Substrate Meaning in Electronics: Essential for Device Stability

In the realm of electronics, a substrate serves as the fundamental foundation upon which electronic components are mounted or fabricated. Essentially, it is the underlying material that supports and connects various components within electronic devices, ranging from semiconductors to printed circuit boards (PCBs). The significance of substrates cannot be overstated; they provide structural integrity, electrical insulation, and thermal management crucial for device performance and reliability. Whether it’s in optimizing signal transmission paths in high-frequency circuits or enhancing the heat dissipation capabilities in power electronics, choosing the right substrate material and design is pivotal. Understanding the role of substrates across different electronic applications illuminates their multifaceted importance in shaping the efficiency, durability, and functionality of modern electronic systems.

Substrate in Semiconductor Technology

Semiconductor substrates form the foundational platform upon which semiconductor devices are fabricated. They provide structural support and serve as the medium for depositing and integrating semiconductor materials, such as silicon or gallium arsenide, to form electronic components.

Definition and Role of Substrates in Semiconductor Devices

Substrates in semiconductor technology refer to the base material onto which layers of semiconductor materials are deposited to create electronic devices like transistors and diodes. They provide mechanical support, electrical insulation, and a stable foundation for semiconductor fabrication processes.

Types of Substrates Used in Semiconductor Manufacturing

- Silicon Substrates: Most commonly used due to its abundance and well-understood properties. Silicon substrates are crucial for CMOS (Complementary Metal-Oxide-Semiconductor) technology.

- Gallium Arsenide (GaAs) Substrates: Used in high-frequency and optoelectronic devices due to its superior electronic properties for applications like LEDs and solar cells.

- Other Substrate Materials: Include silicon carbide (SiC) for power electronics and III-V compound substrates for advanced semiconductor devices.

Importance of Substrate Material Properties in Semiconductor Performance

The properties of the substrate material significantly impact semiconductor device performance:

- Electrical Properties: Substrate materials affect carrier mobility, leakage currents, and parasitic capacitances crucial for circuit speed and power efficiency.

- Thermal Properties: Thermal conductivity influences heat dissipation, critical for maintaining device reliability and performance under varying operational conditions.

- Mechanical Properties: Substrate integrity ensures structural stability and reliability during manufacturing and device operation.

Understanding these aspects allows semiconductor engineers to optimize substrate selection to enhance device performance, reliability, and integration into complex electronic systems.

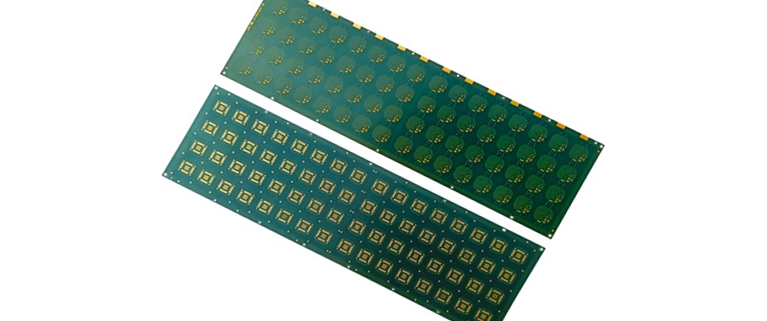

Substrate in PCB (Printed Circuit Board) Technology

In the domain of PCB technology, a substrate refers to the insulating base material upon which the conductive pathways and components of a printed circuit board are constructed. This foundational material provides mechanical support and electrical insulation crucial for the functionality and reliability of electronic circuits.

Definition of Substrate in the Context of PCBs

The substrate in PCBs serves as the physical foundation onto which copper traces, electronic components, and insulating layers are laminated or deposited. It forms the rigid or flexible board that supports the structural integrity of the circuit and facilitates the interconnection of electronic components.

Types of Substrates Used in PCB Manufacturing

- FR4 (Flame Retardant 4): The most widely used substrate material due to its affordability, durability, and good electrical insulation properties. It consists of a fiberglass-reinforced epoxy laminate.

- Flexible Substrates (Polyimide): Used in applications requiring flexibility, such as in wearable electronics or bendable devices. Polyimide substrates offer excellent thermal stability and mechanical flexibility.

- Metal Core PCBs (MCPCBs): Utilized in applications requiring efficient heat dissipation, such as in LED lighting or power electronics. MCPCBs typically use aluminum or copper substrates with high thermal conductivity.

Role of Substrates in PCB Layout and Design

- Mechanical Support: Substrates provide a rigid or flexible platform that supports and protects the electronic components mounted on the PCB.

- Electrical Insulation: Prevents short circuits and ensures proper electrical isolation between conductive traces and components.

- Thermal Management: Influences the PCB’s ability to dissipate heat generated by components, critical for maintaining operational reliability and longevity.

Understanding the role of substrates in PCB technology is essential for designing efficient and reliable electronic circuits tailored to specific application requirements. The choice of substrate material and design directly impacts the performance, durability, and manufacturability of PCBs across diverse electronic devices and industries.

Substrate in Power Electronics

In the realm of power electronics, substrates play a pivotal role in supporting and enhancing the performance of high-power electronic devices and systems. These substrates are specialized materials that facilitate efficient power conversion, heat dissipation, and electrical insulation critical for the reliability and functionality of power electronic applications.

Application of Substrates in Power Electronic Devices

Substrates are integral to various power electronic devices, including:

- Power Modules: Used in inverters, converters, and motor drives for efficient power switching and control.

- High-Power LEDs: Utilized in lighting applications for energy-efficient illumination.

- Electric Vehicle (EV) Power Systems: Employed in traction inverters and battery management systems to regulate power flow.

Specific Requirements and Considerations for Substrates in Power Electronics:

- Electrical and Thermal Conductivity: Substrates must have high electrical conductivity to minimize power losses and high thermal conductivity to effectively dissipate heat generated during operation.

- Mechanical Stability: Ensures the substrate can withstand mechanical stresses and vibrations encountered in industrial and automotive environments.

- Insulating Properties: Provides effective electrical insulation between conducting layers and components to prevent short circuits and ensure operational safety.

Examples of Substrates Used in Power Modules and Converters:

- Direct Bond Copper (DBC) Substrates: Known for their excellent thermal conductivity and robust mechanical properties, DBC substrates are ideal for power modules requiring efficient heat dissipation and high current carrying capacity.

- Aluminum Nitride (AlN) Substrates: Preferred for their exceptional thermal conductivity and electrical insulation properties, AlN substrates are suitable for high-frequency power converters and RF applications.

- Ceramic Substrates: Offer excellent thermal stability and mechanical strength, making them suitable for harsh operating conditions in automotive and aerospace power electronics.

Understanding these substrate characteristics and their application-specific requirements is crucial for designing and manufacturing reliable power electronic systems capable of meeting stringent performance and efficiency standards.

Comparison: DBC (Direct Bond Copper) vs. AMB (Active Metal Brazing)

Explanation of DBC and AMB Technologies

Direct Bond Copper (DBC): Direct Bond Copper involves bonding copper metal directly to a ceramic substrate using a high-temperature process. This creates a robust interface with excellent thermal conductivity, making it suitable for power electronic modules and high-current applications.

Active Metal Brazing (AMB): Active Metal Brazing utilizes a filler metal that is chemically compatible with both the substrate and the component being bonded. This process typically operates at lower temperatures compared to DBC and allows for joining dissimilar materials with different coefficients of thermal expansion.

Contrasting Characteristics, Applications, and Benefits

DBC:

- Characteristics: High thermal conductivity (typically >200 W/m·K), strong mechanical bonding, and capable of handling high currents.

- Applications: Preferred in power modules, such as IGBT modules and thyristors, where efficient heat dissipation and electrical performance are critical.

- Benefits: Excellent reliability due to the direct copper-to-ceramic bond, minimal thermal resistance, and suitability for high-power applications in automotive, renewable energy, and industrial sectors.

AMB:

- Characteristics: Lower processing temperatures compared to DBC, capability to join dissimilar materials, and good thermal and electrical properties.

- Applications: Used in RF/microwave components, sensors, and aerospace applications where joining ceramics to metals or other ceramics is required.

- Benefits: Versatility in material compatibility, ability to join complex geometries, and reduced thermal stress during bonding compared to high-temperature processes like DBC.

Use Cases and Industries:

- DBC: Preferred in industries requiring robust thermal management and high reliability, such as automotive power electronics (e.g., EV inverters), industrial motor drives, and renewable energy systems (e.g., wind and solar inverters).

- AMB: Commonly employed in aerospace for joining ceramic components in sensors and avionics, telecommunications for RF/microwave applications, and medical devices where biocompatible materials are needed.

Understanding the distinct characteristics, applications, and benefits of DBC and AMB technologies allows engineers and manufacturers to choose the most suitable bonding method based on specific performance requirements and operational conditions of their electronic and electrical systems.

Substrate in Biology

In biological contexts, a substrate refers to the substance or molecule upon which an enzyme acts to catalyze a biochemical reaction. This interaction is fundamental to various biological processes and plays a crucial role in maintaining cellular functions and metabolic pathways.

Definition of Substrate in Biological Contexts: In biology, a substrate is a molecular entity that undergoes transformation through enzymatic action. Enzymes, biological catalysts, bind to specific substrates at their active sites, facilitating chemical reactions essential for cellular metabolism, signal transduction, and organismal function.

Examples of Substrates in Biological Processes

- Enzyme-Substrate Interaction: For example, in digestion, enzymes like amylase catalyze the breakdown of starch (substrate) into simpler sugars such as glucose.

- Substrate Binding in Signal Transduction: Receptor proteins on cell membranes bind to specific ligands (substrates), triggering intracellular signaling cascades that regulate gene expression and cellular responses.

- Substrate in Metabolic Pathways: Substrates participate in metabolic pathways where enzymes sequentially modify molecules to produce energy (e.g., ATP synthesis) or synthesize essential biomolecules (e.g., amino acids).

Similarities and Differences Between Biological and Electronic Substrates

- Similarities:

- Both types of substrates serve as foundational materials or entities upon which processes occur (chemical reactions in biology, electrical conduction in electronics).

- Selection of substrate material affects performance and efficiency of respective systems (enzyme activity in biology, electrical conductivity in electronics).

- Differences:

- Biological substrates involve organic molecules and biochemical interactions mediated by enzymes, whereas electronic substrates are typically inorganic materials facilitating electrical conductivity and component integration.

- Biological substrates exhibit complex, dynamic interactions influenced by physiological conditions, whereas electronic substrates are designed for specific, often static electrical properties and mechanical stability.

Understanding these distinctions helps in appreciating how substrate concepts are fundamental across diverse scientific disciplines, shaping our understanding and technological advancements in both biological and electronic systems.

Substrate in CPU (Central Processing Unit)

In the context of CPUs, the substrate refers to the material layer beneath the silicon die that serves as a support structure for the integrated circuit (IC) components and provides electrical and mechanical connections to the motherboard.

Definition of Substrate in the Context of CPUs

The substrate in CPUs acts as a platform that supports and connects the silicon die to the rest of the computer system. It facilitates electrical pathways between the die and external components, such as memory modules and input/output interfaces, while also providing mechanical stability.

Role of Substrate Materials in CPU Performance and Thermal Management

- Electrical Connectivity: The substrate must efficiently transmit signals between the silicon die and external components without introducing significant resistance or interference.

- Thermal Dissipation: Effective thermal management is crucial to dissipate heat generated during CPU operation. Substrate materials with good thermal conductivity help in efficiently transferring heat away from the silicon die to the heatsink or cooling system.

- Mechanical Support: The substrate must provide sufficient structural integrity to withstand mechanical stresses and ensure reliable operation in various environmental conditions.

Evolution of CPU Substrate Technologies

- Ceramic Substrates: Historically used in early CPUs, ceramic substrates provided good thermal conductivity and mechanical strength but were expensive and relatively heavy.

- Organic Substrates (e.g., FR4): Introduced as a cost-effective alternative to ceramics, organic substrates like FR4 offer lighter weight and sufficient electrical insulation. However, they have lower thermal conductivity compared to ceramics.

- Advanced Organic Substrates (e.g., High-Density Interconnect PCBs): Current trends in CPU substrate technology include high-density interconnect (HDI) PCBs, which integrate multiple layers of circuitry to reduce signal propagation delay and improve electrical performance.

- Embedded Die Technologies: Emerging techniques involve embedding the silicon die directly into the substrate material, enhancing thermal and electrical performance by reducing interconnect length and resistance.

Understanding the evolution of CPU substrate technologies underscores ongoing efforts to improve performance, reduce manufacturing costs, and enhance the thermal management capabilities of CPUs in response to increasing computational demands and efficiency requirements.

FAQs About substrate meaning in electronics

In technology, substrates refer to the base materials or foundational layers upon which other materials or components are built or integrated. They provide structural support, electrical pathways, and often play a crucial role in the functionality and performance of electronic, mechanical, or biological systems. Examples include semiconductor substrates in electronics, substrate materials in PCBs, and substrate materials in biotechnology.

In engineering, a substrate generally refers to a material or surface upon which processes or components are applied or integrated. It acts as a foundation that supports and interacts with other materials or systems to achieve desired engineering outcomes. Substrates in engineering can range from structural materials in construction to foundational layers in electronic devices or biological systems.

In a CPU (Central Processing Unit), the substrate refers to the layer or material beneath the silicon die of the CPU. It provides mechanical support and electrical connections between the silicon die and the rest of the computer system, including the motherboard. The substrate plays a critical role in transmitting signals, managing thermal dissipation, and ensuring the structural integrity of the CPU.

In a transistor, the substrate typically refers to the semiconducting material upon which the transistor is fabricated. This substrate can be silicon, gallium arsenide, or other semiconductor materials. The substrate serves as the foundation for forming the transistor’s structure, including the source, drain, and gate regions. It also influences the electrical properties and performance characteristics of the transistor, such as switching speed and power handling capabilities.