In the world of electronics, substrates play a crucial role as the foundational material that supports and connects various components on a circuit board. They provide the necessary mechanical stability and electrical insulation, ensuring reliable performance and durability of electronic devices. Among the diverse substrate options, metalized ceramic substrates stand out for their exceptional thermal conductivity and electrical performance. These substrates are designed to enhance heat dissipation and signal integrity, making them ideal for high-performance and high-frequency applications. This blog will delve into the characteristics and advantages of metalized ceramic substrates, exploring their unique benefits and applications compared to other substrate types.

阅读更多Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the crucial support and connections for electronic components. They ensure electrical signals are routed accurately and reliably between different parts of a device. Traditional PCBs are typically made from materials like FR4, which offer good insulation and mechanical support.

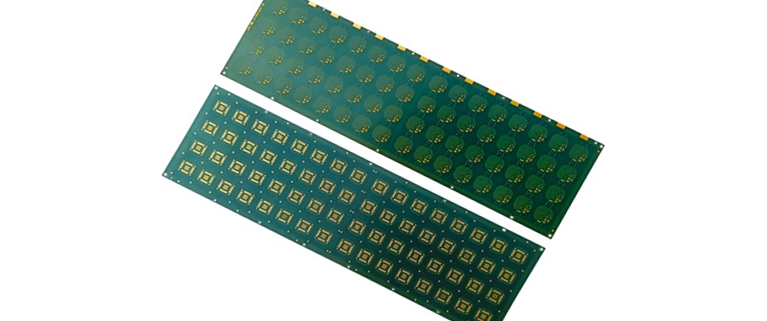

However, as technology advances, there is an increasing demand for PCBs that can handle higher power densities and thermal loads. This is where Metal Core PCBs (MCPCBs) come into play. MCPCBs incorporate a metal core—often aluminum or copper—beneath the dielectric layer to improve heat dissipation and enhance performance. These specialized PCBs are essential in high-power applications such as LED lighting, automotive electronics, and communication equipment, where efficient thermal management is crucial for reliability and longevity.

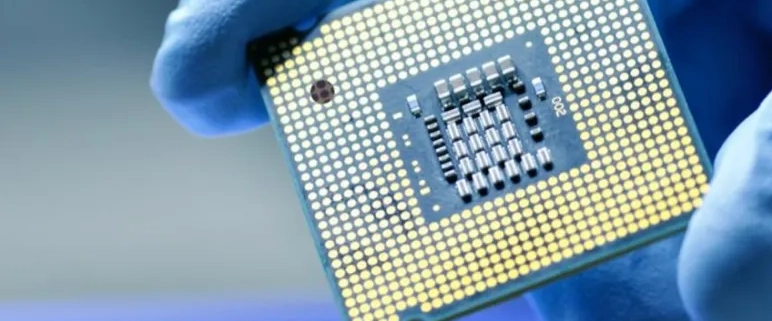

阅读更多In the realm of semiconductor technology, substrates play a pivotal role as foundational materials that support and enhance electronic devices. Defined as the underlying material upon which semiconductor components are built, substrates facilitate crucial functions such as heat dissipation, electrical conduction, and structural integrity within integrated circuits (ICs). Beyond semiconductors, substrates find diverse applications in fields ranging from telecommunications to renewable energy technologies, where their role in providing stable platforms for advanced materials and devices remains indispensable. Understanding the properties and fabrication processes of substrates is not only vital for optimizing semiconductor performance but also for advancing innovations across various technological frontiers, underscoring their broad and profound impact across industries.

阅读更多Substrate packaging is essential in electronics, facilitating the assembly and connection of components on a base material. It ensures mechanical support, electrical pathways, and heat dissipation crucial for integrated circuits (ICs) and electronic devices. Materials like silicon, ceramics, and organic compounds are used based on specific needs. This process is pivotal for enhancing device performance, reliability, and miniaturization in various sectors such as consumer electronics, telecommunications, and automotive industries. As technology advances, substrate packaging evolves to meet demands for smaller, more efficient devices with increased functionality. Its role in semiconductor manufacturing underscores its critical contribution to shaping the future of electronic products across global markets.

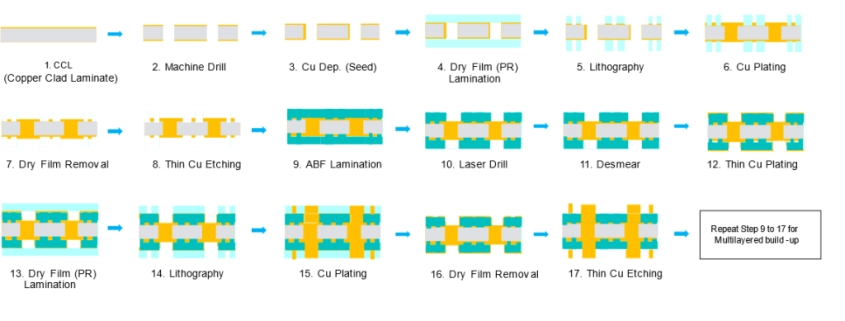

阅读更多In semiconductor manufacturing, a substrate refers to the base material upon which integrated circuits (ICs) are built. It serves as the foundation that supports and interconnects electronic components within the IC. The choice of substrate material significantly impacts the performance, reliability, and manufacturability of ICs. Substrates provide essential functions such as thermal dissipation, electrical insulation, and mechanical support, crucial for maintaining the integrity and longevity of electronic devices. Understanding substrate materials and their manufacturing processes is vital for optimizing IC performance and enabling advancements in semiconductor technology. This blog explores the intricate process flows involved in substrate manufacturing, along with comparisons between different bonding techniques and materials used in semiconductor packaging.

阅读更多Brief Overview: Multi-Chip Modules (MCM) are advanced packaging solutions that integrate multiple integrated circuits (ICs) into a single module. This integration enhances functionality and performance while minimizing the overall size of electronic systems. MCMs are crucial in modern electronics due to their ability to offer high-density interconnections and efficient thermal management, which are essential for sophisticated devices like smartphones, computers, and telecommunications equipment. By consolidating multiple ICs, MCMs also contribute to improved reliability and reduced manufacturing costs.

Objective: This blog aims to provide a comprehensive understanding of MCM substrates. We will delve into what MCM substrates are, their key functions, and their diverse applications. This exploration will highlight the critical role MCM substrates play in advancing electronic technology and their benefits in various high-performance electronic systems.

阅读更多Low Temperature Co-Fired Ceramic (LTCC) technology is a advanced method for creating high-performance electronic substrates by co-firing ceramic and metal layers at relatively low temperatures. This technology is notable for its ability to integrate multiple layers of electronic circuits into a compact and reliable substrate, making it essential for modern electronics.

LTCC technology is significant due to its versatility and high performance. It supports the integration of complex circuitry and components, enabling miniaturization and high-density packaging. This is particularly valuable in applications requiring high-frequency and high-speed signal processing, such as in wireless communication, automotive electronics, and consumer devices. By offering excellent thermal and electrical properties, LTCC substrates enhance the reliability and efficiency of electronic devices, contributing to advancements in technology and performance across various industries.

阅读更多In the intricate world of semiconductor manufacturing, substrate materials play a pivotal role in ensuring the reliability, performance, and longevity of electronic devices. These materials form the foundation upon which semiconductor components are built, providing structural support, electrical connectivity, and thermal management. Substrates are not merely passive carriers; they are integral to the functionality and miniaturization of modern semiconductor devices, facilitating the integration of complex circuits and enabling the compact designs demanded by today’s technology. Understanding the diverse properties and applications of substrate materials is crucial for optimizing semiconductor packaging processes, enhancing device performance, and meeting the evolving demands of industries ranging from consumer electronics to aerospace. This article explores the key considerations and advancements in substrate materials essential for the next generation of semiconductor technologies.

阅读更多In the realm of electronics, a substrate serves as the fundamental foundation upon which electronic components are mounted or fabricated. Essentially, it is the underlying material that supports and connects various components within electronic devices, ranging from semiconductors to printed circuit boards (PCBs). The significance of substrates cannot be overstated; they provide structural integrity, electrical insulation, and thermal management crucial for device performance and reliability. Whether it’s in optimizing signal transmission paths in high-frequency circuits or enhancing the heat dissipation capabilities in power electronics, choosing the right substrate material and design is pivotal. Understanding the role of substrates across different electronic applications illuminates their multifaceted importance in shaping the efficiency, durability, and functionality of modern electronic systems.

阅读更多LED technology has revolutionized the lighting and display industries with its energy efficiency, longevity, and vibrant color output. Initially developed in the early 1960s, LEDs have evolved from simple indicators to sophisticated lighting solutions used in everything from home illumination to high-definition displays and architectural lighting. This advancement is largely due to ongoing innovations in LED materials and designs.

A critical component in LED technology is the substrate material, which serves as the foundation for the LED chip. Substrate materials significantly impact the thermal management, electrical performance, and overall efficiency of LEDs. High-quality substrates ensure effective heat dissipation, stable electrical performance, and prolonged lifespan, directly influencing the brightness and reliability of the LED. Therefore, selecting the appropriate substrate material is essential for optimizing LED performance and ensuring its successful application across various industries.

阅读更多CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午