package substrate technology

Package substrate technology plays a pivotal role in the semiconductor industry, facilitating the assembly and functionality of integrated circuits (ICs). Its significance extends across various application areas, including consumer electronics, telecommunications, automotive, and healthcare devices. This blog aims to delve into the essence of package substrate technology, highlighting its critical functions in IC packaging and testing. We will explore the differences between PCB and package substrates, delve into the materials used, examine their role in semiconductor packaging, introduce innovative technologies like Toppan FCBGA, and speculate on future trends in this dynamic field. Join us as we unravel the intricacies of package substrate technology and its profound impact on modern electronics.

What is a Package Substrate?

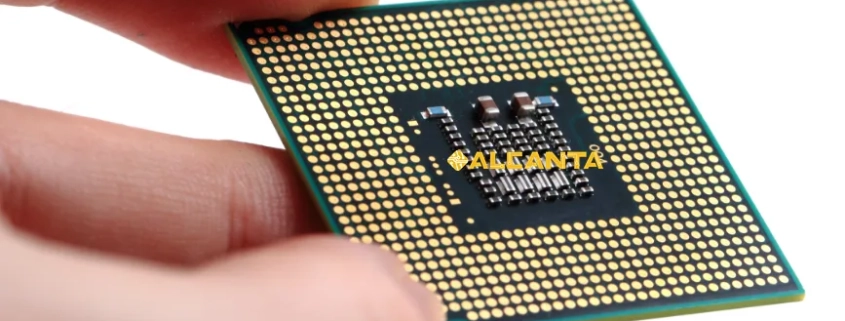

A package substrate serves as a foundational component in integrated circuit (IC) packaging, providing essential support and connectivity for semiconductor devices. Essentially, it is a specialized board that hosts and interconnects various IC components, such as microprocessors, memory chips, and sensors, within a single package. The substrate acts as a bridge between the IC chips and the external environment, facilitating electrical connections, thermal dissipation, and mechanical support.

The primary function of a package substrate is to enable the electrical interconnection between the IC components and the rest of the system, allowing data and signals to flow seamlessly. This interconnectivity is achieved through intricate patterns of conductive traces, vias, and pads fabricated on the substrate surface.

Moreover, package substrates play a critical role in IC packaging and testing processes. During packaging, the substrate provides a stable platform for mounting and bonding IC chips, ensuring proper alignment and connection between the chips and the package. Additionally, the substrate aids in dissipating heat generated by the ICs, thus contributing to overall device reliability and performance.

In testing, package substrates facilitate the application of electrical signals and stimuli to the ICs for functional validation and quality assurance. Through embedded test structures and access points, manufacturers can perform rigorous testing procedures to ensure the integrity and functionality of the packaged ICs before they are deployed in end-user devices.

Overall, package substrates are indispensable components in the semiconductor industry, enabling the packaging and testing of ICs essential for powering a wide range of electronic devices and systems. Their critical role in IC packaging and testing underscores their significance in ensuring the reliability, performance, and functionality of modern semiconductor devices.

Difference Between PCB and Package Substrate:

Printed Circuit Boards (PCBs) and package substrates are both integral components in electronic product manufacturing, yet they serve distinct purposes and exhibit different characteristics.

Characteristics and Uses:

PCB:

PCBs are flat boards typically made of fiberglass-reinforced epoxy laminates, with copper traces etched onto their surface.

They are primarily used for interconnecting and supporting electronic components, such as resistors, capacitors, and integrated circuits (ICs), in various electronic devices.

PCBs provide a platform for mounting and connecting discrete electronic components, facilitating the routing of electrical signals between them.

Package Substrates:

Package substrates are specialized boards designed specifically for mounting and interconnecting IC components within semiconductor packages.

They are made from materials optimized for thermal management and electrical performance, such as ceramic or laminate substrates.

Package substrates feature intricate patterns of conductive traces, vias, and pads tailored to accommodate the specific requirements of IC packaging.

Functions and Application Scenarios:

PCB:

PCBs serve as the backbone of electronic devices, providing structural support and electrical connectivity for a wide range of components.

They are commonly found in consumer electronics, industrial equipment, automotive systems, and telecommunications devices.

PCBs are utilized in applications where discrete electronic components need to be interconnected and mounted onto a single board.

Package Substrates:

Package substrates play a crucial role in IC packaging, enabling the integration and interconnection of multiple IC chips within a single package.

They are essential components in semiconductor devices, such as microprocessors, memory modules, and system-on-chip (SoC) devices.

Package substrates are utilized in applications requiring high-density packaging, advanced thermal management, and optimized electrical performance, such as smartphones, computers, automotive electronics, and medical devices.

In summary, while both PCBs and package substrates are fundamental to electronic product manufacturing, they serve different functions and cater to distinct application scenarios. PCBs are versatile boards used for interconnecting discrete electronic components, whereas package substrates are specialized boards designed specifically for IC packaging, offering enhanced thermal and electrical performance.

Materials for Package Substrates

Package substrates are manufactured using a variety of materials, each chosen for its specific properties and suitability for the intended application. Some common materials used in the manufacturing of package substrates include fiberglass-reinforced resin (FR-4), Multi-Layer Ceramics (MLC), and High-Density Interconnect (HDI) laminates.

Fiberglass-Reinforced Resin (FR-4):

FR-4 is one of the most widely used materials for package substrates due to its excellent electrical insulation properties and cost-effectiveness.

It consists of a woven glass fabric impregnated with epoxy resin, providing mechanical strength and dimensional stability.

FR-4 substrates offer good thermal conductivity and are suitable for standard IC packaging applications, such as ball grid array (BGA) and quad flat package (QFP).

Multi-Layer Ceramics (MLC):

MLC substrates are composed of multiple layers of ceramic material with embedded conductive traces, vias, and pads.

They offer superior thermal conductivity, low dielectric loss, and high mechanical strength, making them ideal for high-power and high-frequency applications.

MLC substrates are commonly used in radio frequency (RF) modules, power amplifiers, and microwave devices where thermal management and signal integrity are critical.

High-Density Interconnect (HDI) Laminates:

HDI laminates are advanced substrates designed for high-density packaging applications, such as flip-chip packaging and system-on-chip (SoC) integration.

They feature microvia technology, allowing for the creation of ultra-fine vias and traces with high aspect ratios.

HDI substrates offer excellent signal integrity, reduced signal loss, and improved electrical performance, making them suitable for high-speed data transmission and advanced packaging technologies.

Analysis of Characteristics and Applicability:

FR-4 substrates are well-suited for standard IC packaging applications where cost-effectiveness and electrical insulation are paramount. However, they may not be suitable for high-frequency or high-power applications due to their limited thermal conductivity.

MLC substrates excel in high-frequency and high-power applications where thermal management and signal integrity are critical. However, they tend to be more expensive than FR-4 substrates and may require specialized manufacturing processes.

HDI laminates offer the highest level of integration and miniaturization, making them ideal for advanced packaging technologies requiring high-density interconnects and fine-pitch components. However, they are typically more expensive than both FR-4 and MLC substrates and may require additional processing steps.

In summary, the choice of substrate material depends on factors such as cost, electrical performance, thermal management requirements, and the specific application needs. Manufacturers must carefully evaluate the characteristics and applicability of different materials to select the most suitable substrate for their packaging requirements.

Role of Package Substrates in Semiconductor Packaging

Package substrates play a crucial role in semiconductor packaging processes, serving as the foundation for mounting and interconnecting integrated circuit (IC) components within a packaged device. Their importance lies in facilitating electrical connections, managing thermal dissipation, and providing mechanical support, all of which are essential for the reliability and functionality of semiconductor devices.

Importance in Semiconductor Packaging Processes:

Package substrates serve as the structural backbone of semiconductor packages, providing a stable platform for mounting and interconnecting IC components.

They enable the integration of multiple IC chips within a single package, allowing for higher levels of integration and functionality in semiconductor devices.

Package substrates play a critical role in miniaturization efforts, as they enable the creation of compact and densely packed semiconductor packages suitable for a wide range of applications.

Electrical Connections:

Package substrates feature intricate patterns of conductive traces, vias, and pads that facilitate electrical connections between IC components and external circuitry.

These conductive pathways enable the transmission of electrical signals between the IC chips and the rest of the system, allowing for data communication and signal processing.

By providing reliable electrical connections, package substrates ensure the proper functioning of semiconductor devices in various electronic systems.

Thermal Management:

Package substrates play a vital role in managing the thermal dissipation of semiconductor devices, as they provide a pathway for heat to dissipate from the IC components to the surrounding environment.

Through the use of thermally conductive materials and design features such as thermal vias and thermal pads, package substrates help dissipate heat generated by the IC chips during operation.

Effective thermal management is essential for preventing overheating and thermal stress, which can degrade device performance and reliability over time.

Mechanical Support:

Package substrates provide mechanical support and protection for IC components, ensuring their stability and integrity within the packaged device.

They help to distribute mechanical stresses and vibrations, reducing the risk of mechanical failure or damage to the IC chips during handling, assembly, and operation.

Package substrates also provide a level of physical protection for the delicate IC components, shielding them from environmental factors such as moisture, dust, and mechanical shock.

In summary, package substrates are integral components in semiconductor packaging processes, enabling electrical connections, thermal management, and mechanical support for IC components within packaged devices. Their role in ensuring the reliability, functionality, and performance of semiconductor devices underscores their importance in the semiconductor industry.

Introduction to Toppan FCBGA Technology

Toppan FCBGA (Flip Chip Ball Grid Array) technology represents a significant advancement in high-performance semiconductor packaging, offering numerous features and advantages over traditional packaging methods. This innovative technology revolutionizes the way integrated circuits (ICs) are packaged, providing enhanced performance, reliability, and versatility.

Features and Advantages of Toppan FCBGA Technology:

Flip Chip Interconnection: Toppan FCBGA technology utilizes flip chip interconnection, where the IC chip is flipped upside down and directly bonded to the package substrate using solder bumps. This configuration minimizes signal propagation distances, reduces inductance, and enhances electrical performance.

High Density Interconnects: Toppan FCBGA packages feature high-density interconnects, allowing for the integration of a large number of signal, power, and ground connections within a compact package footprint. This enables higher levels of integration and functionality in semiconductor devices.

Enhanced Thermal Management: The flip chip configuration of Toppan FCBGA technology enables efficient heat dissipation from the IC chip to the package substrate and surrounding environment. This results in improved thermal management and reduced operating temperatures, leading to enhanced device reliability and longevity.

Mechanical Stability: Toppan FCBGA packages offer superior mechanical stability and robustness, thanks to the direct bond between the IC chip and the package substrate. This minimizes the risk of solder joint fatigue, package warpage, and mechanical failure during operation.

Versatility: Toppan FCBGA technology is highly versatile and can accommodate a wide range of IC types, including microprocessors, memory chips, and system-on-chip (SoC) devices. It is suitable for various applications across industries, including consumer electronics, telecommunications, automotive, and aerospace.

Applications and Impact in High-Performance Semiconductor Packaging:

High-Performance Computing: Toppan FCBGA technology is ideal for high-performance computing applications, such as data centers, supercomputers, and artificial intelligence (AI) systems. Its high-density interconnects and efficient thermal management capabilities make it well-suited for demanding computational tasks.

Networking and Telecommunications: Toppan FCBGA packages are widely used in networking and telecommunications equipment, including routers, switches, and base stations. Their high-speed signal processing capabilities and reliable interconnects ensure seamless data transmission and communication.

Automotive Electronics: Toppan FCBGA technology is increasingly being adopted in automotive electronics, including advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs). Its rugged design, thermal stability, and high reliability make it suitable for harsh automotive environments.

Consumer Electronics: Toppan FCBGA packages find applications in various consumer electronics products, such as smartphones, tablets, and gaming consoles. Their compact size, high performance, and energy efficiency contribute to the development of next-generation consumer devices.

In summary, Toppan FCBGA technology represents a cutting-edge solution for high-performance semiconductor packaging, offering features such as flip chip interconnection, high-density interconnects, enhanced thermal management, and mechanical stability. Its widespread applications across industries underscore its significant impact on the advancement of semiconductor packaging technology.

Future Trends in Package Substrate Technology

As technology continues to evolve, the field of package substrate technology is poised for significant advancements and innovations. Several future development directions and trends are shaping the trajectory of package substrate technology, driven by the demand for higher performance, increased integration, and improved reliability in semiconductor packaging. Additionally, the influence of new technologies and materials is expected to drive transformative changes in the package substrate industry.

Exploring Future Development Directions and Trends:

1. Miniaturization and High-Density Interconnects: The trend towards smaller, more compact electronic devices is driving the development of package substrates with higher levels of integration and miniaturization. Future package substrates are likely to feature even denser interconnects, enabling the integration of more functionality within a smaller footprint.

2. Advanced Thermal Management Solutions: With the increasing power densities of semiconductor devices, effective thermal management is becoming increasingly crucial. Future package substrates are expected to incorporate advanced thermal management solutions, such as embedded heat sinks, microfluidic cooling channels, and advanced materials with enhanced thermal conductivity.

3. Flexible and Stretchable Substrates: The emergence of flexible and stretchable electronics is opening up new possibilities for package substrate technology. Future package substrates may incorporate flexible substrates, such as polyimide or stretchable polymers, to enable conformal integration with curved surfaces and wearable devices.

4. Integration of Heterogeneous Materials: Future package substrates may leverage the integration of heterogeneous materials, such as silicon, ceramics, and organic polymers, to achieve optimal performance and functionality. This approach enables the customization of package substrates to meet specific application requirements, such as high-speed signal processing, RF communication, and power management.

5. Enhanced Reliability and Durability: With the increasing complexity of semiconductor packages, ensuring reliability and durability becomes paramount. Future package substrates are likely to incorporate advanced reliability features, such as built-in self-test capabilities, fault-tolerant designs, and enhanced materials with improved mechanical properties.

6. Integration of Advanced Manufacturing Technologies: The adoption of advanced manufacturing technologies, such as additive manufacturing (3D printing), laser processing, and nanoimprint lithography, is expected to revolutionize package substrate fabrication processes. These technologies enable the rapid prototyping, customization, and mass production of complex package substrates with high precision and efficiency.

Analyzing the Influence of New Technologies and Materials:

1. Advanced Packaging Technologies: The emergence of advanced packaging technologies, such as fan-out wafer-level packaging (FOWLP), 2.5D and 3D integration, and system-in-package (SiP) solutions, is driving the demand for package substrates with enhanced performance and functionality.

2. New Materials for Package Substrates: The development of new materials, such as low-loss dielectrics, high thermal conductivity ceramics, and flexible substrates, is expanding the design possibilities for package substrates. These materials offer improved electrical performance, thermal management, and mechanical flexibility, enabling the development of next-generation semiconductor packages.

3. Emerging Applications: The proliferation of emerging applications, such as 5G communication, Internet of Things (IoT), artificial intelligence (AI), and autonomous vehicles, is driving the demand for package substrates with specific performance requirements. Future package substrates need to be optimized for these applications, offering features such as high-speed signal transmission, low power consumption, and reliability in harsh environments.

In summary, the future of package substrate technology is characterized by advancements in miniaturization, thermal management, flexibility, reliability, and manufacturing technologies. The integration of new materials and technologies is expected to drive transformative changes in the package substrate industry, enabling the development of more advanced and versatile semiconductor packages to meet the evolving demands of the electronics market.

FAQs about package substrate technology

A package substrate is a specialized board used in semiconductor packaging to interconnect and support integrated circuit (IC) components within a single package. It facilitates electrical connections, thermal management, and mechanical support for IC chips.

The main difference between a PCB (Printed Circuit Board) and a package substrate lies in their primary functions and applications. PCBs are used for interconnecting and supporting discrete electronic components, whereas package substrates are specifically designed for mounting and interconnecting IC components within semiconductor packages.

The substrate material for packaging varies depending on the specific requirements of the application. Common materials include fiberglass-reinforced resin (FR-4), Multi-Layer Ceramics (MLC), and High-Density Interconnect (HDI) laminates. These materials offer different electrical, thermal, and mechanical properties to suit various packaging needs.

4. In the context of semiconductors, a substrate refers to the underlying material or base upon which semiconductor devices are fabricated. It provides a foundation for building electronic components and circuits, enabling the integration of active and passive components to form functional semiconductor devices. The substrate also serves as a platform for mounting and interconnecting semiconductor chips within a package, facilitating the electrical connections and heat dissipation necessary for device operation.

发表评论

Want to join the discussion?Feel free to contribute!