Understanding the Features of Special Rogers HDI PCB Board

HDI PCBs, or High-Density Interconnect printed circuit boards, are advanced circuit boards characterized by their high wiring density and smaller size, making them essential in modern electronics. Their ability to support complex designs and high-speed signals has led to widespread adoption in cutting-edge devices such as smartphones, tablets, and medical equipment. Rogers materials, known for their excellent electrical properties, play a crucial role in high-frequency applications, providing superior signal integrity and minimal loss. This article will focus on the unique features and applications of special Rogers HDI PCB boards, exploring how they combine the advantages of HDI technology with the superior performance of Rogers materials. We will delve into their manufacturing processes, specific applications in various industries, and the benefits they offer to engineers and designers looking to optimize their electronic products.

What is an HDI PCB?

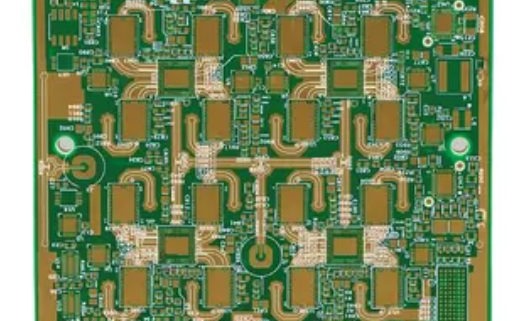

HDI PCBs, particularly the special Rogers HDI PCB board, are defined by their high-density interconnections, which allow for a greater number of connections within a smaller footprint. These boards feature finer traces and spaces, along with microvias—small holes that connect layers within the board—enabling more complex circuit designs. The structural characteristics of HDI PCBs often include multiple layers, with the ability to integrate components on both sides and even within the layers themselves, maximizing efficiency and minimizing space.

Differences in Manufacturing Processes between HDI and Conventional PCBs

The manufacturing processes for HDI PCBs differ significantly from those used for conventional PCBs. HDI fabrication involves advanced techniques such as laser drilling for microvias and controlled depth routing, which are not typically required in standard PCBs. These processes enable the creation of intricate designs that support high-speed signals while maintaining signal integrity.

Common Applications of HDI PCBs

Common applications for HDI PCBs include smartphones, where space and performance are critical; medical devices that require reliable, compact circuitry; and aerospace systems, which demand high reliability and low weight. The versatility and advanced capabilities of special Rogers HDI PCB boards make them essential for modern electronic applications across these industries.

Difference Between HDI and Non-HDI PCBs

Variations in Materials and Layer Count

The differences between HDI and non-HDI PCBs are significant and impact various aspects of design and functionality. One of the primary variations lies in the materials used and the layer count. HDI PCBs, including special Rogers HDI PCB boards, often utilize advanced materials like Rogers laminates, which are designed for high-frequency performance. These materials have specific dielectric properties that enhance signal integrity, making them ideal for applications requiring precision. In contrast, non-HDI PCBs typically use standard FR-4 materials, which may not support the same level of performance in high-speed applications.

Design Complexity and Electrical Performance

Design complexity is another key differentiator. HDI PCBs feature a higher layer count and incorporate techniques like microvias and blind/buried vias, allowing for more intricate designs. This complexity enables the integration of more components into a smaller area, facilitating miniaturization. Non-HDI PCBs, on the other hand, generally have fewer layers and simpler designs, which can limit their application in high-density environments.

Comparison of Manufacturing Costs and Production Timelines

When it comes to manufacturing costs and production timelines, HDI PCBs tend to be more expensive to produce due to their intricate design requirements and the advanced technologies involved in their fabrication. The additional steps needed for drilling microvias and managing multilayer configurations contribute to longer production times. Non-HDI PCBs are typically more cost-effective and quicker to manufacture, making them suitable for applications where performance demands are not as stringent. Ultimately, the choice between HDI and non-HDI PCBs depends on the specific needs of the project, with special Rogers HDI PCB boards offering superior performance for high-frequency applications.

What is a Rogers PCB?

Rogers PCBs are a specialized category of printed circuit boards that utilize high-frequency materials developed by Rogers Corporation. These boards are renowned for their superior electrical performance, particularly in high-speed and high-frequency applications. Rogers PCBs are characterized by their low dielectric loss, stable dielectric constant, and excellent thermal stability, making them ideal for demanding environments where signal integrity is crucial.

Types of Rogers Materials

There are several types of Rogers materials, each designed to meet specific performance criteria. Two popular examples are RO4003C and RO4350B. RO4003C is a cost-effective solution with good electrical performance, making it suitable for a wide range of applications. It has a dielectric constant of approximately 3.38 and is well-regarded for its ease of manufacturing. On the other hand, RO4350B offers enhanced thermal conductivity and lower dielectric loss, making it an excellent choice for high-frequency applications, with a dielectric constant around 3.48. These materials are particularly advantageous in microwave and RF circuit designs.

Benefits of Rogers PCBs in High-frequency and High-speed Circuits

The benefits of Rogers PCBs in high-frequency and high-speed circuits are significant. Their low dielectric loss minimizes signal degradation over distances, ensuring that signals remain clear and accurate, even at high frequencies. Additionally, Rogers materials provide consistent performance across a wide temperature range, which is essential for applications in telecommunications, aerospace, and medical devices. By utilizing Rogers PCBs, designers can achieve higher reliability and better performance in their electronic products, making them a preferred choice in advanced circuit designs, including special Rogers HDI PCB boards.

Features of the Special Rogers HDI PCB

Combining the Advantages of HDI and Rogers Materials

The special Rogers HDI PCB combines the advanced features of high-density interconnect (HDI) technology with the superior properties of Rogers materials, resulting in a circuit board that excels in performance and reliability. One of the standout advantages of this combination is the ability to create intricate circuit designs that maximize space efficiency. By utilizing microvias and fine line technology, special Rogers HDI PCBs enable a higher density of connections in a compact layout, allowing for more functionality within a smaller footprint. This capability is particularly beneficial in modern electronics, where miniaturization is essential for devices like smartphones and wearable technology.

Capabilities for High-density Interconnection and Miniaturization.

Another significant feature of special Rogers HDI PCBs is their enhanced signal integrity. The high-quality Rogers materials contribute to minimal dielectric loss and stable dielectric constants, ensuring that signals maintain their strength and clarity even at high frequencies. This is crucial for applications that rely on precise data transmission, such as telecommunications and aerospace systems. By reducing signal loss, these PCBs help prevent issues such as crosstalk and interference, which can compromise performance in sensitive electronic environments.

Enhanced Signal Integrity and Reduced Signal Loss

The thermal management properties of Rogers materials enhance the overall reliability of special Rogers HDI PCBs. With better heat dissipation capabilities, these boards can operate effectively in high-temperature conditions, making them suitable for a variety of applications, including automotive and industrial electronics. The combination of high-density interconnection, miniaturization, enhanced signal integrity, and superior thermal performance makes special Rogers HDI PCBs an ideal choice for engineers and designers seeking to push the boundaries of electronic design and functionality.

Applications of Special Rogers HDI PCBs

Use Cases in High-frequency Communication Equipment

Special Rogers HDI PCBs are increasingly utilized across various industries due to their superior performance and adaptability in high-frequency applications. One of the primary use cases is in high-frequency communication equipment, such as satellite communications, cellular networks, and microwave devices. These applications demand excellent signal integrity and low-loss transmission to ensure reliable communication, making special Rogers HDI PCBs an ideal choice. Their ability to handle high data rates with minimal signal degradation is critical in ensuring robust and efficient communication systems.

Applications in Automotive Electronics and IoT Devices

In the automotive industry, special Rogers HDI PCBs play a crucial role in the development of advanced driver-assistance systems (ADAS) and infotainment systems. As vehicles become more reliant on electronic components for safety and connectivity, the need for high-performance PCBs that can operate in challenging environments is paramount. Special Rogers HDI PCBs offer the necessary reliability and durability to withstand the thermal and mechanical stresses found in automotive applications, all while providing the high-speed data processing required for modern vehicles.

The Internet of Things (IoT) is another burgeoning field where special Rogers HDI PCBs are making an impact. With the proliferation of smart devices and sensors, there is a growing demand for compact, efficient, and high-performance circuit boards. These PCBs enable seamless connectivity and data transfer in IoT devices, enhancing functionality while minimizing size, which is crucial for wearable technology and smart home applications.

Other Industry Applications

Special Rogers HDI PCBs find applications in the military and medical equipment sectors. In military electronics, reliability and performance under extreme conditions are vital; special Rogers HDI PCBs meet these demands by offering exceptional thermal stability and signal integrity. In medical devices, where precision and reliability are paramount, these PCBs ensure accurate data transmission and functionality in critical healthcare applications, from imaging systems to monitoring devices.

The versatility and advanced capabilities of special Rogers HDI PCBs make them essential across these diverse applications, driving innovation and efficiency in modern electronic systems.

Manufacturing Process for Special Rogers HDI PCBs

Key Technologies in the Manufacturing Process

The manufacturing process for special Rogers HDI PCBs involves several key technologies and steps that ensure high-quality production tailored to the demands of high-frequency applications. One of the most critical technologies used is laser drilling, which enables the creation of microvias. This process allows for the precise drilling of small holes that connect different layers of the PCB, facilitating high-density interconnections. Additionally, advanced etching techniques are employed to produce fine lines and spaces, crucial for maintaining signal integrity in high-speed applications.

Use of Design Tools and Software

Design tools and software play an essential role in the production of special Rogers HDI PCBs. Engineers utilize sophisticated computer-aided design (CAD) software to create detailed layouts that maximize the use of space while ensuring optimal electrical performance. These tools allow for simulations that predict how the PCB will perform under various conditions, helping to refine designs before manufacturing begins. Software platforms also facilitate collaboration among design teams, enabling them to work together effectively on complex projects.

Quality Control and Testing Standards

Quality control and testing standards are paramount in the manufacturing process of special Rogers HDI PCBs. Manufacturers adhere to rigorous industry standards, such as IPC-A-600 for acceptability of printed boards, to ensure that every board meets strict quality requirements. Testing protocols often include electrical tests, such as flying probe testing, which checks for shorts and opens in the circuit, as well as thermal cycling tests to assess the board’s reliability under temperature variations. These quality assurance measures are essential for ensuring that the final product performs reliably in its intended application, especially in critical fields such as telecommunications, aerospace, and medical devices.

The combination of advanced manufacturing technologies, cutting-edge design tools, and stringent quality control processes ensures that special Rogers HDI PCBs are produced to meet the high-performance demands of modern electronic applications, providing reliable solutions for a variety of industries.

FQAs Abut Special Rogers HDI PCB Board

HDI (High-Density Interconnect) PCB boards are advanced printed circuit boards characterized by their high wiring density, compact size, and the use of microvias. These boards allow for more connections within a smaller area, making them ideal for complex electronic designs. HDI technology supports higher layer counts and finer traces, facilitating miniaturization and improved performance in high-speed applications.

The main differences between HDI and non-HDI PCBs include:

Material and Layer Count: HDI PCBs typically use advanced materials and have a higher layer count, allowing for more complex designs.

Design Complexity: HDI boards can incorporate microvias and fine line technology, enabling higher density interconnections. Non-HDI PCBs usually have simpler designs and fewer layers.

Manufacturing Costs and Timelines: HDI PCBs are generally more expensive and time-consuming to manufacture due to the advanced technologies involved, while non-HDI PCBs are more cost-effective and quicker to produce.

Rogers PCBs and FR4 PCBs differ primarily in their material properties:

Material Composition: Rogers PCBs are made from high-frequency materials designed for low dielectric loss and stable dielectric constants, making them suitable for high-speed applications. FR4 is a standard epoxy glass laminate that offers good mechanical properties but higher dielectric loss at high frequencies.

Performance: Rogers PCBs provide better signal integrity and thermal performance, while FR4 boards are more cost-effective and widely used in less demanding applications.

Rogers PCBs are printed circuit boards made from materials developed by Rogers Corporation, known for their excellent electrical performance in high-frequency and high-speed applications. These boards are characterized by low dielectric loss, high thermal stability, and consistent dielectric properties, making them ideal for telecommunications, aerospace, medical devices, and other advanced electronic applications. Rogers materials, such as RO4003C and RO4350B, are specifically engineered to meet the rigorous demands of modern circuit designs.