In the realm of printed circuit boards (PCBs), the substrate serves as the foundational material on which electronic components are mounted and interconnected. Defined as the non-conductive base that supports the conductive traces and components of a PCB, the substrate plays a pivotal role in the board’s performance and reliability. It provides mechanical support, electrical insulation, and influences crucial factors such as signal integrity and thermal management. Essentially, the substrate is the backbone that dictates the PCB’s structural integrity and operational efficiency. Understanding its composition, properties, and selection criteria is paramount for designing PCBs that meet stringent performance requirements across diverse applications in electronics.

阅读更多The Insulated Metal Substrate (IMS) is a crucial component in the realm of modern electronics, known for its superior thermal management properties. Unlike traditional printed circuit boards (PCBs), IMS substrates consist of a metal base, typically aluminum or copper, a dielectric layer, and a conductive copper circuit layer. This unique structure allows for efficient heat dissipation, making IMS substrates indispensable in high-power and high-temperature applications such as LED lighting, automotive electronics, and power modules. The importance of IMS substrates extends beyond their thermal capabilities; they also offer enhanced mechanical stability and reliability, essential for demanding environments. This article aims to delve into the various aspects of IMS substrates, including their materials, manufacturing processes, key features, and real-world applications. Understanding the benefits and applications of IMS substrates is vital for engineers and designers striving to optimize performance and longevity in electronic devices.

阅读更多An Impedance Standard Substrate is a specialized material used to establish precise electrical characteristics, particularly impedance, in electronic circuits. It serves as a benchmark for accurate measurement and calibration, crucial in ensuring consistency and reliability in signal transmission and circuit performance. In the electronics industry, where signal integrity is paramount, these substrates play a vital role in verifying and validating impedance values during PCB (Printed Circuit Board) design and manufacturing. Engineers rely on them to maintain signal quality, prevent data loss, and optimize performance in high-frequency applications such as telecommunications, aerospace, and high-speed digital systems. Their application extends to research and development environments where exact impedance control is necessary for experimental setups and testing procedures, making them indispensable tools in modern electronic design and innovation.

阅读更多Introduction: Integrated Circuit (IC) Substrate PCBs play a pivotal role in modern electronics by providing a specialized foundation for semiconductor packaging. Unlike traditional PCBs, IC Substrate PCBs are engineered with materials like High Temperature Co-Fired Ceramic (HTCC) or Low Temperature Co-Fired Ceramic (LTCC) to meet stringent requirements of miniaturization, thermal management, and electrical performance crucial for ICs. Their significance lies in enhancing the reliability, performance, and functionality of integrated circuits, making them indispensable in applications ranging from telecommunications infrastructure to advanced automotive electronics and consumer devices. Understanding IC Substrate PCBs is essential for grasping how cutting-edge technologies are integrated and optimized, driving innovation in the rapidly evolving semiconductor industry.

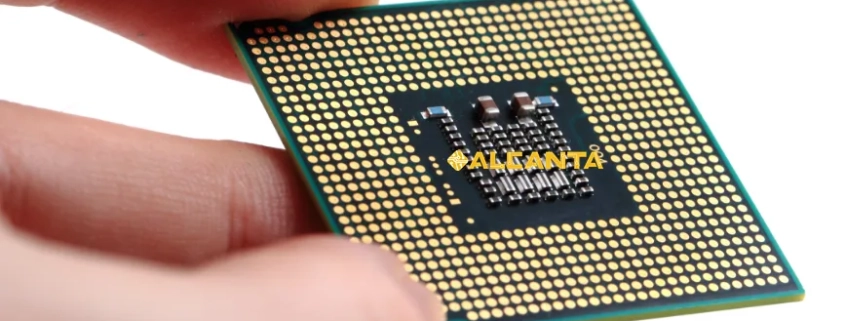

阅读更多An Integrated Circuit (IC) is a miniature electronic circuit that incorporates multiple semiconductor devices and passive components on a single semiconductor substrate, enabling complex functionality in a compact form. A Printed Circuit Board (PCB) is a rigid or flexible board that mechanically supports and electrically connects electronic components using conductive pathways etched from copper sheets laminated onto a non-conductive substrate. In contrast, an IC Substrate serves as a foundation for mounting and interconnecting IC chips, providing electrical pathways and thermal management to ensure reliable performance. The Packaging Substrate, integral to IC Substrates, facilitates the electrical and mechanical interface between the IC chip and the outer packaging, ensuring signal integrity, heat dissipation, and mechanical stability. These components are crucial in modern electronics, enabling miniaturization, high-speed signal transmission, and enhanced functionality in diverse applications.

阅读更多In electronics, a substrate refers to a fundamental material on which electronic components or circuits are fabricated or mounted. It provides a solid base that supports and interconnects various components, enabling their function within electronic devices. Substrates range from semiconductors like silicon and gallium arsenide to specialized materials such as ceramics and polymers used in printed circuit boards (PCBs).

The role of substrates in electronics is crucial, as they not only provide mechanical support but also facilitate electrical connections and thermal management. They influence the performance, reliability, and manufacturability of electronic systems, affecting everything from signal integrity to power dissipation. Understanding substrate properties and choosing the right material is essential for optimizing the functionality and longevity of electronic devices in diverse applications.

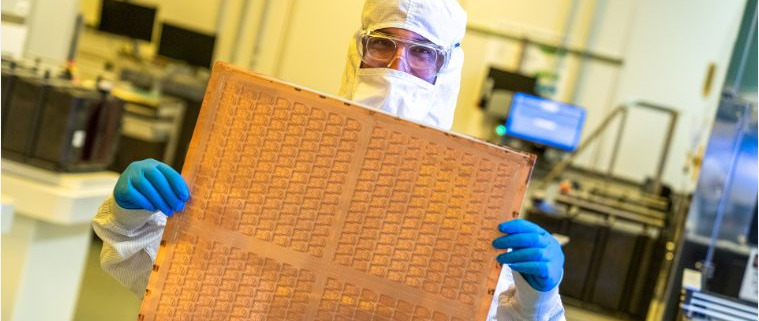

阅读更多Integrated circuits (ICs) are the fundamental building blocks of modern electronic devices, enabling the compact integration of millions to billions of electronic components on a single semiconductor substrate. Their significance in technology spans from everyday consumer electronics to complex industrial applications, driving advancements in computing, telecommunications, and beyond.

Central to the manufacturing of ICs is the role of IC substrates, which serve as the physical foundation for mounting and interconnecting semiconductor devices within the integrated circuit. These substrates not only support the delicate semiconductor components but also facilitate electrical connections, heat dissipation, and signal integrity crucial for the functionality and performance of ICs. Understanding the composition, manufacturing processes, and technological advancements in IC substrates is essential for grasping their pivotal role in advancing electronic innovations globally.

阅读更多IC Package Substrate refers to a crucial component in integrated circuit (IC) packaging, providing a physical and electrical interface between the IC chip and the PCB. Its primary role is to facilitate electrical connections, thermal management, and structural support within a compact form factor. The substrate’s significance lies in optimizing signal integrity, reducing electrical noise, enhancing thermal dissipation efficiency, and ensuring reliability under varying operating conditions. As IC technologies advance, the substrate’s role becomes increasingly vital in meeting demands for higher performance, miniaturization, and reliability in modern electronic devices. Thus, understanding and innovating in IC Package Substrate design and materials are pivotal for advancing semiconductor packaging capabilities.

阅读更多Printed Circuit Boards (PCBs) are the backbone of most electronic devices, providing the necessary platform to connect and support electronic components. PCBs are composed of multiple layers of copper and insulating material laminated together. They offer a compact and efficient way to route electrical signals and power throughout a device, making them indispensable in the manufacture of everything from household electronics to advanced industrial machinery.

In recent years, a new advancement known as Substrate Like PCB (SLP) has emerged, gaining significant traction in modern electronic design. SLPs are an evolution of traditional PCBs, designed to meet the increasing demands for higher density and performance. They utilize advanced materials and manufacturing techniques to create finer circuit patterns, allowing for more compact and efficient designs. This innovation is particularly crucial for the latest generation of consumer electronics, such as smartphones and wearable devices, where space and performance are at a premium. The growing significance of SLP in the industry highlights its potential to push the boundaries of what is possible in electronic design.

阅读更多HTCC (High Temperature Co-Fired Ceramic) substrates are crucial components in the electronics industry due to their exceptional thermal stability, high mechanical strength, and excellent electrical properties. These substrates are designed to withstand high operating temperatures, making them ideal for applications in harsh environments. HTCC substrates are widely used in various high-performance electronic devices, including power modules, sensors, and RF components. Their ability to maintain functionality in extreme conditions ensures reliability and longevity in demanding applications.

The primary purpose of HTCC substrates in modern electronics is to provide a robust and reliable platform for advanced circuitry. As the demand for miniaturization and increased functionality in electronic devices grows, HTCC substrates offer a solution by enabling the integration of complex circuits in a compact form factor. Their superior thermal management capabilities also contribute to the efficient operation of high-power devices, making HTCC substrates indispensable in the development of cutting-edge technologies.

阅读更多CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午