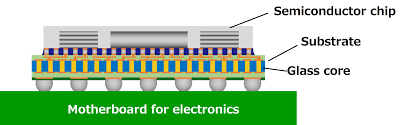

Ceramic substrates have become indispensable in modern technology, serving as a foundation for high-power electronics, RF applications, LEDs, and other high-performance devices. Their unique properties, such as high thermal conductivity, excellent electrical insulation, and mechanical strength, make them a preferred choice in demanding environments. However, how to choose a ceramic substrate that perfectly matches specific application requirements remains a critical decision for engineers and manufacturers.

Selecting the right ceramic substrate is essential for optimizing device performance, ensuring reliability, and extending product lifespan. A poorly chosen substrate could lead to overheating, inefficiencies, or even device failure in critical systems.

This blog will explore the key considerations in how to choose a ceramic substrate, including material properties, application demands, and cost factors. By understanding these aspects, you can make informed decisions and achieve the best performance for your projects.