advantages of ceramic substrate

Ceramic substrates have gained significant attention in the electronics industry due to their exceptional properties and versatility. Composed of inorganic materials, these substrates play a crucial role in various electronic applications, particularly in high-performance and high-reliability devices. The advantages of ceramic substrate over traditional materials, such as FR-4 and metals, are numerous. They offer superior thermal stability, ensuring consistent performance even in extreme environments. Additionally, ceramic substrates provide excellent electrical insulation, which minimizes signal loss and enhances overall circuit efficiency. Their mechanical strength and durability make them ideal for demanding applications, including aerospace and automotive industries. As the demand for advanced electronic components continues to grow, understanding the advantages of ceramic substrate becomes essential for engineers and designers aiming to innovate and improve their products.

Key Advantages of Ceramic Substrates

Thermal Stability

One of the most notable advantages of ceramic substrates is their exceptional thermal stability. These materials can withstand high temperatures without degrading, making them suitable for applications in extreme environments, such as power electronics and aerospace components. Ceramic substrates typically exhibit a thermal expansion coefficient that closely matches that of silicon, minimizing the risk of thermal stress during operation. This high-temperature resistance ensures reliable performance and longevity, allowing devices to operate efficiently even in conditions where traditional materials would fail. As a result, ceramic substrates are increasingly utilized in applications where heat management is critical, helping to maintain optimal functioning of electronic circuits.

Electrical Insulation

Ceramic substrates also excel in providing excellent electrical insulation. With their high dielectric strength, these materials effectively minimize signal loss and interference, which is essential for maintaining the integrity of electronic signals. This property is particularly advantageous in high-frequency applications, where even minor losses can lead to significant performance degradation. The low electrical conductivity of ceramic substrates ensures that they can separate conductive paths without compromising performance. Consequently, designers can achieve better circuit performance, enhanced reliability, and improved energy efficiency. The superior electrical insulation properties of ceramic substrates make them a preferred choice in various electronic applications, further solidifying their importance in modern technology.

Mechanical Strength

Durability and Toughness

Ceramic substrates are renowned for their durability and toughness, making them an excellent choice for demanding applications. They exhibit a remarkable resistance to wear and corrosion, allowing them to maintain structural integrity in harsh environments. This durability is critical in industries such as automotive and aerospace, where components are subjected to mechanical stress, temperature fluctuations, and corrosive substances. Unlike many traditional materials, ceramics can withstand significant mechanical loads without deforming or failing, providing long-lasting performance. Their resistance to chemical corrosion further enhances their usability in applications where exposure to harsh chemicals is common, ensuring that devices remain reliable over time.

Lightweight Properties

In addition to their mechanical strength, ceramic substrates are relatively lightweight compared to metals and other materials. This characteristic not only helps reduce the overall weight of electronic devices but also contributes to enhanced design flexibility. Designers can create compact and efficient designs without sacrificing strength or performance. The lightweight nature of ceramic substrates enables innovations in portable electronics, where weight is a critical factor. By integrating ceramic substrates, manufacturers can achieve more efficient designs while maintaining robust performance, making them an attractive option in a variety of applications, from consumer electronics to advanced industrial systems.

Design Flexibility

Complex Geometries

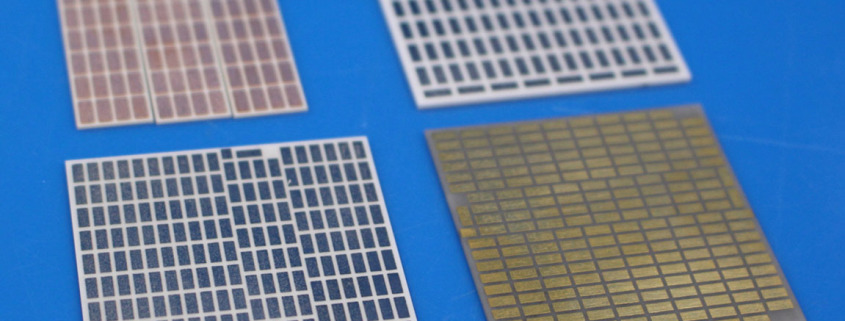

Ceramic substrates offer exceptional design flexibility, allowing engineers to create complex geometries that meet specific application requirements. Unlike traditional materials that may limit design possibilities due to their mechanical properties, ceramics can be precisely engineered to achieve intricate shapes and features. This capability is particularly valuable in advanced electronics, where space is often constrained, and components need to be arranged in innovative ways. The ability to produce detailed patterns and structures enhances the functionality of the devices, enabling better thermal management and improved signal routing. As a result, designers can optimize performance while minimizing the size and weight of the final product, making ceramic substrates an ideal choice for modern electronic applications.

Integration with Other Materials

Another advantage of ceramic substrates is their compatibility with a variety of other materials, facilitating hybrid designs that leverage the strengths of multiple substances. This integration allows for the combination of ceramics with metals, polymers, and other composites to enhance overall performance and reliability. For instance, ceramic substrates can be combined with metal conductors to create robust and thermally efficient packages. Such hybrid designs enable better heat dissipation and improved electrical performance, which is crucial for high-power applications. The versatility of ceramic substrates in integrating with different materials empowers engineers to innovate and develop tailored solutions that meet the diverse needs of today’s electronic landscape, fostering advancements in technology across various sectors.

Applications of Ceramic Substrates

Electronics and Circuit Boards

Ceramic substrates are widely used in the electronics industry, particularly in high-performance and high-reliability applications. Their unique properties, such as excellent thermal management and electrical insulation, make them ideal for advanced circuit boards, especially in power electronics and RF devices. Ceramic substrates support the integration of multi-layer circuits, enabling compact designs that enhance device functionality while ensuring signal integrity. In applications like microwave communication, LED technology, and high-frequency circuits, ceramic substrates help mitigate heat buildup and improve efficiency, making them essential in modern electronic systems. As demand for smaller, faster, and more efficient devices grows, the role of ceramic substrates in electronics will continue to expand, paving the way for innovative solutions.

Aerospace and Automotive Industries

In the aerospace and automotive sectors, ceramic substrates play a crucial role in critical components that require robust materials capable of withstanding harsh conditions. These industries often face challenges such as extreme temperatures, vibration, and corrosive environments, making the durability and reliability of materials paramount. Ceramic substrates are utilized in various applications, including engine control units, sensors, and high-power modules, where their thermal stability and mechanical strength are vital. By providing reliable performance in these demanding environments, ceramic substrates contribute to the overall safety and efficiency of aerospace and automotive systems. As technology advances and the push for lightweight, high-performance components continues, ceramic substrates are poised to become increasingly integral to these industries, driving innovation and enhancing operational capabilities.

Comparison with Other Substrate Materials

Ceramic vs. FR-4

When comparing ceramic substrates to FR-4, a commonly used material in printed circuit boards, several performance differences become apparent. Ceramic substrates excel in thermal stability, allowing them to operate efficiently in high-temperature environments without degrading. In contrast, FR-4 is limited by its thermal properties and can suffer from delamination and performance issues at elevated temperatures. Additionally, ceramic substrates provide superior electrical insulation, which is crucial in high-frequency applications, reducing signal loss and improving overall circuit performance. While ceramic substrates may have a higher initial cost compared to FR-4, their longevity and reliability in demanding conditions often justify the investment. Over time, the durability of ceramic materials can lead to lower maintenance and replacement costs, making them a more economical choice in applications where performance and lifespan are critical.

Ceramic vs. Metal

The comparison between ceramic substrates and metal materials reveals distinct advantages for ceramics, particularly in thermal management and weight reduction. Ceramic substrates demonstrate exceptional thermal conductivity, allowing for efficient heat dissipation, which is vital in high-power applications. Metals, while conductive, can retain heat and may require additional cooling mechanisms, complicating the design and increasing overall system weight. Furthermore, ceramic substrates are significantly lighter than metals, providing a crucial benefit in applications where weight savings are essential, such as aerospace and portable electronics. This lightweight characteristic enhances design flexibility and promotes the creation of compact, efficient devices. Overall, the advantages of ceramic substrates in thermal management and weight reduction position them as a superior choice in many high-performance applications, highlighting their growing importance in modern technology.

FAQs About advantages of ceramic substrate

High Hardness: Ceramic materials are extremely hard, making them resistant to wear and abrasion.

Thermal Stability: They can withstand high temperatures without significant degradation, suitable for extreme environments.

Chemical Resistance: Ceramics are resistant to corrosion and chemical attack, ensuring durability in harsh conditions.

Electrical Insulation: Many ceramic materials exhibit excellent dielectric properties, making them ideal for electrical insulation.

Low Density: Ceramics are typically lightweight, which is beneficial for applications in aerospace and automotive industries.

Enhanced Mechanical Properties: Ceramic composites combine the strengths of different materials, leading to improved toughness and impact resistance.

Lightweight: They maintain low weight while providing high strength, which is crucial for applications where weight is a concern.

Improved Thermal Conductivity: Composites can be engineered to offer better heat dissipation compared to traditional ceramics.

Tailored Properties: The composition can be adjusted to meet specific performance requirements, including flexibility, strength, and thermal resistance.

Resistance to Fracture: The inclusion of reinforcing materials can enhance the fracture toughness of ceramics.

Wear Resistance: Ceramic inserts are highly resistant to wear, making them ideal for cutting and machining applications.

Heat Resistance: They can withstand high temperatures, which is beneficial in high-speed machining.

Chemical Stability: Ceramic inserts resist chemical wear, providing longevity in challenging environments.

Improved Surface Finish: They often produce a better surface finish on machined parts compared to traditional materials.

Reduced Tool Weight: Ceramic inserts are lighter than metal counterparts, leading to easier handling and potentially reduced

Biocompatibility: Many ceramic biomaterials are biocompatible, making them suitable for medical applications like implants.

Chemical Inertness: They resist corrosion and degradation in biological environments, ensuring long-term stability.

Bone Integration: Certain ceramic materials can promote bone growth and integration, making them ideal for orthopedic applications.

Low Density: Ceramic biomaterials are often lightweight, which is advantageous in reducing the overall load on the body.

Customizable Properties: The mechanical and physical properties can be tailored for specific medical applications, enhancing performance in vivo.