Key Properties of FR4 Substrate Material in PCB Design

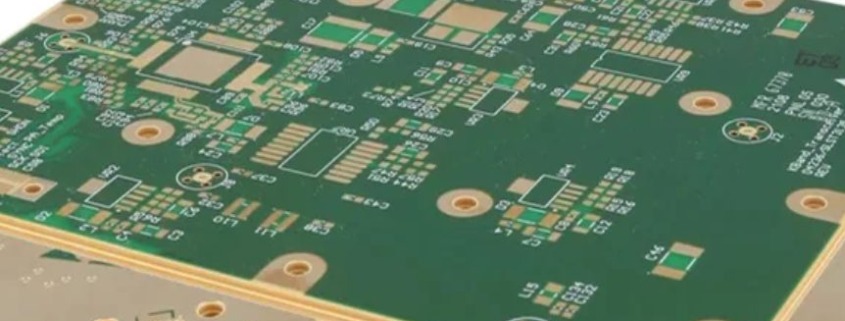

FR4 substrate material is one of the most widely used materials in the PCB (Printed Circuit Board) industry. It is a composite material made from an epoxy resin and fiberglass cloth, offering excellent electrical insulation and mechanical strength. The “FR” in FR4 stands for “flame retardant,” which refers to its ability to resist fire, making it a reliable and safe choice for electronic applications. FR4 has become the industry standard for PCB manufacturing due to its cost-effectiveness and versatility.

The widespread use of FR4 substrate material in PCB production is primarily due to its balanced properties. It provides good electrical performance at a relatively low cost, making it ideal for mass production of consumer electronics, automotive components, and industrial devices. FR4’s ability to handle various environmental conditions, coupled with its mechanical durability, has made it a go-to material for diverse industries such as telecommunications, automotive electronics, and consumer technology.

What is FR4 Substrate Material?

FR4 substrate material is a widely used material in the production of printed circuit boards (PCBs). It is a type of composite material that consists of an epoxy resin and fiberglass cloth, which are combined to form a rigid and flame-retardant board. The “FR” in FR4 stands for “flame retardant,” signifying its ability to resist combustion and improve safety in electronic applications. This unique property makes FR4 substrate material an ideal choice for a wide range of electronic devices, from consumer electronics to industrial equipment.

The Composition of FR4

The composition of FR4 includes two main components: the epoxy resin, which provides the insulating properties, and the fiberglass cloth, which reinforces the material, giving it strength and durability. This combination results in a substrate that offers both excellent electrical insulation and mechanical robustness, while being lightweight and easy to manufacture.

Different Types of FR4 and Their Differences

Different types of FR4 materials exist, with slight variations in their characteristics. For instance, FR4 and FR-4 are essentially the same material, but “FR-4” is a more commonly used designation in the PCB industry. The differences between these types may include variations in the resin composition, which can affect performance in high-frequency or high-temperature environments. However, in general, FR4 substrate material is suitable for a broad range of applications, including consumer electronics, automotive systems, telecommunications, and industrial control systems.

Common Applications of FR4

Common applications of FR4 include circuit boards for smartphones, laptops, gaming consoles, medical devices, and automotive electronics. Its versatility and reliable performance make it the material of choice for most PCB designs, especially in applications where cost-effectiveness and standard electrical performance are crucial.

Key Properties of FR4 Substrate Material

FR4 substrate material is known for its balanced properties, making it highly suitable for a wide range of PCB applications. These key properties include its dielectric constant, thickness, mechanical strength, thermal stability, and electrical performance. Understanding these characteristics is essential for choosing the right material for specific electronic designs.

Dielectric Constant

The dielectric constant (Dk) of a material measures its ability to store electrical energy when an electric field is applied. For FR4 substrate material, the typical dielectric constant range is between 4.0 and 5.0, though it may vary depending on the specific resin system used. The dielectric constant of FR4 plays a critical role in high-frequency signal transmission.

In high-speed PCB designs, particularly for RF (Radio Frequency) and high-frequency applications, the dielectric constant of the material significantly influences the impedance and signal propagation speed. A higher dielectric constant can cause signal distortion and reduce performance in high-frequency circuits. Therefore, understanding and managing the dielectric constant of FR4 is crucial for maintaining signal integrity in high-speed and RF PCBs.

Thickness

FR4 PCBs come in a variety of thicknesses, typically ranging from 0.2 mm to 3.2 mm (0.008 inches to 0.125 inches). The thickness choice depends on several factors, including the mechanical strength required, the desired thermal dissipation, and the number of layers in the PCB.

Thicker FR4 boards tend to provide better mechanical strength and thermal conductivity, while thinner boards are often used for compact or lightweight designs. The thickness of FR4 also impacts the board’s impedance and signal integrity, making it a key parameter when designing high-speed circuits. For multi-layer PCBs, the thickness of the FR4 substrate material must be carefully selected to ensure reliable performance across all layers and to maintain the required signal integrity.

Mechanical Properties

FR4 substrate material is known for its mechanical strength and durability, which are essential for maintaining the integrity of PCBs in demanding environments. Some of the key mechanical properties of FR4 include:

- Strength: FR4 has good tensile and compressive strength, allowing it to withstand stress and pressure without cracking or deforming. This makes it suitable for applications requiring robustness and stability.

- Hardness: FR4 is moderately hard, which provides resistance to wear and scratches, making it a durable choice for many electronic applications.

- Bending Resistance: FR4 also has good bending resistance, meaning it can endure mechanical stresses without excessive flexing or warping, which is crucial for the long-term reliability of the PCB.

Thermal Stability

FR4 exhibits good thermal stability, which is important for maintaining consistent performance under varying temperature conditions. The coefficient of thermal expansion (CTE) of FR4 is typically in the range of 13-17 ppm/°C, meaning it expands and contracts relatively slowly with changes in temperature. This characteristic helps prevent warping or cracking during thermal cycling, which is especially important for devices that experience frequent temperature fluctuations.

While FR4 has decent thermal resistance, it is not ideal for applications with extreme thermal management requirements. In such cases, materials with higher thermal conductivity, such as ceramic or specialized high-performance substrates, might be preferred.

Electrical Properties

FR4 substrate material is primarily chosen for its excellent insulating properties, which prevent electrical shorts between traces and components. This ensures that the electrical circuits on the PCB remain isolated from one another, reducing the risk of electrical interference or failure.

- Insulation: FR4 provides excellent electrical insulation with a high dielectric strength (typically around 50-100 kV/mm), making it suitable for a wide range of electrical applications, from low-voltage to high-voltage circuits.

- Conductivity Performance: While FR4 is an insulating material, it does not conduct electricity. However, its performance in high-frequency circuits may be affected by surface roughness, as smoother surfaces tend to improve the conductivity of the copper traces and reduce signal loss. The surface roughness of FR4 affects both the signal transmission and the adhesion of copper layers, making it an important factor to consider during PCB fabrication.

FR4 substrate material offers a well-rounded combination of electrical, mechanical, and thermal properties that make it suitable for most standard PCB designs. However, for specialized applications requiring superior high-frequency performance or extreme thermal stability, other materials might be considered. Nonetheless, the overall versatility and cost-effectiveness of FR4 ensure its continued dominance in PCB manufacturing.

FR4 PCB Fabrication

FR4 substrate material is integral to the PCB fabrication process, serving as the foundation for the production of printed circuit boards. The process of fabricating an FR4 PCB involves several key steps, from preparation and patterning to surface treatment. Each step ensures the final PCB meets the required performance, reliability, and quality standards. Here’s an in-depth look at how FR4 is used in PCB fabrication and the common processes involved.

How FR4 is Used in PCB Fabrication

FR4 is chosen for PCB fabrication due to its excellent balance of mechanical strength, electrical insulation, and thermal stability. It serves as the base material for the PCB, providing both structural support and electrical isolation for the circuit traces. The process typically begins with the preparation of the FR4 substrate, which may come in a variety of thicknesses depending on the design requirements.

Once the FR4 material is selected, the next step involves bonding copper foil to both sides of the FR4 substrate. This is done through a lamination process, where heat and pressure are applied to adhere the copper foil to the FR4 base. This copper foil will eventually be patterned to form the electrical circuit traces on the PCB.

Key Fabrication Steps

The fabrication of FR4 PCBs typically follows these key steps:

- Cutting:

The FR4 substrate is first cut to the desired size and shape according to the design specifications. This is typically done using precision cutting machines or lasers to ensure the exact dimensions are achieved.

- Lamination:

During this step, the copper foil is laminated onto the FR4 substrate using a combination of heat and pressure. The copper is bonded to the surface of the FR4, forming the initial conductive layer that will later be etched into circuit traces.

- Photoresist Coating and Exposure:

After lamination, a layer of photoresist is applied to the copper-clad FR4. The photoresist is sensitive to ultraviolet (UV) light and will harden in the areas exposed to light. A photomask, which contains the PCB’s circuit pattern, is placed over the photoresist, and UV light is applied to transfer the design onto the substrate. The areas exposed to UV light harden, while the unexposed areas remain soft and are washed away, revealing the copper traces underneath.

- Etching:

The PCB is then subjected to an etching process, usually using a chemical solution, which removes the unprotected copper from the areas where the photoresist was washed away. This step forms the copper traces that create the electrical connections between components on the PCB. The remaining copper, now in the shape of the circuit design, is protected by the hardened photoresist.

- Drilling:

After etching, holes are drilled into the PCB for components to be mounted and for interlayer connections in multi-layer PCBs. High-precision drilling machines are used to ensure the accuracy of hole placement and size. These holes are then plated with copper to create electrical connections between different layers in multi-layer designs.

- Plating:

In this step, the drilled holes are plated with copper to ensure electrical continuity between the layers. A layer of copper is deposited on the hole walls, allowing the electrical signals to travel from one layer of the PCB to another. The plating process may also involve the addition of other materials, such as nickel or gold, to improve electrical performance.

- Soldermask Application:

A layer of soldermask is applied to the PCB to protect the copper traces from oxidation and prevent solder from bridging between the traces during component soldering. The soldermask is typically green, but it can come in other colors as well. It is applied over the entire surface, except for the areas where components will be soldered.

- Silkscreen Printing:

A silkscreen layer is applied to mark component designations, logos, or other important information on the PCB. This step uses a stencil and ink to print the desired patterns onto the surface of the board.

Surface Treatment Methods for FR4 PCBs

Once the basic fabrication steps are completed, the PCB undergoes various surface treatment processes to enhance its performance and ensure the quality of the electrical connections. Surface treatment methods are used to protect the exposed copper traces, improve solderability, and reduce the risk of oxidation. The two most common surface treatments for FR4 PCBs are:

1. HASL (Hot Air Solder Leveling)

- Process: HASL is one of the most common surface treatments used in PCB fabrication. In this process, the PCB is dipped into a molten solder bath, and then hot air is blown across the surface to level the solder, leaving a thin, uniform coating of solder on the copper pads and traces.

- Advantages:

- Cost-effective and widely used for standard PCBs.

- Provides a reliable and durable finish for most electronic applications.

- Improves solderability and ensures that components can be easily soldered onto the PCB.

- Disadvantages:

- HASL may leave a rough surface finish, which can be problematic for fine-pitch components or high-frequency applications that require a smoother surface for better conductivity.

2. ENIG (Electroless Nickel Immersion Gold)

- Process: ENIG is a more advanced surface treatment method that involves a two-step process. First, a layer of nickel is deposited onto the exposed copper, followed by the immersion of the PCB in a gold bath to create a thin layer of gold over the nickel. This process results in a flat, smooth surface that is ideal for fine-pitch components and high-reliability applications.

- Advantages:

- Provides a very smooth and flat surface, ideal for fine-pitch components and high-frequency circuits.

- Excellent corrosion resistance and enhanced solderability.

- Preferred for high-end, high-performance PCBs, especially in telecommunications and medical devices.

- Disadvantages:

- More expensive compared to HASL, making it less cost-effective for budget-sensitive projects.

The fabrication of FR4 PCBs involves several crucial steps, including cutting, lamination, photoresist application, etching, drilling, and surface treatments. Each of these processes ensures that the PCB meets the required performance standards, while surface treatments like HASL and ENIG provide additional benefits in terms of solderability and longevity. By selecting the right fabrication methods and surface treatments, manufacturers can produce high-quality FR4 PCBs that meet the demands of various electronic applications.

Advantages of FR4 Substrate Material

FR4 substrate material is a popular choice in PCB manufacturing due to its many advantages. It combines affordability, versatility, and reliable performance, making it ideal for a wide range of electronic applications. Let’s explore the key benefits that make FR4 such a widely used material in the electronics industry.

Cost-effective and Widely Available

One of the primary advantages of FR4 substrate material is its cost-effectiveness. As a widely used material in PCB production, FR4 is mass-produced, which significantly lowers its cost compared to other high-performance PCB materials like ceramics or high-frequency composites. This makes FR4 an attractive option for manufacturers looking to keep production costs low without sacrificing essential performance qualities. Its availability is another key factor contributing to its widespread use. FR4 is easily sourced from many suppliers around the world, making it a reliable and readily accessible material for PCB fabrication.

Stable Physical Properties and Good Electrical Performance

FR4 offers stable physical properties, which are crucial for ensuring the longevity and reliability of electronic devices. It maintains consistent performance across a wide range of environmental conditions, including temperature fluctuations, humidity, and mechanical stress. The dielectric properties of FR4 allow it to provide good electrical insulation, ensuring reliable signal transmission and preventing unwanted electrical interference or shorts between traces.

The electrical performance of FR4, while not as high as some advanced materials (such as Rogers or Teflon), is still sufficient for most consumer and industrial applications. Its electrical insulation helps to maintain circuit integrity, while its ability to handle moderate frequencies makes it a versatile material for general-purpose PCBs.

Suitable for a Wide Range of Electronic Applications

FR4 substrate material is extremely versatile and suitable for a wide range of electronic applications. Some of the most common uses include:

- Consumer Electronics: FR4 is used in the manufacturing of PCBs for devices such as smartphones, computers, televisions, and gaming consoles. Its cost-effectiveness and reliable performance make it an ideal choice for mass-produced consumer products.

- Automotive: In the automotive industry, FR4 is used for circuit boards in control systems, sensors, and safety mechanisms. The material’s stability in high temperatures and mechanical stress makes it a reliable choice for automotive electronics that need to withstand extreme conditions.

- Industrial: FR4 is also used in industrial equipment such as robotics, control systems, and automation devices. Its strength and ability to handle diverse operating environments make it suitable for industrial applications where reliability and durability are critical.

Excellent Heat Resistance and Mechanical Strength

Another major advantage of FR4 substrate material is its heat resistance. It is known for its ability to withstand relatively high temperatures without degrading, making it suitable for use in applications that involve heat generation, such as power electronics or automotive systems. The coefficient of thermal expansion (CTE) of FR4 is well-suited for most general-purpose PCBs, as it ensures the material expands and contracts at a manageable rate in response to temperature changes.

FR4 has good mechanical strength, which helps the PCB maintain its structural integrity under physical stress. Its combination of flexural strength, hardness, and bending resistance ensures that the PCB remains durable even in the face of mechanical strain, vibrations, or impacts, making it ideal for electronics that are subjected to constant movement or environmental stress.

Environmentally Friendly and Compliant with ROHS Standards

As environmental concerns have become increasingly important in the electronics industry, FR4 has emerged as a compliant material for environmental standards, particularly the ROHS (Restriction of Hazardous Substances) directive. This regulation restricts the use of certain hazardous materials, such as lead, cadmium, and mercury, in electronic products. FR4 is typically made without the use of these restricted substances, making it environmentally friendly and compliant with ROHS standards.

This compliance ensures that products made with FR4 substrate material can be safely disposed of or recycled, contributing to the reduction of electronic waste and environmental pollution. The widespread adoption of ROHS-compliant materials like FR4 has become a key consideration for manufacturers who are aiming to meet sustainability goals and adhere to global environmental regulations.

The advantages of FR4 substrate material make it the go-to choice for a wide range of PCB applications. Its cost-effectiveness, stable physical properties, and good electrical performance make it suitable for both mass-produced consumer electronics and more demanding industrial or automotive applications. Additionally, its heat resistance, mechanical strength, and environmental compliance further contribute to its widespread use. These qualities ensure that FR4 continues to be a reliable and popular material in the world of PCB fabrication.

Disadvantages of FR4 Substrate Material

While FR4 substrate material offers many advantages, it also has some limitations that make it less suitable for certain high-performance applications. These disadvantages mainly arise from its electrical, thermal, and mechanical properties, which can be a limiting factor in some specialized designs. Below are some of the key drawbacks of using FR4 in PCB fabrication.

Lower High-Frequency Performance

One of the primary disadvantages of FR4 substrate material is its lower performance at high frequencies. The dielectric constant (Dk) of FR4 typically ranges from 4.0 to 5.0, which is higher than many high-frequency PCB materials. As the frequency of electrical signals increases, the dielectric properties of FR4 can cause signal loss, distortion, and slower transmission speeds. This makes FR4 less suitable for applications that require precise signal integrity at high frequencies.

In high-frequency circuits, such as those used in RF (Radio Frequency) and microwave communications, FR4 may not offer the required performance due to its higher dielectric loss and slower signal propagation. As such, FR4 substrates may cause higher signal attenuation, reduced bandwidth, and poor impedance control when used in high-speed designs.

Limitations Compared to High-Frequency Materials Like Rogers or Teflon

When compared to high-frequency materials like Rogers or Teflon, FR4 substrate material falls short in several key areas. Rogers materials, such as Rogers 4350B and Rogers 5880, have a much lower dielectric constant and loss tangent, allowing for superior high-frequency performance and better signal integrity at higher speeds. Teflon-based substrates are also superior for high-frequency applications due to their extremely low loss and stable dielectric properties.

In applications requiring low signal loss, high-speed performance, or precise impedance control (e.g., high-speed digital circuits, RF systems), Rogers and Teflon materials are the preferred choice. These advanced materials are specially designed for use in environments with demanding high-frequency requirements, whereas FR4’s higher dielectric constant and loss characteristics make it unsuitable for ultra-high-frequency and RF applications.

Not Suitable for Ultra-High-Frequency Applications

FR4 is generally not suitable for ultra-high-frequency (UHF) applications, such as those used in 5G networks, satellite communications, or radar systems. At frequencies above several gigahertz, the signal loss and impedance mismatch inherent in FR4’s dielectric properties become more pronounced, leading to performance degradation and poor signal integrity.

In these high-performance applications, materials designed specifically for microwave or UHF applications—such as Rogers’ RO3000 series or Teflon-based materials—are required. These materials are engineered to have lower dielectric loss and more stable performance at higher frequencies, making them more effective for ultra-high-frequency applications where signal transmission integrity is paramount.

Limited Thermal Conductivity: Thermal Management Concerns

FR4 substrate material has limited thermal conductivity compared to specialized materials such as ceramics or metal-based PCBs. While FR4 can handle typical electronic operating temperatures, its thermal dissipation is not as efficient as other materials. This limitation can create thermal management concerns, especially in power electronics or high-current circuits where heat generation is significant.

In high-power applications, excessive heat can lead to component failure, reduced efficiency, or even thermal damage to the PCB itself. Since FR4 has a relatively low thermal conductivity (typically around 0.3 W/m·K), it may not be effective in dispersing heat efficiently, which can lead to hot spots and reduced reliability over time. In such cases, other PCB materials with better thermal conductivity, such as ceramic substrates or metal core PCBs, are often preferred.

Higher Moisture Absorption Rate: Can Affect Performance

Another drawback of FR4 is its higher moisture absorption rate compared to some other materials. FR4 can absorb moisture from the environment, especially if not properly sealed with a soldermask or protective coating. This moisture absorption can cause the material to expand and contract, which may lead to delamination (separation of layers) or reduced dielectric strength.

Moisture can also significantly impact the electrical properties of FR4, such as dielectric constant and loss tangent, leading to unpredictable behavior in circuits. In environments with high humidity or where the PCB will be exposed to moisture over time, the moisture absorption of FR4 can cause signal degradation, impaired insulation, and potential circuit failure.

To mitigate this, FR4 PCBs must be carefully sealed and treated during fabrication to reduce the potential for moisture-related performance issues. However, for high-humidity environments or applications requiring consistent dielectric properties, materials with lower moisture absorption rates, such as ceramic-based substrates, are often a better choice.

Despite its many advantages, FR4 substrate material does have some notable drawbacks, particularly in high-performance, high-frequency, and high-thermal applications. The lower high-frequency performance and limited suitability for ultra-high-frequency circuits make FR4 less ideal for RF, microwave, and high-speed designs. Additionally, its limited thermal conductivity and higher moisture absorption rate can create challenges in heat management and long-term reliability, especially in power-sensitive applications.

For most standard PCB applications, FR4 remains an excellent choice due to its cost-effectiveness, mechanical strength, and reliable electrical performance. However, for more demanding environments, designers may need to consider alternative materials like Rogers, Teflon, or ceramics that offer superior performance in terms of frequency handling, thermal dissipation, and moisture resistance.

Applications of FR4 PCBs

FR4 substrate material is widely used across various industries due to its balanced performance, reliability, and cost-effectiveness. From consumer electronics to industrial systems, FR4-based printed circuit boards (PCBs) serve as the foundation for many devices. Below, we’ll explore the main applications of FR4 PCBs in different sectors, highlighting the versatility and practicality of this material.

Consumer Electronics

FR4 PCBs are the most commonly used circuit board material in consumer electronics. The demand for reliable, affordable, and durable electronics has made FR4 the go-to choice for a range of consumer products. These PCBs are used in:

- Smartphones: FR4 substrates are used in the PCB assemblies of smartphones, where their balance of performance and cost-effectiveness makes them suitable for complex circuit designs while keeping production costs manageable. FR4’s stability, electrical insulation, and good mechanical strength allow for reliable signal transmission and high-density component placement, crucial for modern smartphones.

- TVs and Displays: FR4 is used in the circuit boards of flat-panel displays, where it ensures proper functioning of the screen’s power and control circuits. The material’s durability helps maintain performance, even with the high operational demands of large-screen televisions.

- Computers and Laptops: FR4 PCBs are integral to motherboards, graphics cards, power supplies, and other internal components of personal computers and laptops. The material’s ability to handle moderate frequencies and maintain electrical performance under normal operating conditions makes it a standard choice in these applications.

Given its wide availability and cost-effectiveness, FR4 is essential for manufacturing consumer electronic devices that require stable and reliable PCB performance at competitive prices.

Industrial Equipment

In industrial equipment, FR4 PCBs are used in a variety of applications, such as control systems, sensors, and automation devices. The robust physical properties of FR4, including its mechanical strength and thermal stability, make it a suitable choice for the demanding conditions found in industrial environments. Common uses include:

- Control Boards: FR4 is used in PLC (Programmable Logic Controller) boards, motor control systems, and other equipment where precision, reliability, and durability are essential. The material’s good insulation properties help ensure the integrity of the electrical signals transmitted through the control boards, while its thermal stability ensures the circuits remain operational in high-temperature environments.

- Sensors: In industrial automation and robotics, FR4 PCBs serve as the substrate for sensors that detect and monitor various physical parameters like pressure, temperature, and motion. FR4’s mechanical properties help ensure the sensor boards remain stable and resistant to vibration or mechanical shock, critical for sensors used in dynamic industrial applications.

- Automation Systems: FR4 is widely used in the manufacturing of PCBs for industrial automation equipment such as conveyor systems, robotic arms, and process monitoring systems. These devices rely on high-performance and durable PCBs to manage and execute tasks efficiently, which is where the reliability and electrical performance of FR4 become crucial.

For industrial applications that require reliable, robust, and cost-effective solutions, FR4 PCBs provide the necessary durability and performance.

Automotive Electronics

The automotive industry has seen significant growth in the use of electronic systems in vehicles, and FR4 PCBs are a key material for many automotive applications. From engine management to safety systems, FR4 provides the stability and electrical performance needed in automotive electronics. Key uses include:

- Battery Management Systems (BMS): FR4 is used in BMS that monitor and manage the charging and discharging of electric vehicle (EV) batteries. As EV technology evolves, the need for efficient power management and thermal regulation increases, and FR4’s thermal stability and mechanical strength make it ideal for these systems.

- In-Vehicle Electronics: FR4 PCBs are used in a wide range of in-vehicle electronic systems, including infotainment, navigation systems, and ADAS (Advanced Driver Assistance Systems). The increasing complexity of in-car electronics, with features like touchscreen displays, connectivity, and autonomous driving aids, requires a reliable and stable substrate material like FR4 for PCB assemblies. Additionally, FR4’s good heat resistance and mechanical robustness ensure reliable operation in the harsh automotive environment.

- Safety Systems: FR4 is also used in airbag control modules, braking systems, and other critical safety electronics. The material’s high mechanical strength ensures that it can withstand the vibration, shock, and high temperatures often experienced in automotive applications, ensuring the safe operation of these systems.

As the automotive sector continues to adopt more electronic and smart technologies, FR4 remains a reliable choice for manufacturers looking to balance cost and performance in automotive PCBs.

Communication Devices

FR4 PCBs are fundamental to the operation of various communication devices. From infrastructure equipment to consumer communication products, FR4 is used to create the PCBs that ensure efficient signal transmission, connectivity, and device operation. Notable applications include:

- Infrastructure Equipment: FR4 is used in the production of PCBs for routers, switches, and network equipment. These devices are integral to the functioning of the internet and communication networks. FR4’s electrical performance and cost-effectiveness make it an ideal choice for the high-volume production of communication devices that require reliable data transmission and low-cost manufacturing.

- Cellular and Wireless Communication Devices: FR4 is used in mobile devices, wireless communication systems, and Wi-Fi modules. While FR4 is not suitable for ultra-high-frequency communication like millimeter-wave (5G), it performs well in sub-6 GHz frequency ranges, which are common in many communication applications.

- Telecommunications Equipment: FR4 substrates are also widely used in telecom infrastructure, such as base stations, transmitters, and receivers, where reliable electrical properties and stability are essential for communication signals. The mechanical strength and thermal stability of FR4 ensure that the equipment can handle the operational demands of continuous signal transmission.

In the telecommunications industry, where performance and reliability are paramount, FR4 remains a dependable and affordable material for manufacturing PCBs in communication devices.

FR4 substrate material plays a vital role in the electronics industry and is used in an extensive range of applications. From consumer electronics like smartphones and computers to industrial equipment and automotive electronics, FR4’s versatility, cost-effectiveness, and reliable performance make it the material of choice for a wide variety of devices and systems. Additionally, in communication devices, FR4 offers the necessary performance for ensuring signal transmission and connectivity. While other materials may be required for high-frequency or high-power applications, FR4 remains a dependable and widely used material in everyday electronic products.

FR4 vs Other PCB Substrates

While FR4 is the most commonly used PCB substrate due to its cost-effectiveness and versatility, other materials like Rogers, flexible substrates, Teflon, and ceramics offer distinct advantages in specific applications. Let’s explore how FR4 compares with other popular PCB substrates in terms of performance, applications, and material properties.

FR4 vs Rogers PCB: Differences in High-Frequency Performance

Rogers PCBs, such as RO4350B or RO4003C, are designed to offer superior high-frequency performance compared to FR4 substrates. The primary differences between FR4 and Rogers PCBs lie in their dielectric properties, which are critical for high-speed or RF (Radio Frequency) applications.

- Dielectric Constant: The dielectric constant (Dk) of FR4 typically ranges from 4.0 to 5.0, whereas Rogers materials have a much lower Dk (around 3.0 to 3.5), making them ideal for high-frequency signal transmission. A lower Dk reduces signal loss and improves signal integrity at high frequencies, which is why Rogers PCBs are preferred for high-speed digital circuits and RF applications.

- Loss Tangent: Rogers materials also have a lower loss tangent compared to FR4. The loss tangent (which indicates how much energy is lost in the form of heat during signal transmission) of Rogers is much lower, making it a better choice for applications requiring minimal signal degradation at higher frequencies.

- Applications: FR4 is often suitable for general-purpose PCBs, including consumer electronics, industrial equipment, and automotive systems, where signal frequencies are moderate. In contrast, Rogers PCBs are typically used in high-frequency applications, such as microwave circuits, 5G networks, and satellite communications, where signal integrity and low loss are paramount.

While FR4 is still the go-to material for most applications due to its cost, Rogers is the preferred material for advanced designs that require excellent high-frequency performance and minimal signal loss.

FR4 vs Flex PCB Substrate: Choosing Flexible PCB Materials

Flexible PCBs (Flex PCBs) are made from materials that allow the board to bend or flex during operation. When comparing FR4 with flexible PCB substrates, the key difference lies in the mechanical properties and form factor.

- Flexibility: FR4 is a rigid material, meaning it does not bend or conform to different shapes. In contrast, flexible PCBs are made from materials like polyimide or PET (Polyethylene Terephthalate), which allow the PCB to be bent, twisted, and folded, making them ideal for applications where space is limited or the PCB needs to fit into unusual shapes or enclosures.

- Mechanical Strength: While FR4 has good mechanical strength, it lacks the flexibility required in many applications. Flexible PCBs, on the other hand, offer excellent mechanical strength while maintaining their ability to bend, which is essential in products like wearable devices, smartphones, and foldable electronics.

- Applications: FR4 is primarily used in rigid PCBs for everyday electronics, but when designing products that need to conform to irregular shapes or fit into small or compact spaces, flexible PCBs are more appropriate. Applications such as wearables, medical devices, and foldable displays are ideal for flexible substrates, while FR4 remains the best choice for general-purpose, rigid designs.

FR4 vs Teflon: Comparison in High-Frequency and High-Temperature Environments

Teflon, also known as PTFE (Polytetrafluoroethylene), is a high-performance PCB substrate material that is often used in specialized applications where high-frequency or high-temperature performance is required. When comparing FR4 to Teflon, the differences are most notable in dielectric properties and thermal performance.

- High-Frequency Performance: Teflon is known for its exceptionally low dielectric constant (around 2.0 to 2.5) and very low loss tangent, which makes it highly effective for high-frequency applications. In contrast, FR4’s higher dielectric constant (4.0 to 5.0) leads to more signal degradation and loss at high frequencies. Therefore, Teflon is preferred in RF and microwave applications, such as 5G circuits and satellite communication systems, where minimal signal loss is crucial.

- Thermal Stability: Teflon also has better thermal stability compared to FR4, with a higher temperature tolerance. Teflon can withstand temperatures of up to 250°C, while FR4 is typically limited to around 130°C to 140°C. This makes Teflon PCBs ideal for high-temperature environments, such as aerospace, military applications, and industrial electronics, where extreme heat is a concern.

- Applications: While FR4 is used in a wide variety of electronic products, Teflon is typically reserved for high-performance applications that demand both high-frequency operation and high thermal tolerance. For general consumer electronics or industrial devices, FR4 offers a cost-effective solution, but for highly specialized aerospace or high-speed communication applications, Teflon is the better choice.

FR4 vs Ceramic PCB: Application Scenarios and Performance Comparison

Ceramic PCBs are made from materials like alumina or aluminum nitride, which are known for their superior thermal conductivity and high-temperature resistance. When comparing FR4 to ceramic PCBs, several key differences arise in terms of thermal management, electrical performance, and cost.

- Thermal Conductivity: One of the most notable advantages of ceramic PCBs is their superior thermal conductivity, typically ranging from 170 W/m·K for alumina to 200 W/m·K for aluminum nitride. In comparison, FR4 has a much lower thermal conductivity of around 0.3 W/m·K. This makes ceramic PCBs ideal for power electronics or LED applications, where heat dissipation is critical. Ceramic materials efficiently conduct heat away from sensitive components, preventing overheating and improving system reliability.

- Electrical Performance: Ceramic PCBs also exhibit excellent electrical insulation and low loss at high frequencies, making them suitable for high-power applications and RF circuits. In contrast, FR4 is better for moderate frequencies and general-purpose applications. Ceramic PCBs provide better signal integrity in high-frequency environments and higher dielectric strength than FR4.

- Cost and Manufacturing: Ceramic PCBs are more expensive than FR4 due to the high cost of materials and the more complex manufacturing processes. FR4, being a much cheaper and easier material to work with, is the more cost-effective option for mass-produced consumer electronics. However, for high-power or high-frequency applications, ceramic PCBs are worth the investment, particularly when thermal management and signal integrity are critical.

- Applications: FR4 is widely used in consumer electronics, automotive systems, and industrial equipment, while ceramic PCBs are typically found in high-power LED lighting, power converters, high-frequency RF devices, and aerospace electronics, where the need for efficient heat dissipation and high-frequency performance outweighs cost considerations.

The choice of PCB substrate material depends heavily on the specific requirements of the application. FR4 remains the most widely used substrate due to its cost-effectiveness and versatility, making it ideal for most general-purpose applications. However, for high-frequency, high-temperature, or specialized applications, materials such as Rogers, Teflon, flexible substrates, and ceramic offer distinct advantages. Each material has its strengths and limitations, and selecting the right one depends on the performance needs, environmental factors, and budget of the particular project. By understanding these differences, designers can make more informed decisions when selecting the optimal PCB substrate material for their specific needs.

Future of FR4 Substrate in PCB Design

As the electronic industry continues to evolve, the demands for higher-performance and more reliable printed circuit boards (PCBs) are rapidly increasing. While FR4 has long been the standard for PCB design, technological innovations are continuously enhancing its capabilities. However, with the rise of high-frequency and high-speed applications, FR4 faces growing competition from advanced materials. Despite this, there is still a promising future for FR4 substrates as they adapt to these new demands. Below, we’ll explore the future of FR4 substrate in PCB design, examining innovations in the material itself, industry trends, and potential hybrid solutions.

Technological Innovations in FR4 Material

The future of FR4 substrates lies in technological advancements that address the growing demands for better performance in areas like thermal management, signal integrity, and electrical efficiency. Some of the innovations that are shaping the future of FR4 include:

- Enhanced Thermal Management: One of the primary limitations of traditional FR4 is its relatively low thermal conductivity, which can be a concern in high-power applications where heat dissipation is critical. However, researchers and manufacturers are working on advanced FR4 composites that incorporate ceramic fillers, graphene, or nanomaterials to improve thermal performance. These innovations enhance the material’s ability to dissipate heat more efficiently, making FR4 PCBs suitable for power electronics, LED lighting, and other high-heat applications that were traditionally dominated by ceramic or metal-core PCBs.

- Improved High-Frequency Performance: FR4 traditionally struggles in high-frequency environments, with higher dielectric constant and loss tangent that contribute to signal degradation. To address this, manufacturers are focusing on developing low-loss FR4 variants with better electrical properties, such as lower dielectric constant and lower loss tangent. These innovations aim to improve signal integrity in RF applications, helping FR4 keep up with the rising demands for high-speed digital circuits, 5G technologies, and internet of things (IoT) devices.

- Eco-Friendly and ROHS-Compliant Variants: Another innovation in FR4 substrates is the development of eco-friendly materials that meet RoHS (Restriction of Hazardous Substances) and other environmental standards. The industry is increasingly moving towards lead-free and halogen-free versions of FR4 to meet stricter regulatory requirements, ensuring that FR4 PCBs remain sustainable and safe for global production and disposal.

Trends of FR4 Being Replaced by Higher-Performance Materials

Despite these innovations, FR4 may not be sufficient to meet the demands of certain high-performance applications that require extremely high-frequency operation, high-speed signal transmission, or high thermal management capabilities. As a result, FR4 is facing increasing competition from specialized substrates such as Rogers, Teflon, ceramic, and flexible materials. The key trends driving the replacement or hybridization of FR4 with more advanced materials include:

- High-Frequency Demands: As 5G networks, Wi-Fi 6, and satellite communication systems continue to expand, the need for low-loss, high-performance materials increases. Materials like Rogers and Teflon are specifically designed for high-frequency applications, offering better signal integrity and lower loss tangent compared to FR4. These materials are more capable of handling the demands of microwave and millimeter-wave frequencies that are commonly used in advanced communication systems.

- High-Speed and High-Density Circuits: The increasing speed and complexity of digital devices require high-speed PCBs that can handle fast signal transmission without introducing significant delays or signal degradation. Advanced materials like Rogers or Teflon offer better performance in high-speed designs, making them the preferred choice in data centers, high-performance computing, and 5G infrastructure. These materials allow for low-loss signal transmission, ensuring that high-speed data can be transmitted with minimal latency.

- Miniaturization and Flexible Designs: As electronic devices become smaller and more compact, there is a growing trend towards flexible electronics, where traditional rigid FR4 PCBs are replaced or supplemented with flexible substrates like polyimide or PET. These flexible materials allow for bending, folding, and conforming to complex geometries, enabling more compact designs for wearables, medical devices, and smart packaging. Additionally, combining FR4 with flexible substrates can create hybrid PCBs that offer the best of both worlds—rigid, high-density areas for components and flexible regions for conformable designs.

Combining FR4 with Other High-Performance Substrates for Optimal Design Solutions

Despite its limitations, FR4 is unlikely to disappear entirely from the PCB industry. Instead, it is expected to be used in hybrid designs where its cost-effectiveness and reliability are complemented by the superior properties of advanced materials. By combining FR4 with higher-performance substrates, designers can create optimal solutions that meet the specific needs of each application. Here are some examples of how this hybrid approach can work:

- FR4 + Rogers: For high-frequency applications like 5G, RF, and satellite communication systems, FR4 can be used for the non-critical parts of the PCB, while Rogers can be employed in the high-speed or signal-sensitive areas. This combination ensures that the PCB remains cost-effective while maintaining optimal performance where it matters most.

- FR4 + Ceramic: In applications that require high thermal conductivity (e.g., power electronics and LED lighting), FR4 can be paired with ceramic substrates to improve heat dissipation without sacrificing the overall flexibility and cost-effectiveness of the design. Ceramic PCBs handle the thermal load in power components, while FR4 is used for the remaining circuitry.

- FR4 + Flexible Substrates: For applications that demand both rigid and flexible PCB capabilities (e.g., wearables, medical devices, and consumer electronics), a combination of FR4 and flexible substrates can provide the necessary functionality. FR4 can be used in areas where rigidity is essential, while flexible materials allow for curved or foldable designs, enabling more compact and adaptable devices.

The future of FR4 substrates in PCB design will likely be shaped by both technological innovations within the material itself and the increasing trend toward hybrid PCB designs. While FR4 will continue to be widely used for cost-effective, general-purpose applications, its limitations in high-frequency, high-speed, and high-thermal environments are pushing manufacturers and designers to explore higher-performance materials like Rogers, Teflon, ceramics, and flexible substrates. The future lies in combining FR4 with other advanced materials to achieve the best of both worlds: cost-effectiveness and high-performance. As FR4 evolves, it will remain a staple in PCB design, especially in hybrid solutions that meet the demands of modern electronics.

FQAs Abut FR4 Substrate Material

FR4 PCB is typically made from a combination of epoxy resin and fiberglass cloth. The resin acts as a binder, while the fiberglass provides reinforcement, giving the board its strength and durability. The material is also infused with flame retardant additives, which give it the “FR” (flame-retardant) designation. This composition results in a rigid, durable substrate commonly used in standard PCBs for various electronic devices.

The substrate material of a flexible PCB is typically a flexible polymer film. Common materials include polyimide (such as Kapton) and polyester. These materials are highly flexible, allowing the PCB to bend, fold, and conform to different shapes. The flexibility of these substrates makes them ideal for applications in wearables, medical devices, and other compact or flexible electronics.

While FR4 is a widely used and cost-effective PCB material, it does have some drawbacks:

Limited high-frequency performance: FR4 has a relatively high dielectric constant and loss tangent, which can cause signal degradation in high-frequency applications.

Poor thermal conductivity: FR4 has lower thermal conductivity compared to materials like ceramics or metal-core PCBs, making it less suitable for high-power or high-heat applications.

Moisture absorption: FR4 tends to absorb moisture, which can lead to deliquescence and impact its performance, especially in humid environments.

Not suitable for ultra-high-frequency applications: FR4 is not ideal for high-speed or ultra-high-frequency circuits, where materials like Rogers or Teflon are more suitable.

PCBs can be made from a variety of substrate materials, depending on the requirements of the application. Common materials include:

FR4: The most widely used material for general-purpose PCBs, made from epoxy resin and fiberglass.

Polyimide: Used in flexible PCBs due to its excellent flexibility and thermal stability.

Ceramic: Provides superior thermal conductivity and is used in high-power or high-frequency applications.

Rogers: A high-performance material used for RF and high-frequency PCBs, offering low dielectric loss and stable performance.

Teflon: Used in high-frequency and microwave applications due to its low dielectric constant and excellent signal integrity.