Top Global ABF Substrate Companies in Semiconductor Packaging

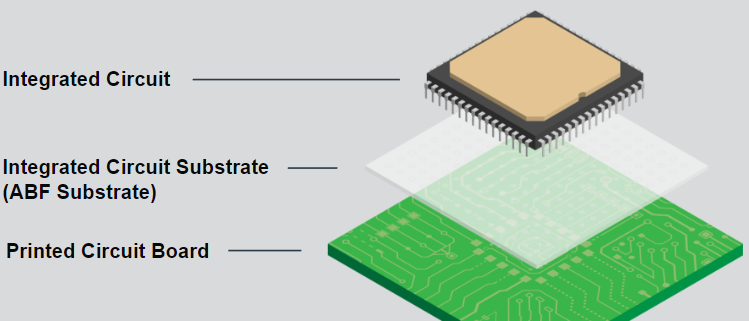

An ABF (Ajinomoto Build-up Film) substrate is a crucial component in semiconductor packaging, providing the necessary insulation and structural support for complex electronic circuits. Developed by Ajinomoto, a Japanese company, ABF technology emerged in the late 1990s as a solution to the growing demand for miniaturized, high-performance electronic devices. ABF substrates are made from a specialized resin material that offers excellent thermal and electrical insulation properties, making them ideal for use in high-density, multi-layered PCBs (Printed Circuit Boards).

The significance of ABF substrates in electronic packaging lies in their ability to meet the rigorous demands of modern electronics, such as smartphones, servers, and AI processors. By enabling the creation of smaller, faster, and more efficient chips, ABF substrates play a pivotal role in advancing technology, driving innovation in industries ranging from consumer electronics to data centers.

Major ABF Substrate Companies

Leading ABF Substrate Companies Globally

The ABF substrate market is dominated by several key players that have established themselves as leaders in the industry. Companies like Shinko Electric Industries, Ibiden, Nan Ya PCB, and Unimicron are at the forefront of ABF substrate manufacturing. Shinko Electric Industries, with its advanced technology and high-quality products, holds a significant market share, particularly in high-performance computing and networking sectors. Ibiden, known for its innovative approaches and strong R&D capabilities, has carved out a substantial portion of the market, particularly in the automotive and consumer electronics sectors. Nan Ya PCB and Unimicron are also major players, known for their extensive production capacities and ability to meet the growing global demand for ABF substrates.

Supplier Analysis

- Ajinomoto

Ajinomoto is the pioneer of ABF materials, having developed the original ABF technology that revolutionized semiconductor packaging. The company’s unique position as the inventor of ABF substrates gives it a competitive edge, as it continues to lead in innovation and product development. Ajinomoto’s ABF materials are widely recognized for their superior quality, reliability, and performance, making them the preferred choice for many semiconductor manufacturers. - Other Key Suppliers

Other leading ABF substrate companies, such as Shinko Electric Industries, Ibiden, Nan Ya PCB, and Unimicron, have made significant contributions to the advancement of ABF substrate technology. These companies have introduced innovations in material composition, manufacturing processes, and product applications, helping to push the boundaries of what ABF substrates can achieve. Their continuous efforts in research and development ensure that ABF substrates remain at the cutting edge of electronic packaging technology, meeting the ever-increasing demands of modern electronics.

ABF Material Properties

Fundamental Characteristics of ABF Material

ABF (Ajinomoto Build-up Film) materials are known for their exceptional physical and chemical properties, which make them ideal for advanced semiconductor packaging. One of the most critical properties of ABF materials is their low dielectric constant, which helps to reduce signal loss and improve the overall performance of high-speed electronic devices. This low dielectric constant is essential for maintaining signal integrity in dense, high-frequency circuits.

Another important characteristic of ABF materials is their controlled thermal expansion coefficient (CTE), which closely matches that of silicon wafers. This compatibility minimizes the risk of mechanical stress and potential damage during thermal cycling, ensuring the reliability and longevity of the packaged device. ABF materials also exhibit excellent heat resistance, allowing them to withstand the high temperatures involved in semiconductor manufacturing processes without degrading. This heat resistance is crucial for maintaining the integrity of the substrate during soldering and other thermal operations.

These properties collectively enhance the performance and reliability of ABF substrates in semiconductor packaging, making them a preferred choice for applications that demand high performance and durability.

Comparison: ABF vs. BT Substrates

When comparing ABF substrates to BT (Bismaleimide-Triazine) substrates, several key differences emerge in terms of material properties, manufacturing processes, and application scenarios. ABF substrates have a lower dielectric constant than BT substrates, which gives them a significant advantage in high-frequency applications where signal integrity is critical. This makes ABF substrates more suitable for high-performance computing (HPC), networking, and telecommunications, where high data transmission speeds and low signal loss are paramount.

In terms of thermal properties, ABF substrates offer better thermal stability and a more closely matched CTE with silicon, reducing the risk of mechanical failures in high-reliability applications. BT substrates, on the other hand, are often used in less demanding applications where cost is a significant factor, such as consumer electronics.

The manufacturing process for ABF substrates involves a more complex build-up process, allowing for the creation of multi-layer structures with fine line widths and high-density interconnects. This complexity enables ABF substrates to support the latest semiconductor technologies, such as advanced processors and memory devices, which require dense packaging and high electrical performance.

In contrast, BT substrates are typically used in simpler, low-cost applications where high performance is not the primary concern. The dominance of ABF substrates in high-performance computing and high-frequency applications underscores their superiority in scenarios where performance, reliability, and thermal management are critical.

ABF Substrate Manufacturing & Packaging

ABF Packaging Process

The application of ABF substrates in semiconductor packaging involves a multi-step process that integrates the substrate with the semiconductor die to form a reliable and high-performance package. The process begins with the lamination of ABF materials onto a core substrate, followed by the build-up of multiple insulating and conductive layers through sequential photolithography, etching, and metallization. This build-up process allows for the creation of fine line widths and high-density interconnects, which are essential for advanced semiconductor devices.

ABF substrates are particularly advantageous in electronic packaging due to their ability to support high-frequency signals with minimal loss. The low dielectric constant of ABF materials reduces signal distortion, ensuring better signal integrity in high-speed applications. Additionally, ABF substrates offer excellent thermal management properties, which help dissipate heat efficiently, reducing the risk of overheating and improving the reliability of the packaged device.

The precision and reliability of the ABF packaging process make it the preferred choice for applications that require high performance, such as processors, memory chips, and other components in high-performance computing, telecommunications, and automotive electronics.

ABF Lamination and Processing

The lamination process for ABF substrates is a critical step in ensuring the overall performance and stability of the final package. This process involves bonding the ABF material to the core substrate under controlled temperature and pressure conditions. The key challenge in ABF lamination lies in achieving uniform adhesion and minimizing defects such as voids, delamination, or warping, which can compromise the electrical and mechanical integrity of the substrate.

To address these challenges, manufacturers employ advanced lamination techniques, such as vacuum lamination, to ensure that the ABF material adheres evenly across the entire surface of the substrate. Proper control of temperature, pressure, and lamination speed is crucial to achieving the desired level of adhesion without introducing stress or distortion.

In addition to lamination, the processing of ABF substrates involves precise photolithography and etching to define the fine circuit patterns required for high-density interconnects. Maintaining tight tolerances during these steps is essential to ensure that the final substrate meets the required specifications for electrical performance and reliability.

To ensure the high performance and stability of ABF substrates, manufacturers conduct rigorous testing and quality control measures at each stage of the lamination and processing cycle. This includes thermal cycling, electrical testing, and mechanical stress tests to identify and address any potential weaknesses before the substrate is integrated into the final semiconductor package.

The combination of advanced lamination techniques, precise processing, and stringent quality control ensures that ABF substrates deliver the performance, reliability, and longevity required for the most demanding electronic applications.

ABF Substrate Market & Supply Chain

ABF Substrate Companies List

The global ABF substrate market is dominated by a select group of companies that have established themselves as leaders in the production and supply of this critical material. Key players in the ABF substrate industry include:

- Shinko Electric Industries: A major supplier of ABF substrates, Shinko is known for its advanced manufacturing capabilities and strong R&D focus. The company’s ABF substrates are widely used in high-performance computing and networking applications.

- Ibiden: Ibiden is a leading Japanese manufacturer with a significant market share in the ABF substrate sector. The company is recognized for its innovative approaches to substrate design and production, catering to the automotive and consumer electronics markets.

- Nan Ya PCB: A prominent Taiwanese company, Nan Ya PCB is a key supplier of ABF substrates, known for its large-scale production capacity and strong presence in the global market. Nan Ya’s ABF substrates are essential for many high-performance electronics, including AI processors and servers.

- Unimicron: Another major player from Taiwan, Unimicron is renowned for its expertise in high-density interconnect (HDI) substrates, including ABF substrates. The company serves a broad range of industries, from consumer electronics to telecommunications.

- Ajinomoto: Although primarily known for developing the original ABF material, Ajinomoto continues to play a critical role in the supply chain by providing the base materials that other companies use to manufacture ABF substrates. Ajinomoto’s unique position as the inventor of ABF technology gives it a strategic advantage in the market.

These companies collectively control a significant portion of the ABF substrate market, and their products are integral to the performance of advanced semiconductor devices.

Supply Chain Issues for ABF Substrates

Reasons for the ABF Substrate Shortage

The ABF substrate market has faced significant supply chain challenges in recent years, driven by a combination of increased demand, production bottlenecks, and broader industry disruptions. One of the primary reasons for the ABF substrate shortage is the surge in demand for high-performance computing devices, driven by trends such as the rise of AI, 5G, and data center expansions. As these technologies require more advanced semiconductors, the demand for ABF substrates has outpaced the supply.

Analysis of Recent Supply Chain Issues

The global semiconductor industry has been grappling with supply chain disruptions, including shortages of raw materials, logistical delays, and capacity constraints at manufacturing plants. The production of ABF substrates is particularly complex, requiring advanced materials, precise manufacturing processes, and significant capital investment. Any disruption in this tightly controlled process can lead to significant delays and reduced output. Additionally, the limited number of suppliers capable of producing ABF substrates has made the market vulnerable to supply chain shocks.

Impact of the Chip Shortage Crisis on ABF Substrates

The broader semiconductor chip shortage has further exacerbated the ABF substrate supply issues. As chip manufacturers struggle to meet the unprecedented demand for semiconductors, the pressure on the ABF substrate supply chain has intensified. This shortage has had a ripple effect across the electronics industry, leading to production delays, increased costs, and, in some cases, the inability to meet market demand for high-performance electronic devices.

The ABF substrate shortage has underscored the critical importance of supply chain resilience in the semiconductor industry. Companies are now exploring ways to expand production capacity, diversify supply sources, and invest in new technologies to mitigate the impact of future disruptions. However, these solutions require time and significant investment, meaning that the ABF substrate market is likely to remain tight in the near term.

Future Trends in ABF Substrates

Market Outlook for ABF Substrates

The future of the ABF substrate market is closely tied to the ongoing advancements in semiconductor technology and the increasing demand for high-performance electronic devices. As industries such as artificial intelligence (AI), 5G communications, and autonomous vehicles continue to grow, the need for more powerful and efficient semiconductors will drive the demand for ABF substrates. These substrates are crucial for supporting the high-density interconnects and low-latency requirements of next-generation computing and networking hardware.

In the coming years, ABF substrates are expected to see expanded applications in emerging technologies, including quantum computing, advanced driver-assistance systems (ADAS), and edge computing. These fields require substrates that can handle increasingly complex circuits and higher data processing speeds, areas where ABF substrates excel. The continued miniaturization of electronic components and the push towards higher integration levels will further reinforce the importance of ABF substrates in the semiconductor industry.

To meet the anticipated surge in demand, ABF substrate suppliers are investing heavily in expanding their production capacities and upgrading their manufacturing technologies. Companies are building new facilities, adopting more efficient production methods, and enhancing their supply chains to ensure they can keep pace with future market needs. Additionally, collaborations with semiconductor manufacturers are becoming more common, allowing suppliers to align their product development closely with the specific requirements of their clients.

Innovation and R&D

Innovation in ABF substrate technology is critical for maintaining its relevance and competitive edge in the fast-evolving semiconductor landscape. Research and development (R&D) efforts are focused on improving the material properties of ABF substrates, such as further reducing the dielectric constant to minimize signal loss and enhancing the thermal conductivity to better manage heat dissipation in high-power applications. These improvements will be essential as semiconductor devices continue to shrink in size while increasing in complexity and performance.

Emerging fields such as flexible electronics and wearable devices may also benefit from advancements in ABF substrate technology. Developing more flexible, lightweight, and durable ABF materials could open up new application areas where traditional rigid substrates are less effective. Additionally, as the industry explores more sustainable manufacturing practices, there is potential for ABF substrates to incorporate eco-friendly materials and processes, reducing the environmental impact of semiconductor production.

Looking ahead, the integration of ABF substrates with advanced packaging technologies, such as 2.5D and 3D IC packaging, will likely become more prominent. These technologies require substrates that can support high-density interconnects across multiple layers and different components, making ABF substrates an ideal choice. The ongoing R&D in this area will be crucial for enabling the next generation of semiconductor devices that are more powerful, energy-efficient, and versatile.

In conclusion, the future of ABF substrates is bright, with significant growth expected as new technologies emerge and existing applications continue to evolve. The commitment of suppliers to innovation and capacity expansion will ensure that ABF substrates remain a cornerstone of the semiconductor industry for years to come.

FAQs About abf substrate companies

Key suppliers of ABF substrates include Shinko Electric Industries, Ibiden, Nan Ya PCB, Unimicron, and Ajinomoto. Shinko and Ibiden are major players known for their advanced manufacturing capabilities and significant market share. Nan Ya PCB and Unimicron are also prominent suppliers, providing high-quality ABF substrates for a range of applications. Ajinomoto, the original developer of ABF technology, plays a crucial role in supplying the base materials used by other manufacturers.

The ABF substrate shortage is driven by a surge in demand for high-performance semiconductors used in advanced technologies like AI, 5G, and data centers. Supply chain disruptions, production bottlenecks, and the COVID-19 pandemic have exacerbated the shortage. Limited production capacity and logistical challenges further contribute to the tight supply of ABF substrates.

BT (Bismaleimide-Triazine) and ABF (Ajinomoto Build-up Film) substrates differ primarily in material properties and applications. ABF substrates have a lower dielectric constant and better thermal expansion properties compared to BT substrates, making them more suitable for high-frequency and high-performance applications. BT substrates are often used in less demanding, cost-sensitive applications. ABF substrates support finer line widths and higher-density interconnects, which are crucial for advanced semiconductor devices.

Ajinomoto is the primary producer of ABF (Ajinomoto Build-up Film) materials. The company developed the ABF technology and continues to supply the material used by other manufacturers to produce ABF substrates. Other companies, like Shinko Electric Industries, Ibiden, and Nan Ya PCB, use Ajinomoto’s ABF materials to create their substrates.