Elevating Electronics: Ceramic Substrate PCB

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, providing a platform to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. PCBs are found in virtually all electronic devices, from simple gadgets to complex computing systems.

Ceramic substrate PCBs, a specialized type of PCB, use ceramic materials such as alumina, aluminum nitride, or silicon nitride as the base. These substrates offer superior thermal conductivity, mechanical strength, and electrical insulation compared to traditional materials like FR-4 (a composite of woven glass fabric and epoxy resin). Due to their exceptional properties, ceramic substrate PCB are crucial in high-power, high-frequency, and high-reliability applications. They are commonly used in aerospace, automotive electronics, medical devices, and communication equipment, where performance and durability are paramount. The unique advantages of ceramic substrates make them indispensable in advancing technology in these critical fields.

Manufacturing of Ceramic Substrate PCB

Major Manufacturers

Several major global and local manufacturers specialize in ceramic substrate PCBs, leveraging advanced technology and extensive experience to produce high-quality products. Notable global manufacturers include Kyocera, Rogers Corporation, and CoorsTek. These companies are renowned for their innovation in materials science and precision manufacturing capabilities. In the local markets, companies such as Shenzhen Kinwong Electronic and CETC (China Electronics Technology Group Corporation) play a significant role, providing competitive products tailored to regional demands. These manufacturers often collaborate with various industries to develop customized solutions that meet specific requirements.

Manufacturing Process

The production of ceramic substrate PCBs involves several meticulous steps to ensure the final product’s reliability and performance. The process typically includes:

- Material Selection: Choosing the appropriate ceramic material (e.g., alumina, aluminum nitride) based on the desired thermal and electrical properties.

- Lamination: Layers of ceramic material are laminated together under high pressure and temperature to form a dense, homogenous substrate.

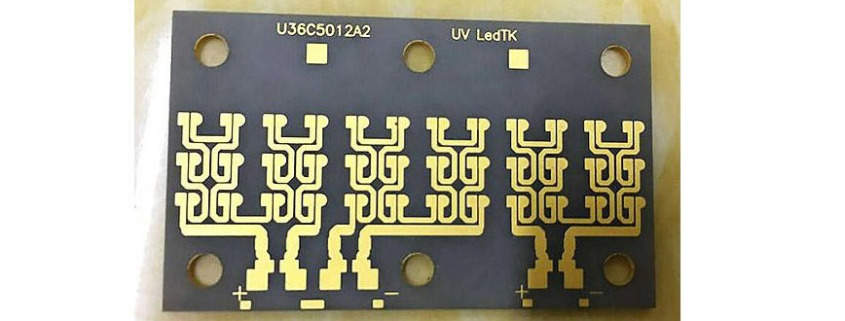

- Printing: Conductive patterns are printed onto the ceramic substrate using screen printing or photolithography techniques, which define the electrical pathways.

- Plating: The printed substrates undergo a plating process, typically involving copper or other metals, to enhance conductivity and durability of the traces.

- Sintering: The substrates are sintered at high temperatures to solidify the ceramic material and bond the conductive layers, ensuring structural integrity.

- Drilling and Routing: Precision drilling and routing create vias and other necessary features for component placement and interconnectivity.

- Surface Finishing: Surface finishes such as gold or nickel plating are applied to protect the conductive traces and improve solderability.

- Testing and Inspection: Rigorous testing and inspection processes ensure each PCB meets the required specifications and quality standards before shipment.

Pricing Factors

The cost of ceramic substrate PCBs is influenced by several key factors:

- Material Costs: High-quality ceramic materials like alumina and aluminum nitride are more expensive than traditional substrates like FR-4, significantly impacting the overall cost.

- Manufacturing Processes: The sophisticated and precise manufacturing processes required for ceramic PCBs, including high-temperature sintering and fine patterning, add to the production costs.

- Production Scale: Larger production volumes can reduce per-unit costs due to economies of scale, while smaller, customized batches may be more expensive.

- Technological Complexity: Advanced designs with multiple layers, fine traces, and intricate patterns require more complex manufacturing techniques, increasing costs.

- Quality and Testing: Ensuring high reliability and performance through rigorous testing and quality control measures also adds to the overall cost.

By understanding these factors, manufacturers and consumers can better navigate the market dynamics and make informed decisions regarding the use and production of ceramic substrate PCBs.

Characteristics of Ceramic Substrate PCB

Thermal Conductivity

Ceramic substrate PCBs are renowned for their exceptional thermal conductivity, which is significantly higher than that of traditional PCB materials like FR-4. The thermal conductivity of ceramic substrates, such as alumina (Al2O3), aluminum nitride (AlN), and silicon nitride (Si3N4), ranges from 20 to 200 W/m·K, compared to around 0.3 W/m·K for FR-4. This high thermal conductivity enables efficient heat dissipation from electronic components, reducing thermal stress and preventing overheating. As a result, ceramic substrate PCBs are ideal for high-power and high-frequency applications where thermal management is crucial, such as in power electronics, LED lighting, and RF modules. The improved heat dissipation enhances the performance and reliability of electronic devices, ensuring stable operation even under high thermal loads.

Mechanical Properties

Ceramic substrate PCBs exhibit superior mechanical properties compared to conventional substrates. They possess high strength, hardness, and wear resistance, making them suitable for demanding environments:

- Strength: Ceramic substrates can withstand significant mechanical stress and pressure without deforming or cracking, which is vital for applications involving high mechanical loads.

- Hardness: The hardness of ceramics like alumina and aluminum nitride provides excellent resistance to scratches and abrasion, ensuring the longevity and durability of the PCB.

- Wear Resistance: The wear resistance of ceramic materials helps maintain the integrity of the PCB surface over extended periods of use, even in harsh conditions, making them suitable for industrial and automotive applications where durability is paramount.

Electrical Properties

Ceramic substrate PCBs offer excellent electrical properties, contributing to their widespread use in advanced electronic applications:

- Dielectric Constant: Ceramic materials have a low dielectric constant, typically ranging from 6 to 10, which helps reduce signal loss and supports high-frequency signal transmission. This makes ceramic PCBs suitable for high-speed digital and RF applications, where maintaining signal integrity is critical.

- Insulation Properties: The superior insulation properties of ceramic substrates prevent electrical leakage and ensure reliable operation of electronic circuits. The high insulation resistance and low dielectric loss contribute to the overall performance and efficiency of the PCB.

- Thermal Stability: Ceramics maintain their electrical properties over a wide temperature range, ensuring consistent performance in varying thermal environments. This stability is crucial for applications exposed to extreme temperatures, such as aerospace and automotive electronics.

In summary, the combination of high thermal conductivity, robust mechanical properties, and excellent electrical characteristics makes ceramic substrate PCBs an ideal choice for a wide range of advanced electronic applications. These properties enable the design of reliable, high-performance devices capable of operating efficiently under challenging conditions, thus meeting the demanding requirements of modern technology.

Comparison of Ceramic Substrate PCB with Other PCBs

Ceramic Substrate PCB vs. FR-4 PCB

- Comparison of Thermal Conductivity

- Ceramic Substrate PCB: Ceramic substrates like alumina, aluminum nitride, and silicon nitride have thermal conductivities ranging from 20 to 200 W/m·K. This high thermal conductivity allows for efficient heat dissipation, making ceramic PCBs ideal for high-power applications where managing heat is critical.

- FR-4 PCB: FR-4, a composite material made of woven fiberglass and epoxy resin, has a thermal conductivity of approximately 0.3 W/m·K. This significantly lower thermal conductivity can lead to heat buildup, making FR-4 less suitable for high-power or thermally demanding applications.

- Comparison of Mechanical Properties

- Ceramic Substrate PCB: Ceramics exhibit high strength, hardness, and wear resistance. They are capable of withstanding significant mechanical stress without deforming or cracking, and their hardness makes them resistant to scratches and abrasion.

- FR-4 PCB: While FR-4 offers good mechanical stability and is widely used due to its robustness, it is not as strong or wear-resistant as ceramic materials. FR-4 can be more susceptible to mechanical damage under high-stress conditions.

- Comparison of Electrical Properties

- Ceramic Substrate PCB: Ceramics have excellent electrical properties, including low dielectric constant (typically 6 to 10) and high insulation resistance. These properties minimize signal loss and ensure reliable electrical insulation, making ceramic PCBs suitable for high-frequency and high-voltage applications.

- FR-4 PCB: FR-4 has a higher dielectric constant (around 4.5) and lower insulation resistance compared to ceramics. While it performs adequately for many general electronic applications, it is less effective in high-frequency and high-voltage scenarios.

- Cost and Application Field Comparison

- Ceramic Substrate PCB: Generally more expensive due to the cost of raw materials and the complexity of the manufacturing process. However, the high performance justifies the cost in applications requiring superior thermal management, mechanical strength, and electrical performance, such as aerospace, automotive electronics, and high-power LED lighting.

- FR-4 PCB: More cost-effective and widely used in consumer electronics, general computing, and telecommunications. Its lower cost and adequate performance make it the go-to choice for a wide range of standard applications.

Ceramic Substrate PCB vs. Conventional PCBs

- Material Comparison

- Ceramic Substrate PCB: Made from high-performance ceramic materials like alumina, aluminum nitride, and silicon nitride. These materials provide superior thermal, mechanical, and electrical properties.

- Conventional PCBs: Typically made from materials such as FR-4, CEM-1, and CEM-3, which are composites of fiberglass and epoxy resins or other laminates. These materials are cost-effective and provide satisfactory performance for many applications.

- Performance Advantages and Limitations

- Ceramic Substrate PCB:

- Advantages: High thermal conductivity, excellent mechanical strength, superior electrical insulation, and stability at high temperatures.

- Limitations: Higher cost, more complex manufacturing processes, and potential brittleness compared to some composite materials.

- Conventional PCBs:

- Advantages: Lower cost, ease of manufacturing, and versatility in a wide range of applications.

- Limitations: Lower thermal conductivity, less mechanical strength, and potentially lower performance in high-frequency or high-power applications.

- Ceramic Substrate PCB:

- Application Scenarios Comparison

- Ceramic Substrate PCB: Ideal for applications where high thermal management, mechanical durability, and electrical performance are essential. Examples include high-power RF devices, power electronics, high-brightness LED lighting, automotive electronics, aerospace systems, and medical devices.

- Conventional PCBs: Suitable for consumer electronics, general computing, telecommunications, and other standard applications where the performance requirements are less demanding, and cost-efficiency is a priority.

While ceramic substrate PCBs offer significant advantages in terms of thermal management, mechanical strength, and electrical performance, their higher cost and manufacturing complexity limit their use to specialized, high-performance applications. In contrast, conventional PCBs, particularly those made from FR-4, provide a cost-effective solution for a broad range of standard electronic applications, making them the most widely used type of PCB in the industry.

Multilayer Ceramic PCB

Structure of Multilayer Ceramic PCBs

Multilayer ceramic PCBs (MLC PCBs) are designed to stack multiple layers of ceramic substrates, each with its own set of conductive pathways, to create a compact, high-density interconnect structure. The layers are separated by dielectric ceramic material and interconnected by vias, which are vertical connections drilled through the layers and filled with conductive material. This multilayer structure allows for more complex circuit designs, greater functionality, and improved performance in a smaller footprint compared to single-layer PCBs. The key components of a multilayer ceramic PCB include:

- Substrate Layers: Multiple ceramic layers, typically made from materials like alumina or aluminum nitride, which provide a stable and thermally conductive base.

- Conductive Traces: Thin layers of conductive material, such as copper or silver, printed or deposited on each ceramic layer to form the circuit pathways.

- Vias: Vertical conductive connections that link the different layers, enabling electrical signals to travel between them.

- Dielectric Layers: Insulating ceramic material that separates the conductive layers, ensuring electrical isolation and stability.

Manufacturing Techniques

The manufacturing of multilayer ceramic PCBs involves several advanced techniques and processes to ensure high precision and reliability:

- Ceramic Tape Casting: Thin layers of ceramic material are produced by tape casting, where a slurry of ceramic powder and binder is spread onto a flat surface and dried to form flexible ceramic tapes.

- Layer Stacking: Multiple ceramic tapes are stacked together, with each layer carefully aligned. Conductive patterns are printed on each layer using screen printing or photolithography.

- Lamination: The stacked layers are laminated under high pressure and temperature to bond them into a single, solid structure. This process also involves the inclusion of vias to connect the layers.

- Via Formation: Vias are drilled through the laminated layers using laser or mechanical drilling techniques. These vias are then filled with conductive materials, such as copper or silver paste.

- Sintering: The laminated structure is subjected to high-temperature sintering, which fuses the ceramic material and conductive traces, creating a robust and stable multilayer PCB.

- Surface Finishing: The PCB undergoes surface finishing processes, such as plating with gold or nickel, to enhance the durability and solderability of the conductive traces.

- Testing and Inspection: Rigorous testing, including electrical, thermal, and mechanical evaluations, ensures that the multilayer ceramic PCB meets the required specifications and performance standards.

Application Examples

Multilayer ceramic PCBs are utilized in various high-end electronic devices where their superior properties provide significant advantages:

- Aerospace Electronics: In aerospace applications, MLC PCBs are used in avionics, satellite systems, and missile guidance systems due to their ability to withstand extreme temperatures, mechanical stress, and radiation.

- Medical Devices: High-reliability medical equipment, such as MRI machines, ultrasound devices, and implantable medical devices, rely on MLC PCBs for their excellent thermal management, biocompatibility, and precision.

- Automotive Electronics: MLC PCBs are found in advanced driver-assistance systems (ADAS), engine control units (ECUs), and other automotive electronic systems that require high reliability and performance under harsh operating conditions.

- Telecommunication Equipment: High-frequency communication devices, including 5G base stations and radar systems, benefit from the low dielectric loss and high thermal conductivity of MLC PCBs, which ensure signal integrity and performance.

- Power Electronics: Devices like power converters, inverters, and motor drives use MLC PCBs for their superior heat dissipation and electrical insulation, crucial for managing high power levels efficiently.

Multilayer ceramic PCBs offer unmatched performance in thermal management, mechanical strength, and electrical properties, making them essential in applications demanding high reliability and efficiency. Their sophisticated manufacturing processes and advanced design capabilities enable the development of compact, high-performance electronic devices across various industries.

Analysis of Ceramic Substrate Materials

What is a Ceramic Substrate?

A ceramic substrate is a type of base material used in the production of printed circuit boards (PCBs) that is made from ceramic materials. These substrates provide excellent thermal and electrical properties, making them ideal for high-performance and high-reliability applications. The most commonly used ceramic materials for substrates include:

- Alumina (Al2O3): The most widely used ceramic substrate material, known for its good thermal conductivity, electrical insulation, and mechanical strength.

- Aluminum Nitride (AlN): Offers higher thermal conductivity than alumina, making it suitable for applications requiring efficient heat dissipation.

- Silicon Nitride (Si3N4): Known for its excellent mechanical properties and thermal stability, it is often used in high-stress and high-temperature environments.

Choosing Ceramic Substrate Materials

Selecting the appropriate ceramic substrate material involves evaluating the specific requirements of the application and balancing the pros and cons of each material:

- Alumina (Al2O3)

- Pros: Good thermal conductivity (20-30 W/m·K), high electrical insulation, cost-effective, widely available.

- Cons: Lower thermal conductivity compared to other ceramics like AlN, moderate mechanical strength.

- Suitable Scenarios: General high-performance applications, consumer electronics, and automotive electronics.

- Aluminum Nitride (AlN)

- Pros: Excellent thermal conductivity (170-200 W/m·K), good electrical insulation, low dielectric constant, low thermal expansion.

- Cons: Higher cost compared to alumina, more complex manufacturing process.

- Suitable Scenarios: High-power electronics, RF and microwave devices, LED lighting, and applications requiring efficient heat dissipation.

- Silicon Nitride (Si3N4)

- Pros: Exceptional mechanical strength, high thermal stability, good thermal conductivity (85-90 W/m·K), excellent wear resistance.

- Cons: High cost, more specialized manufacturing processes.

- Suitable Scenarios: Aerospace, automotive engines, and high-stress industrial applications where mechanical robustness is critical.

Comparison with FR-4 Materials

Comparing ceramic substrates with FR-4 materials highlights the differences in performance, cost, and application areas:

- Performance

- Thermal Conductivity:

- Ceramic Substrates: Ranges from 20 W/m·K (alumina) to 200 W/m·K (aluminum nitride), providing excellent heat dissipation capabilities.

- FR-4: Approximately 0.3 W/m·K, significantly lower, leading to potential heat buildup in high-power applications.

- Mechanical Properties:

- Ceramic Substrates: High strength, hardness, and wear resistance, suitable for high-stress environments.

- FR-4: Adequate mechanical stability but less robust compared to ceramics, more susceptible to mechanical damage under extreme conditions.

- Electrical Properties:

- Ceramic Substrates: Low dielectric constant, high insulation resistance, and stable performance at high frequencies and temperatures.

- FR-4: Higher dielectric constant (around 4.5), lower insulation resistance, adequate for many standard applications but less effective in high-frequency or high-voltage scenarios.

- Thermal Conductivity:

- Cost

- Ceramic Substrates: Generally more expensive due to the cost of raw materials and sophisticated manufacturing processes.

- FR-4: More cost-effective, widely available, and easier to manufacture, making it the preferred choice for many cost-sensitive applications.

- Application Areas

- Ceramic Substrates: Ideal for high-performance, high-reliability applications such as aerospace, automotive electronics, medical devices, power electronics, and high-frequency communication devices. They are used where superior thermal management, mechanical strength, and electrical performance are crucial.

- FR-4: Widely used in consumer electronics, general computing, telecommunications, and other standard applications where the performance demands are lower and cost-efficiency is a priority.

Ceramic substrates offer significant advantages in thermal, mechanical, and electrical performance, making them suitable for specialized, high-demand applications. However, their higher cost and more complex manufacturing processes limit their use compared to the more cost-effective and versatile FR-4 materials, which dominate the market for general electronic applications.

Other Substrates Used in PCBs

Common Types of Substrates

In addition to ceramic substrates and FR-4, several other substrate materials are commonly used in PCB manufacturing. These materials vary in terms of their properties, costs, and suitable applications:

- FR-4 (Flame Retardant 4): A composite material made of woven fiberglass cloth with an epoxy resin binder that is flame resistant. It is the most widely used PCB substrate due to its good balance of performance and cost.

- CEM-1 (Composite Epoxy Material 1): Made of a paper core with one layer of woven fiberglass cloth. It offers good electrical properties and is often used in single-sided PCBs.

- CEM-3 (Composite Epoxy Material 3): Similar to FR-4 but with a non-woven fiberglass core. It is less expensive than FR-4 and is used for double-sided and multilayer PCBs in less demanding applications.

- Polyimide: Known for its excellent thermal stability and flexibility, polyimide substrates are used in flexible and high-temperature PCBs.

- PTFE (Polytetrafluoroethylene): Offers excellent high-frequency performance and low dielectric constant, making it ideal for RF and microwave applications.

- Metal Core (Aluminum, Copper): Used to enhance heat dissipation, metal core PCBs are employed in high-power applications such as LED lighting and power supplies.

Performance Comparison of Various Substrates

A comparison of the different substrate materials highlights their respective strengths and weaknesses in terms of thermal conductivity, electrical performance, and mechanical performance:

- Thermal Conductivity

- Ceramic Substrates (Alumina, Aluminum Nitride, Silicon Nitride): High thermal conductivity (20-200 W/m·K) allows for efficient heat dissipation.

- FR-4: Low thermal conductivity (~0.3 W/m·K), which can lead to heat buildup.

- CEM-1: Similar to FR-4 but with slightly lower thermal performance.

- CEM-3: Comparable to FR-4 in thermal performance.

- Polyimide: Moderate thermal conductivity, suitable for high-temperature applications.

- PTFE: Low thermal conductivity but adequate for RF applications where thermal management is less critical.

- Metal Core: Very high thermal conductivity, excellent for dissipating heat in high-power applications.

- Electrical Performance

- Ceramic Substrates: Low dielectric constant, high insulation resistance, excellent for high-frequency and high-voltage applications.

- FR-4: Moderate dielectric constant (~4.5), suitable for general-purpose applications.

- CEM-1: Good electrical properties for single-sided PCBs.

- CEM-3: Similar electrical performance to FR-4.

- Polyimide: Excellent electrical performance, stable across a wide temperature range.

- PTFE: Very low dielectric constant, ideal for high-frequency applications.

- Metal Core: Typically used with an insulating layer; electrical performance depends on the dielectric material used.

- Mechanical Performance

- Ceramic Substrates: High strength, hardness, and wear resistance, suitable for high-stress environments.

- FR-4: Good mechanical stability and robustness for most applications.

- CEM-1: Adequate mechanical performance for simpler, single-sided PCBs.

- CEM-3: Slightly less robust than FR-4 but adequate for many applications.

- Polyimide: Excellent flexibility and thermal stability, ideal for flexible PCBs and high-temperature environments.

- PTFE: Good mechanical properties but can be more challenging to process due to its softness.

- Metal Core: Excellent mechanical strength and rigidity, enhancing the durability of the PCB.

Summary of Applications

- FR-4: Dominates the PCB market due to its versatility, cost-effectiveness, and adequate performance for most consumer electronics, computing, and telecommunications applications.

- CEM-1: Used in cost-sensitive, single-sided PCB applications like consumer electronics.

- CEM-3: Suitable for double-sided and multilayer PCBs in less demanding environments, such as home appliances.

- Polyimide: Preferred for flexible PCBs and applications requiring high thermal stability, like aerospace and medical devices.

- PTFE: Chosen for high-frequency RF and microwave applications due to its low dielectric constant.

- Metal Core: Utilized in high-power, high-heat applications like LED lighting, automotive electronics, and power supplies, where efficient heat dissipation is crucial.

The choice of PCB substrate material depends on the specific performance requirements, cost constraints, and application scenarios. Each substrate material offers unique advantages that make it suitable for particular types of electronic devices and environments.

Applications and Market Prospects

Major Application Areas of Ceramic Substrate PCBs

- Aerospace: Ceramic substrate PCBs are extensively used in aerospace applications due to their ability to withstand extreme temperatures, mechanical stress, and radiation. They are employed in avionics systems, satellite communications, radar systems, and onboard control systems.

- Automotive Electronics: In the automotive industry, ceramic substrate PCBs play a crucial role in advanced driver-assistance systems (ADAS), engine control units (ECUs), powertrain systems, and in-vehicle infotainment systems. Their high thermal conductivity and mechanical strength make them suitable for the demanding automotive environment.

- Medical Devices: Ceramic substrate PCBs are essential components in medical devices such as MRI machines, ultrasound equipment, implantable medical devices, and diagnostic devices. Their reliability, biocompatibility, and thermal stability are critical for ensuring the safe and effective operation of medical equipment.

- Communication Equipment: Ceramic substrate PCBs are widely used in communication equipment, including cellular base stations, RF modules, satellite communication systems, and high-speed data transmission equipment. Their low dielectric loss and high-frequency performance enable reliable signal transmission in telecommunications networks.

- LED Lighting: Ceramic substrate PCBs are increasingly used in high-brightness LED lighting applications due to their excellent thermal conductivity and heat dissipation properties. They help improve the efficiency and longevity of LED lighting systems in commercial, industrial, and residential settings.

Market Trends and Future Prospects

- Growing Demand for High-Performance Electronics: The increasing demand for high-performance electronic devices in various industries, including aerospace, automotive, and telecommunications, is driving the growth of the ceramic substrate PCB market. As electronic devices become more advanced and compact, the need for reliable and efficient PCBs with superior thermal management and electrical performance is rising.

- Shift towards Electric Vehicles (EVs): The rapid growth of the electric vehicle market is creating opportunities for ceramic substrate PCBs in automotive electronics. EVs require sophisticated power electronics systems, battery management systems, and onboard chargers, all of which rely on ceramic substrate PCBs for their high reliability and thermal efficiency.

- Advancements in 5G Technology: The deployment of 5G networks worldwide is driving demand for ceramic substrate PCBs in communication equipment such as 5G base stations, antennas, and RF modules. Ceramic substrates enable the high-frequency performance and thermal management required for 5G infrastructure, supporting faster data speeds and lower latency.

- Emerging Applications in Healthcare: With the increasing focus on healthcare and medical technology, ceramic substrate PCBs are finding new applications in medical devices and diagnostic equipment. As medical devices become more complex and compact, ceramic substrates are essential for ensuring the reliability and safety of these devices in critical healthcare settings.

- Technological Innovations: Ongoing technological innovations in ceramic substrate materials, manufacturing processes, and design techniques are driving the development of more advanced and efficient PCBs. The introduction of new ceramic materials with enhanced thermal conductivity, electrical performance, and mechanical properties is expanding the capabilities of ceramic substrate PCBs in various industries.

The ceramic substrate PCB market is poised for significant growth driven by the increasing demand for high-performance electronics, advancements in key industries such as automotive, telecommunications, and healthcare, and ongoing technological innovations. As the need for reliable, efficient, and compact electronic devices continues to grow, ceramic substrate PCBs will play a crucial role in enabling these advancements and shaping the future of electronic technology.

FAQs About ceramic substrate pcb

A ceramic substrate is a type of base material used in printed circuit boards (PCBs) that is made from ceramic materials like alumina, aluminum nitride, or silicon nitride. These substrates offer superior thermal conductivity, mechanical strength, and electrical insulation properties, making them ideal for high-performance and high-reliability applications.

The main difference between ceramic substrate and FR-4 lies in their composition and properties. Ceramic substrates are made from ceramic materials like alumina or aluminum nitride, offering high thermal conductivity and mechanical strength. In contrast, FR-4 is a composite material made of woven fiberglass cloth impregnated with epoxy resin. While FR-4 is cost-effective and versatile, it has lower thermal conductivity and mechanical strength compared to ceramic substrates.

Ceramic materials for PCBs refer to substrates made from ceramics like alumina, aluminum nitride, or silicon nitride. These materials offer excellent thermal management, mechanical durability, and electrical insulation properties, making them suitable for high-performance electronic applications where reliability and efficiency are paramount.

Various substrates are used in PCB manufacturing, including ceramic, FR-4, CEM-1, CEM-3, polyimide, PTFE, and metal core substrates. The choice of substrate depends on factors such as thermal management requirements, electrical performance, mechanical strength, and cost constraints.