate: Composition and Properties

Components of ABF Substrate

Understanding what ABF substrate comprises is essential for grasping its role in the semiconductor industry. ABF substrate, short for Ajinomoto Build-Up Film substrate, consists of several intricate components meticulously engineered to meet the demanding requirements of modern electronic devices. The primary constituents include:

- Polymer Matrix: At the core of ABF substrate lies a polymer matrix, typically composed of materials like epoxy resin or polyimide. This matrix provides structural support and electrical insulation crucial for semiconductor applications.

- Copper Foils: Thin layers of copper foils are intricately integrated into ABF substrate to form conductive pathways for electrical signals. These foils enable efficient connectivity within semiconductor devices, facilitating the transmission of signals.

- Dielectric Layers: Interspersed between the copper foils, dielectric layers act as insulating barriers, preventing short circuits and signal interference. These layers enhance the reliability and performance of semiconductor devices utilizing ABF substrate.

Material Composition and Structure

The material composition and structure of ABF substrate are carefully engineered to meet the stringent requirements of the semiconductor industry. This composition and structure play a vital role in determining the functionality and suitability of ABF substrate for various electronic devices. Key elements include:

- Base Layer: ABF substrate’s foundation is formed by the polymer matrix, providing mechanical support and stability. This base layer serves as the platform upon which other components are integrated.

- Copper Clad Layers: Thin copper foils are laminated onto the polymer matrix to create conductive pathways. These copper clad layers facilitate efficient electrical connectivity within semiconductor devices, ensuring the transmission of signals.

- Dielectric Layers: Dielectric layers, situated between the copper foils, serve as insulating barriers. These layers prevent signal interference and ensure the integrity of electrical connections within semiconductor devices utilizing ABF substrate.

Physical and Chemical Properties

ABF substrate exhibits unique physical and chemical properties optimized for semiconductor applications. These properties are crucial for assessing the performance and suitability of ABF substrate for various electronic devices. Key characteristics include:

- High Electrical Conductivity: The copper foils integrated into ABF substrate offer exceptional electrical conductivity, enabling efficient signal transmission within semiconductor devices.

- Thermal Stability: ABF substrate demonstrates robust thermal stability, ensuring reliable performance under challenging temperature conditions encountered during semiconductor processing and operation.

- Low Dielectric Constant: Dielectric layers within ABF substrate possess a low dielectric constant, minimizing signal loss and distortion. This characteristic enhances the overall performance and reliability of semiconductor devices utilizing ABF substrate.

What is ABF Substrate: Manufacturing Process

ABF (Ajinomoto Build-Up Film) substrates are essential in high-density integrated circuit packaging, enabling intricate circuitry and supporting advanced semiconductor applications. The manufacturing process involves multiple precise steps, from material preparation to final quality assurance, ensuring superior performance and reliability.

Material Preparation

The foundation of ABF substrates lies in high-quality raw materials. Ajinomoto’s proprietary resin systems, primarily polyimide or epoxy-based, form the core of these substrates. Polyimide provides excellent thermal resistance, while epoxy ensures strong mechanical and electrical properties. These are supplemented with curing agents for enhanced stability. Filler materials like glass fibers or inorganic additives are incorporated to improve mechanical strength and maintain a stable coefficient of thermal expansion, ensuring compatibility with high-performance electronic devices.

Lamination and Shaping

The structural integrity of ABF substrates is achieved through advanced lamination processes. Multiple resin films are stacked and pressed under controlled heat and pressure, creating a uniform multilayer structure. Precision laser drilling techniques, such as CO₂ or UV laser systems, are employed to create microvias smaller than 50 microns, enabling high-density interconnections. Post-drilling, thorough cleaning ensures the vias are ready for metallization.

Formation of Conductive Pathways

The conductive layers are created through chemical deposition and electroplating of copper. This step ensures robust electrical connectivity across the substrate and within the microvias. Circuit patterns are defined using photolithography, followed by etching to remove excess copper. This results in precise and intricate conductive traces, with advanced technologies achieving line widths and spacing as fine as 10 microns.

Packaging and Testing

Surface treatments, such as Electroless Nickel Immersion Gold (ENIG) or Organic Solderability Preservatives (OSP), are applied to enhance solderability and protect against oxidation. Rigorous quality inspections, including Automated Optical Inspection (AOI) and electrical tests, verify the substrate’s performance. Environmental tests, such as thermal cycling and humidity resistance evaluations, ensure durability under real-world conditions.

Key Manufacturers and Suppliers

Several leading companies play a pivotal role in the ABF substrate market:

- Ajinomoto Co., Inc. is the originator of ABF technology, offering industry-leading resin systems that cater to high-end applications in CPUs and GPUs.

- Ibiden Co., Ltd. delivers premium ABF substrates with cutting-edge manufacturing processes, serving clients like Intel.

- Shinko Electric Industries Co., Ltd. specializes in high-performance IC substrates used in memory and communication devices.

- Unimicron Technology Corp. leads in Taiwan with innovative ABF solutions for data centers and AI technologies.

- Nan Ya Printed Circuit Board Corp. provides cost-effective substrates for diverse applications, from automotive electronics to cloud computing.

Key Technical Considerations in ABF Substrate Design

This section outlines the critical factors to consider when designing ABF substrates, ensuring optimal performance and reliability in semiconductor applications.

Coefficient of Thermal Expansion (CTE) Matching

CTE matching is essential to ensure compatibility between the substrate and the semiconductor chip, particularly under varying thermal conditions.

Material Engineering: Resin formulations and filler materials are carefully selected to achieve low and stable CTE values, ensuring dimensional stability and thermal reliability.

Compatibility with Chip Materials: The ABF substrate must closely align its CTE with the silicon die to minimize mechanical stress during thermal cycling. Disparities in expansion rates can lead to delamination, cracking, or solder joint failure.

High-Density I/O Requirements

Modern semiconductor devices demand substrates that support high input/output (I/O) densities, driving the need for advanced design solutions.

Interlayer Connection Optimization: The size, distribution, and reliability of microvias are critical for achieving efficient electrical interconnections between layers. Designers must consider via-in-pad designs and stacked via configurations to support high I/O densities without compromising mechanical integrity.

Miniaturization Challenges: As chip designs continue to shrink, ABF substrates must accommodate increased pin counts and complex signal routing within limited space. This necessitates advanced photolithography and precision laser drilling technologies to produce microvias and fine line/spacing patterns.

Signal Integrity and Power Distribution Network (PDN)

Maintaining signal integrity and an efficient PDN are critical for ensuring high performance and minimizing electromagnetic interference (EMI).

Low-Impedance Design: PDN optimization focuses on creating uniform power and ground planes to minimize impedance. This ensures stable power delivery and reduces voltage fluctuations, crucial for high-speed signal transmission.

Signal Integrity Analysis: Techniques such as impedance matching, controlled dielectric properties, and the use of low-loss materials help reduce crosstalk, signal reflection, and attenuation.

Thermal Management and Reliability

Efficient thermal management and long-term reliability are vital for ABF substrates, especially in high-performance and high-power applications.

Long-Term Reliability Testing: ABF substrates undergo rigorous testing to validate their resistance to moisture, aging, and thermal stress. Key metrics include warpage control, delamination resistance, and solder joint durability under prolonged operational conditions.

Selection of Thermal Interface Materials: Integrating materials with high thermal conductivity, such as metal layers or specialized fillers, ensures effective heat dissipation and stability during operation.

ABF Substrate Assembly Process Issues

The assembly process of ABF (Ajinomoto Build-Up Film) substrates plays a critical role in ensuring the high performance, reliability, and functionality of semiconductor packages. However, several challenges can arise during the assembly of ABF substrates, particularly due to their unique properties and advanced design requirements. Below are some key issues commonly encountered during the ABF substrate assembly process:

Microvia and Via Formation Challenges

One of the critical aspects of ABF substrate assembly is the formation of microvias, which are necessary for high-density interconnects. The precision required for laser drilling or other via creation methods is very high. Any slight misalignment or incomplete via formation can lead to defects in the circuit path, impacting the substrate’s electrical performance. To address this, advances in laser drilling technologies and equipment calibration can help improve the accuracy of microvia formation. Ensuring precise process control and monitoring during via creation can minimize these defects.

Thermal Management During Assembly

ABF substrates are often used in high-performance applications where heat dissipation is essential. During the assembly process, maintaining the integrity of the thermal management features, such as heat sinks and thermal vias, is crucial. However, thermal stresses can occur during the reflow soldering process, potentially causing delamination or warpage. Proper thermal profile management is necessary to avoid excessive thermal cycling during assembly. Using appropriate temperature control during reflow soldering and ensuring adequate cooling rates can help mitigate thermal stress.

Alignment and Registration Accuracy

ABF substrates are typically used in multi-layer designs, and precise alignment is necessary during the bonding process. Misalignment between layers or poor registration can lead to functional failures and significant yield loss. Automated optical alignment and laser-guided processes can ensure precise alignment during bonding. Careful handling and high-precision assembly tools are essential for minimizing alignment issues.

Soldering Challenges

Soldering defects, such as insufficient solder joints, solder bridging, or cold solder joints, can occur when assembling ABF substrates with advanced components, especially when the components have high-density I/O or fine-pitch connections. Employing advanced soldering techniques, such as controlled atmosphere soldering and precise temperature profiles during reflow, can reduce soldering issues. In addition, the use of high-quality solder pastes and fluxes designed for fine-pitch and microelectronic applications is critical to achieving reliable joints.

Warpage and Stress During the Reflow Process

Warpage during the reflow soldering process is a concern for ABF substrates, especially in multi-layered, thin-film constructions. Uneven heating or improper cooling rates can lead to mechanical stress and warping of the substrate, affecting component placement and solder joint integrity. To address warpage, it is essential to control the thermal profile during soldering. Additionally, using substrates with balanced thermal expansion properties and ensuring proper lamination and curing of the films can help reduce the likelihood of warpage.

Surface Finish and Reliability

The surface finish of ABF substrates, such as the copper layer, plays a critical role in solderability and long-term performance. Poor surface finishes can cause poor wetting during soldering, leading to weak electrical connections or premature failure. Ensuring proper surface preparation before assembly, such as applying a consistent surface finish (e.g., ENIG, OSP, or other plating methods), will enhance solderability. Implementing pre-assembly cleaning processes can further improve the reliability of the connections.

High Density I/O (HDI) and Component Integration

With ABF substrates enabling higher I/O densities and smaller pitches, integrating advanced components with fine-pitch leads or microbumps can lead to challenges in assembly, especially if the assembly equipment isn’t designed for ultra-fine pitch handling. Specialized assembly equipment capable of handling fine-pitch components and precise placement is necessary. Additionally, the use of flip-chip bonding or micro bumping technology can support this high-density assembly while maintaining reliability and performance.

Comparison of ABF Substrates and Other Substrate Materials

Distinction between ABF and BT Substrates

When evaluating substrate materials in the semiconductor industry, a prominent comparison often arises between ABF (Ajinomoto Build-Up Film) and BT (Bismaleimide Triazine) substrates. Understanding the differences between these materials sheds light on their unique characteristics and suitability for various applications:

- Composition: ABF substrates primarily consist of a polymer matrix, copper foils, and dielectric layers, offering excellent electrical conductivity and thermal stability. In contrast, BT substrates utilize a different composition, typically comprising a resin system reinforced with woven glass fabric.

- Dielectric Constant: ABF substrates generally exhibit a lower dielectric constant compared to BT substrates. This lower dielectric constant in ABF substrates minimizes signal loss and distortion, making them preferable for high-frequency applications requiring precise signal integrity.

- Manufacturing Process: The manufacturing processes for ABF and BT substrates differ significantly. ABF substrates typically undergo a build-up process, where layers of polymer and copper are sequentially deposited and patterned. BT substrates, on the other hand, involve the lamination of pre-preg layers and copper foils followed by drilling and plating processes.

- Flexibility: ABF substrates are known for their flexibility and ability to accommodate complex interconnect designs, making them suitable for applications requiring high-density interconnects and miniaturization. In contrast, BT substrates may offer better mechanical rigidity and stability, making them suitable for applications where robustness is paramount.

Advantages and Limitations

Understanding the advantages and limitations of ABF substrates compared to BT substrates is crucial for selecting the most suitable material for specific semiconductor applications:

Advantages of ABF Substrates

- Superior electrical performance with lower dielectric constant.

- Flexibility to accommodate complex interconnect designs.

- Enhanced signal integrity, particularly for high-frequency applications.

- Potential for miniaturization and higher packaging densities.

- Compatibility with advanced semiconductor packaging technologies.

Limitations of ABF Substrates

- May exhibit lower mechanical strength and rigidity compared to BT substrates.

- Limited availability of high-temperature variants for applications requiring extreme operating conditions.

- Higher cost compared to traditional substrate materials, impacting overall manufacturing expenses.

- Complexity in manufacturing processes may lead to longer lead times and production challenges.

While ABF substrates offer advantages such as superior electrical performance and flexibility, they also have limitations in terms of mechanical strength and cost. The choice between ABF and BT substrates depends on specific application requirements, cost considerations, and performance expectations in the semiconductor industry.

Applications in Semiconductor Industry

ABF substrates play a pivotal role in the semiconductor industry, offering versatile solutions for various applications. Understanding their applications sheds light on their significance in modern electronic devices.

Role in Semiconductor Packaging

ABF substrates are extensively utilized in semiconductor packaging, where they serve as the foundation for assembling and interconnecting semiconductor components. Their role in packaging encompasses:

- Flip-Chip Packaging: ABF substrates facilitate flip-chip packaging, a widely adopted technique in semiconductor assembly. In this process, semiconductor chips are directly mounted onto the substrate, with their active side facing downwards. ABF substrates provide the necessary electrical connections and thermal management required for reliable device operation.

- Multi-Chip Modules (MCMs): ABF substrates enable the integration of multiple semiconductor chips within a single package, forming multi-chip modules (MCMs). These modules offer enhanced performance and functionality by combining diverse chip functionalities in a compact form factor. ABF substrates provide the necessary interconnectivity and insulation to ensure the seamless operation of MCMs.

- High-Speed Data Transmission Systems: In high-speed data transmission systems, such as those used in telecommunications and data centers, ABF substrates play a crucial role in facilitating signal transmission at high frequencies. Their low dielectric constant and excellent electrical properties enable the efficient propagation of signals, ensuring reliable data communication.

Integration with Advanced Technologies

ABF substrates are at the forefront of innovation, continually evolving to meet the demands of advanced semiconductor technologies. Their integration with advanced technologies includes:

- 5G and Beyond: As the telecommunications industry transitions to 5G and beyond, the demand for high-performance semiconductor devices is increasing. ABF substrates play a vital role in enabling the development of next-generation communication systems by providing the necessary connectivity and signal integrity.

- Artificial Intelligence (AI) and Machine Learning: The rise of AI and machine learning applications requires semiconductor devices capable of processing vast amounts of data efficiently. ABF substrates support the development of AI hardware by offering high-speed interconnects and thermal management solutions, enabling the seamless integration of AI accelerators and processors.

- Internet of Things (IoT): In the IoT ecosystem, semiconductor devices must be compact, energy-efficient, and capable of seamless connectivity. ABF substrates facilitate the development of IoT devices by providing compact packaging solutions and enabling efficient communication between sensors, actuators, and processing units.

ABF substrates are indispensable in the semiconductor industry, playing a vital role in packaging semiconductor devices and integrating with advanced technologies such as 5G, AI, and IoT. Their versatility and reliability make them the substrate of choice for a wide range of semiconductor applications.

Market Trends and Demand

Current Market Landscape

The market for ABF substrates in the semiconductor industry is dynamic and competitive, driven by technological advancements and evolving consumer demands. Several key factors influence the current market landscape:

- Increasing Demand for High-Performance Devices: The growing demand for high-performance semiconductor devices, driven by applications such as data centers, telecommunications, and automotive electronics, is fueling the demand for ABF substrates. These substrates offer superior electrical properties and thermal performance, making them ideal for advanced semiconductor applications.

- Rapid Adoption of Advanced Packaging Technologies: With the rise of advanced packaging technologies such as flip-chip packaging and system-in-package (SiP), there is a growing need for high-density interconnect solutions. ABF substrates enable the miniaturization and integration of semiconductor devices, meeting the requirements of modern electronics.

- Expansion of 5G Infrastructure: The deployment of 5G networks worldwide is driving demand for semiconductor devices capable of supporting high-speed data transmission. ABF substrates play a crucial role in enabling the development of 5G infrastructure by providing high-speed interconnect solutions for communication chips and RF components.

Growth Projections and Forecasts

The market for ABF substrates is poised for significant growth in the coming years, driven by technological advancements and increasing demand for high-performance semiconductor devices. Key growth projections and forecasts include:

- Rising Adoption of AI and IoT Technologies: The adoption of artificial intelligence (AI) and Internet of Things (IoT) technologies is expected to drive demand for semiconductor devices with enhanced processing capabilities and connectivity. ABF substrates, with their high-density interconnect solutions, are well-positioned to cater to this growing demand.

- Expansion of Automotive Electronics: The automotive industry is increasingly incorporating semiconductor devices for advanced driver assistance systems (ADAS), infotainment systems, and autonomous driving technologies. ABF substrates, with their reliability and thermal management capabilities, are essential for meeting the stringent requirements of automotive electronics applications.

- Emergence of Advanced Packaging Solutions: The emergence of advanced packaging solutions such as fan-out wafer-level packaging (FOWLP) and embedded die packaging is driving demand for ABF substrates. These substrates enable the integration of multiple chips within a single package, enhancing device performance and reducing form factor.

The market for ABF substrates in the semiconductor industry is experiencing robust growth, driven by increasing demand for high-performance devices, rapid adoption of advanced packaging technologies, and expansion of 5G infrastructure. With technological advancements and evolving consumer demands, ABF substrates are expected to play a significant role in shaping the future of semiconductor devices and applications.

Case Study: Ajinomoto Build-Up Film (ABF)

Overview of Ajinomoto’s ABF Technology

Ajinomoto Build-Up Film (ABF) is a cutting-edge technology developed by Ajinomoto Fine-Techno Co., Inc., a leading manufacturer in the semiconductor industry. ABF technology revolutionizes semiconductor packaging by offering advanced solutions for high-density interconnects and thermal management. Here’s an in-depth look at the features and benefits of Ajinomoto’s ABF technology:

Features and Benefits

- High-Density Interconnects: Ajinomoto’s ABF technology enables the creation of high-density interconnects, allowing for the integration of multiple semiconductor components within a compact form factor. This feature is particularly beneficial for applications requiring miniaturization and enhanced performance.

- Excellent Electrical Performance: ABF substrates exhibit superior electrical properties, including low signal loss and high signal integrity. This ensures reliable communication between semiconductor devices, making them suitable for high-speed data transmission systems and telecommunications infrastructure.

- Enhanced Thermal Management: Ajinomoto’s ABF technology incorporates advanced thermal management solutions, allowing for efficient heat dissipation from semiconductor devices. This feature is critical for maintaining optimal operating temperatures and ensuring the long-term reliability of electronic devices, especially in high-power applications.

- Compatibility with Advanced Packaging Techniques: ABF substrates are compatible with various advanced packaging techniques, including flip-chip packaging, system-in-package (SiP), and fan-out wafer-level packaging (FOWLP). This versatility enables semiconductor manufacturers to adopt the most suitable packaging solution for their specific application requirements.

- Reliability and Durability: ABF substrates are engineered to meet stringent reliability standards, ensuring consistent performance under harsh operating conditions. They exhibit excellent mechanical strength and resistance to environmental factors such as moisture, humidity, and thermal cycling, making them ideal for a wide range of applications.

- Cost-Effectiveness: Despite their advanced features and performance benefits, ABF substrates offer cost-effective solutions for semiconductor packaging. Their efficient manufacturing process and economies of scale contribute to lower overall production costs, providing value to semiconductor manufacturers and end-users alike.

Ajinomoto’s ABF technology represents a significant advancement in semiconductor packaging, offering high-density interconnects, excellent electrical performance, enhanced thermal management, and compatibility with advanced packaging techniques. With its reliability, durability, and cost-effectiveness, ABF substrates are poised to play a crucial role in driving innovation and advancement in the semiconductor industry.

FAQs About What is ABF substrate

What is ABF material?

ABF material, short for Ajinomoto Build-Up Film, is a specialized substrate used in semiconductor packaging, offering high-density interconnects and advanced thermal management properties.

The main difference between BT (Bismaleimide Triazine) and ABF substrates lies in their material composition and manufacturing process. While both are used in semiconductor packaging, ABF substrates typically offer superior electrical performance and thermal management compared to BT substrates.

Several companies manufacture ABF substrates, including Ajinomoto Fine-Techno Co., Inc., Shinko Electric Industries Co., Ltd., and Kyocera Corporation. These companies specialize in producing high-quality ABF substrates to meet the demands of the semiconductor industry.

The demand for ABF substrate is driven by the increasing need for high-performance semiconductor devices in various applications such as telecommunications, data centers, automotive electronics, and consumer electronics. As technology advances and new applications emerge, the demand for ABF substrate is expected to continue growing steadily.

Contact Us NOW