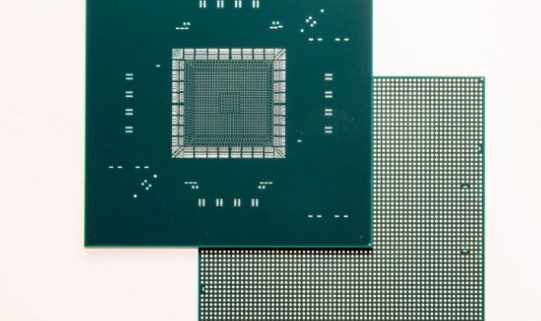

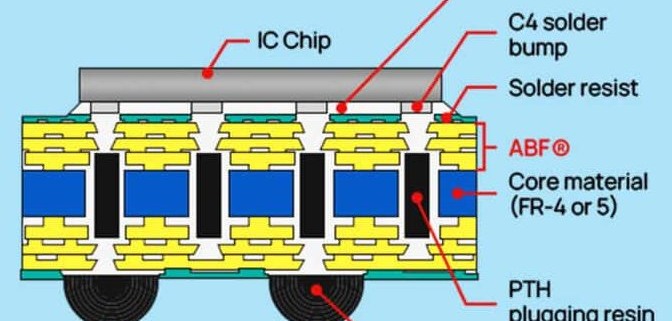

Electronic packaging is essential in modern technology, providing support, electrical interconnections, and thermal management for semiconductor components. Substrates, the foundation of this packaging, play a crucial role in ensuring the functionality and reliability of electronic devices. Among various packaging technologies, FCBGA (Flip-Chip Ball Grid Array) is particularly important for its high-density, high-performance applications in CPUs, GPUs, and advanced systems. A significant advancement in FCBGA packaging is the use of FCBGA Glass Substrate, which offers superior thermal stability, dimensional accuracy, and compatibility with fine-line routing. These benefits make glass substrates increasingly vital in meeting the performance and reliability needs of next-generation devices, including those in AI, 5G, and IoT applications.

Semiconductor packaging is a crucial process in modern electronics, ensuring that integrated circuits (ICs) are securely connected to external systems while maintaining high performance and reliability. As electronic devices become smaller and more powerful, the choice of substrate material becomes critical, as it directly impacts heat dissipation, signal integrity, and electrical functionality. The FCBGA ABF substrate has emerged as a key solution in the industry, combining the high-density interconnection and thermal management benefits of FCBGA (Flip Chip Ball Grid Array) with the superior electrical performance and miniaturization capabilities of ABF (Ajinomoto Build-up Film). This powerful combination allows the FCBGA ABF substrate to meet the ever-growing demands of advanced electronic devices in sectors such as AI, telecommunications, and automotive technologies, making it an essential component in the future of semiconductor packaging.

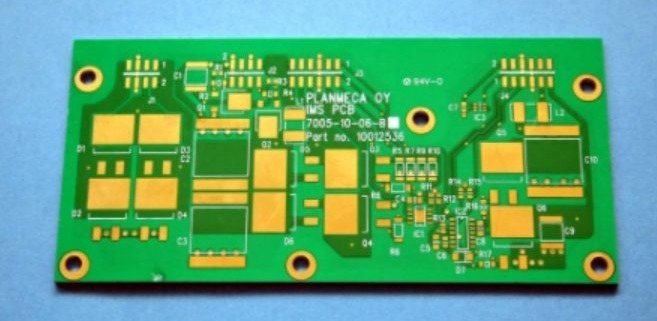

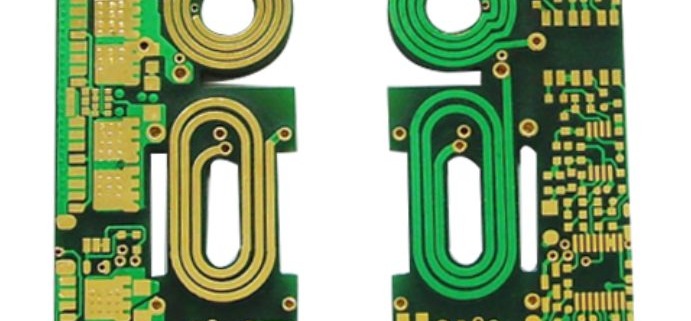

Rogers PCB refers to printed circuit boards made from specialized laminates developed by Rogers Corporation, a leading PCB manufacturer based in the USA. Known for their superior material properties, Rogers PCBs are widely used in high-performance applications that demand low loss, high signal integrity, and efficient thermal management. Rogers offers a variety of materials such as the 4350, RO4835, and Duroid series, which are especially valuable in industries like telecommunications, aerospace, and medical devices. High-density circuits, or HDI, involve closely spaced components and small vias, allowing for more complex and compact designs. High density Rogers PCB circuits board are essential in industries such as RF/microwave communications, medical diagnostics, and aerospace, where space is limited but performance is crucial. These HDI Rogers PCBs enable faster signal transmission, reduced size, and improved reliability, making them indispensable for next-generation electronic devices.

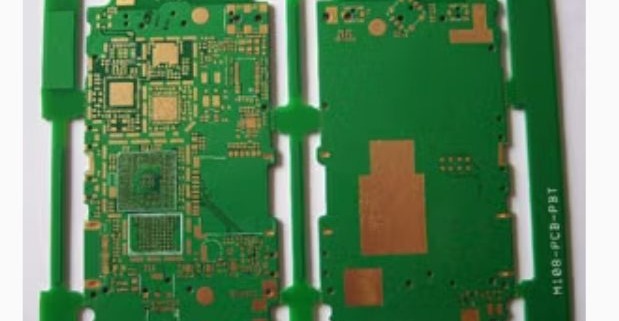

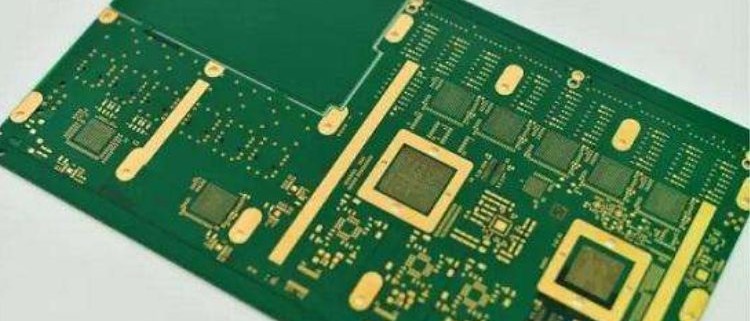

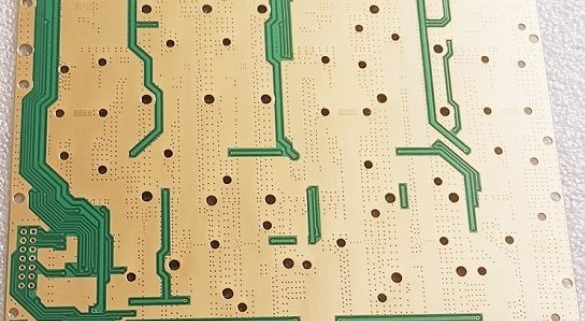

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing the necessary platform for connecting and supporting electronic components. As technology advances, the need for more compact, efficient, and powerful electronic systems has increased, making high-density PCBs essential in today’s market. High-density online Rogers PCB circuits board technology, specifically, plays a crucial role in meeting these demands. It enables the production of compact, multi-layer PCBs that can handle higher frequencies and offer better thermal management, making them ideal for cutting-edge applications in telecommunications, automotive, and medical devices. Rogers PCB materials, known for their superior electrical properties and thermal stability, are widely used in high-density circuit board designs. These materials offer the performance required for high-frequency, high-speed applications, setting them apart from traditional PCB solutions. As the demand for smaller and more efficient devices continues to grow, high-density online Rogers PCB circuits board technology remains at the forefront of advanced electronics.

Printed Circuit Boards (PCBs) are crucial components in modern electronics, providing the necessary electrical pathways to connect and support various electronic parts. The quality of materials used in PCB manufacturing plays a significant role in ensuring the performance, reliability, and longevity of electronic devices. One notable material is Rogers PCB, developed by Rogers Corporation, which is renowned for its high-frequency performance, low signal loss, and excellent thermal stability. These characteristics make Rogers PCBs ideal for demanding applications in industries like telecommunications, aerospace, and medical technology. For high-performance devices, gold plating Rogers PCB printed circuits corp offers additional durability and enhanced electrical conductivity, further elevating the reliability and efficiency of these advanced PCBs.

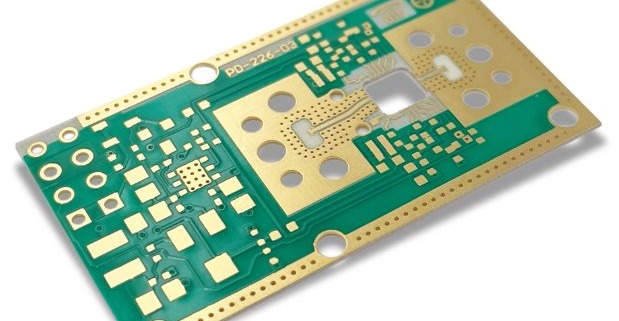

Rogers PCB is a specialized printed circuit board designed for high-frequency and high-performance applications, making it ideal for industries like telecommunications, aerospace, and automotive. With its low signal loss and excellent thermal stability, Rogers PCB ensures superior performance in demanding environments. To further enhance its durability and electrical conductivity, gold plating is often applied as a surface finish, offering corrosion resistance, low contact resistance, and long-lasting performance, which are essential for high-frequency applications. Focusing on gold plating Rogers PCB low volume PCB production allows for tailored, high-quality PCB manufacturing in smaller batches, making it a cost-effective solution for prototyping, research, and custom projects, where rapid design iterations or specialized solutions are crucial. This approach ensures that industries can meet performance standards without compromising on efficiency or cost.

PCB (Printed Circuit Board) fabrication is a multi-step process that involves design, material selection, drilling, etching, and surface finishing. Among the various materials used, Rogers stands out for its excellent high-frequency performance, making it ideal for specialized applications like telecommunications, aerospace, and RF circuits. Gold plating is often applied to Rogers PCBs to enhance conductivity, provide corrosion resistance, and improve durability. When considering the gold plating Rogers PCB fabrication price, it is essential to balance the need for high-performance materials and surface finishes with the associated costs. The combination of Rogers materials and gold plating leads to a premium price due to the specialized manufacturing process, making it crucial to understand cost factors when choosing the right PCB for your project.

Rogers PCBs (Printed Circuit Boards) are widely used in high-performance applications due to their exceptional material properties, such as superior signal integrity, low loss, and high-frequency capability. These boards are ideal for industries like telecommunications, aerospace, and defense, where reliability and performance are critical. Gold plating Rogers PCB plays a vital role in enhancing their functionality. By applying a thin layer of gold, which is known for its excellent conductivity and resistance to corrosion, manufacturers can improve solderability, reduce wear, and ensure stable electrical connections over time. This gold plating ensures that Rogers PCBs perform optimally in high-speed and high-frequency applications, maintaining signal integrity in even the most demanding environments, making it a preferred choice for advanced technology.

Rogers 4003C is a high-frequency laminate material that offers exceptional performance in demanding RF (radio frequency) and microwave applications. Known for its excellent dielectric properties, it ensures minimal signal loss and stable transmission, making it a preferred choice for circuits that require high precision. Gold plating Rogers 4003C PCB combines the unique advantages of this advanced laminate with the superior conductivity and corrosion resistance of gold. This integration enhances performance in high-frequency applications where signal integrity is critical. The low signal loss and high performance of Rogers 4003C make it an ideal material for designing PCBs in industries such as telecommunications, aerospace, and electronics. By using gold plating Rogers 4003C PCB, manufacturers can ensure longer-lasting and more reliable connections, further boosting the material’s already outstanding performance in high-frequency environments.

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing the physical foundation for connecting and supporting electronic components. They serve as the backbone for everything from consumer gadgets to advanced industrial devices. The design and material of a PCB greatly influence its performance, reliability, and cost. Among the most commonly used materials for PCB manufacturing are FR4 and Rogers, each offering distinct advantages for different applications. FR4 is a widely used material known for its durability and affordability, while Rogers is recognized for its superior electrical performance, especially in high-frequency circuits. In this blog, we will compare FR4 Rogers double sided PCB solutions, exploring the differences in material properties, performance characteristics, and suitable applications. Our aim is to help you understand which material is best suited for your specific needs, whether you’re designing consumer electronics or high-performance communication systems.

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Understanding the Benefits of Polyimide Flexible PCB Technology2025-06-03 - 3:17 上午

Understanding the Benefits of Polyimide Flexible PCB Technology2025-06-03 - 3:17 上午 Building a Custom Keyboard with a Keyboard Flexible PCB2025-05-30 - 3:22 上午

Building a Custom Keyboard with a Keyboard Flexible PCB2025-05-30 - 3:22 上午 Advantages of Using FPC Flexible PCB in Modern Electronics2025-05-29 - 4:20 上午

Advantages of Using FPC Flexible PCB in Modern Electronics2025-05-29 - 4:20 上午 Essential Design Guidelines for Flexible Rigid PCB Success2025-05-28 - 3:28 上午

Essential Design Guidelines for Flexible Rigid PCB Success2025-05-28 - 3:28 上午