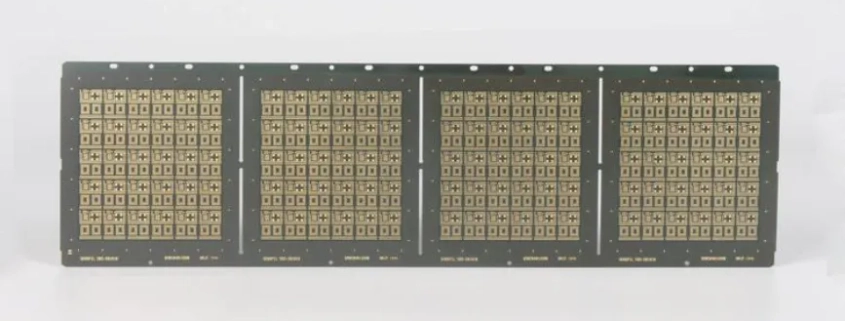

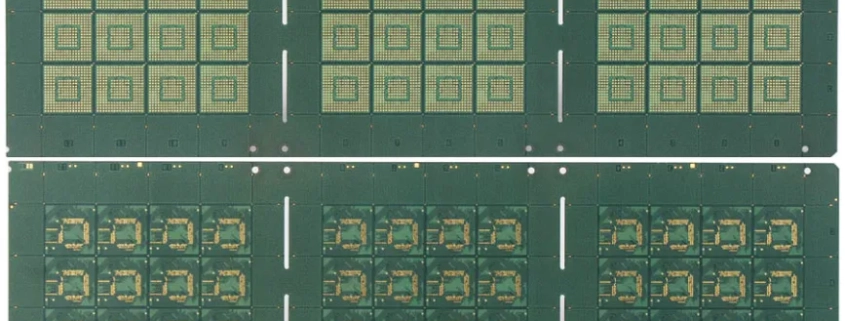

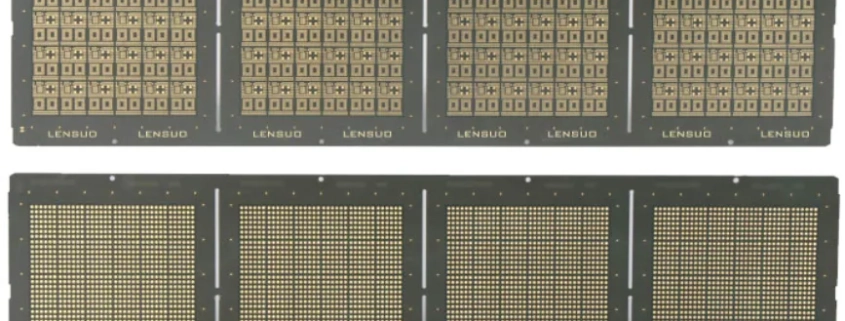

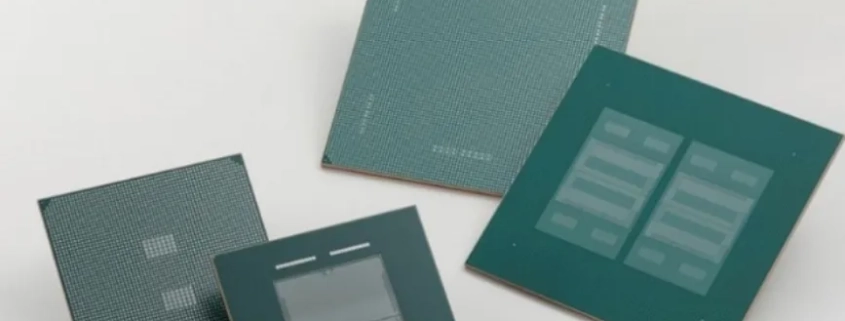

Flip Chip technology has revolutionized the semiconductor industry, offering enhanced performance and reliability in electronic packaging. Its development has been propelled by the need for miniaturization, increased functionality, and higher interconnection densities in electronic devices. In this context, Multilayer Flip Chip Substrate emerges as a critical component, providing a robust foundation for advanced packaging solutions. Its significance lies in enabling high-density interconnects, minimizing signal delay, and enhancing thermal management, crucial for modern electronics. By facilitating the seamless integration of semiconductor devices onto substrates, Multilayer Flip Chip Substrate elevates the efficiency and performance of various applications, ranging from telecommunications and automotive electronics to industrial automation. Understanding its role is pivotal for grasping the transformative potential of contemporary electronic packaging solutions.

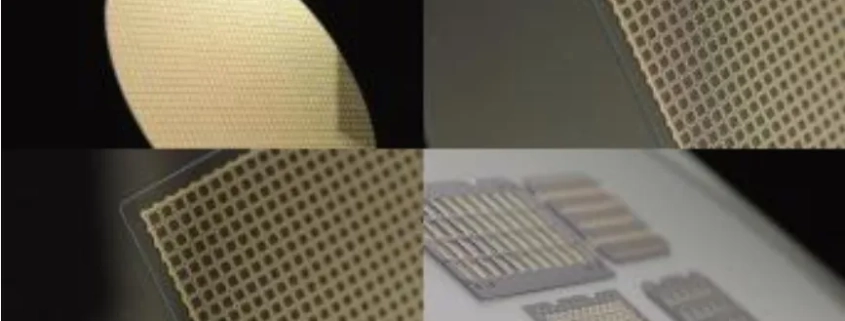

阅读更多In the realm of electronic devices, substrates serve as the foundational blocks upon which circuits are built. These substrates not only provide structural support but also play critical roles in heat dissipation, electrical insulation, and overall device reliability. As electronics become increasingly compact and powerful, the demand for substrates that can withstand higher temperatures and provide superior electrical insulation has surged. Enter Microtrace Ceramic Substrates, a leader in the industry known for their advanced ceramic materials. These substrates leverage materials like Aluminum Oxide and Silicon Nitride, which are pivotal in enhancing the performance and longevity of electronic components. Microtrace’s commitment to innovation is evident in their substrates’ ability to meet the rigorous demands of modern electronics, making them indispensable in fields ranging from aerospace to consumer electronics. This makes Microtrace Ceramic Substrates a key player in pushing the boundaries of what’s possible in technology.

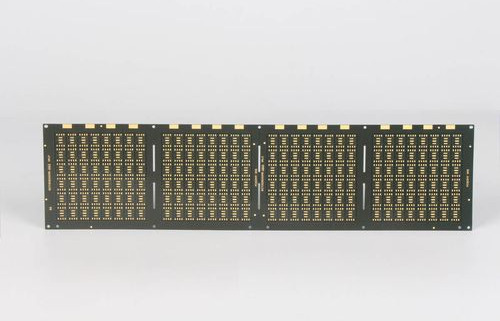

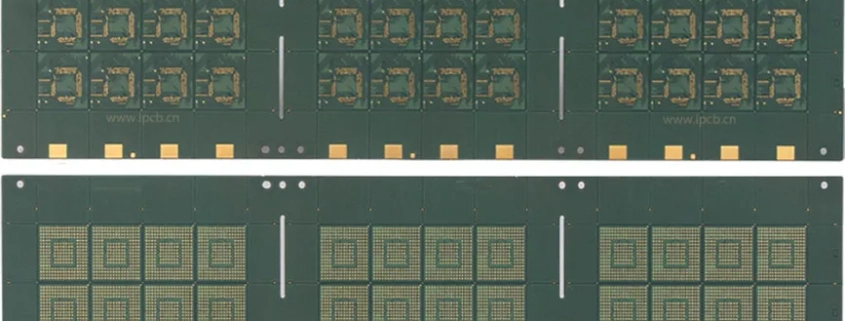

阅读更多Printed Circuit Board (PCB) design and manufacturing are critical processes in the electronics industry, forming the backbone of almost all electronic devices. PCBs serve as the foundation for mounting and interconnecting various electronic components, from simple resistors to complex microprocessors. The design phase involves creating a layout that ensures optimal performance and reliability, while manufacturing transforms this layout into a physical board through precise fabrication techniques.

Understanding design rules and specifications is paramount for producing high-quality PCBs. These rules, such as trace width, spacing, and via size, dictate the electrical and physical properties of the board. Adhering to these specifications ensures signal integrity, minimizes electromagnetic interference (EMI), and enhances overall device performance. Moreover, compliance with manufacturing capabilities prevents defects, reduces production costs, and accelerates time-to-market. As the electronics industry advances, mastering these design principles is essential for innovation and maintaining competitive edge in the market.

阅读更多In the realm of printed circuit boards (PCBs), the choice of substrate material can dramatically influence the performance of the final product. Rogers RO4350B PCBs stand out for their superior high-frequency performance, making them an indispensable component in advanced electronic applications. This material is particularly pivotal in sectors such as aerospace, telecommunications, and high-speed digital circuits where reliability and efficiency are paramount. The RO4350B offers low dielectric loss, excellent impedance control, and high thermal stability, attributes that are essential for the aforementioned demanding applications.

In this blog, we will delve into what makes Rogers RO4350B such a preferred material in the PCB industry. We will explore its unique properties, compare it with other common materials like Rogers 4003c and traditional FR4, and highlight its various advantages and applications. Our discussion aims to provide a comprehensive understanding of Rogers RO4350B PCBs and their critical role in modern electronics.

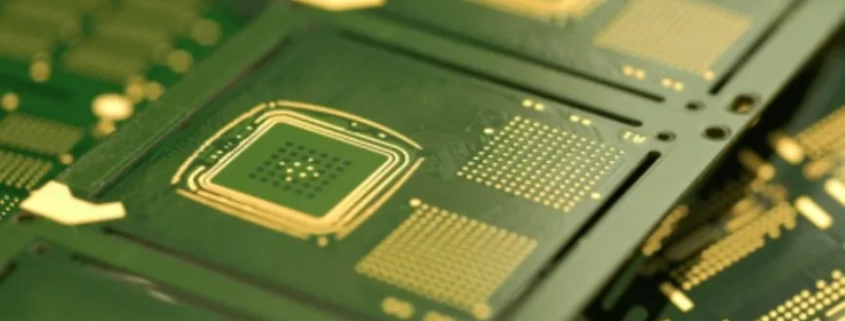

阅读更多The FCBGA (Flip Chip Ball Grid Array) technology revolutionizes electronic packaging, offering enhanced performance and reliability. It facilitates the direct connection of the chip to the package substrate, optimizing signal integrity and thermal management. The substrate serves as a foundation, providing electrical connections and mechanical support crucial for chip integration. With its intricate layout of conductive traces and insulating layers, the FCBGA substrate ensures efficient power distribution and signal transmission while mitigating issues like noise and heat dissipation. Its compact structure and high-density interconnects make it ideal for demanding applications in computing, networking, and telecommunications, where space constraints and performance demands are paramount. Understanding the intricacies of FCBGA substrate is essential for harnessing its full potential in cutting-edge electronic systems.

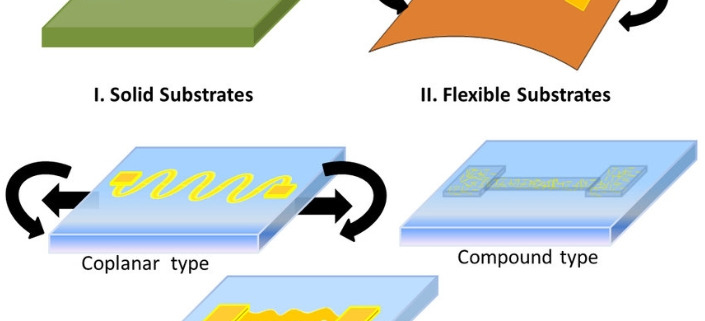

阅读更多Flexible electronics, an innovative field at the intersection of materials science and electronics, promises to revolutionize the way we interact with technology. At its core lies the concept of creating electronic devices that can bend, stretch, and conform to various surfaces. Flexible substrates, essential components of these devices, play a pivotal role in enabling their functionality. These substrates provide the necessary support and flexibility for electronic components, allowing them to maintain performance even under dynamic conditions. The significance of flexible substrates in the electronics industry cannot be overstated, as they unlock new possibilities for wearable devices, foldable displays, and biomedical sensors. As research and development in flexible electronics continue to advance, understanding the fundamentals of flexible substrates becomes increasingly crucial for realizing the full potential of this transformative technology.

阅读更多VT 901 is a specialized high-temperature engineering plastic known for its superior mechanical strength and chemical resistance. This material is particularly significant in industries where extreme conditions prevail, as it maintains stability and performance at elevated temperatures and in corrosive environments. Its resilience makes it an invaluable component in aerospace, automotive, and electronics industries, where reliability and durability under stress are crucial.

Material science plays a pivotal role in driving industrial innovation by creating substances like VT 901 that meet specific, demanding needs of modern technology. Advances in material science lead to developments that can transform entire industries, enhancing product performance and sustainability. VT 901 is a prime example of how innovative materials can lead to more efficient, reliable, and environmentally friendly technological solutions.

阅读更多In the rapidly evolving landscape of modern electronics, Advanced Cavity PCBs (Printed Circuit Boards) stand as a testament to innovation and precision engineering. These specialized boards integrate intricately designed cavities within their structure, revolutionizing thermal management, electromagnetic compatibility, and overall performance. As industries across the globe increasingly rely on intricate electronic systems, the demand for sophisticated PCBs continues to soar. From aerospace and automotive to medical devices and consumer electronics, the need for highly reliable, compact, and efficient PCB solutions has become paramount. Advanced Cavity PCBs emerge as a cornerstone technology meeting these evolving demands, offering unparalleled versatility and functionality in an ever-expanding array of applications.

阅读更多Flip Chip technology represents a significant advancement in semiconductor packaging, offering a compact and high-performance solution for various electronic devices. Its applications extend to the realm of Radio Frequency (RF) packaging, where demands for enhanced performance and miniaturization are paramount. In this context, the role of Flip Chip RF Package Substrates Manufacturer products becomes indispensable. These products serve as the backbone for efficient RF signal transmission, ensuring minimal signal loss and optimal performance. As RF devices continue to proliferate across industries such as telecommunications, automotive, and aerospace, the importance of reliable and high-quality Flip Chip RF Package Substrates becomes increasingly evident. This blog explores the critical role of these substrates in facilitating seamless RF communication and the pivotal contributions of manufacturers in driving innovation within this domain.

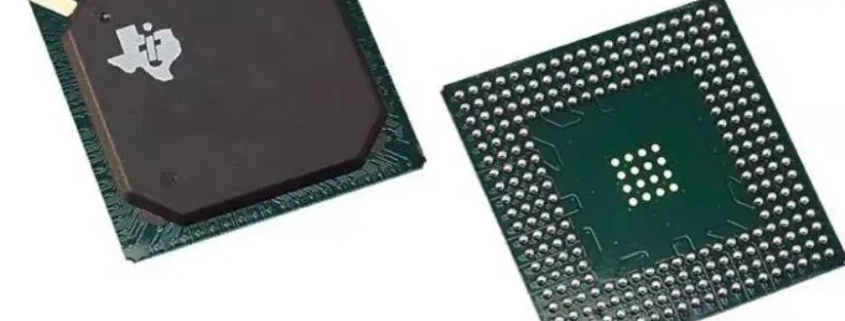

阅读更多PGA (Pin Grid Array) chip technology plays a pivotal role in the landscape of computer hardware, offering a robust foundation for various components, particularly CPUs. Its significance lies in its ability to facilitate efficient communication between the CPU and other hardware elements. PGA chips ensure reliable connectivity, enabling seamless data transmission and processing, thereby optimizing overall system performance. Beyond CPUs, PGA technology extends its reach to encompass a diverse array of hardware components, ranging from graphics cards to network adapters. Its versatility and reliability make PGA chips indispensable in modern computing systems, powering everything from personal computers to enterprise-level servers. This introduction sets the stage for a comprehensive exploration of PGA chip products, shedding light on their functionality, applications, and future prospects in the ever-evolving realm of computer hardware.

阅读更多CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午