Detailed Insights into Ceramic Substrate and FR4 Cost Analysis

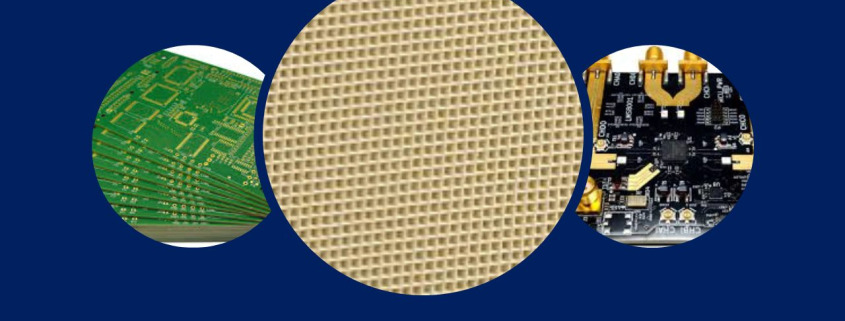

Ceramic substrates and FR4 are critical materials in the electronics industry, each serving distinct purposes, and understanding their cost differences is essential. Ceramic substrates are known for their excellent thermal conductivity and high-frequency performance, making them ideal for power electronics and high-temperature applications. On the other hand, FR4 is a widely used epoxy laminate material, appreciated for its versatility and cost-effectiveness in standard PCB applications. A ceramic substrate and FR4 cost analysis enables manufacturers to evaluate both the initial and long-term expenses associated with each type. By conducting this analysis, businesses can determine the most suitable material for their specific needs, balancing performance requirements with budget considerations. This comprehensive ceramic substrate and FR4 cost analysis ensures manufacturers make optimal investments while maintaining product reliability and efficiency.

4o

Detailed Cost Analysis of Ceramic Substrates in Relation to Ceramic Substrate and FR4 Cost Analysis

Material Costs

Ceramic substrates are primarily made from materials such as alumina, zirconia, and silicon nitride, sourced from various suppliers worldwide. The prices of these materials can fluctuate due to factors such as supply chain disruptions, changes in raw material availability, and global demand. Understanding these fluctuations is crucial for budgeting, as significant price variations can impact overall project costs.

Production Costs

The production of ceramic substrates involves complex processes like sintering and machining, which require precision and expertise. This complexity directly influences manufacturing costs, as specialized labor and intricate quality control measures are necessary. Additionally, the capital investment in advanced manufacturing equipment, such as CNC machines and kilns, can be substantial. Ongoing maintenance of this equipment is also a consideration, as it can lead to unexpected expenses and downtime if not properly managed.

Long-term Usage Costs

The lifespan and reliability of ceramic substrates play a vital role in the overall cost analysis. While they often come with higher initial costs, their durability can lead to reduced replacement frequency and lower long-term maintenance costs. In applications where performance and reliability are paramount, investing in ceramic substrates can ultimately result in lower total costs compared to less reliable alternatives. Evaluating these factors within the framework of the ceramic substrate and FR4 cost analysis enables manufacturers to make informed decisions that align with their operational goals.

Detailed Cost Analysis of FR4

Material Costs

FR4 substrates are primarily composed of woven fiberglass and epoxy resin, which are readily available and widely used materials in the electronics industry. The market pricing for FR4 can vary based on factors such as resin quality, thickness, and specific application requirements. The supply-demand dynamics also play a crucial role; increased demand for consumer electronics can lead to temporary price surges. However, the relatively stable supply chain for FR4 materials generally keeps costs predictable, making it an economically viable choice for many applications.

Production Costs

The manufacturing process for FR4 is known for its efficiency, leveraging techniques such as lamination and curing that streamline production. This efficiency translates to lower labor costs and faster turnaround times, making FR4 an attractive option for manufacturers. Additionally, the equipment required for FR4 production, including presses and lamination machines, tends to be less specialized than that for ceramic substrates. This not only reduces initial investment costs but also enhances production flexibility, allowing manufacturers to adapt quickly to changing market demands.

Long-term Usage Costs

While FR4 is generally less expensive upfront, its durability and long-term performance are essential factors in cost analysis. FR4 substrates are known for their adequate thermal and mechanical properties, but they may not perform as well in extreme conditions compared to ceramic substrates. This can lead to more frequent replacements or repairs in high-stress applications. Evaluating the durability and potential maintenance costs associated with FR4 helps manufacturers understand the overall financial implications, ensuring that they make cost-effective decisions for their specific use cases.

Comparative Cost Analysis

Direct Cost Comparison

When comparing the initial investment and production costs of ceramic substrates and FR4, it’s clear that ceramic substrates generally require a higher upfront capital outlay. The materials for ceramic substrates, along with their complex manufacturing processes, contribute to elevated initial costs. In contrast, FR4’s lower material costs and simpler production methods make it a more affordable choice initially. For manufacturers looking to minimize expenses, FR4 often appears more attractive. However, it’s essential to consider the full scope of costs, including potential savings in efficiency and performance for ceramic substrates, especially in high-reliability applications.

Indirect Cost Analysis

The long-term impacts of performance and reliability significantly influence the overall cost analysis of both materials. Ceramic substrates, despite their higher initial costs, offer superior thermal and electrical performance, leading to reduced failures and longer service life in critical applications. This reliability can translate to lower maintenance and replacement costs over time. Conversely, while FR4 may seem economically advantageous upfront, its performance limitations in high-temperature or high-stress environments can lead to increased downtime and replacement costs, ultimately affecting the total cost of ownership. Manufacturers must weigh these long-term implications carefully when making material selections.

Applicability and Market Trends

Different application scenarios heavily influence material selection, with trends in the electronics market shaping these decisions. For high-frequency, high-power applications, such as in telecommunications and automotive electronics, the superior performance of ceramic substrates often justifies their higher costs. Conversely, FR4 remains a dominant choice for consumer electronics and lower-stress applications due to its cost-effectiveness and availability. As market demands evolve, including the push for more sustainable and efficient products, manufacturers may need to reassess their material choices. Trends toward miniaturization and enhanced performance will likely drive a continued interest in advanced materials like ceramic substrates, further impacting the comparative cost analysis.

Conclusion

In summary, both ceramic substrates and FR4 offer unique advantages and cost considerations that can significantly impact electronic design and manufacturing. Ceramic substrates, while initially more expensive, provide exceptional performance and reliability in high-frequency and high-temperature applications, making them a worthwhile investment for critical uses. Conversely, FR4 is cost-effective and widely applicable in standard electronics, particularly where budget constraints are a primary concern.

Manufacturers should carefully evaluate their specific needs, considering both the short-term and long-term costs associated with each material. By analyzing the performance requirements and potential future trends in their applications, businesses can make informed decisions that align with their operational goals and financial parameters. Ultimately, selecting the right substrate material is crucial for optimizing both performance and cost-effectiveness in electronic products.