Key Considerations on How to Choose a Ceramic Substrate for Applications

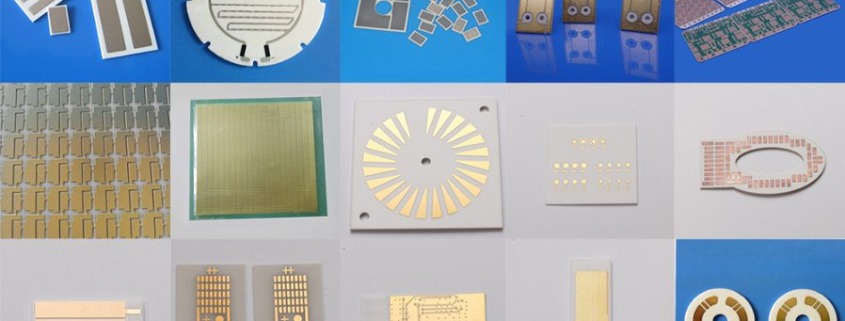

Ceramic substrates have become indispensable in modern technology, serving as a foundation for high-power electronics, RF applications, LEDs, and other high-performance devices. Their unique properties, such as high thermal conductivity, excellent electrical insulation, and mechanical strength, make them a preferred choice in demanding environments. However, how to choose a ceramic substrate that perfectly matches specific application requirements remains a critical decision for engineers and manufacturers.

Selecting the right ceramic substrate is essential for optimizing device performance, ensuring reliability, and extending product lifespan. A poorly chosen substrate could lead to overheating, inefficiencies, or even device failure in critical systems.

This blog will explore the key considerations in how to choose a ceramic substrate, including material properties, application demands, and cost factors. By understanding these aspects, you can make informed decisions and achieve the best performance for your projects.

What Are Ceramic Substrates and How to Choose a Ceramic Substrate?

Ceramic substrates are specialized materials known for their exceptional properties, including high thermal conductivity, robust mechanical strength, and low dielectric loss. These characteristics make ceramic substrates a preferred choice in various advanced electronic applications where performance and reliability are paramount. Understanding what ceramic substrates are and how to choose a ceramic substrate involves examining their types and applications.

Common Types of Ceramic Substrates

- Alumina (Al₂O₃):

- The most commonly used ceramic substrate.

- Offers excellent thermal and mechanical properties at a relatively low cost.

- Ideal for general-purpose applications.

- Aluminum Nitride (AlN):

- Known for its high thermal conductivity, making it suitable for high-power devices requiring efficient heat dissipation.

- Slightly more expensive than alumina but superior for heat management.

- Silicon Nitride (Si₃N₄):

- Provides exceptional mechanical strength and thermal stability.

- Best suited for applications in environments with high vibration or stress.

- Zirconia (ZrO₂):

- Offers excellent toughness and wear resistance.

- Typically used in specialized or niche applications.

Applications of Ceramic Substrates

Ceramic substrates are widely applied in high-power devices, RF circuits, and semiconductor packaging due to their ability to manage heat and withstand electrical and mechanical stresses. They are also essential in LED lighting systems, where efficient heat dissipation and long-term reliability are critical.

For those exploring how to choose a ceramic substrate, consider factors like thermal performance, mechanical demands, and application-specific requirements. Proper selection ensures optimized performance and prolonged lifespan in demanding electronic systems.

Key Factors to Consider When Choosing a Ceramic Substrate

Selecting the right ceramic substrate is critical for achieving optimal performance in advanced electronic applications. To understand how to choose a ceramic substrate, you must consider several key factors that directly impact its suitability for specific use cases.

Thermal Conductivity

High thermal conductivity is essential for managing heat in high-power applications. Materials like aluminum nitride (AlN) are ideal, as they provide superior heat dissipation compared to other ceramics. For example, AlN substrates are widely used in LED systems, where efficient heat management is crucial for maintaining brightness and extending lifespan. Failing to choose a substrate with adequate thermal conductivity can lead to overheating and device failure.

Mechanical Strength

Mechanical strength is a critical consideration in environments prone to vibration, impact, or mechanical stress. Silicon nitride (Si₃N₄) substrates excel in these conditions due to their remarkable toughness and resistance to cracking. For applications such as automotive or aerospace electronics, where devices must endure mechanical strain, Si₃N₄ is an excellent choice.

Electrical Insulation and Dielectric Properties

Electrical insulation and low dielectric constant are vital for RF and microwave circuits. Materials like alumina (Al₂O₃) and aluminum nitride (AlN) ensure minimal signal loss and interference, making them ideal for high-frequency applications. When considering how to choose a ceramic substrate for these purposes, low dielectric loss is a key factor to optimize signal integrity.

Dimensional Stability

Dimensional stability ensures that the substrate can maintain its integrity in high-temperature environments. Matching the thermal expansion coefficient (CTE) of the ceramic substrate to that of other materials in the system (e.g., semiconductors or metal layers) prevents mechanical stress and ensures reliability. This factor is particularly important in applications like power electronics and semiconductor packaging.

Cost and Availability

Cost and availability play a crucial role. While high-performance materials like aluminum nitride and silicon nitride offer exceptional properties, they are more expensive. Alumina, on the other hand, is cost-effective and suitable for many general-purpose applications. Balancing performance with budget constraints is essential when deciding how to choose a ceramic substrate that meets project requirements.

By carefully evaluating these factors, you can ensure that the ceramic substrate you select delivers the performance, reliability, and cost-effectiveness needed for your specific application.

Comparison of Common Ceramic Substrates

Understanding the differences between various ceramic substrates is essential when determining how to choose a ceramic substrate. Each material offers unique properties that make it suitable for specific applications. Below is a detailed comparison of three widely used ceramic substrates: alumina (Al₂O₃), aluminum nitride (AlN), and silicon nitride (Si₃N₄).

Thermal Conductivity

- Alumina (Al₂O₃): Offers moderate thermal conductivity, which is adequate for many general-purpose applications. However, it may struggle to dissipate heat efficiently in high-power or high-temperature systems.

- Aluminum Nitride (AlN): Renowned for its high thermal conductivity, AlN is the go-to material for applications requiring excellent heat dissipation, such as power modules and LED lighting.

- Silicon Nitride (Si₃N₄): Provides moderate thermal conductivity but compensates with other strengths, making it ideal for environments with mixed performance requirements.

Mechanical Strength

- Alumina (Al₂O₃): Has high mechanical strength and can withstand moderate mechanical stress, making it versatile for many applications.

- Aluminum Nitride (AlN): While AlN has excellent thermal properties, its mechanical strength is only moderate, making it less suitable for harsh environments with significant vibration or impact.

- Silicon Nitride (Si₃N₄): Excels in mechanical strength, outperforming other ceramics in applications exposed to extreme mechanical or thermal stress, such as aerospace and automotive systems.

Electrical Insulation

- Alumina (Al₂O₃): Offers excellent electrical insulation, making it suitable for devices requiring high dielectric strength, such as RF circuits and semiconductor packaging.

- Aluminum Nitride (AlN): Combines excellent electrical insulation with high thermal conductivity, making it ideal for applications where both properties are critical.

- Silicon Nitride (Si₃N₄): Provides good electrical insulation but slightly lags behind alumina and AlN in this category. It is more commonly chosen for its mechanical advantages.

Cost

- Alumina (Al₂O₃): The most cost-effective ceramic substrate, alumina strikes a balance between performance and affordability, making it the most popular choice for general-purpose applications.

- Aluminum Nitride (AlN): High performance comes with a high cost. AlN is significantly more expensive than alumina, which may limit its use in cost-sensitive projects.

- Silicon Nitride (Si₃N₄): Moderately priced, silicon nitride is a suitable choice for applications where mechanical strength and durability justify the additional cost.

Summary Table

| Property | Alumina (Al₂O₃) | Aluminum Nitride (AlN) | Silicon Nitride (Si₃N₄) |

|---|---|---|---|

| Thermal Conductivity | Moderate | High | Moderate |

| Mechanical Strength | High | Moderate | High |

| Electrical Insulation | Excellent | Excellent | Good |

| Cost | Low | High | Moderate |

How to Choose a Ceramic Substrate Based on Comparisons

When deciding how to choose a ceramic substrate, consider the specific needs of your application:

- For cost-effective general applications, alumina (Al₂O₃) is a reliable choice.

- If thermal management is crucial, prioritize aluminum nitride (AlN) despite its higher cost.

- For environments with extreme mechanical demands, silicon nitride (Si₃N₄) offers unmatched durability and strength.

By analyzing these comparisons, you can confidently select the ceramic substrate that aligns with your performance and budget requirements.

How to Match Specific Application Requirements

When selecting a ceramic substrate, understanding how to choose a ceramic substrate that aligns with the specific demands of your application is crucial. Different applications have distinct performance requirements, and choosing the right material can significantly impact the efficiency, reliability, and longevity of your electronic devices. Below are key considerations for matching ceramic substrates to specific application needs.

High-Power Electronics

In high-power electronics, efficient heat management is essential to prevent overheating, which can degrade performance and damage components. Aluminum Nitride (AlN) is the ideal choice for these applications due to its high thermal conductivity. AlN substrates efficiently dissipate heat from power modules, LED lights, and other high-power devices, ensuring that the system operates at optimal temperatures. When how to choose a ceramic substrate for high-power applications, prioritize materials with superior thermal performance to protect your components and extend their lifespan.

Example: In power modules, AlN substrates can dissipate heat effectively, ensuring the longevity of the components by preventing thermal stress.

RF and Microwave Circuits

For RF and microwave circuits, signal integrity and minimal loss are critical factors. Materials with low dielectric loss, such as alumina (Al₂O₃) and aluminum nitride (AlN), are excellent choices. These materials ensure that electromagnetic signals pass through the substrate with minimal interference, preserving the quality of the signal and ensuring efficient operation. How to choose a ceramic substrate for RF and microwave applications depends on selecting materials with the lowest possible dielectric constant and loss, as these properties influence signal speed and energy efficiency.

Example: In high-frequency applications like microwave circuits, both alumina and AlN substrates maintain low signal loss, improving the performance of communication systems.

High Mechanical Strength Requirements

In applications where substrates are exposed to mechanical stress, vibration, or impact, choosing a material with high mechanical strength is essential. Silicon Nitride (Si₃N₄) is ideal for such environments due to its outstanding toughness and resistance to cracking. It can withstand harsh conditions without compromising structural integrity, making it perfect for use in automotive electronics, aerospace components, and other systems requiring durability.

When considering how to choose a ceramic substrate for applications with high mechanical demands, silicon nitride is a top contender, offering the durability necessary to endure extreme conditions.

Example: In aerospace or automotive systems, silicon nitride substrates provide the necessary mechanical strength to maintain functionality even in challenging environments.

By understanding the specific requirements of your application, you can better assess how to choose a ceramic substrate that meets your needs. Whether it’s for high-power electronics requiring heat dissipation, RF circuits demanding low dielectric loss, or mechanical strength for demanding environments, selecting the right ceramic substrate ensures optimal performance and reliability.

Case Studies and Practical Applications

To better understand how to choose a ceramic substrate, examining real-world applications and case studies provides valuable insights. Each case highlights the specific benefits of choosing the right ceramic substrate based on performance requirements, cost considerations, and environmental factors. Below, we explore three distinct case studies that demonstrate the practical use of ceramic substrates in different industries.

Case Study 1: Why Aluminum Nitride Substrates Were Chosen for a High-Frequency RF Module

A leading telecommunications company developed a high-frequency RF (Radio Frequency) module for a next-generation wireless communication system. The RF module needed to maintain signal integrity at high frequencies while managing heat dissipation due to the high power involved.

- Challenge: The substrate for the RF module had to offer low dielectric loss to ensure minimal signal attenuation, as well as excellent thermal conductivity to prevent overheating in the high-power environment.

- Solution: Aluminum nitride (AlN) was selected as the ceramic substrate material. AlN’s low dielectric loss ensures optimal signal transmission, while its high thermal conductivity allows for effective heat dissipation, even at high power levels. This combination is essential for RF applications that require both heat management and electrical performance.

- Result: The use of AlN significantly improved the module’s performance, leading to faster communication speeds and longer system lifespans due to enhanced heat management. This case illustrates how choosing the right ceramic substrate—AlN in this case—was crucial for optimizing performance in high-frequency RF modules.

Case Study 2: Cost-effective Solutions Using Alumina Substrates in LED Applications

A large manufacturer of LED lighting solutions was looking to improve the performance and longevity of their products, which were being used in commercial and residential lighting. Given the rapid adoption of energy-efficient LED lighting, the company needed a reliable, cost-effective substrate for their LED modules.

- Challenge: The LED modules needed a substrate that could withstand high temperatures and ensure efficient heat dissipation, without driving up production costs.

- Solution: Alumina (Al₂O₃) was chosen due to its balance between cost-effectiveness and thermal conductivity. Alumina provides adequate thermal management at a significantly lower price point than more advanced materials like aluminum nitride. The ceramic also offers excellent electrical insulation properties, essential for stable LED performance.

- Result: By using alumina substrates, the company was able to reduce costs while maintaining the thermal stability needed to prevent overheating in LED systems. The decision allowed for mass production of cost-effective, reliable, and long-lasting LED lighting products. This case highlights how alumina offers a practical solution in applications where cost is a critical factor without compromising basic performance requirements.

Case Study 3: The Role of Silicon Nitride Substrates in Extending Device Lifespan in Vibration-Prone Environments

An aerospace company was designing a new set of sensors and electronic components for use in aircraft engines, where vibration and thermal cycling are common. These components needed to operate reliably in harsh environments, with the capacity to endure mechanical stress and extreme temperature variations over prolonged periods.

- Challenge: The primary challenge was selecting a substrate material that could withstand high mechanical stress, vibration, and thermal cycling while maintaining the electrical and thermal properties necessary for long-term reliability.

- Solution: Silicon nitride (Si₃N₄) was selected due to its high mechanical strength and exceptional resistance to thermal shock and vibration. Si₃N₄’s high toughness ensures that it can resist cracking under mechanical stress, and its thermal stability makes it ideal for use in components exposed to fluctuating temperatures, as in engine environments.

- Result: The use of silicon nitride substrates extended the lifespan of the electronic components, ensuring their continued reliability in vibration-prone and high-temperature environments. This case underscores how Si₃N₄’s mechanical strength and durability make it the optimal choice for applications that demand long-term performance in challenging conditions.

These case studies show how how to choose a ceramic substrate depends on specific application needs:

- Aluminum nitride (AlN) is ideal for high-frequency RF applications, providing both excellent heat dissipation and low dielectric loss.

- Alumina (Al₂O₃) offers a cost-effective solution in LED applications, balancing thermal performance with affordability.

- Silicon nitride (Si₃N₄) proves to be the best choice for high-mechanical-strength environments, offering durability and reliability in vibration-prone and extreme temperature conditions.

Each case highlights the importance of selecting the right material based on the unique demands of the application, reinforcing the critical role ceramic substrates play in enhancing the performance and longevity of advanced technologies.

Future Trends and Technological Outlook

As industries continue to evolve, the ceramic substrate market is experiencing significant advancements driven by innovations in material science, environmental sustainability, and market dynamics. Looking ahead, several key trends are shaping the future of ceramic substrates, providing exciting opportunities and challenges for manufacturers and consumers alike. Let’s explore these emerging trends and technological advancements.

Innovations in Ceramic Substrate Materials: The Rise of Nanoceramics

The quest for higher performance in electronic devices is leading to the development of new, cutting-edge materials. One of the most promising innovations in the field of ceramic substrates is the development of nanoceramics. Nanoceramics refer to ceramic materials that are engineered at the nanometer scale, offering enhanced properties such as superior thermal conductivity, greater mechanical strength, and improved electrical insulation.

- Advantage: Nanoceramics promise to push the boundaries of ceramic substrates, enabling even better performance in high-power electronics, RF circuits, and advanced sensor technologies. Their ability to withstand extreme conditions while offering high precision makes them suitable for applications in aerospace, automotive, and medical devices.

- Example: Nanoceramics are being explored for power electronics, where the increased thermal conductivity and reduced dielectric loss will enhance device efficiency and longevity. These innovations are particularly relevant for devices like high-performance power transistors, where thermal management is critical.

As manufacturers continue to explore and refine nanoceramic technologies, we can expect these materials to play an increasingly prominent role in the future of ceramic substrates, offering unprecedented performance levels in next-generation electronic devices.

Sustainability: Reducing Environmental Impact in Manufacturing Processes

Environmental sustainability is becoming a central focus in almost every manufacturing industry, and ceramic substrates are no exception. The production of ceramic materials traditionally involves high-energy processes that can have a substantial environmental footprint. As awareness of environmental concerns increases, there is growing pressure on manufacturers to innovate more sustainable practices in the production of ceramic substrates.

- Eco-friendly Materials: Research is underway to develop alternative, more environmentally friendly materials that reduce the use of rare earth elements and other harmful substances. For example, materials that are easier to recycle or that have a lower carbon footprint during production are gaining attention.

- Energy-efficient Production: Advances in green manufacturing technologies aim to lower the energy consumption of substrate production processes. This could include innovations in kiln technologies or more efficient ways to synthesize ceramic powders, reducing the environmental impact without compromising the material’s essential properties.

- Waste Reduction: Manufacturers are also focusing on reducing waste in the ceramic substrate production process by utilizing recycling techniques to reclaim excess materials, further reducing the overall environmental impact.

In the future, sustainable practices will become an integral part of ceramic substrate manufacturing, with the industry making strides toward a more eco-conscious approach while still meeting performance and cost requirements.

Market Demand: Balancing High Performance with Cost-effective Solutions

As the demand for electronic devices grows across various industries, there is an increasing need to balance high performance with cost-effective solutions. The market for ceramic substrates is witnessing rising demand across sectors like automotive, telecommunications, healthcare, and consumer electronics. However, the increasing complexity and performance demands of these applications are putting pressure on manufacturers to offer more advanced materials at a reasonable cost.

- High-Performance Materials: Industries like 5G communications and electric vehicles require ceramic substrates with exceptional thermal and electrical properties. In these sectors, the demand for advanced ceramic materials such as aluminum nitride (AlN) and silicon nitride (Si₃N₄) is on the rise due to their ability to handle high heat flux and demanding mechanical stresses. However, the cost of these advanced materials remains high.

- Cost-effective Solutions: While high-performance materials are essential for cutting-edge applications, the market also needs affordable alternatives that can perform at a high level without driving up production costs. Alumina (Al₂O₃), for example, remains a popular choice for many applications where cost is a critical factor, such as LED lighting and consumer electronics, due to its relatively low price point combined with good electrical insulation and thermal performance.

- Customization: Manufacturers are increasingly offering customized ceramic substrates that can meet the specific needs of a given application while balancing cost and performance. For instance, manufacturers may develop tailored substrates that offer optimal performance for a particular frequency range or power level, helping to bridge the gap between cutting-edge performance and cost-effectiveness.

As market demand continues to grow, the ability to strike a balance between performance, innovation, and affordability will remain a crucial challenge for manufacturers in the ceramic substrate industry.

The future of ceramic substrates is shaped by exciting developments in material science, sustainability initiatives, and evolving market needs. Innovations in nanoceramics are set to enhance the capabilities of ceramic substrates, while sustainable manufacturing practices will help minimize the environmental impact of production processes. At the same time, the demand for high-performance, cost-effective solutions continues to grow, presenting opportunities for manufacturers to meet the needs of diverse industries.

As these trends unfold, how to choose a ceramic substrate will become an increasingly important decision for engineers and manufacturers, with new materials and technologies offering both challenges and opportunities in achieving optimal performance.