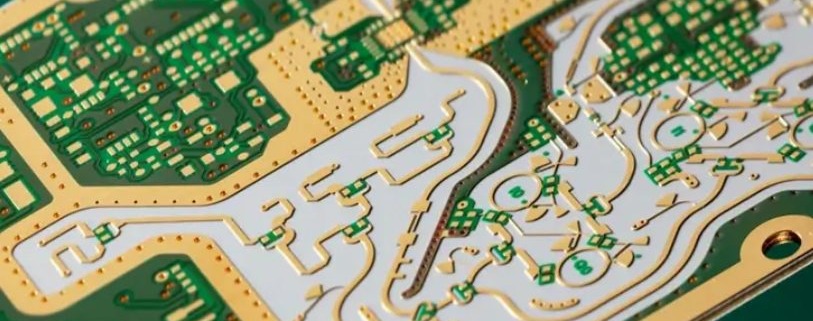

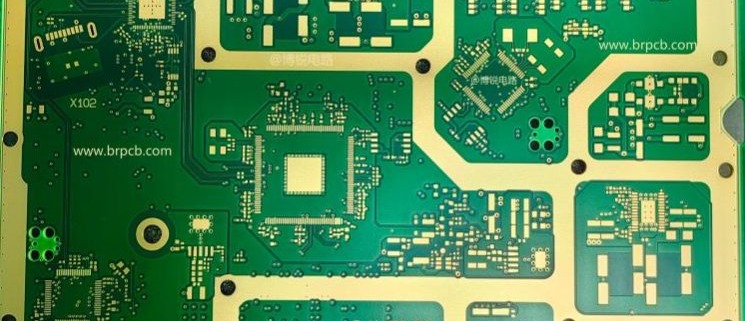

Rogers PCBs are essential components in modern electronic devices, widely recognized for their superior performance in high-frequency and high-speed applications. These materials are particularly valued in industries such as telecommunications, aerospace, and medical devices, where reliable signal integrity and thermal management are critical. The dielectric constant is a key parameter that defines how a material interacts with electric fields, influencing signal propagation speed and attenuation. In PCB design, understanding the rogers pcb dielectric constant is crucial, as it directly affects the overall performance of the circuit. A lower dielectric constant typically leads to higher signal speeds, making Rogers materials ideal for advanced applications. As engineers increasingly demand high-performance solutions, the significance of dielectric constant in Rogers PCBs cannot be overstated, making it a vital consideration in the design and selection process.

阅读更多Rogers PCB laminates play a crucial role in the electronics industry, especially in applications that require high-performance and reliability. These laminates are designed to deliver excellent electrical properties, thermal stability, and minimal signal loss, making them ideal for high-frequency circuits used in telecommunications, aerospace, and medical devices. As the demand for advanced electronic systems continues to grow, the importance of Rogers PCB laminates becomes increasingly evident, as they support the development of innovative technologies.

Rogers Corporation, a leader in the PCB materials field, has established a strong reputation for manufacturing high-quality laminates that meet the evolving needs of engineers and designers. With a commitment to research and development, Rogers consistently advances its product offerings, ensuring that their laminates remain at the forefront of technology. By providing solutions that enhance performance and reliability, Rogers Corporation plays a pivotal role in shaping the future of electronic devices through its superior rogers pcb laminates.

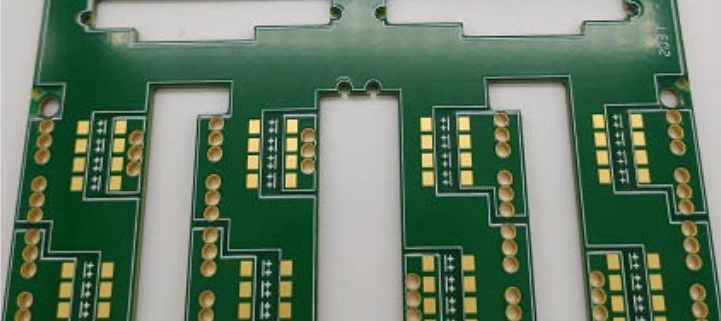

阅读更多Printed Circuit Boards (PCBs) are essential components in modern electronic devices, serving to connect and support electronic components while ensuring effective transmission of signals and power. The design and material selection of PCBs directly impact the performance, reliability, and manufacturing costs of devices, making the choice of suitable PCB materials crucial.

FR4 is a commonly used material in PCB manufacturing, prized for its superior mechanical strength and electrical insulation properties. Its characteristics make it an ideal choice for both high-frequency and low-frequency electronic applications. Understanding “what is FR4 PCB” helps designers and engineers make informed material choices, ensuring their products remain competitive in an ever-evolving technological landscape. As electronic technology advances, the applications of FR4 continue to expand, further driving the growth of the PCB industry.

阅读更多Printed Circuit Boards (PCBs) are essential components in modern electronics, serving as the backbone for connecting various electronic elements in devices ranging from smartphones to industrial machinery. Their design and material selection play a crucial role in determining the performance, reliability, and overall functionality of electronic products. Among the various materials used in PCB manufacturing, Rogers and FR-4 have emerged as significant options. Rogers materials, known for their high-frequency performance and low-loss characteristics, are ideal for applications requiring precision and signal integrity, such as telecommunications and aerospace. In contrast, FR-4 is a widely used, cost-effective laminate that provides excellent electrical insulation and mechanical strength, making it suitable for a broad range of general electronics. This article will delve into the features and applications of both Rogers and FR-4 materials, focusing on the advantages of utilizing a rogers fr4 pcb configuration in advanced electronic designs.

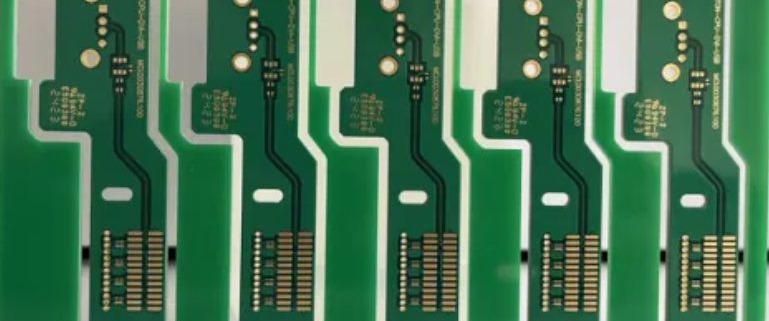

阅读更多Printed Circuit Boards (PCBs) are essential components in modern electronics, providing the backbone for electrical connections in devices ranging from smartphones to industrial machinery. Among the various materials used for PCBs, FR-4 and Rogers stand out due to their unique properties. FR-4 is a widely-used fiberglass material known for its cost-effectiveness and versatility in general applications. In contrast, Rogers materials, such as RO4350, offer superior performance for high-frequency applications, making them ideal for advanced technology needs. This article will delve into the concept of mixed FR-4 + Rogers PCB, exploring how combining these materials can optimize performance and reduce costs. We will discuss the individual characteristics of FR-4 and Rogers, compare their benefits, and highlight real-world applications where this hybrid approach excels. By understanding the strengths of both materials, designers can make informed decisions for their PCB projects.

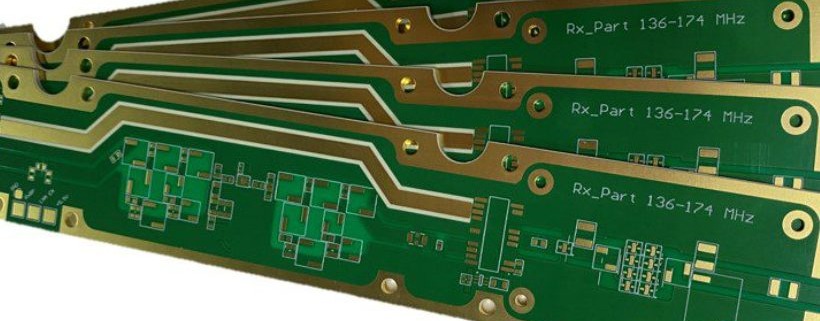

阅读更多Rogers PCB is renowned for its exceptional performance in high-frequency and high-reliability applications, making it a crucial component in the electronics industry. These printed circuit boards utilize advanced materials that enable superior electrical performance, thermal management, and mechanical stability. As the demand for sophisticated electronic devices continues to grow, Rogers PCB materials have become essential for applications in telecommunications, automotive, and aerospace sectors.

Rogers Corporation, founded in 1832, has established itself as a leader in high-frequency circuit materials and innovative solutions. With a commitment to quality and technological advancement, the company specializes in developing cutting-edge materials, including the highly sought-after Rogers PCB laminate. This laminate is designed to meet the stringent demands of modern electronics, ensuring reliability and performance in even the most challenging environments.

阅读更多Rogers PCB materials are renowned for their exceptional performance in high-frequency applications, making them a top choice for engineers and designers in various industries. These materials, including popular variants like Rogers 4003 and Rogers 4350B, are specifically engineered to minimize signal loss and enhance thermal stability, crucial for modern electronic devices. Understanding the properties of these materials is vital for optimizing circuit designs, particularly in telecommunications, aerospace, and medical applications.

One of the key characteristics of Rogers PCB materials is their dielectric constant, which significantly influences signal integrity and performance. The dielectric constant measures a material’s ability to store electrical energy in an electric field, impacting the speed at which signals propagate through the PCB. Therefore, comprehending the rogers pcb material dielectric constant is essential for designers aiming to achieve reliable and efficient circuit performance in high-frequency environments.

阅读更多Rogers PCB materials are crucial in advanced electronic applications, especially in high-frequency and microwave circuits. Known for their exceptional dielectric properties and thermal stability, these materials ensure optimal performance in demanding environments. Rogers Corporation, a leader in the PCB material industry, has been at the forefront of developing innovative laminate solutions for over 180 years. Their commitment to quality and performance has established them as a trusted name among engineers and manufacturers. The extensive range of products, including the well-regarded Rogers PCB material datasheet, provides valuable information on specifications and applications, enabling designers to select the most suitable materials for their projects. As the demand for high-performance electronics grows, Rogers Corporation continues to set the standard for reliability and excellence in PCB materials, reinforcing its position as a key player in the market.

阅读更多Rogers Corporation is a leader in high-frequency material technology, providing advanced solutions that meet the needs of industries requiring exceptional electrical performance, such as telecommunications, automotive, and aerospace. Known for its high-performance materials like RO4003C and RO4350B, Rogers products enable engineers to achieve consistent signal integrity in challenging high-frequency environments.

For PCB designers, tools like the Rogers PCB Calculator play a crucial role. These calculators simplify complex impedance and layer stack calculations, allowing designers to efficiently evaluate materials and predict circuit behavior. The Rogers PCB Calculator aids in fine-tuning essential properties, such as dielectric constant and impedance, which are fundamental to achieving optimal signal performance in PCB designs. Choosing Rogers PCB materials and leveraging these calculation tools can save design time, reduce costs, and significantly enhance the quality and reliability of high-frequency circuits.

阅读更多Rogers Corporation is a leading global provider of innovative materials and solutions, recognized for its expertise in high-frequency printed circuit boards (PCBs) and advanced electronic materials. With a strong emphasis on research and development, Rogers has established itself as a key player in industries such as telecommunications, automotive, and aerospace. The company’s commitment to quality and innovation has positioned it as a trusted partner for businesses seeking reliable and high-performance materials. This article aims to delve into Rogers products, showcasing their diverse applications and highlighting the significance of these materials in modern technology. By exploring the various offerings from Rogers, readers will gain insights into how these products are integral to advancements in electronics and beyond.

阅读更多CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午