Benefits of Ceramic Substrate Circuit Board in Power Electronics

A Ceramic Substrate Circuit Board is an advanced type of PCB known for its exceptional thermal and mechanical properties, making it vital in modern electronics. Unlike traditional materials like FR4, ceramic substrates offer high-temperature resistance and superior thermal conductivity, allowing for effective heat dissipation in demanding applications. These unique properties enable ceramic substrates to maintain stability and reliability even in extreme operating conditions, which is critical for high-performance electronics.

Due to these advantages, Ceramic Substrate Circuit Boards are widely used in power electronics, where efficient thermal management is essential to prevent overheating. They are also preferred in high-frequency devices and advanced electronic systems, as the material’s excellent electrical insulation supports stable signal transmission. With their robust performance characteristics, ceramic substrate boards are key components in cutting-edge applications, providing essential support for industries that require both durability and precision in their electronic components.

What is a Ceramic Substrate Circuit Board?

A Ceramic Substrate Circuit Board is a specialized type of PCB made from ceramic materials known for their superior thermal and electrical properties. These circuit boards play a crucial role in PCB assemblies by providing a stable base that can withstand high temperatures, allowing for efficient heat dissipation and reliable performance. Unlike standard substrates, ceramic materials offer a combination of high mechanical strength and thermal stability, making them essential in applications requiring durable and precise components.

The primary materials used in ceramic substrate manufacturing include alumina (Al₂O₃), aluminum nitride (AlN), and beryllium oxide (BeO). Alumina is commonly used due to its cost-effectiveness and balanced properties, while aluminum nitride provides higher thermal conductivity, ideal for high-power applications. Beryllium oxide, though costly, offers exceptional thermal performance and is used in critical high-performance applications.

Ceramic substrates are the preferred choice for power electronics and high-performance systems because they support high-density circuits and withstand extreme thermal conditions. This resilience and efficiency make Ceramic Substrate Circuit Boards essential for applications such as power modules, automotive electronics, and high-frequency communication devices.

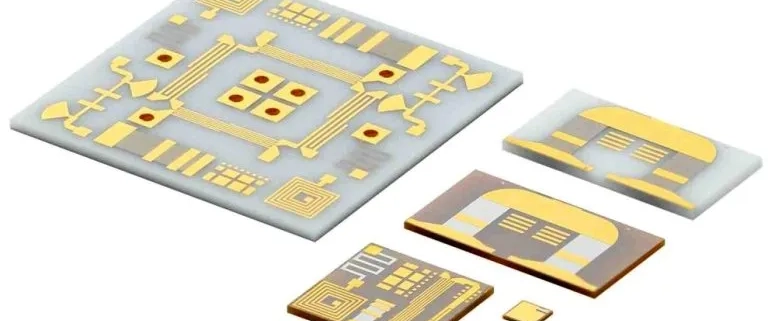

Types of Ceramic Substrate Circuit Boards

Ceramic Substrate Circuit Boards are available in different material types, each with distinct properties tailored to specific applications.

- Alumina Ceramic Substrate: Made from aluminum oxide (Al₂O₃), alumina substrates are widely used due to their cost-effectiveness and balanced properties. These substrates offer good thermal conductivity, electrical insulation, and mechanical stability, making them suitable for a range of applications, including automotive electronics, consumer electronics, and LED lighting. However, alumina’s thermal conductivity is lower than some other ceramics, which may limit its use in extremely high-power applications.

- Aluminum Nitride Ceramic Substrate: Known for its superior thermal conductivity, aluminum nitride (AlN) ceramic is ideal for high-power devices and applications that demand efficient heat dissipation. With excellent electrical insulation and thermal properties, AlN substrates are commonly used in power modules, RF applications, and microelectronics. While more expensive than alumina, AlN provides enhanced performance, especially in environments where rapid heat dissipation is critical.

- Beryllium Oxide Ceramic Substrate: Offering one of the highest thermal conductivities among ceramics, beryllium oxide (BeO) substrates excel in high-performance applications. These substrates support exceptional thermal management, making them valuable for power electronics, aerospace, and medical devices. However, beryllium oxide is more expensive and requires careful handling due to toxicity concerns, limiting its use to specialized, high-end applications.

Each ceramic material offers unique strengths: alumina balances cost and performance for general applications, aluminum nitride provides superior thermal conductivity for high-power electronics, and beryllium oxide offers unparalleled thermal performance for specialized, high-demand applications. The choice of ceramic substrate depends on the specific requirements for thermal management, electrical insulation, and cost efficiency in the intended application area.

Manufacturing Process of Ceramic PCBs

The manufacturing process of Ceramic Substrate Circuit Boards involves several advanced techniques tailored to maximize performance in high-temperature and high-power applications. Each method comes with unique advantages, making it suitable for specific applications and requirements.

- Thick-Film and Thin-Film Techniques:

- In thick-film technology, conductive, resistive, and insulating layers are screen-printed onto ceramic substrates. This technique is versatile, providing a robust, durable circuit with good thermal and electrical properties, making it ideal for power electronics and automotive applications. Thick-film circuits are cost-effective for large production volumes but offer lower resolution and precision.

- Thin-film technology, on the other hand, deposits ultra-thin conductive and resistive layers on the ceramic surface using vacuum deposition methods, allowing for high-precision circuit patterns. Thin-film circuits provide superior performance in high-frequency applications, such as RF and microwave, but the process is more expensive and complex, often reserved for applications requiring extreme precision.

- High-Temperature Co-fired Ceramic (HTCC) and Low-Temperature Co-fired Ceramic (LTCC):

- In HTCC manufacturing, ceramic materials like alumina are mixed with metal powders and then fired at temperatures exceeding 1,600°C. This process produces highly durable substrates with good thermal and electrical characteristics. HTCC is favored for high-power applications due to its heat resistance, but it has limitations in the design complexity and miniaturization of circuits.

- LTCC technology involves co-firing at lower temperatures (around 850°C) and uses glass-ceramic materials, allowing for the integration of more complex circuit layouts, such as multilayered and embedded components. LTCC substrates are suitable for compact electronic devices, such as sensors and communication modules, offering a good balance between performance and design flexibility. However, LTCC has lower thermal conductivity compared to HTCC.

- Direct Bonded Copper (DBC) and Direct Plated Copper (DPC):

- DBC is a process where a copper layer is bonded directly onto a ceramic substrate, typically using aluminum oxide or aluminum nitride. This method offers excellent thermal conductivity and strong adhesion, making it ideal for high-power applications, such as IGBT modules and power amplifiers. DBC substrates are widely used in power electronics due to their heat management capabilities.

- DPC involves plating copper directly onto the ceramic surface, allowing for fine patterning and high precision in circuit designs. DPC substrates are beneficial for applications needing intricate circuit layouts, such as RF and high-frequency devices. The process, however, is more costly than DBC and may require additional manufacturing steps, limiting its use in certain high-volume applications.

Pros and Cons of Each Process:

- Thick-film: Cost-effective, durable; limited precision.

- Thin-film: High-precision, ideal for RF; more expensive.

- HTCC: High thermal resilience; limited miniaturization.

- LTCC: Compact, multilayer options; lower thermal conductivity.

- DBC: Excellent for high power; less precise patterning.

- DPC: High precision; higher cost.

Choosing the appropriate manufacturing process for Ceramic Substrate Circuit Boards depends on the application’s requirements for thermal management, precision, cost, and production volume. Each method offers distinct benefits that can support various industrial needs, from power electronics to high-frequency communication systems.

Ceramic PCB vs. FR4

When comparing Ceramic PCBs with traditional FR4 boards, significant differences arise in their physical and electrical properties, which influence their suitability for various applications. Ceramic materials such as alumina, aluminum nitride, and beryllium oxide offer substantial advantages over FR4, particularly in thermal and mechanical performance.

- Physical and Electrical Properties: Ceramic PCBs are known for their high thermal conductivity, which far exceeds that of FR4. This capability allows ceramic boards to effectively dissipate heat generated by high-power components, reducing thermal strain and enhancing durability. Additionally, ceramic materials exhibit better mechanical strength than FR4, making them more resilient to vibration, mechanical stress, and extreme environmental conditions. From an electrical standpoint, ceramic substrates offer superior insulation and lower dielectric loss, essential for high-frequency and high-power applications. FR4, while adequate for most consumer electronics, has limited thermal performance and higher dielectric loss, which can hinder signal integrity in high-speed circuits.

- Advantages of Ceramic in Thermal Conductivity, Mechanical Strength, and Environmental Adaptability: Ceramic substrates provide unparalleled thermal conductivity, a property crucial for power electronics and LED applications where efficient heat management is necessary. Furthermore, ceramic boards withstand higher mechanical loads and offer excellent structural stability, ideal for aerospace, automotive, and industrial settings where mechanical reliability is paramount. Ceramic’s resilience to extreme temperatures and humidity also makes it highly adaptable to harsh environmental conditions, whereas FR4 may degrade or lose performance in such conditions.

- Benefits of Ceramic in High-Temperature and High-Frequency Applications: In applications that demand high temperatures, such as power modules or RF equipment, ceramic PCBs provide significant benefits. Their high thermal tolerance prevents heat-related damage and reduces failure risks, allowing devices to operate consistently even under prolonged thermal stress. Additionally, ceramic’s low dielectric loss and stable electrical properties are advantageous in high-frequency applications, where signal integrity and minimal interference are crucial. This makes ceramic substrates the preferred choice for RF circuits, microwave communication devices, and other high-frequency applications, where FR4 may struggle to maintain signal quality and consistency.

While FR4 remains a cost-effective and widely used material, ceramic PCBs offer distinct advantages in thermal management, mechanical strength, and performance under challenging environmental conditions. These qualities make ceramic the superior choice for high-power, high-frequency, and high-temperature applications, providing reliability and performance that FR4 cannot match in demanding scenarios.

Design Considerations for Multilayer Ceramic PCBs

When designing Multilayer Ceramic PCBs, several factors need to be considered to leverage the unique advantages of ceramic materials while addressing any potential challenges in comparison to traditional FR4-based PCBs. These considerations primarily involve thermal management, mechanical strength, electrical performance, and the adaptability of the material to high-performance applications.

- Comparison of Physical and Electrical Properties: Ceramic substrates, including alumina, aluminum nitride, and beryllium oxide, exhibit superior physical and electrical properties compared to FR4. While FR4, a fiberglass-reinforced epoxy laminate, is widely used for standard PCBs, it has limited thermal conductivity and mechanical strength. In contrast, ceramic materials offer high thermal conductivity, ensuring efficient heat dissipation, which is essential for high-power devices such as power electronics, LED applications, and RF circuits. Ceramics also offer lower dielectric loss, making them more suitable for high-frequency applications where maintaining signal integrity is crucial.Mechanical strength is another key advantage of ceramic over FR4. Ceramic substrates are more durable and resistant to mechanical stress, vibration, and thermal cycling, making them ideal for aerospace, automotive, and industrial applications where physical reliability is critical. The high mechanical strength of ceramics contributes to the stability of multilayer ceramic PCBs, allowing them to withstand the stresses imposed by complex, high-performance devices.In terms of electrical properties, ceramic PCBs provide excellent insulation and high-voltage resistance. Their high dielectric constant and low electrical loss make them suitable for use in RF and microwave applications, where signal clarity and integrity are crucial for device performance. On the other hand, FR4, while sufficient for most general-purpose electronics, tends to exhibit higher signal attenuation at high frequencies, limiting its effectiveness in high-performance applications.

- Ceramic Material Advantages in Thermal Conductivity, Mechanical Strength, and Environmental Adaptability: Thermal conductivity is one of the key reasons ceramic materials are preferred over FR4 in many advanced applications. Ceramic substrates can efficiently dissipate heat generated by power-intensive components, reducing the risk of overheating and extending the lifespan of the device. Materials like aluminum nitride (AlN) and beryllium oxide (BeO) offer exceptional thermal conductivity, which is crucial in power electronics, high-power LEDs, and laser diodes.Additionally, ceramics are highly resistant to thermal expansion and thermal cycling, making them ideal for use in high-temperature environments. Multilayer ceramic PCBs maintain their structural integrity even when exposed to rapid temperature fluctuations, unlike FR4, which may expand, contract, or degrade over time due to prolonged exposure to heat.In terms of mechanical strength, ceramic materials are significantly more durable than FR4, providing high dimensional stability and resilience to mechanical stress. This characteristic is particularly important in applications where the PCB will be subjected to mechanical vibrations, such as in automotive or military systems.Environmental adaptability is another strength of ceramic PCBs. They perform well in challenging environments, including exposure to humidity, extreme temperatures, and harsh chemicals. This makes ceramics ideal for use in industries such as aerospace, medical, and industrial control systems, where environmental conditions can vary greatly.

- Unique Benefits of Ceramic in High-Temperature and High-Frequency Applications: Ceramic substrates offer distinct advantages in high-temperature applications, where FR4 materials would typically fail. For example, ceramic PCBs can withstand temperatures in excess of 300°C, making them ideal for applications like power electronics, high-efficiency converters, and automotive power modules, where high heat levels are generated. The high melting point of ceramic materials ensures that they do not degrade under such conditions, unlike FR4, which may soften or burn at high temperatures.In high-frequency applications, ceramic substrates offer low dielectric loss, which ensures that signals are transmitted with minimal attenuation. This is a key factor in applications like microwave devices, RF circuits, and communication systems, where maintaining signal integrity is paramount. Ceramic’s ability to handle high-frequency signals with minimal signal distortion or loss makes it far superior to FR4 in these use cases.

In multilayer ceramic PCBs, the ability to stack layers of ceramic material enables the creation of more compact, high-density circuit boards that meet the rigorous thermal and mechanical demands of modern electronic devices. The integration of multiple ceramic layers allows for the embedding of passive components like resistors and capacitors, further enhancing the board’s functionality and reducing the need for additional components.

When designing multilayer ceramic PCBs, the selection of ceramic materials plays a crucial role in maximizing performance in applications requiring high thermal conductivity, mechanical strength, and environmental stability. Ceramic substrates outperform FR4 in demanding environments such as high-power electronics, high-frequency systems, and extreme temperature applications, making them the ideal choice for next-generation electronic devices. Designers must consider these properties to fully exploit the benefits of ceramic materials in the most critical applications.

Applications of Ceramic Substrate Circuit Boards

Ceramic substrate circuit boards have emerged as a crucial material in a variety of industries, offering unmatched performance in applications that require high thermal conductivity, mechanical strength, and stability under extreme conditions. Below, we delve into some of the most prominent applications where ceramic PCBs are being utilized.

- Electric Vehicles and New Energy: Ceramic substrates are increasingly being used in the electric vehicle (EV) and new energy sectors, primarily in the development of battery management systems (BMS) and electric drive modules. In EVs, efficient heat management is critical due to the high energy demands placed on batteries and drive systems. Ceramic PCBs provide excellent thermal conductivity, allowing for better heat dissipation, which helps prevent overheating and enhances the overall efficiency and longevity of battery packs. The high mechanical strength of ceramic also ensures the durability of components in rugged automotive environments. Additionally, ceramic substrates are ideal for managing power conversion systems, where high reliability is paramount. Their ability to withstand high temperatures makes them perfect for the demanding conditions of electric vehicle components that require stability and performance in high-heat scenarios.

- Medical Devices: In medical devices, particularly those requiring high precision and reliability, ceramic PCBs play a vital role. Applications like implantable devices, surgical instruments, and diagnostic equipment require materials that can withstand extreme conditions and deliver consistent performance over long periods. Ceramic substrates are known for their excellent insulation properties, which help ensure that sensitive medical devices function without interference from external electrical signals. Their thermal stability and resistance to corrosion also make them suitable for devices exposed to harsh environments, such as sterilization processes or high temperatures. Furthermore, the biocompatibility of certain ceramic materials like alumina is an advantage in applications where components may come into contact with bodily fluids. Ceramic substrates’ high reliability and stability make them a preferred choice in medical electronics, ensuring the safety and longevity of critical medical devices.

- Power Electronics: Power electronics benefit significantly from the use of ceramic substrates, especially in power conversion and high-frequency switching applications. Ceramic PCBs are ideal for use in power supplies, inverters, converters, and voltage regulators due to their superior thermal conductivity, which helps to dissipate the heat generated during power conversion processes. High-performance power modules in industrial systems, such as motor drives, power inverters, and solar power converters, rely on ceramic substrates to handle the substantial heat load generated by power switching components like IGBTs (Insulated Gate Bipolar Transistors) and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors). Ceramic’s ability to maintain structural integrity under thermal and mechanical stress ensures reliable operation in environments that experience frequent power fluctuations. Additionally, high-frequency switching applications in power electronics benefit from ceramic substrates’ ability to handle high voltages and minimize signal loss or degradation during power transmission.

- 5G and High-Frequency Communication: In the rapidly growing field of 5G communications and high-frequency signal transmission, ceramic substrates offer distinct advantages over traditional PCB materials like FR4. 5G networks require high-frequency circuits capable of transmitting signals at very high speeds with minimal loss. Ceramic materials like aluminum nitride (AlN) and beryllium oxide (BeO) are particularly well-suited for these high-frequency applications due to their low dielectric loss, which minimizes signal attenuation and ensures clear, reliable communication. The thermal conductivity of ceramic also plays a crucial role in the performance of high-frequency devices by managing the heat generated during high-speed signal transmission. These substrates are used in RF modules, antennas, switches, and amplifiers that are essential components of 5G base stations, as well as in satellite communication systems, mobile phones, and wireless network infrastructure. The ability of ceramics to perform reliably under high heat and high-frequency conditions ensures that 5G networks operate at peak performance with minimal interference.

Ceramic substrate circuit boards are indispensable in a wide range of advanced electronic applications, from electric vehicles and new energy systems to medical devices, power electronics, and 5G communications. Their ability to handle extreme temperatures, dissipate heat, and maintain electrical stability under high-frequency conditions makes them a key material for next-generation electronics that require high reliability, performance, and durability. As technology continues to advance, the demand for ceramic substrates is expected to grow, particularly in industries that require robust, high-performance materials for mission-critical applications.

Recommended Ceramic PCB Manufacturers

The global demand for ceramic PCBs has spurred the growth of numerous specialized manufacturers offering high-quality ceramic substrate circuit boards. Below is an overview of some leading manufacturers known for their expertise in ceramic PCB production, including Heraeus, Sierra Assembly, and Rocket PCB. Each of these manufacturers brings distinct capabilities to the table, catering to various industries ranging from power electronics to high-frequency communication.

ALCANTAPCB:is a leading manufacturer specializing in the production of ceramic PCBs, particularly known for its advanced ceramic substrates used in high-performance electronic applications. With a focus on providing high-quality and reliable solutions, ALCANTAPCB has earned a reputation for delivering tailored ceramic PCB solutions for a wide range of industries, including automotive, telecommunications, medical devices, and power electronics.

Their expertise lies in the production of high-temperature co-fired ceramics (HTCC) and low-temperature co-fired ceramics (LTCC), making them ideal for power electronics that require high thermal conductivity and excellent electrical insulation. ALCANTAPCB offers multilayer ceramic PCBs, which are essential for high-frequency communication devices and power modules that demand durability under extreme conditions.

What sets ALCANTAPCB apart is their ability to provide custom designs with precision fabrication, ensuring that each product meets the specific requirements of the application. Whether you’re looking for ceramic substrates for power modules, LED technology, or high-frequency circuits, ALCANTAPCB’s extensive experience and commitment to quality make them a reliable choice for your ceramic PCB needs.

Heraeus: Heraeus is a renowned leader in the field of advanced electronic materials, including metal-ceramic substrates. The company is widely recognized for its high-performance ceramic substrates used in power electronics, automotive, medical devices, and telecommunications. Heraeus specializes in high-temperature co-fired ceramics (HTCC) and low-temperature co-fired ceramics (LTCC), offering excellent thermal management solutions for applications requiring high thermal conductivity and electrical insulation. Their metal-ceramic substrates are particularly sought after for power modules, LED technology, and high-power devices, where performance under extreme conditions is critical. Heraeus’s focus on customized solutions for demanding applications sets them apart in industries requiring precision and reliability in high-performance settings.

Sierra Assembly: Sierra Assembly is a leading PCB fabrication and assembly service provider that also specializes in ceramic substrates. They offer a wide range of ceramic PCB manufacturing options, including HTCC, LTCC, and thin-film ceramics. Sierra Assembly’s expertise lies in producing multilayer ceramic PCBs and advanced ceramic substrates for industries such as medical electronics, automotive, telecommunications, and industrial applications. Their ceramic substrates are particularly valued for their high reliability, low dielectric loss, and high-frequency stability. Sierra Assembly provides custom design support, helping customers develop highly specialized ceramic PCBs tailored to unique project requirements. Their robust capabilities in both prototype and high-volume production make them a versatile choice for various industries.

Rocket PCB: Rocket PCB is a global PCB manufacturer with a strong emphasis on ceramic PCB technology. The company provides comprehensive solutions for ceramic substrate circuit boards, offering both thick-film and thin-film ceramic PCBs. Rocket PCB is known for its high-precision ceramic PCBs, which are used extensively in industries such as power electronics, high-frequency communication, and automotive applications. They specialize in Direct Bonded Copper (DBC) technology, which is ideal for power modules, and Direct Plated Copper (DPC) for high-performance applications. Rocket PCB is recognized for its ability to deliver fast turnaround times, competitive pricing, and high-quality ceramic substrates that meet the stringent demands of RF components, LED modules, and high-power devices. Their ability to combine high reliability with cost-effective production makes them a popular choice among customers looking for reliable ceramic PCB solutions.

Summary of Each Manufacturer’s Specialties

| Manufacturer | Specialties | Main Products | Typical Applications |

| ALCANTAPCB | High-performance ceramic PCBs, customized ceramic solutions | HTCC, LTCC, multilayer ceramic PCBs | Power electronics, automotive, medical devices, high-frequency communication |

| Heraeus | Metal-ceramic substrates, high-performance ceramic substrates | HTCC, LTCC, metal-ceramic substrates | Power modules, LED technology, high-power electronics, automotive |

| Sierra Assembly | Multilayer ceramic PCBs, advanced ceramic substrates | HTCC, LTCC, thin-film ceramics | Medical devices, telecommunications, industrial applications |

| Rocket PCB | High-precision ceramic PCBs, DBC and DPC technology | Thick-film and thin-film ceramic PCBs | Power electronics, high-frequency communication, automotiveabout |

About Ceramic Substrate Circuit Board FQAS

A ceramic substrate for power electronics refers to a material used as the base for electronic components and circuits in high-power applications. These substrates are typically made from materials like aluminum nitride (AlN), alumina (Al₂O₃), or beryllium oxide (BeO), which are known for their excellent thermal conductivity and electrical insulation properties. In power electronics, ceramic substrates are crucial because they efficiently manage the heat generated by power devices such as power transistors, diodes, and power converters. The ability of ceramics to dissipate heat prevents overheating and ensures the reliable operation of power components, making them essential for power modules, LED drivers, and motor control systems.

The best substrate for a PCB depends on the specific requirements of the application, such as electrical performance, cost, thermal management, and flexibility. FR4 (a fiberglass-epoxy laminate) is the most commonly used substrate material for general-purpose PCBs due to its cost-effectiveness and adequate mechanical and electrical properties. However, for high-performance applications like power electronics, high-frequency devices, and LED modules, materials like ceramic substrates (e.g., aluminum nitride and alumina) offer superior thermal conductivity, high voltage resistance, and electrical insulation. Other alternatives like polyimide and PTFE may be ideal for flexible or high-speed circuits.

A ceramic substrate is a type of substrate material made from ceramic compounds, such as alumina, aluminum nitride, or beryllium oxide. Ceramic substrates are known for their high thermal conductivity, electrical insulation, and mechanical strength, which makes them ideal for high-power, high-frequency, and high-temperature electronic applications. They are often used in power electronics, LED technology, and telecommunication devices due to their superior heat dissipation properties. Ceramic substrates are also highly resistant to chemical corrosion and can withstand harsh environmental conditions, making them suitable for demanding applications like automotive and military electronics.

The substrate of a circuit board is the foundational material that provides mechanical support and electrical insulation to the components of the PCB. It acts as the base layer to which electrical traces, vias, and components are attached. The substrate material is crucial for the overall performance of the circuit board, as it influences the electrical conductivity, thermal dissipation, flexibility, and durability of the PCB. Common substrate materials include FR4 (fiberglass-epoxy laminate), which is widely used in standard PCBs, as well as ceramic materials, polyimide, and PTFE for specialized applications. The choice of substrate material depends on the application’s requirements for heat management, electrical insulation, and mechanical strength.