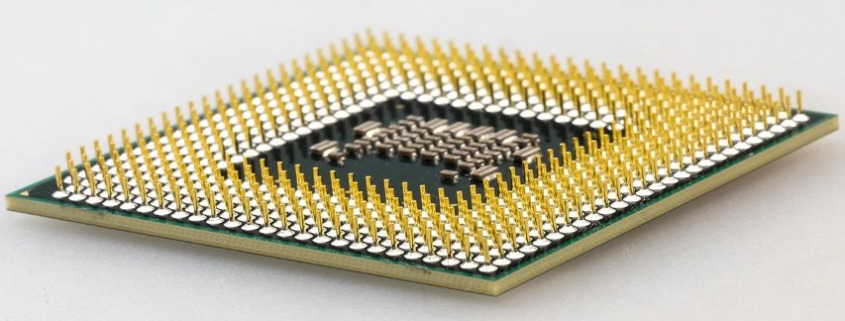

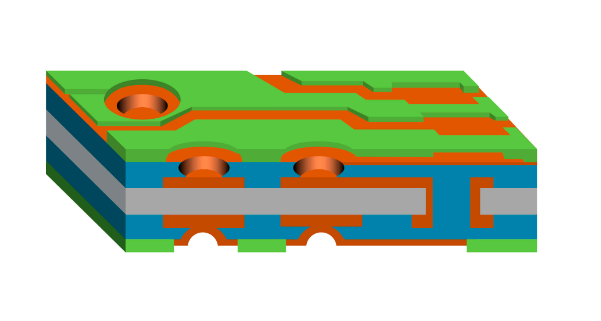

An IC substrate is a crucial material that supports and connects the components of an integrated circuit (IC), ensuring proper electrical connectivity and efficient heat dissipation. Its role is vital in determining the performance, reliability, and durability of an IC. Without a high-quality substrate, an IC would face challenges such as poor thermal management and signal integrity issues. The process of how IC substrates are made involves selecting materials like ceramics, metals, and organic laminates, followed by a multi-step manufacturing procedure that includes material preparation, lamination, etching, and testing. These steps are designed to create a substrate that can support the IC while meeting strict electrical and mechanical requirements. Ultimately, the quality of the substrate plays a significant role in enhancing the overall performance and longevity of the integrated circuit in various applications.

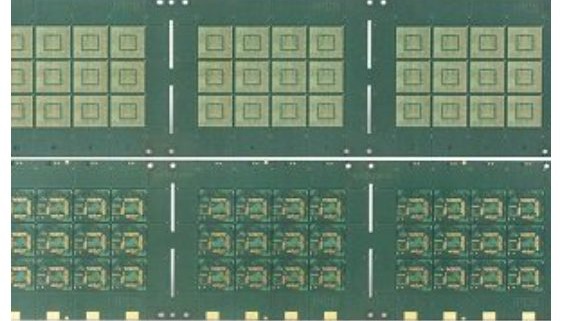

IC substrates, or integrated circuit substrates, are vital components in the semiconductor industry, providing mechanical support, electrical connections, and thermal management for integrated circuits (ICs) in electronic devices. These substrates play a crucial role in integrated circuit packaging by ensuring the secure mounting of IC chips and facilitating their seamless interaction with other electronic components. China plays a significant role in the global IC substrate market, driven by its robust manufacturing capabilities and increasing expertise. As the demand for advanced electronics continues to grow, China’s manufacturers, such as EFPCB and RayPCB, have become key contributors to the global supply of China IC substrates, supporting industries ranging from consumer electronics to telecommunications and automotive. Their contributions are vital in meeting the growing global need for high-quality IC substrates.

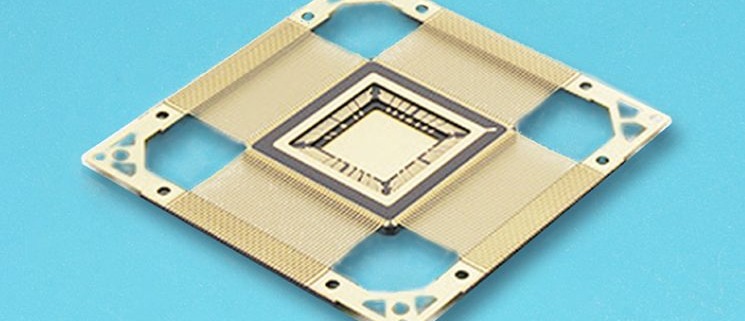

The BGA IC substrate plays a pivotal role in modern electronics, serving as a critical component for connecting semiconductor chips to PCBs while ensuring signal integrity and thermal management. BGA, short for Ball Grid Array, is a widely used IC packaging technology that leverages an array of solder balls for efficient electrical and mechanical connections. The BGA IC substrate provides a foundation for this packaging, supporting compact, high-density designs essential for advanced applications.

In today’s semiconductor industry, the demand for advanced IC packaging is rapidly growing, driven by technologies such as 5G, AI, and IoT. These innovations require packaging solutions like FC BGA (Flip-Chip Ball Grid Array) that can handle higher frequencies, better thermal dissipation, and reduced signal interference.

By bridging the gap between chips and circuit boards, BGA IC substrates are indispensable for ensuring the reliability and performance of cutting-edge devices in consumer electronics, data centers, and mobile technologies.

IC substrates play a vital role in the semiconductor industry, acting as the foundation that connects semiconductor chips to the system, ensuring electrical interconnection, signal integrity, and thermal management. With the rapid advancement of semiconductor technologies, the demand for high-performance, reliable, and compact IC substrates has grown significantly. ASE Group, a global leader in semiconductor manufacturing services, stands out for its unique contributions to the IC substrate domain. Known for its innovation and expertise, ASE provides cutting-edge solutions in IC substrate design and production. The company’s advanced capabilities in manufacturing ASE IC substrates have made it a key player in enabling high-density packaging and high-speed communication, which are critical for the success of modern electronic applications. ASE’s commitment to delivering state-of-the-art IC substrates has solidified its position as an industry leader in semiconductor packaging.

The IC substrate is the physical foundation that supports and interconnects the integrated circuit (IC) chip, playing a crucial role in the overall performance of electronic devices. It serves as the platform upon which the IC is mounted, enabling it to function effectively in complex systems. In addition to providing mechanical support, the IC substrate also ensures proper thermal dissipation, preventing the IC from overheating during operation. This is essential for maintaining the reliability and longevity of the device. Furthermore, the IC substrate facilitates electrical connections between the IC chip and the external components of the system, allowing the IC to transmit signals and power efficiently. In summary, the IC substrate is a vital component in modern electronics, enabling the IC to perform its tasks while ensuring the overall stability and performance of electronic devices. Understanding what is IC substrate and its critical functions can help us appreciate the intricate design behind today’s advanced technology.

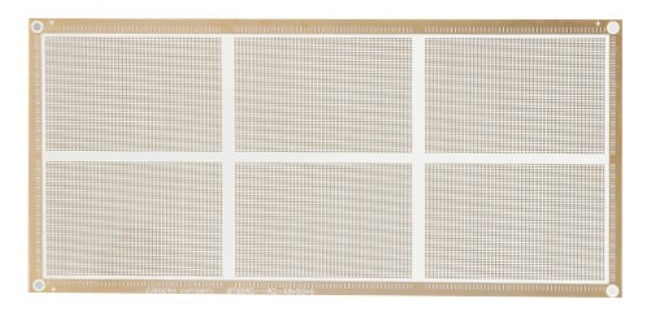

IC substrates are essential components in the semiconductor industry, providing a crucial foundation for integrated circuits (ICs). These substrates serve as the base material on which the microelectronic components of an IC are built. The primary function of IC substrates is to offer mechanical support, ensuring the stability and integrity of the integrated circuit, while also facilitating electrical connections between the various components. In addition to providing structural support, IC substrates play a vital role in heat dissipation, helping to manage the thermal output generated by the IC. As the demand for more advanced, high-performance semiconductor devices grows, the complexity of the IC substrate manufacturing process continues to evolve. With new materials and technologies being introduced, the IC substrate manufacturing process must meet stringent requirements to ensure reliability, performance, and miniaturization of modern ICs. This article will explore the critical steps and challenges involved in the IC substrate manufacturing process.

An IC substrate is a crucial component in integrated circuit packaging, providing both physical support and electrical connections for semiconductor chips. It serves as the base material that connects the microelectronic components within an IC, ensuring the proper functioning of the device. The primary function of an IC substrate is to support the chip physically while facilitating electrical communication between the chip and the external environment, such as the motherboard or other devices. These substrates are typically made from high-performance materials like ceramics or organic compounds, depending on the specific requirements of the IC. IC substrate manufacturers play a vital role in ensuring the reliability, performance, and durability of the ICs, as they provide the foundation on which these chips are built. The quality of the substrate directly impacts the efficiency and effectiveness of the integrated circuits, making it a critical aspect of modern electronics.

Ceramic substrate electronics play a pivotal role in modern technology, offering unmatched performance for various high-demand applications. Ceramic substrates are highly valued in electronics due to their unique properties, including exceptional thermal conductivity, excellent electrical insulation, and superior mechanical strength. These attributes make them indispensable for high-performance devices that require efficient heat dissipation and reliable operation under extreme conditions.

In power electronics, ceramic substrates are extensively used in applications like IGBT modules, inverters, and other high-power components, where their ability to handle high voltages and temperatures is critical. Additionally, their robustness and reliability make them a preferred choice for advanced technologies in automotive, aerospace, and communication industries.

This article aims to provide a comprehensive exploration of ceramic substrate electronics by delving into their types, applications, manufacturing processes, and future trends. By understanding these aspects, readers can gain deeper insights into the innovation and potential of ceramic substrates in advancing electronic technologies.

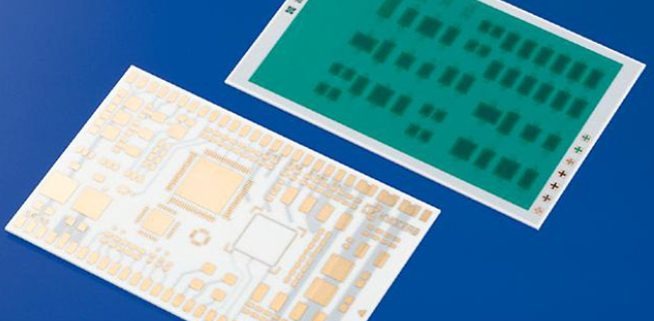

Substrates play a vital role in the electronics industry as they serve as the foundation for mounting and interconnecting electronic components. Among various types of substrates, ceramic substrate vs BT stand out due to their distinct properties and applications. Ceramic substrates, known for their high thermal conductivity, mechanical strength, and excellent heat resistance, are widely used in high-power applications like LED modules and power electronics. On the other hand, BT substrates, made from Bismaleimide-Triazine resin, are valued for their low dielectric constant, superior mechanical properties, and compatibility with advanced semiconductor packaging technologies, such as BGA and CSP.

This blog focuses on a detailed comparison of ceramic substrate vs BT, aiming to assist engineers and decision-makers in selecting the most suitable substrate material for their specific needs. Understanding the differences will enable professionals to optimize performance, reliability, and cost-effectiveness in their electronic designs.

High-Temperature Co-Fired HTCC Ceramic substrates are advanced materials widely used in the electronics and power device industries. These substrates are manufactured through a high-temperature sintering process that ensures exceptional durability and performance. Known for their excellent thermal stability, electrical insulation properties, and resistance to extreme temperatures, HTCC ceramic substrates have become indispensable in modern electronic technologies. Their ability to support complex multilayer circuit designs while maintaining reliability makes them ideal for high-power applications, such as LED packaging, RF modules, and power electronics.

In addition to their inherent advantages, HTCC ceramic substrates are often compared with Low-Temperature Co-Fired Ceramic (LTCC) substrates. This blog will provide a comprehensive overview of HTCC ceramic substrates, delving into their unique manufacturing process, key features, and differences from LTCC. Furthermore, we will highlight their significant applications across various industries and discuss their role in shaping future electronic advancements.

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午