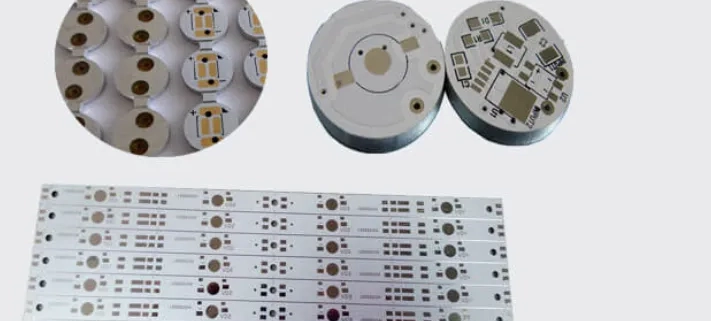

A copper core PCB is a type of metal core PCB where a thick copper plate is used as the central substrate layer. Unlike standard FR4 boards, copper provides excellent heat dissipation, mechanical stability, and higher current carrying capacity. This makes copper core PCBs ideal for high-power electronics, LED modules, RF amplifiers, and automotive systems where thermal management is critical.

A microwave PCB is a specialized high-frequency circuit board used for RF and microwave applications. Leading microwave PCB manufacturers design these boards with low-loss materials and precise impedance control, ensuring stable performance in 5G, radar, aerospace, and satellite communications. 阅读更多

Flexible printed circuit boards (Flex PCBs or FPCs) are essential components in modern electronics, offering compact size, lightweight design, and exceptional flexibility. Unlike rigid PCBs, FPCs can bend, fold, and twist to fit into complex device geometries, making them ideal for smartphones, wearable devices, medical equipment, and automotive electronics. Rigid-flex PCBs combine both rigid and flexible sections, enabling high-density connections where space is limited.

Flex PCBs provide design freedom but require precise manufacturing techniques to ensure reliability and durability. Understanding the materials, process flow, and limitations is key to designing and producing high-quality flexible circuits.

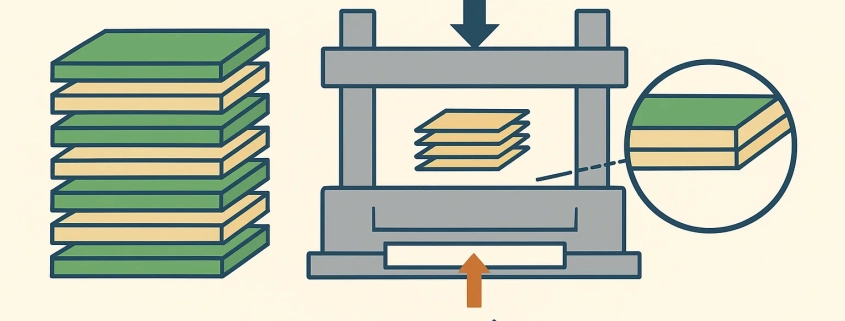

Modern electronics rely on multilayer PCBs (Printed Circuit Boards) to achieve compact size, high performance, and complex interconnections. One of the most critical steps in building multilayer boards is PCB lamination—a process of bonding layers of copper foil and dielectric materials together under heat and pressure. While “lamination” in general refers to applying a protective layer on surfaces, PCB lamination is a far more advanced technique essential for electronic manufacturing.

Printed circuit boards (PCBs) are the backbone of modern electronics, powering everything from smartphones and computers to industrial machinery. But even the most carefully designed PCB can fail due to faulty components, poor solder joints, or damaged traces. That’s why PCB testing is critical—not just in manufacturing, but also during troubleshooting and repair.

In this article, we’ll walk through how to test a PCB with a multimeter, explore different PCB testing methods, highlight testing equipment and software, and explain how to identify faulty PCBs. Whether you’re a hobbyist repairing a circuit board or a professional engineer working on quality control, this guide will help you approach PCB testing systematically. 阅读更多

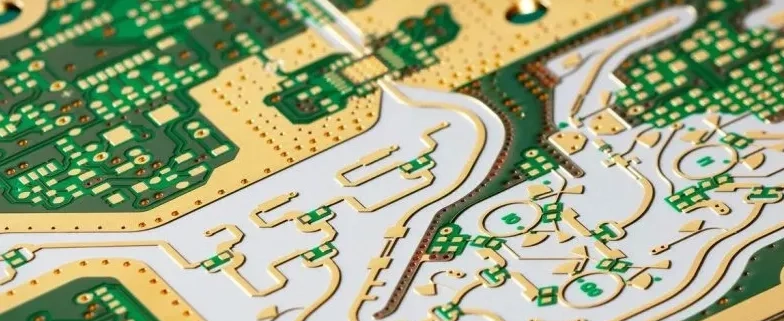

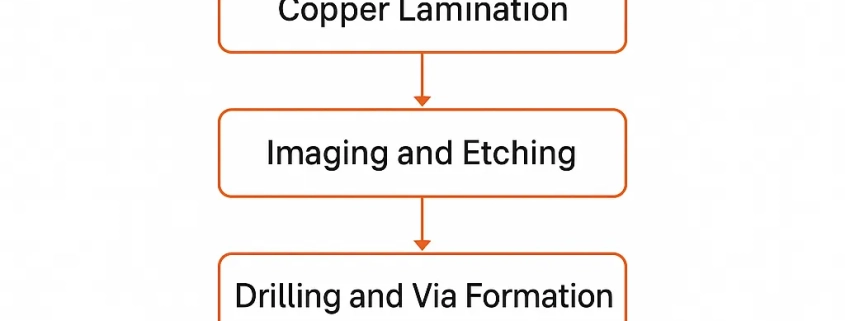

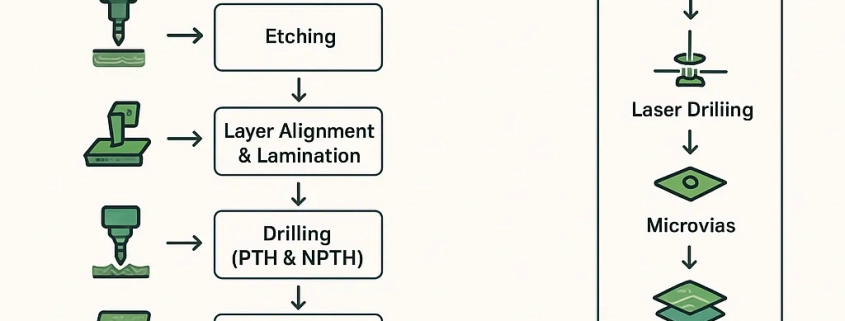

Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the foundation for electrical connections between components. Understanding the PCB manufacturing process is essential for designers, engineers, and manufacturers who aim to ensure reliability, performance, and cost-effectiveness in electronic products.

Plated Through Hole (PTH) PCB technology ensures reliable electrical connections and mechanical strength in circuit boards. Unlike NPTH, PTH holes are copper-plated to connect layers and support components. Designers must optimize hole size, annular ring, and thermal performance while distinguishing PTH from vias, which primarily handle interlayer routing—from PTH resistors and connectors to the complete PCB manufacturing process.

In modern electronics manufacturing, PCBs have become denser, more complex, and packed with components that are nearly impossible to inspect visually. Traditional optical inspection methods can reveal surface defects, but they fall short when it comes to hidden solder joints, multilayer structures, or internal cracks. This is where PCB X-ray inspection steps in—offering an unparalleled look inside the board without physically damaging it.

From automated X-ray inspection (AXI) systems in high-volume SMT lines to compact desktop units for prototyping labs, the technology has become essential for ensuring product reliability in industries like automotive, aerospace, consumer electronics, and medical devices.

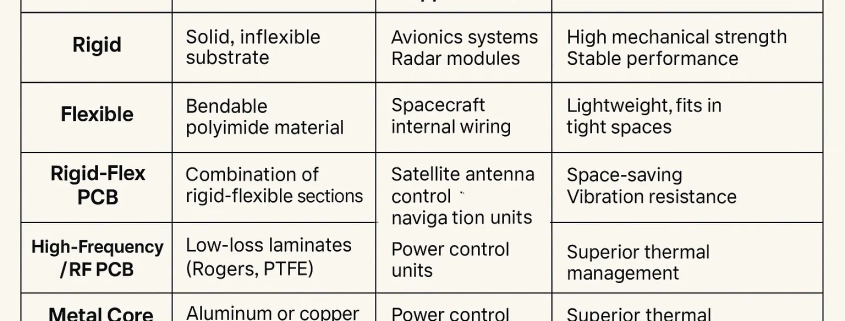

Aerospace PCBs are specialized printed circuit boards designed for the demanding requirements of aviation, space exploration, and defense applications. Unlike standard commercial PCBs, aerospace-grade boards must operate flawlessly in extreme environmental conditions, withstand high mechanical stress, and meet stringent quality and safety certifications.

From avionics systems in passenger aircraft to communication modules in satellites, these PCBs form the backbone of modern aerospace technology. 阅读更多

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午