A flexible printed circuit board (FPC) is a type of PCB designed to bend, twist, or fold to fit complex electronic assemblies. Unlike rigid PCBs, flexible PCBs offer mechanical adaptability, reduced weight, and space efficiency—making them ideal for compact or dynamic applications. Among various materials used, polyimide flexible PCB stands out as the industry standard for high-performance flex designs. Polyimide, known for its excellent thermal stability, chemical resistance, and mechanical strength, enables reliable operation in demanding environments like aerospace, medical devices, and wearable electronics. This article provides a comprehensive look at polyimide flexible PCB, covering its material properties, how it compares to traditional FR4 boards, key manufacturers in the market, and typical application scenarios. Whether you’re an engineer, designer, or buyer, understanding the advantages of polyimide flexible PCB is essential to making informed decisions in modern electronic product development. 阅读更多

A keyboard flexible PCB is a type of printed circuit board specifically designed to offer bendability and shape adaptability, making it ideal for unconventional keyboard layouts like split, curved, or ergonomic designs. Unlike traditional rigid PCBs, which are made from solid fiberglass (FR4), flexible PCBs use materials like polyimide substrates and copper foil, allowing them to flex and conform to custom contours. These properties enable innovative designs that would be difficult or impossible with standard rigid boards. In mechanical keyboard builds—particularly custom ergonomic models such as the Dactyl—keyboard flexible PCB solutions are gaining popularity for their space-saving benefits, clean internal wiring, and structural versatility. As more DIY keyboard enthusiasts seek out unique, high-performance layouts, the demand for keyboard flexible PCB technology is increasing, supported by advancements in manufacturing and community-driven open-source projects. 阅读更多

A Printed Circuit Board (PCB) is the foundation of most electronic devices, providing mechanical support and electrical connections for electronic components. As technology evolves toward miniaturization and portability, the demand for more adaptable circuit solutions has led to the development of fpc flexible pcb technology. Unlike traditional rigid and inflexible boards, flexible printed circuits offer a bendable, lightweight alternative that can conform to complex shapes and dynamic movements. This flexibility makes them ideal for compact devices like smartphones, wearables, medical implants, and automotive sensors. The evolution of flexible circuit technology marks a major step in modern electronics, allowing for increased design freedom, improved reliability, and space efficiency. With electronics becoming more integrated into daily life and industrial systems, the importance of these flexible solutions continues to grow, replacing rigid boards in many critical applications where space-saving and flexibility are essential. 阅读更多

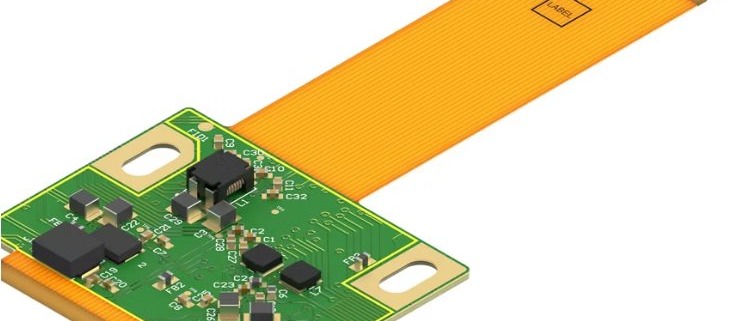

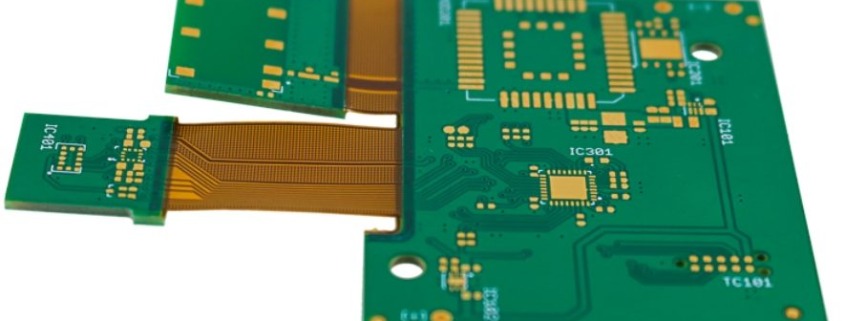

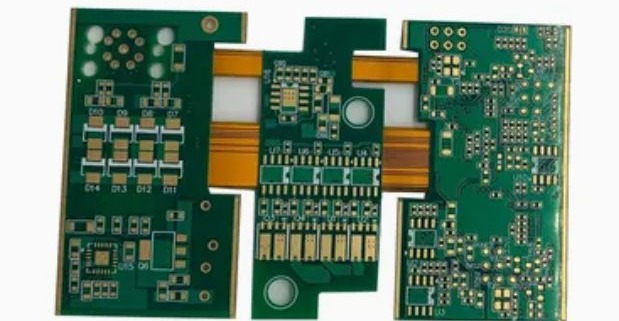

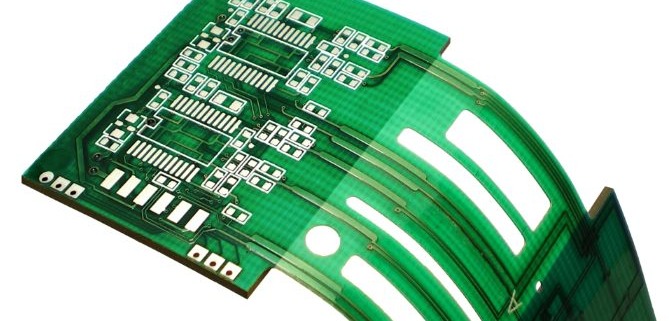

A flexible rigid PCB, also known as a rigid-flex PCB, is a hybrid circuit board that combines elements of both rigid and flexible substrates into a single unit. This design allows the board to bend and fold while maintaining structural stability in specific areas. The evolution of flexible rigid PCB technology stems from the need for compact, lightweight, and high-reliability electronic solutions in increasingly complex devices. Over the years, this PCB type has gained widespread adoption across various industries, including aerospace, medical devices, automotive systems, and consumer electronics. Unlike traditional rigid PCBs, which are entirely stiff, or flexible PCBs, which lack structural support, a flexible rigid PCB provides the best of both worlds—mechanical durability where needed and flexibility for space-saving and dynamic applications. This combination not only enhances design freedom but also reduces interconnection issues, making it a go-to choice for cutting-edge electronics. 阅读更多

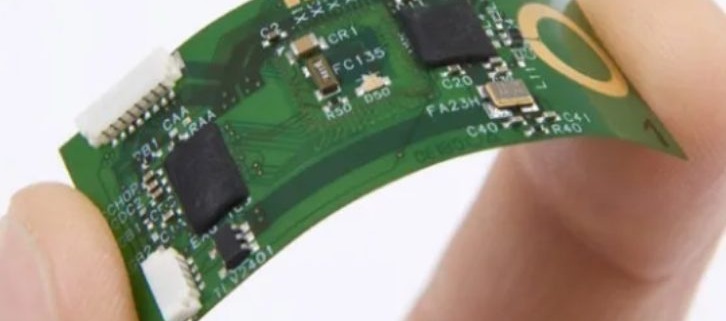

A Flexible PCB (Flex PCB) is a type of printed circuit board designed to bend, twist, or fold into shape without damaging the circuitry. Unlike rigid PCBs, flexible PCBs are built using materials like polyimide or polyester, making them ideal for applications requiring compact and dynamic configurations. Today, Flex PCBs are becoming increasingly essential in modern electronics such as wearable devices, medical equipment, aerospace systems, and compact consumer gadgets. Their ability to save space, reduce weight, and withstand mechanical stress makes them a preferred choice for innovative product designs. In this fast-paced tech landscape, flexible pcb prototyping plays a vital role in accelerating development cycles. Rapid prototyping allows engineers to validate designs quickly, identify potential issues early, and refine products before mass production. As demand for smarter, smaller, and more durable electronics rises, flexible pcb prototyping becomes a critical step in turning ideas into market-ready solutions. 阅读更多

Flexible PCBs, also known as flex circuits, are lightweight, bendable electronic interconnects used across a wide range of applications such as wearable technology, medical devices, automotive systems, and aerospace electronics. These circuits allow designers to save space, reduce weight, and improve mechanical flexibility in compact or moving products. One of the most critical design parameters in flex circuit development is flexible PCB thickness. This factor significantly influences the circuit’s ability to bend without damage, carry current effectively, and fit within mechanical enclosures. Whether a design requires extreme flexibility for dynamic applications or added stiffness for stable routing, PCB thickness must be carefully selected to meet both electrical and mechanical requirements. This article provides an in-depth look into how to evaluate, choose, and optimize board thickness for various use cases. By understanding these principles, designers and engineers can make more informed decisions when developing reliable, high-performance flexible electronic solutions. 阅读更多

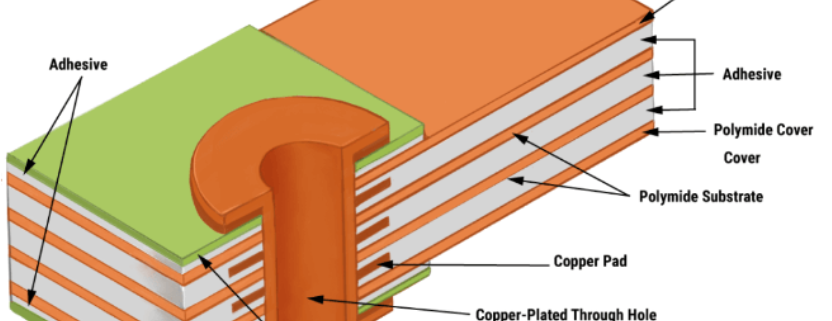

In the world of modern electronics, where compact, lightweight, and durable designs are increasingly essential, the flexible pcb substrate plays a pivotal role. A flexible insulating material serves as the foundational layer in the construction of bendable printed circuit boards, allowing circuits to twist, bend, and conform to complex shapes without breaking or losing functionality. Unlike traditional rigid boards, it provides mechanical adaptability while maintaining high electrical performance.

The importance of this material lies in its ability to support the miniaturization trend in electronics. As devices like smartwatches, fitness trackers, foldable phones, and advanced automotive systems shrink in size, these substrates enable engineers to create more intricate, space-efficient layouts. In aerospace, where weight savings and reliability are critical, this material is also indispensable.

From wearable health monitors to satellite communication modules, this foundational layer underpins many of today’s cutting-edge applications, helping engineers push the boundaries of design and performance.

A flexible pcb prototype is an early-stage version of a flexible printed circuit board used for design validation before full-scale production. Unlike traditional rigid PCBs, flexible PCBs can bend, fold, and conform to complex shapes, making them ideal for modern compact and lightweight electronic devices. The flexible pcb prototype allows engineers to test mechanical and electrical performance under real-world conditions, reducing development risk and cost.

In today’s electronics industry, the demand for flexibility, durability, and space efficiency continues to grow. As a result, flexible printed circuit boards play a critical role in the rapid development and advancement of smart technology.

Typical applications include wearables, such as fitness trackers and smartwatches, medical devices like portable monitors, mobile electronics including foldable phones and tablets, and high-performance systems in aerospace and automotive sectors, where reliability and flexibility are essential. These flexible circuits enable engineers to bring advanced designs to life quickly and efficiently.

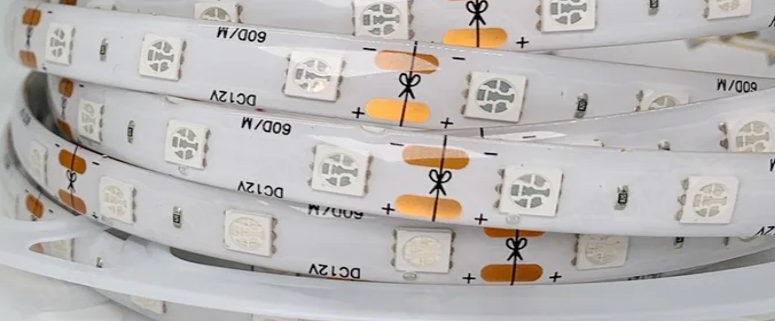

The evolution of LED technology has dramatically transformed the lighting and electronics industries over the past two decades. From bulky, power-hungry incandescent bulbs to compact and energy-efficient LED solutions, lighting has become smarter, more versatile, and environmentally friendly. As applications expanded—from home décor to automotive and wearable tech—the need for adaptable circuit solutions emerged. This is where the flexible led pcb comes in.

A flexible led pcb is a type of printed circuit board that incorporates LED components on a bendable substrate, typically made from polyimide or PET materials. Unlike traditional rigid boards, it can conform to curved surfaces, making it ideal for applications with space or shape constraints.

Today, the flexible led pcb is gaining rapid popularity in modern lighting and electronic designs. Its unique combination of flexibility, lightweight construction, and design freedom makes it a preferred choice for next-generation devices, including smart wearables, architectural lighting, and dynamic display systems.

In today’s fast-evolving electronics industry, flexible PCBs have become essential components for devices that demand compact design, lightweight materials, and high durability. Unlike traditional rigid boards, flexible PCBs can bend and fold, making them ideal for modern applications such as wearable technology, medical devices, automotive electronics, and industrial control systems. These industries rely on flexible circuit boards to meet increasingly complex performance and space constraints. As demand grows, choosing the right flexible PCB supplier is more important than ever. A reliable supplier not only ensures product quality and fast turnaround times but also offers engineering support and customization services to match your exact needs. This blog is designed to help engineers, buyers, and product developers navigate the process of finding and evaluating the best flexible PCB supplier. From understanding capabilities to comparing top providers, this guide covers all essential aspects to support successful sourcing decisions in today’s competitive market. 阅读更多

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Understanding the Benefits of Polyimide Flexible PCB Technology2025-06-03 - 3:17 上午

Understanding the Benefits of Polyimide Flexible PCB Technology2025-06-03 - 3:17 上午 Building a Custom Keyboard with a Keyboard Flexible PCB2025-05-30 - 3:22 上午

Building a Custom Keyboard with a Keyboard Flexible PCB2025-05-30 - 3:22 上午 Advantages of Using FPC Flexible PCB in Modern Electronics2025-05-29 - 4:20 上午

Advantages of Using FPC Flexible PCB in Modern Electronics2025-05-29 - 4:20 上午 Essential Design Guidelines for Flexible Rigid PCB Success2025-05-28 - 3:28 上午

Essential Design Guidelines for Flexible Rigid PCB Success2025-05-28 - 3:28 上午