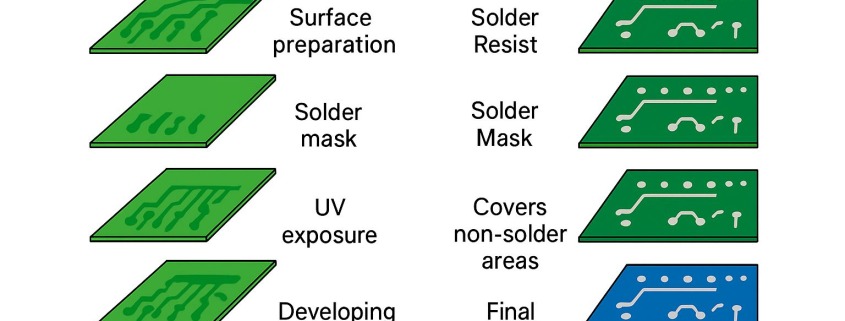

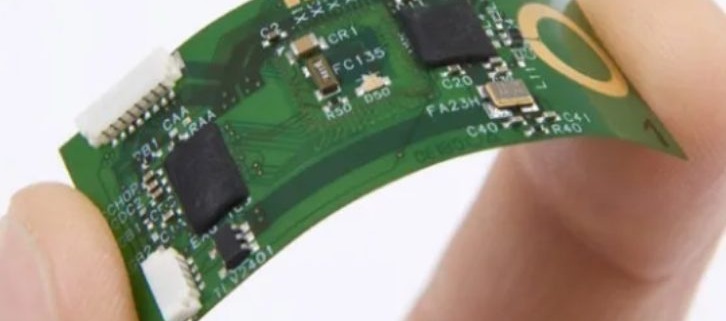

If you’ve ever taken a close look at a printed circuit board (PCB), you’ve probably noticed the smooth, colored coating covering most of the copper traces. That layer is called the solder mask (also known as solder resist), and it’s one of the unsung heroes of PCB manufacturing.

Without solder mask, PCBs would be far more vulnerable to short circuits, corrosion, and handling damage. It’s not just cosmetic — the solder mask plays a critical role in ensuring long-term reliability, high manufacturing yields, and stable electrical performance.

Before we dive in, let’s clear one point: the “mask” we’re discussing here is part of the PCB itself, not the respirator mask you might wear for safety when soldering. 阅读更多