A COB LED, or Chip on Board LED, revolutionizes lighting technology. Unlike traditional LEDs, which rely on individual diodes, COB LEDs amalgamate multiple LED chips onto a singular substrate. This innovative packaging method enhances luminosity, creating a concentrated and uniform light source. COB LEDs are renowned for their efficiency and versatility, making them ideal for various applications, from indoor lighting to commercial displays. By maximizing the use of space and resources, COB LEDs represent a significant advancement in illumination technology, promising brighter, more consistent lighting solutions for a multitude of settings.

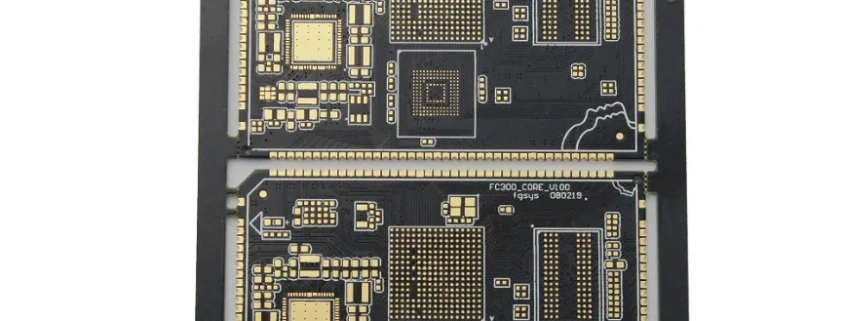

阅读更多FR4, standing for Flame Retardant 4, is a widely used material in the manufacturing of printed circuit boards (PCBs). Its versatility, durability, and excellent electrical properties make it indispensable in modern electronics. FR4 consists of layers of fiberglass cloth impregnated with epoxy resin, offering both mechanical strength and electrical insulation. PCBs made from FR4 exhibit high thermal stability, allowing them to withstand the rigors of various electronic applications. Understanding the properties and specifications of FR4 is crucial for engineers and designers aiming to optimize the performance and reliability of their electronic devices. In this exploration, we delve into the composition, properties, applications, and significance of FR4 PCB material, shedding light on its pivotal role in the electronics industry.

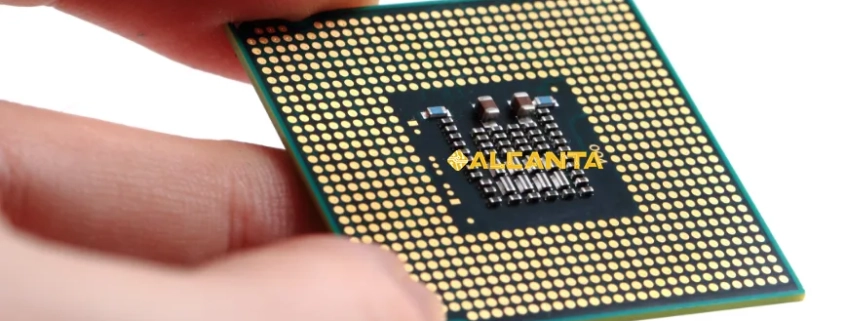

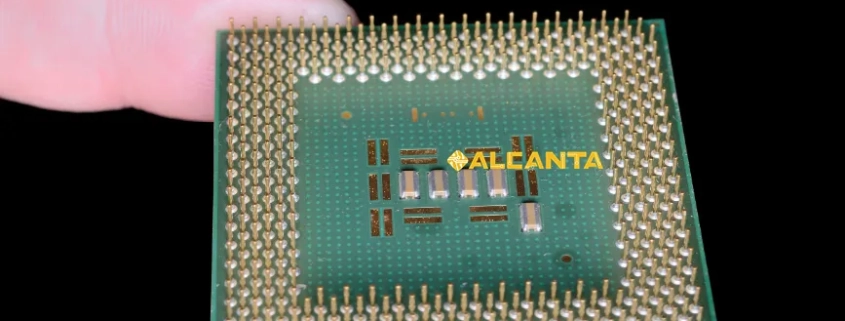

Ball Grid Array (BGA) substrates serve as critical components in modern electronics, facilitating the connection between integrated circuits and printed circuit boards (PCBs). These substrates feature a grid of solder balls underneath the chip, enabling efficient heat dissipation and electrical connectivity. However, to optimize the performance and reliability of BGA substrates, manufacturers employ advanced fabrication techniques such as etch back.

Etch back, a crucial process in semiconductor manufacturing, involves selectively removing material layers to achieve desired electrical and mechanical properties. In the context of BGA substrate design, etch back plays a vital role in fine-tuning the substrate’s dimensions, ensuring precise alignment and robust interconnection. Understanding the significance of etch back in BGA substrate design is essential for engineers and manufacturers striving for excellence in electronic component production.

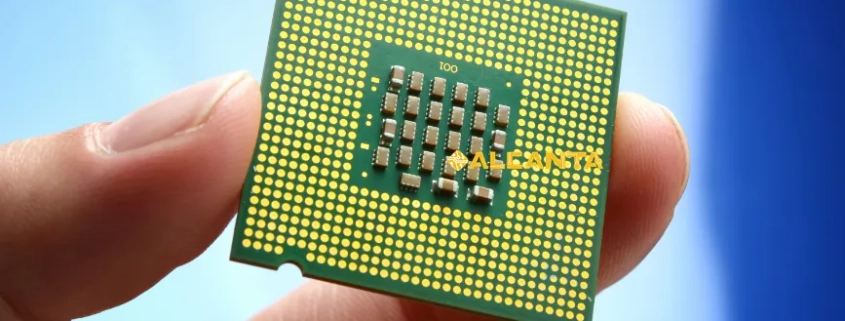

阅读更多Flip chip technology represents a pivotal advancement in semiconductor packaging, revolutionizing the landscape of modern electronics. Its significance lies in its ability to enhance performance, reliability, and miniaturization of electronic devices. Flip chip ball grid array (BGA) packaging, a variant of flip chip technology, holds particular importance in semiconductor packaging. It offers increased I/O density, improved thermal performance, and enhanced electrical performance, making it ideal for high-performance applications such as CPUs, GPUs, and networking devices. Understanding the intricacies of flip chip BGA packaging is crucial for engineers and manufacturers aiming to stay at the forefront of semiconductor technology.

阅读更多Etch back, a pivotal process in semiconductor manufacturing, involves selectively removing material from the surface of a substrate to enhance its properties. In the realm of Ball Grid Array (BGA) substrate production, etch back plays a paramount role. It ensures the precise modification of substrate layers, optimizing electrical performance and thermal conductivity. By meticulously controlling material removal, etch back refines the substrate’s surface, paving the way for seamless integration of semiconductor components. This process is indispensable in achieving the stringent specifications demanded by modern electronic devices. In the following discourse, we delve into the intricacies of etch back, unraveling its nuances and its profound impact on the evolution of BGA substrate technology.

阅读更多In the intricate world of electronic packaging, Ball Grid Array (BGA) technology stands as a pivotal advancement. BGA packages have revolutionized the way electronic components are interconnected on circuit boards, offering enhanced performance, reliability, and compactness. Central to the functionality of BGA packages is the substrate, a foundational layer that hosts the intricate network of connections. Among the myriad factors influencing BGA performance, substrate thickness emerges as a critical consideration. This introductory section sets the stage for a comprehensive exploration of BGA substrate thickness, delving into its significance, types, standard sizes, and distinguishing features compared to related technologies. By understanding the role of substrate thickness, we uncover key insights into optimizing BGA performance and reliability.

阅读更多BGA (Ball Grid Array) is a crucial packaging technology in the semiconductor industry, facilitating compact and efficient electronic devices. At the heart of BGA lies its substrate, a foundational component that provides mechanical support, electrical connectivity, and thermal management to the integrated circuit. BGA substrate suppliers play a pivotal role in ensuring the availability of high-quality materials tailored to the demanding requirements of modern electronics. These suppliers not only provide substrates with precise dimensions and thermal properties but also innovate to meet evolving industry standards and technological advancements. Their contributions are instrumental in enabling the production of reliable and high-performance semiconductor packages, driving progress in various electronic applications.

阅读更多In the realm of electronic products, the application of BGA (Ball Grid Array) packaging technology has revolutionized the landscape of component integration and miniaturization. BGA offers advantages such as increased pin count, better thermal performance, and enhanced electrical connectivity. However, amidst the continuous quest for innovation, a new advancement emerges: Bus Less BGA Substrate. This cutting-edge technology represents a paradigm shift in BGA packaging, eliminating the need for traditional bus structures within the substrate. By streamlining the architecture, Bus Less BGA Substrate not only enhances signal integrity and reduces power consumption but also opens doors to more compact and efficient electronic designs. Its introduction marks a significant stride towards the next generation of electronic packaging solutions.

阅读更多Flip Chip BGA Substrate represents a pivotal advancement in electronic packaging, revolutionizing the way electronic components are interconnected and mounted onto substrates. This innovative technology enables higher component density, improved thermal performance, and enhanced electrical connectivity, making it a cornerstone of modern electronic devices. Its significance in the electronics industry lies in its ability to meet the ever-growing demand for smaller, faster, and more reliable electronic products. By facilitating compact and efficient designs, Flip Chip BGA Substrate not only drives innovation but also enables the development of cutting-edge applications in fields such as telecommunications, automotive electronics, and medical devices. In this blog, we delve into the intricacies of Flip Chip BGA Substrate,

阅读更多In today’s electronics landscape, Ball Grid Array (BGA) substrates stand as critical components, facilitating the intricate interconnection of integrated circuits (ICs). These substrates serve as the foundation for mounting and connecting ICs to circuit boards, enabling efficient heat dissipation, signal transmission, and mechanical stability. BGA technology revolutionized electronics manufacturing by offering higher pin densities, improved thermal performance, and enhanced reliability compared to traditional packaging methods. As miniaturization and performance demands continue to escalate, the significance of BGA substrates only amplifies, underscoring their pivotal role in driving innovation and pushing the boundaries of electronic design.

阅读更多CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午