Navigating Semiconductor Terrain: Interposer vs Substrate

In the world of advanced electronics, how chips are packaged can make or break a device’s performance. The debate of interposer vs substrate revolves around two key components that shape the functionality, speed, and efficiency of modern systems.

An interposer acts as a bridge that connects multiple chips within a single package, enabling high-speed data transfer and efficient integration. Meanwhile, a substrate serves as the foundation, providing electrical interconnections and thermal management between the chip and the circuit board.

Understanding the unique roles of interposer vs substrate is essential to grasp how cutting-edge technologies like 2.5D packaging and high-bandwidth memory (HBM) are evolving. Both elements are pivotal in designing high-performance systems, but their differences determine when and how each should be used to achieve optimal results.

What is an Interposer?

The Role of an Intermediate Layer

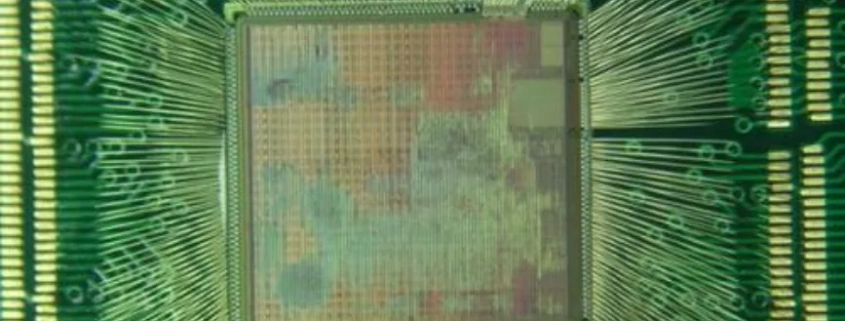

An interposer is a crucial intermediate layer in semiconductor packaging, serving as a bridge between the integrated chip (IC) and the underlying substrate or printed circuit board (PCB). Its primary purpose is to facilitate high-density electrical connections and enable advanced functionalities that standard substrates cannot achieve. The interposer improves signal routing, power distribution, and thermal management, particularly in applications requiring compact, high-performance multi-chip integration.

Interposers are often used in 2.5D packaging, where multiple chips are mounted side-by-side on a single interposer, connected through fine-pitch wiring. This allows for higher interconnection density while maintaining signal integrity and reducing latency compared to traditional packaging methods.

Materials: Silicon, Glass, Organic Substrates

Interposers can be made from various materials, each offering unique advantages for specific applications:

-

Silicon Interposer:

- Characteristics:

- High thermal conductivity.

- Compatibility with through-silicon via (TSV) technology for vertical interconnections.

- Extremely fine line and spacing capabilities for dense interconnects.

- Applications: High-performance computing, GPUs, FPGAs, and AI accelerators.

- Drawback: Higher cost compared to organic alternatives.

- Characteristics:

-

Glass Interposer:

- Characteristics:

- Excellent electrical insulation properties.

- Lower cost than silicon interposers.

- Potential for high thermal stability.

- Applications: Emerging in high-frequency and optical applications.

- Drawback: Manufacturing and processing challenges compared to silicon.

- Characteristics:

-

Organic Interposer:

- Characteristics:

- Flexible and cost-effective.

- Easier to manufacture compared to silicon or glass.

- Lower density interconnects than silicon.

- Applications: Consumer electronics and less performance-critical systems.

- Drawback: Limited thermal and mechanical performance.

- Characteristics:

Applications: 2.5D Packaging, HBM, and More

Interposers are essential for enabling advanced packaging technologies, particularly in applications that demand high bandwidth, reduced form factors, and enhanced electrical performance:

-

2.5D Packaging:

In 2.5D configurations, chips such as GPUs, CPUs, or AI accelerators are mounted on a silicon interposer, which serves as a communication hub. This design allows for high interconnect density and efficient routing of signals between chips, leading to improved performance and energy efficiency. -

High-Bandwidth Memory (HBM):

Interposers play a critical role in HBM integration, connecting memory stacks and logic chips in high-performance systems. The short interconnect distances provided by the interposer reduce latency and improve bandwidth, making them ideal for demanding workloads such as AI training, graphics rendering, and scientific simulations. -

Multi-Chip Integration:

Interposers enable seamless integration of heterogeneous chips, including processors, memory, and specialized accelerators. This flexibility supports modular designs and faster time-to-market for new products. -

Signal Integrity and Power Distribution:

By providing optimized signal routing and power delivery paths, interposers improve system performance, reduce noise, and enhance overall reliability.

Key Technologies: Silicon Interposer and TSV (Through-Silicon Via)

One of the most significant advancements in interposer technology is the use of Through-Silicon Via (TSV) in silicon interposers. TSV technology allows for vertical interconnections through the silicon substrate, significantly enhancing interconnect density and reducing parasitic effects.

-

Silicon Interposer with TSV:

- TSVs are tiny holes drilled into the silicon interposer and filled with conductive materials (such as copper) to create electrical connections between different layers or chips.

- TSV-based interposers are critical for achieving low-latency, high-bandwidth interconnects in advanced systems.

-

RDL (Redistribution Layer):

- Silicon interposers often include redistribution layers for fine-pitch wiring, enabling precise routing of signals between chips and substrate connections.

Advantages of Interposers

- High Interconnection Density: Supports advanced designs with tightly packed components.

- Signal Quality: Reduces latency, noise, and crosstalk for better performance.

- Scalability: Facilitates multi-chip systems in compact, efficient layouts.

- Thermal Management: Silicon interposers, in particular, provide excellent heat dissipation.

What is a Substrate?

Mechanical and Electrical Foundation for Chips

A substrate is a key component in semiconductor packaging that serves as the mechanical and electrical foundation for integrated circuits (ICs). It provides a stable platform to support the chip while establishing electrical connections between the chip and the external environment, such as a printed circuit board (PCB).

The substrate is a critical layer in chip packaging, acting as both a physical support structure and a conduit for signals and power. It houses the interconnections that distribute electrical signals from the IC to the PCB and vice versa. Additionally, it plays an essential role in thermal management by dissipating heat generated by the IC, thereby ensuring system reliability and performance.

Materials: BT Resin, Organic Substrates

Substrates are typically made from a range of materials, chosen for their mechanical strength, electrical properties, and thermal performance. The two most common materials used are:

-

BT Resin (Bismaleimide-Triazine Resin):

- Characteristics:

- High thermal stability.

- Excellent mechanical strength and dimensional stability.

- Good electrical insulation properties.

- Applications: Widely used in high-performance semiconductor packages, such as BGA (Ball Grid Array) and CSP (Chip-Scale Package).

- Characteristics:

-

Organic Substrates:

- Characteristics:

- Cost-effective and lightweight.

- Suitable for large-scale manufacturing.

- Good flexibility but with limited thermal performance compared to ceramic or metal-based substrates.

- Applications: Common in consumer electronics and less-demanding applications.

- Characteristics:

Other materials, like ceramics (for high-temperature environments) and metal-core substrates (for enhanced thermal conductivity), are used in specialized applications.

Applications: Traditional Packages (e.g., BGA, CSP)

Substrates are essential in various traditional and advanced IC packaging methods. Key applications include:

-

- A packaging technology where the chip is mounted on a substrate, with solder balls on the bottom for electrical connections.

- Substrate provides mechanical support for the chip and routing for signal and power distribution.

-

Chip-Scale Package (CSP):

- Miniaturized packaging method where the chip size is almost the same as the substrate size.

- Used in mobile devices and compact consumer electronics.

-

Flip-Chip Packaging:

- Substrate connects to the IC through bumping (flip-chip solder balls), offering high-density interconnections for high-performance devices like processors and GPUs.

-

Embedded Substrate Technology:

- Used in advanced designs where components like passive elements are embedded directly into the substrate for improved performance and reduced footprint.

Functions and Characteristics: Electrical Interconnection, Thermal Management

Substrates perform several vital functions in IC packaging, ensuring both mechanical and electrical integration:

-

Electrical Interconnection:

- Acts as a wiring platform for the IC, routing electrical signals between the chip and the PCB.

- Supports multi-layer wiring to enable high-density interconnections in complex systems.

- Includes power and ground planes to ensure efficient power distribution and minimize electrical noise.

-

Thermal Management:

- Dissipates heat generated by the IC, protecting the device from overheating and ensuring reliable operation.

- Advanced substrates may include features like thermal vias, heat spreaders, or metal cores to enhance thermal conductivity.

-

Mechanical Support:

- Provides a rigid and stable platform for the IC, ensuring durability during operation and resistance to physical stresses, such as thermal cycling and mechanical shocks.

-

Protection Against Environmental Factors:

- Protects the IC from contaminants, moisture, and mechanical damage during both the manufacturing process and device operation.

Advantages of Substrates

- Cost-Effectiveness: Organic substrates, in particular, are economical and scalable for high-volume production.

- Versatility: Compatible with various packaging technologies, from traditional wire-bond packages to modern flip-chip designs.

- Customizability: Can be tailored for specific applications with different material properties and layouts.

- Enhanced Signal Integrity: Multi-layer substrates with well-designed traces minimize signal loss and crosstalk.

Emerging Trends in Substrate Technology

As electronic devices demand higher performance and smaller form factors, substrates are evolving with new features:

- Advanced Substrate Designs: Higher layer counts and finer pitches for high-density interconnections.

- Integration of Passive Components: Embedding capacitors, resistors, and inductors directly within the substrate.

- Use in 2.5D and 3D Packaging: Substrates serve as the foundational layer for complex interposers and multi-die stacks.

Interposer vs Substrate: Functional and Performance Comparison

Understanding the differences between interposers and substrates is critical to selecting the right solution for specific semiconductor packaging needs. This section provides a detailed comparison of their functionality, materials, manufacturing processes, and performance characteristics.

Functional Comparison

-

Interposer

- High I/O Density:

Interposers are specifically designed to enable high Input/Output (I/O) density, allowing them to support advanced multi-chip modules (MCMs) and high-bandwidth memory (HBM). Their fine-pitch routing capabilities provide precise electrical connections for tightly packed chips, which is essential for high-performance computing and AI applications. - Multi-Chip Integration:

Interposers act as a platform to integrate multiple chips (heterogeneous integration) into a single package. This is particularly valuable in 2.5D packaging, where logic dies, memory stacks, and accelerators are interconnected through the interposer, enabling modular system design and higher functionality in smaller form factors.

- High I/O Density:

-

Substrate

- Bridge Between Chips and PCBs:

Substrates provide the mechanical and electrical interface between the IC and the PCB. They distribute power and signals from the chip to the larger system while ensuring physical support. Substrates are more focused on basic connectivity and packaging in traditional semiconductor devices. - Support for Various Packages:

Substrates are the foundation for packaging technologies like BGA (Ball Grid Array), CSP (Chip Scale Package), and flip-chip designs, which are widely used in consumer electronics and general-purpose devices.

- Bridge Between Chips and PCBs:

Material and Manufacturing Process Comparison

-

Interposer

- Silicon-Based with TSV Technology:

Interposers are often made from silicon, leveraging advanced Through-Silicon Via (TSV) technology to create vertical electrical interconnections. TSVs allow interposers to achieve extremely high interconnect density and short signal paths, significantly improving performance. - Advanced Manufacturing:

The fabrication of silicon interposers involves complex processes such as TSV etching, filling with conductive materials (e.g., copper), and redistribution layers (RDL) for signal routing. This precision manufacturing allows for finer line widths and higher I/O counts. - Alternative Materials:

While silicon is the most common material, glass and organic interposers are emerging for specific use cases, offering cost benefits or better electrical insulation properties.

- Silicon-Based with TSV Technology:

-

Substrate

- Organic-Based, Multilayer Wiring:

Substrates are typically constructed using organic materials, such as BT resin (bismaleimide-triazine resin), which provide a cost-effective and flexible platform. They use multilayer wiring structures to route signals and power between the IC and the PCB. - Simple Manufacturing Process:

The manufacturing process of substrates involves standard PCB-like technologies, including laminating organic layers, applying copper traces for wiring, and forming vias for vertical interconnections. While simpler and less costly than interposer fabrication, it supports lower interconnect densities.

- Organic-Based, Multilayer Wiring:

Performance Comparison

-

Signal Integrity and Precision

- Interposer:

- Offers superior signal integrity due to shorter and more precise interconnect paths.

- The use of TSVs and fine-pitch wiring minimizes parasitic effects (e.g., capacitance and inductance) and reduces signal degradation, making interposers ideal for high-frequency and high-bandwidth applications.

- Substrate:

- Provides adequate signal routing for standard applications but is limited by larger interconnect pitches and less precise routing compared to interposers.

- Signal loss and crosstalk are more pronounced, particularly in high-speed designs.

- Interposer:

-

Thermal Management and Power Optimization

- Interposer:

- Silicon interposers excel in thermal conductivity, efficiently dissipating heat generated by high-power ICs. This helps maintain performance and reliability in advanced systems.

- Power delivery is more efficient due to shorter interconnection paths and lower resistance.

- Substrate:

- Organic substrates have moderate thermal management capabilities, which can be enhanced with additional components like heat spreaders or thermal vias.

- Power optimization is limited by higher resistance and longer interconnect paths.

- Interposer:

-

Cost and Reliability

- Interposer:

- High manufacturing complexity and advanced materials make interposers significantly more expensive than substrates. Silicon interposers, in particular, are costly due to TSV fabrication.

- Reliability is high in controlled environments but may face challenges with mechanical stress due to material rigidity.

- Substrate:

- Cost-effective and suitable for high-volume production, substrates are widely used in consumer electronics.

- Organic materials are more flexible and resilient to mechanical stress but less durable under extreme thermal or electrical conditions.

- Interposer:

| Aspect | Interposer | Substrate |

|---|---|---|

| Primary Role | High I/O density, multi-chip integration | Bridge chips and PCBs |

| Materials | Silicon, glass, organic | BT resin, organic substrates |

| Signal Integrity | High, with precise routing and TSVs | Moderate, limited by interconnect size |

| Thermal Management | Excellent, with high conductivity | Adequate, with additional components |

| Cost | High | Low |

| Applications | 2.5D packaging, HBM, high-performance ICs | Traditional packages like BGA, CSP |

Related Technological Extensions: Interposer vs Substrate in Advanced Packaging

This section explores key technological extensions and comparisons within the context of Interposer vs Substrate, highlighting innovations, material advancements, and practical applications in semiconductor packaging.

Silicon Interposer vs Substrate

-

Advantages and Challenges of Silicon Interposers

-

Advantages:

- High Density Interconnects: Silicon interposers enable extremely fine-pitch routing and support TSV (Through-Silicon Via) technology, which facilitates efficient vertical connections.

- Thermal Management: The excellent thermal conductivity of silicon helps dissipate heat effectively in high-power systems like GPUs and AI accelerators.

- Signal Integrity: Shorter interconnect paths and lower parasitics ensure minimal signal loss and better performance in high-frequency applications.

-

Challenges:

- Cost: Silicon interposers are expensive to manufacture due to advanced processes like TSV etching and fine-line patterning.

- Mechanical Fragility: Silicon’s brittle nature makes it prone to cracking under mechanical stress, requiring additional protective measures in packaging.

-

-

Performance Comparison with Organic Substrates

- Silicon interposers far outperform organic substrates in terms of I/O density, signal integrity, and thermal conductivity, making them ideal for high-performance applications.

- Organic substrates, while less precise and thermally efficient, are cost-effective and easier to manufacture, making them suitable for consumer electronics and traditional packaging.

Interposer vs PCB

-

Differences in Purpose and Manufacturing

-

Purpose:

- An interposer is an intermediate layer that connects multiple chips or bridges chips to substrates. It focuses on high-density connections and multi-chip integration in advanced systems.

- A PCB (Printed Circuit Board) is the base layer that connects packaged ICs, providing mechanical support and facilitating power and signal distribution across the entire system.

-

Manufacturing:

- Interposers, especially silicon-based ones, require advanced fabrication technologies like TSV and redistribution layers, making them complex and costly to produce.

- PCBs are manufactured using simpler processes, such as lamination and through-hole plating, which allow for large-scale production at lower costs.

-

-

Practical Choices in High-Performance Systems

- In high-performance computing and AI applications, interposers are used to integrate heterogeneous chips efficiently, enhancing overall system performance.

- PCBs remain the standard choice for connecting packaged ICs and other components in broader electronic systems due to their versatility and affordability.

RDL Interposer vs Silicon Interposer

-

Definition and Role of Redistribution Layer (RDL)

- Redistribution Layer (RDL):

- RDL is a metallization layer added to chips or interposers to rearrange the input/output connections, enabling fine-pitch routing and improved interconnect density.

- RDL interposers leverage this layer to provide flexible signal routing between components, even without TSVs, making them a cost-effective alternative to traditional silicon interposers.

- Redistribution Layer (RDL):

-

Differences in Design and Application

- Silicon Interposer:

- Relies on TSVs to achieve vertical connections, making it suitable for high-performance applications like HBM and 2.5D packaging.

- Best suited for systems requiring ultra-high interconnect density and advanced thermal management.

- RDL Interposer:

- Utilizes redistribution layers without the complexity of TSVs, offering lower costs and simpler manufacturing.

- Often used in less demanding applications where TSV-level performance is not necessary, such as mobile devices or IoT systems.

- Silicon Interposer:

| Aspect | Silicon Interposer | Organic Substrate | RDL Interposer | PCB |

|---|---|---|---|---|

| Purpose | High-density interconnects, multi-chip integration | Basic chip-to-PCB bridge | Cost-effective signal redistribution | System-level connectivity |

| Key Technology | TSV, advanced lithography | Multilayer organic wiring | Redistribution layer (RDL) | Copper traces, through-hole vias |

| Performance | Superior signal integrity, thermal management | Moderate signal and thermal performance | Balanced performance, lower cost | Reliable and cost-effective |

| Applications | High-performance computing, HBM | Consumer electronics, traditional ICs | IoT, mobile devices | General electronic systems |

Types and Applications of Interposers: Interposer vs Substrate in Modern Electronics

In the ongoing discussion of interposer vs substrate, understanding the various types of interposers and their specific applications is crucial. Interposers come in multiple forms, each tailored for different performance requirements and use cases. This section explores the primary types of interposers and their real-world applications, particularly in advanced semiconductor packaging.

Different Types of Interposers

-

Silicon Interposer

- Overview:

A silicon interposer is the most advanced type, widely used in high-performance semiconductor applications. It incorporates TSV (Through-Silicon Via) technology to enable vertical interconnections between dies. - Advantages:

- High interconnect density with fine-pitch routing.

- Superior thermal conductivity, which aids in heat dissipation.

- Minimal signal loss, ensuring excellent signal integrity for high-frequency applications.

- Applications:

- Essential in 2.5D IC packaging, where it connects high-bandwidth memory (HBM) with processing units, such as GPUs and AI accelerators.

- Overview:

-

Organic Interposer

- Overview:

Organic interposers are a cost-effective alternative to silicon interposers, made using organic materials similar to those in traditional substrates. - Advantages:

- Lower manufacturing cost compared to silicon.

- Lightweight and flexible, making them ideal for mobile and consumer electronics.

- Limitations:

- Lower interconnect density and weaker thermal performance compared to silicon.

- Applications:

- Used in less demanding applications, such as IoT devices and low-power wearable electronics.

- Overview:

-

Glass Interposer

- Overview:

A glass interposer is an emerging technology that combines high electrical insulation with good mechanical properties. - Advantages:

- Excellent electrical insulation reduces crosstalk and interference.

- Smooth surface ensures high precision for fine-pitch connections.

- Low thermal expansion coefficient aligns well with silicon chips, reducing stress during operation.

- Challenges:

- Fragility and manufacturing complexity compared to organic interposers.

- Applications:

- Targeted for RF (radio frequency) devices, MEMS (microelectromechanical systems), and advanced optical interconnects.

- Overview:

Real-World Application Cases

-

Role in 2.5D IC Packaging

- How Interposers Excel:

In 2.5D packaging, interposers serve as a bridging layer to integrate multiple chips, such as logic dies and HBM, on a single platform.- Silicon interposers, in particular, enable high-bandwidth communication between dies by providing dense, short interconnects.

- This capability surpasses what organic substrates alone can achieve, highlighting the differences in performance between interposer vs substrate technologies.

- Use Case:

Companies like AMD and NVIDIA utilize silicon interposers in their high-performance GPUs, combining HBM with processing cores to achieve unparalleled data throughput and power efficiency.

- How Interposers Excel:

-

Efficient Interconnection Between HBM and Logic Chips

- Why Interposers Are Essential:

High-bandwidth memory demands extremely high I/O density and low latency communication with processing units. Interposers are uniquely equipped to handle these requirements due to their fine-pitch routing and superior signal integrity.- In the interposer vs substrate comparison, interposers provide the precision and performance required for memory-intensive operations, whereas substrates focus on cost-effective scaling for broader applications.

- Use Case:

- In AI and machine learning systems, silicon interposers are used to connect HBM stacks to custom accelerators, optimizing computational throughput while minimizing power consumption.

- Why Interposers Are Essential:

Collaboration Between Interposer and Substrate: Interposer vs Substrate in Hybrid Packaging Solutions

In the evolving landscape of semiconductor packaging, the collaboration between interposers and substrates has become essential. The debate surrounding interposer vs substrate often overlooks their complementary roles in hybrid packaging designs, where their combined strengths enable advanced system architectures. This section explores how interposers and substrates work together to meet the demands of modern electronic systems, with a focus on high-performance applications and market trends.

Hybrid Designs in Modern Packaging

Hybrid packaging combines the precision and high-performance capabilities of interposers with the scalability and cost-effectiveness of substrates.

- Design Concept:

- The interposer serves as a high-density routing layer, connecting multiple chips such as logic dies and high-bandwidth memory (HBM).

- The substrate acts as the interface between the interposer and the printed circuit board (PCB), providing mechanical support and broader signal distribution.

- Example:

- In 2.5D packaging, silicon interposers are integrated onto organic substrates, leveraging the best of both technologies to achieve performance and affordability.

How Interposers Address Substrate Limitations

-

High-Density Routing

- Substrates are limited in their ability to handle fine-pitch interconnects, making them unsuitable for high I/O applications. Interposers, particularly silicon-based ones, overcome this by offering ultra-fine routing and TSV (Through-Silicon Via) technology for vertical interconnections.

- This collaboration is particularly evident in advanced packaging solutions like HBM, where interposers bridge the gap between tightly packed memory stacks and the larger substrate.

-

Thermal Optimization

- Substrates struggle with effective heat dissipation, especially in high-power systems. Interposers, especially silicon interposers, provide superior thermal conductivity, efficiently dissipating heat generated by densely packed components.

- In interposer vs substrate scenarios, interposers enhance overall system reliability by addressing the thermal challenges substrates alone cannot resolve.

Case Study: Packaging of High-Performance GPUs and AI Accelerators

The collaboration between interposers and substrates is exemplified in high-performance computing systems such as GPUs and AI accelerators.

-

System Requirements:

- High-bandwidth, low-latency connections between processing cores and HBM.

- Efficient power delivery and thermal management to sustain intensive workloads.

-

Solution:

- A silicon interposer integrates HBM stacks with the processing unit, ensuring high I/O density and short signal paths for optimal performance.

- An organic substrate supports the interposer, providing a cost-effective platform for connecting the package to the PCB.

-

Impact:

- Companies like NVIDIA and AMD have adopted this hybrid approach to deliver GPUs that power AI, machine learning, and data center operations, achieving unparalleled computational efficiency and performance.

High-Density Routing and Thermal Optimization

In the context of interposer vs substrate, their collaboration addresses two critical challenges in modern semiconductor design:

-

High-Density Routing:

- Interposers provide the fine-pitch wiring required for dense chip-to-chip connections, especially in multi-die systems. Substrates extend these connections to the PCB, scaling the design for broader system integration.

-

Thermal Optimization:

- Silicon interposers contribute superior heat dissipation, reducing the thermal burden on substrates and enabling stable operation in high-performance systems.

Market Trends and Evolving Demands

-

Demand for High-Performance Packaging

- The rise of AI, 5G, and edge computing drives the need for hybrid solutions that combine interposer precision with substrate scalability.

- Advanced packaging, such as chiplet-based designs, increasingly relies on the complementary strengths of interposers and substrates.

-

Cost-Performance Balance

- While silicon interposers dominate high-end applications, emerging materials like glass interposers aim to lower costs without sacrificing performance. Substrates, particularly organic ones, continue to evolve with finer routing capabilities to meet mid-range market demands.

-

Sustainability and Scalability

- As the semiconductor industry moves toward greener practices, hybrid designs offer a path to balance performance with sustainable material usage, leveraging the complementary roles of interposer vs substrate technologies.

The Role of Substrate in Semiconductor

Definition of Substrate

In semiconductor technology, a substrate refers to a base material on which various semiconductor components are fabricated or assembled. It serves as the foundation for the semiconductor device, providing mechanical support, electrical connectivity, and thermal management. Substrates are typically made of materials like silicon, glass, or organic substrates such as laminate or epoxy resins.

Role of Substrate in IC Packaging and Testing

1. Mechanical Support: Substrates offer structural integrity to the semiconductor device, ensuring stability and durability during handling, assembly, and operation.

2. Electrical Connectivity: Substrates provide pathways for electrical signals to flow between different components within the semiconductor package. They often contain conductive traces, vias, and pads that facilitate interconnections between integrated circuits, external interfaces, and power sources.

3. Thermal Management: Substrates help dissipate heat generated by the integrated circuits, ensuring optimal operating temperatures and preventing thermal stress that can degrade performance or reliability.

Comparison with Leadframe

1. Material Composition: Leadframes are typically made of metal alloys such as copper or iron-nickel, while substrates can be made of a variety of materials including silicon, organic substrates, or glass.

2. Construction: Leadframes consist of a metal frame with leads that connect the integrated circuit to the external package, whereas substrates provide a more integrated platform with embedded wiring and circuitry.

3. Application: Leadframes are commonly used in traditional IC packaging methods like dual in-line packages (DIPs) and quad flat packages (QFPs), whereas substrates are essential components in advanced packaging technologies such as flip-chip, chip-on-board, and system-in-package (SiP) configurations. Substrates offer greater flexibility in design and functionality, making them suitable for diverse packaging requirements in modern semiconductor devices.

Applications of Interposer and Substrate

Purpose of Interposer

1. Signal Routing: Interposers facilitate the routing of high-speed signals between different integrated circuits (ICs) or between an IC and other components in a semiconductor package. They provide a platform for the integration of through-silicon vias (TSVs) or re-distribution layers (RDLs) to enable efficient signal transmission.

2. Interconnection Enhancement: Interposers enhance the connectivity between heterogeneous components, such as a microprocessor and memory modules, enabling tighter integration and improved system performance.

3. Thermal Management: Some interposers incorporate thermal management features such as heat spreaders or thermal vias to dissipate heat generated by the integrated circuits, ensuring optimal operating conditions and preventing thermal-related issues.

Purpose of Substrate

1. Structural Support: Substrates provide a robust foundation for semiconductor devices, ensuring mechanical stability and durability during handling, assembly, and operation.

2. Electrical Pathways: Substrates host conductive traces, vias, and pads that enable electrical connectivity between various components within the semiconductor package. They serve as conduits for signal transmission, power distribution, and ground connections.

3. Heat Dissipation: Substrates aid in thermal management by facilitating the transfer of heat away from the integrated circuits, thereby maintaining optimal operating temperatures and preventing thermal-induced failures.

Applications of Interposer and Substrate in 2.5D CoWoS

In 2.5D Chip-on-Wafer-on-Substrate (CoWoS) technology:

1. Interposer: Interposers play a crucial role in connecting multiple silicon dies or chips on a silicon interposer, enabling high-bandwidth communication between them. This architecture allows for the integration of diverse functionalities, such as logic, memory, and heterogeneous components, onto a single package.

2. Substrate: The substrate serves as the foundation for the entire 2.5D CoWoS assembly, providing mechanical support and electrical connectivity for the interposer and the stacked silicon dies. It also facilitates thermal management by dissipating heat away from the integrated circuits to ensure reliable operation.

These applications highlight the complementary roles of interposers and substrates in enabling advanced packaging solutions like 2.5D CoWoS, which offer enhanced performance, integration, and scalability for semiconductor devices.

See Also: THE FUTURE OF BGA: STREAMLINED EFFICIENCY WITH BUS LESS SUBSTRATE

Pros and Cons Comparison

1. Interposer:

– Pros:

– Enables high-density interconnects and heterogeneous integration.

– Enhances signal integrity and system performance.

– Allows for flexible routing and integration of active components.

– Cons:

– Higher manufacturing complexity and cost compared to traditional substrates.

– Limited scalability for certain applications.

– Potential reliability issues with TSVs or complex interposer architectures.

2. Substrate:

– Pros:

– Provides robust structural support and electrical connectivity.

– Cost-effective solution for many semiconductor packaging applications.

– Well-established manufacturing processes and materials.

– Cons:

– Limited in terms of signal routing complexity compared to interposers.

– May not be suitable for advanced packaging techniques like 2.5D or 3D integration.

– Less flexibility in design and integration of active components compared to interposers.

Understanding the differences and trade-offs between interposers and substrates is essential for selecting the most suitable packaging solution for specific semiconductor applications. Each has its advantages and limitations, and the choice depends on factors such as performance requirements, cost considerations, and manufacturing constraints.

Contact Us NOW

FAQs about interposer vs substrate

The purpose of an interposer is to serve as a bridge between different semiconductor components, facilitating connections and enabling efficient signal transmission between them.

The substrate in a semiconductor serves as the foundation for various semiconductor components. It provides structural support, electrical pathways, and thermal management for the semiconductor device.

Various materials can be used in interposers, including silicon, organic substrates like laminate or epoxy resins, and sometimes ceramics. Silicon interposers offer high performance and bandwidth, while organic substrates are cost-effective and flexible in design.

The main difference between a substrate and a leadframe lies in their composition and application. Substrates are typically thicker and provide a more integrated platform for semiconductor devices, hosting conductive traces and vias for electrical connectivity. Leadframes, on the other hand, are thin metal frames with leads that connect the integrated circuit to the external package. They are commonly used in traditional IC packaging methods like dual in-line packages (DIPs) and quad flat packages (QFPs).