CPU Substrate: The Core of Processor Technology

In the intricate world of processor technology, the CPU substrate serves as the vital foundation upon which the entire architecture is built. A CPU substrate refers to the underlying material or structure that supports the intricate circuitry and components of a central processing unit (CPU). This substrate plays a pivotal role in ensuring the reliability, performance, and functionality of the CPU. Serving as both a physical and electrical backbone, the substrate facilitates the interconnection of various components, dissipates heat, and provides mechanical support. Without a robust and efficient substrate, the intricate microarchitecture of modern processors would struggle to function optimally, impacting everything from computational speed to power efficiency. Thus, understanding the nuances and significance of CPU substrates is crucial in unlocking the potential of cutting-edge processor technology.

Understanding CPU Substrates: A Comprehensive Exploration

What is a Substrate?

A substrate in the realm of CPU technology refers to the underlying material or structure that forms the foundation of a central processing unit (CPU). It provides physical support and electrical connections for the intricate circuitry and components that comprise the CPU.

Types of Substrates in Technology

- Glass Core Substrate: This type of substrate utilizes glass as the core material, offering excellent thermal and electrical properties. Glass core substrates are commonly used in high-performance CPUs due to their superior heat dissipation capabilities and reliability.

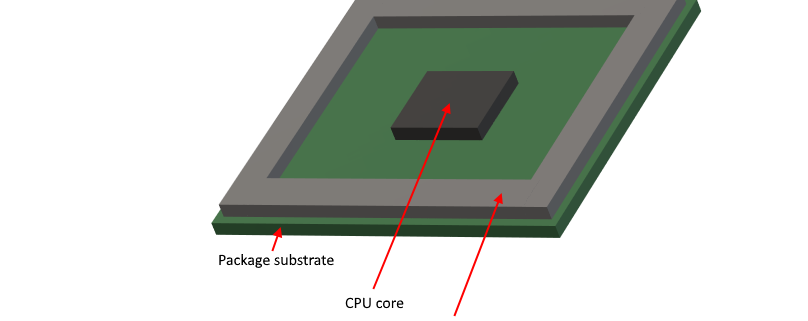

- Package Substrate Material: The package substrate material serves as the base upon which the CPU chip is mounted and interconnected with other components. It is typically made of materials like FR-4 (flame retardant) or laminate, providing mechanical support and electrical pathways for the CPU.

- IC Substrate: IC substrates are specifically designed to accommodate integrated circuits (ICs) within the CPU. They often feature multiple layers of conductive traces and insulating materials to facilitate the complex interconnections required for modern processors.

- Coreless Substrate: Coreless substrates represent a revolutionary approach in CPU substrate design by eliminating the traditional silicon core. Instead, they rely on innovative materials and fabrication techniques to achieve enhanced performance and efficiency while reducing size and weight.

- Semco Substrate: Semco substrates, short for semiconductor substrates, are tailored for semiconductor devices like CPUs. They are engineered to meet stringent requirements for electrical conductivity, thermal management, and signal integrity, ensuring optimal performance and reliability.

Understanding the diverse range of substrate types is essential for designing CPUs that meet the demands of today’s computing landscape. Each substrate type offers unique advantages and challenges, influencing factors such as thermal management, signal propagation, and overall performance.

Exploring CPU Substrate: Unveiling the Backbone of Processor Technology

What Constitutes the Substrate of a CPU?

The substrate of a CPU is a complex amalgamation of materials and structures meticulously designed to provide physical support, electrical connectivity, and thermal management for the processor. It typically consists of multiple layers of materials, including silicon, metal traces, insulating layers, and sometimes advanced materials like glass or ceramics. These layers are intricately patterned and interconnected to form a robust foundation for mounting and integrating the various components of the CPU, such as the semiconductor die, interconnects, and packaging elements.

Role of Substrate in Chip Design

The substrate plays a multifaceted role in the design and performance of a CPU. Firstly, it provides a mechanical foundation for mounting and securing the semiconductor die, ensuring structural integrity and reliability under various operating conditions. Secondly, the substrate facilitates electrical connections between the die and other components, such as memory modules and peripheral interfaces, enabling data transfer and signal propagation throughout the system. Additionally, the substrate contributes to thermal management by dissipating heat generated during CPU operation, thereby preventing overheating and ensuring optimal performance and longevity.

Comparison: CPU Substrate vs. PCB

While both CPU substrates and printed circuit boards (PCBs) serve as essential components in electronic devices, they differ significantly in terms of design, functionality, and performance characteristics. CPU substrates are specifically tailored for high-performance microprocessors, featuring advanced materials and intricate designs optimized for dense integration and high-speed signal processing. In contrast, PCBs are more generalized in their application, serving as platforms for mounting various electronic components, including CPUs, memory modules, and peripherals, in a wide range of devices.

Furthermore, CPU substrates typically exhibit superior thermal and electrical properties compared to PCBs, owing to their specialized construction and materials. While both substrates and PCBs play crucial roles in the functionality of electronic systems, CPU substrates are meticulously engineered to meet the stringent demands of modern computing applications, where performance, reliability, and efficiency are paramount.

Exploring Package Types: FCCSP vs. FCBGA on CPU Substrate

FCCSP (Flip-Chip Chip Scale Package)

- Characteristics: FCCSP is a compact packaging technology where the semiconductor die is flipped upside down and directly mounted onto the substrate, minimizing the footprint and maximizing the number of connections. It typically features a high-density array of solder bumps on the die’s surface, enabling efficient electrical interconnection with the substrate.

- Applications: FCCSP is commonly used in applications where space constraints are critical, such as mobile devices, wearables, and other compact electronic systems. Its small form factor and high interconnect density make it ideal for integrating powerful CPUs into miniature devices without compromising performance.

FCBGA (Flip-Chip Ball Grid Array)

- Characteristics: FCBGA is a packaging technology similar to FCCSP, wherein the semiconductor die is flipped and mounted onto the substrate. However, FCBGA utilizes an array of solder balls on the substrate instead of bumps on the die, providing robust electrical connections and improved thermal dissipation capabilities.

- Applications: FCBGA is widely employed in applications requiring high-performance computing, such as desktop computers, servers, and network infrastructure. Its robust construction and efficient heat dissipation make it suitable for handling the rigorous demands of modern CPU architectures in various computing environments.

Key Differences between FCCSP and FCBGA

- Interconnection Method: FCCSP utilizes solder bumps on the die, while FCBGA utilizes solder balls on the substrate for electrical interconnection.

- Thermal Performance: FCBGA typically offers better thermal performance than FCCSP due to its larger solder ball size and enhanced heat dissipation capabilities.

- Application Focus: FCCSP is primarily focused on compact, space-constrained applications, whereas FCBGA is more commonly found in high-performance computing applications where thermal management and reliability are paramount.

- Cost: Due to its smaller size and simplified interconnection process, FCCSP may be more cost-effective for certain applications compared to FCBGA, which requires more sophisticated manufacturing processes.

Coreless Substrate: A Breakthrough in Processor Technology

Definition and Characteristics of Coreless Substrate

Coreless substrates represent a paradigm shift in CPU substrate design by eschewing the traditional silicon core found in conventional substrates. Instead, they employ innovative materials and fabrication techniques to create a substrate without a central core. Coreless substrates typically consist of multiple layers of advanced materials such as ceramics, polymers, or composites, intricately engineered to provide structural integrity, electrical connectivity, and thermal management for the CPU.

Advantages and Disadvantages Advantages

- Improved Thermal Performance: Coreless substrates offer superior thermal dissipation capabilities compared to traditional silicon-based substrates, thanks to their enhanced thermal conductivity and reduced thermal resistance.

- Reduced Size and Weight: By eliminating the silicon core, coreless substrates enable the fabrication of thinner and lighter CPUs, making them ideal for compact and portable devices.

- Enhanced Electrical Performance: The absence of a silicon core reduces parasitic capacitance and inductance, leading to improved signal integrity and higher-speed operation.

- Flexibility in Design: Coreless substrates provide greater flexibility in substrate design, allowing for customized layouts and integration of additional components, such as embedded passives or power delivery networks.

Disadvantages:

- Complex Manufacturing Process: Fabricating coreless substrates requires advanced manufacturing processes and materials, leading to higher production costs and potential challenges in scalability.

- Increased Vulnerability to Mechanical Stress: Without the structural support provided by a silicon core, coreless substrates may be more susceptible to mechanical stress and damage during handling and assembly.

Applications in Modern CPUs

Coreless substrates are gaining traction in modern CPU designs, particularly in high-performance computing and mobile devices where thermal management and miniaturization are critical. They are well-suited for applications such as:

- High-Performance Computing: Coreless substrates enable the development of CPUs optimized for high-speed computing tasks, such as data centers, supercomputers, and artificial intelligence applications.

- Mobile Devices: The compact size and enhanced thermal performance of coreless substrates make them ideal for integration into smartphones, tablets, and other portable electronics, where space and power constraints are paramount.

- Embedded Systems: Coreless substrates can be used in embedded systems and IoT devices to achieve efficient thermal management and compact form factors without compromising performance.

Coreless substrates represent a groundbreaking advancement in CPU substrate technology, offering a compelling blend of improved thermal performance, reduced size, and enhanced design flexibility for a wide range of computing applications.

Exploring Substrate Beyond Hardware: Software Substrate

Definition and Concept

In computing, a software substrate refers to the underlying framework or infrastructure that supports the execution of software applications and services. It encompasses various layers of software components, libraries, and APIs (Application Programming Interfaces) that provide essential functionalities and services to application developers. The concept of a software substrate emphasizes the abstraction and encapsulation of underlying hardware complexities, enabling developers to focus on building higher-level software solutions without being burdened by hardware-specific details.

Role of Software Substrate in Computing

The software substrate plays a crucial role in enabling efficient and scalable software development, deployment, and execution. Some key functions and roles include:

- Abstraction of Hardware Complexity: Software substrates abstract away the intricacies of underlying hardware, providing a standardized interface for software developers to interact with hardware resources such as processors, memory, storage, and network devices.

- Resource Management: Software substrates manage system resources efficiently, allocating and deallocating resources dynamically to meet the demands of running applications while optimizing resource utilization.

- Security and Isolation: Software substrates provide mechanisms for enforcing security policies and isolating software components to prevent unauthorized access and ensure data privacy and integrity.

- Interoperability: Software substrates facilitate interoperability between different software components and services by providing standardized communication protocols, data formats, and APIs.

- Scalability and Flexibility: Software substrates enable the development of scalable and flexible software solutions by providing support for distributed computing, load balancing, fault tolerance, and other techniques for handling varying workloads and resource requirements.

Examples and Applications

Examples of software substrates include:

- Operating Systems (OS): OS such as Linux, Windows, macOS, and various Unix derivatives serve as fundamental software substrates that provide a platform for running applications and managing system resources.

- Middleware and Frameworks: Middleware platforms like Java EE, .NET Framework, and cloud computing frameworks such as Kubernetes and Docker provide higher-level abstractions and services for developing and deploying distributed applications.

- Runtime Environments: Runtime environments like the Java Virtual Machine (JVM) and the Common Language Runtime (CLR) in .NET provide a runtime substrate for executing bytecode or intermediate language code, respectively, enabling platform-independent execution of applications.

- Development Tools and Libraries: Development tools and libraries such as compilers, interpreters, APIs, and SDKs (Software Development Kits) provide essential building blocks and utilities for software development, extending the capabilities of software substrates and simplifying application development.

Software substrates are essential components of modern computing ecosystems, providing a foundational layer of abstraction, management, and support for building and running software applications across diverse hardware platforms and environments.

The Evolution of CPU Substrate Technology

Historical Overview

The history of CPU substrate technology dates back to the early days of semiconductor development. Initially, CPUs were mounted on ceramic substrates, which provided mechanical support and electrical connectivity. Over time, advancements in material science and manufacturing processes led to the adoption of silicon substrates, which offered superior thermal properties and cost-effectiveness. Throughout the decades, CPU substrate technology evolved rapidly alongside advancements in microprocessor architecture, packaging techniques, and manufacturing technologies. The transition from through-hole mounting to surface mount technology (SMT) revolutionized CPU packaging, enabling higher component density, improved electrical performance, and reduced form factors.

Recent Advancements and Trends

In recent years, CPU substrate technology has witnessed several significant advancements and trends:

- Advanced Packaging Techniques: The adoption of advanced packaging techniques such as flip-chip technology, system-in-package (SiP), and 3D packaging has enabled higher levels of integration, improved electrical performance, and enhanced thermal management in modern CPUs.

- Material Innovations: The development of novel substrate materials and fabrication processes, including coreless substrates, low-temperature co-fired ceramics (LTCC), and embedded passives, has expanded the design possibilities and performance capabilities of CPU substrates.

- Miniaturization and Integration: The trend towards miniaturization and integration has driven the development of smaller, thinner, and more efficient CPU substrates, enabling the production of compact and power-efficient devices such as smartphones, tablets, and wearable gadgets.

- Heterogeneous Integration: The integration of diverse components, such as CPUs, GPUs, memory, and sensors, within a single package or die, has become increasingly prevalent, leading to the emergence of heterogeneous integration technologies that demand advanced substrate solutions.

Future Prospects and Challenges

Looking ahead, the future of CPU substrate technology is characterized by several prospects and challenges:

- Further Miniaturization: Continued efforts to shrink feature sizes and increase component density will drive the development of even smaller and more efficient CPU substrates, challenging existing manufacturing processes and materials.

- Enhanced Thermal Management: As CPUs continue to deliver higher levels of performance, managing heat dissipation remains a critical challenge. Future substrate technologies will focus on improving thermal conductivity, heat spreading, and thermal interface materials to address these challenges.

- Integration of Advanced Functionalities: The integration of advanced functionalities such as heterogeneous integration, photonic components, and neuromorphic computing elements within CPU substrates will require innovative substrate designs and materials capable of supporting diverse requirements.

- Sustainability and Environmental Concerns: As the demand for electronic devices grows, there is increasing pressure to develop sustainable and environmentally friendly substrate materials and manufacturing processes that minimize energy consumption, waste generation, and resource depletion.

The evolution of CPU substrate technology is driven by a combination of historical legacy, recent advancements, and future prospects, shaping the trajectory of semiconductor packaging and enabling the development of ever more powerful and versatile computing devices.

FAQs About CPU Substrate

The substrate of a CPU refers to the underlying material or structure that supports the intricate circuitry and components of the central processing unit. It typically consists of multiple layers of materials such as silicon, metal traces, insulating layers, and sometimes advanced materials like glass or ceramics. The substrate provides physical support, electrical connectivity, and thermal management for the CPU.

In the context of a chip, the substrate refers to the base material upon which semiconductor devices, such as transistors and interconnects, are fabricated. It serves as the foundation for building the integrated circuits that comprise the chip. The substrate may be made of materials like silicon, gallium arsenide, or other semiconductor materials.

A software substrate refers to the underlying framework or infrastructure that supports the execution of software applications and services. It encompasses various layers of software components, libraries, and APIs that provide essential functionalities and services to application developers. The software substrate abstracts away the complexities of underlying hardware, enabling developers to focus on building higher-level software solutions.

In a broader technological context, the term “substrate” refers to any underlying material or structure upon which other materials or components are deposited or integrated. For example, in electronics, a substrate may serve as the base for mounting and interconnecting electronic components. In manufacturing processes like semiconductor fabrication, the substrate provides the foundation for building integrated circuits. The choice of substrate material and design significantly impacts the performance, reliability, and functionality of the final product.