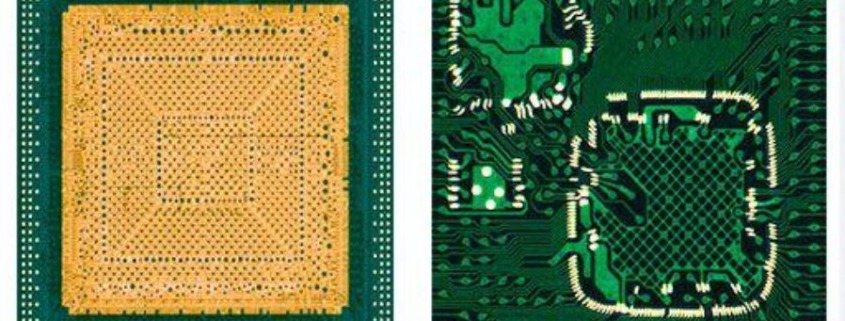

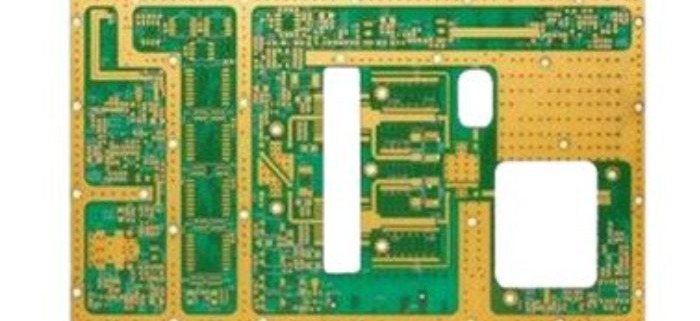

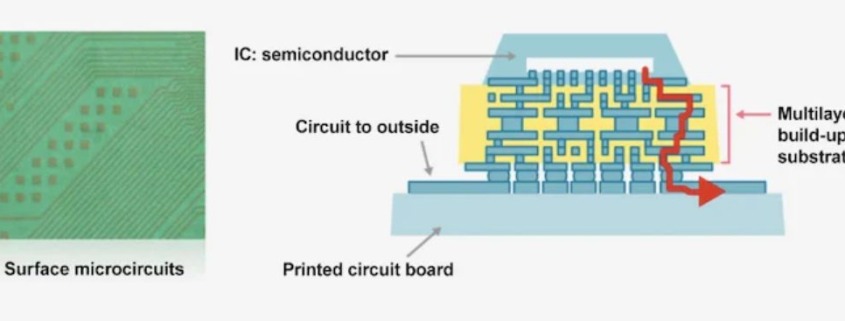

An alluminum substrate is a type of base material used in printed circuit boards (PCBs) that incorporates a metal core, typically aluminum, to provide superior heat dissipation and mechanical stability. Unlike traditional FR4 boards, an alluminum substrate PCB can effectively manage high thermal loads, making it essential in high-power and thermally demanding applications. In modern electronics, this material plays a critical role in ensuring performance and longevity, especially where compact layouts and high currents are involved.

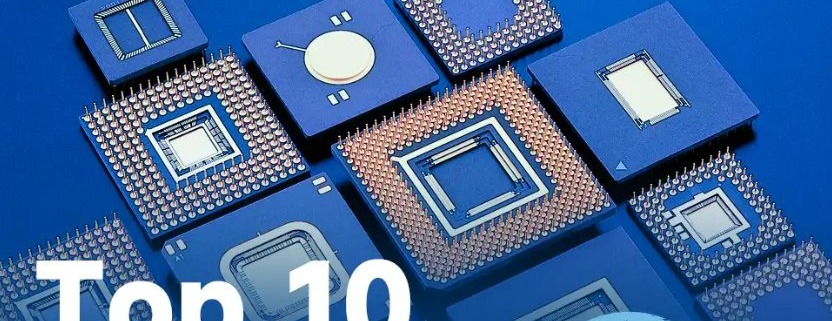

Industries such as LED lighting, automotive systems, and power electronics widely use alluminum substrate PCBs due to their reliability and efficiency. For example, products like 2 layer alluminum substrate PCB are commonly used in automotive headlights and industrial lighting modules. Reputable manufacturers like Pcbway alluminum substrate solutions offer custom stackups and thermal design optimization. As technology evolves, the alluminum substrate continues to be a go-to material in high-performance electronic design.