The Role of Rogers PCB Material Dielectric Constant in Design

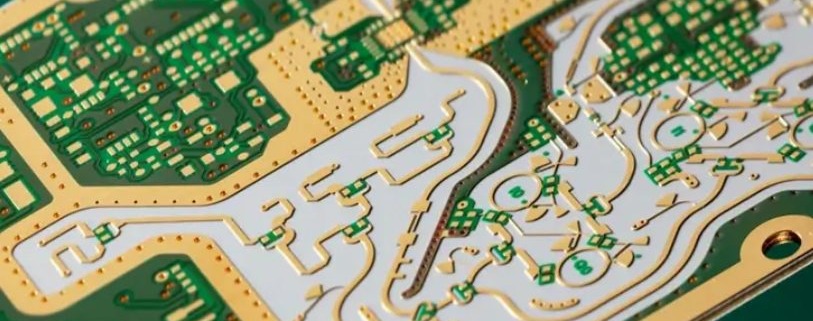

Rogers PCB materials are renowned for their exceptional performance in high-frequency applications, making them a top choice for engineers and designers in various industries. These materials, including popular variants like Rogers 4003 and Rogers 4350B, are specifically engineered to minimize signal loss and enhance thermal stability, crucial for modern electronic devices. Understanding the properties of these materials is vital for optimizing circuit designs, particularly in telecommunications, aerospace, and medical applications.

One of the key characteristics of Rogers PCB materials is their dielectric constant, which significantly influences signal integrity and performance. The dielectric constant measures a material’s ability to store electrical energy in an electric field, impacting the speed at which signals propagate through the PCB. Therefore, comprehending the rogers pcb material dielectric constant is essential for designers aiming to achieve reliable and efficient circuit performance in high-frequency environments.

What is Dielectric Constant(Rogers PCB Material Dielectric Constant)?

Definition of Rogers PCB Material Dielectric Constant

The dielectric constant, often denoted as ε, is a fundamental property of materials that quantifies their ability to store electrical energy in an electric field. In the context of PCB materials, the dielectric constant reflects how well a material can insulate and influence the propagation of electrical signals. For Rogers PCB materials, the dielectric constant is a critical parameter that helps determine their suitability for high-frequency applications.

Importance of Dielectric Constant for Signal Integrity and Performance

The importance of the dielectric constant cannot be overstated, as it directly impacts signal integrity and overall performance. A lower dielectric constant typically results in faster signal propagation speeds, which is essential for high-speed digital and RF applications. Conversely, a higher dielectric constant can lead to increased capacitance, potentially causing delays in signal transmission. Therefore, understanding the rogers pcb material dielectric constant is essential for designers who want to ensure optimal performance and reliability in their circuit designs. By selecting materials with the appropriate dielectric constant, engineers can minimize signal loss, reduce electromagnetic interference, and enhance the overall efficiency of their PCBs.

Dielectric Constant of Common PCB Materials

When designing PCBs, understanding the dielectric constant of various materials is crucial for optimizing performance. Different PCB materials have distinct dielectric constants, which significantly influence signal transmission and overall circuit behavior. Here, we compare the dielectric constants of commonly used PCB materials, focusing on FR-4 and Rogers materials.

Comparison of Dielectric Constants

- FR-4:

- FR-4 is the most widely used material for PCBs, particularly in consumer electronics. Its typical dielectric constant ranges from 4.2 to 4.5, depending on the specific formulation and thickness. While it is cost-effective and offers decent performance, its higher dielectric constant can lead to signal degradation at high frequencies.

2. Rogers Materials:

- Rogers PCB materials, such as RO4003 and RO4350B, are engineered for high-frequency applications. The dielectric constant for RO4003 is approximately 3.48, while RO4350B maintains a similar value. This lower dielectric constant compared to FR-4 allows Rogers materials to provide better signal integrity and lower loss, making them ideal for telecommunications, aerospace, and high-speed digital applications.

Overview of FR-4 vs. Rogers

The primary difference between FR-4 and Rogers materials lies in their dielectric properties. While FR-4 is suitable for many general-purpose applications, its higher dielectric constant can hinder performance in high-frequency circuits. In contrast, Rogers materials are specifically designed to minimize signal loss and maintain high performance, thanks to their lower dielectric constants. This characteristic makes Rogers materials preferable for applications requiring precision and reliability.

Typical Values for Various PCB Materials

- FR-4: 4.2 to 4.5

- Rogers 4003: ~3.48

- Rogers 4350B: ~3.48

- Rogers 5880: ~2.94

- Other materials: Typical values for specialized materials can vary widely, so it’s essential to refer to the manufacturer’s datasheets for precise specifications.

The choice of PCB material based on dielectric constant is crucial for achieving the desired performance, especially in high-frequency applications. Understanding the differences between FR-4 and Rogers materials can help designers make informed decisions for their projects.

Dielectric Constant of Rogers Materials

Rogers materials are specifically designed for high-frequency applications, offering excellent electrical properties that are crucial for maintaining signal integrity. Here, we explore the dielectric constants of three prominent Rogers materials: Rogers 4003, Rogers 4350B, and Rogers 5880.

Rogers 4003

Rogers 4003 is a popular choice for RF and microwave applications due to its balanced performance characteristics.

- Dielectric Constant: The dielectric constant of Rogers 4003 is approximately 3.48.

- Specifications:

- Thickness: Available in various thicknesses ranging from 0.005″ to 0.060″.

- Loss Tangent (tan δ): Around 0.0027 at 10 GHz, indicating low signal loss.

- Thermal Stability: High thermal stability, making it suitable for applications requiring reliable performance under varying temperatures.

Rogers 4003 is commonly used in antennas, filters, and other high-frequency components, where maintaining signal integrity is essential.

Rogers 4350B

Rogers 4350B is another widely utilized material known for its superior performance in demanding applications.

- Dielectric Constant: The dielectric constant of Rogers 4350B is also around 3.48.

- Overview:

- Thickness: Available in thicknesses from 0.005″ to 0.062″.

- Loss Tangent (tan δ): Approximately 0.0015 at 10 GHz, making it one of the lowest-loss materials in the Rogers lineup.

- Applications: Ideal for high-frequency circuits, telecommunications, and aerospace applications due to its excellent thermal and electrical performance.

The low loss and consistent dielectric constant of Rogers 4350B make it a preferred choice for designers seeking optimal performance in high-speed and high-frequency applications.

Rogers 5880

Rogers 5880 is another advanced laminate, particularly suitable for applications requiring a low dielectric constant.

- Characteristics:

- Dielectric Constant: The dielectric constant of Rogers 5880 is approximately 2.94, which is significantly lower than both Rogers 4003 and 4350B.

- Application Areas: Primarily used in high-speed digital applications and RF circuits where signal integrity and speed are critical.

Rogers 5880’s lower dielectric constant contributes to reduced capacitance and improved signal propagation speeds, making it an excellent choice for cutting-edge technologies.

Rogers materials like 4003, 4350B, and 5880 provide a range of dielectric constants and characteristics tailored for various high-frequency applications. Understanding the specific dielectric constant values and their implications is essential for selecting the right material for PCB designs, ensuring optimal performance and reliability.

Impact of Dielectric Constant on Performance

The dielectric constant of PCB materials plays a critical role in determining the performance of electronic circuits, especially in high-frequency applications. Understanding how the dielectric constant affects signal propagation speed and attenuation is essential for designers aiming to achieve optimal circuit performance.

How Dielectric Constant Affects Signal Propagation Speed and Attenuation

- Signal Propagation Speed:

- The dielectric constant (ε) directly influences the speed at which electrical signals travel through a material. The speed of a signal in a dielectric medium is given by the equation:

[

v = \frac{c}{\sqrt{\epsilon_r}}

]

where (c) is the speed of light in a vacuum and (\epsilon_r) is the relative dielectric constant of the material. - A lower dielectric constant results in a higher propagation speed. For example, Rogers materials like RO5880, with a dielectric constant of approximately 2.94, allow signals to propagate faster than those in FR-4, which has a dielectric constant of about 4.2. This increased speed can be crucial in high-speed digital and RF applications, reducing delays and improving overall system performance.

2. Signal Attenuation:

- The dielectric constant also affects the attenuation of signals as they travel through the PCB material. Higher dielectric constants typically result in increased dielectric loss, which can lead to greater signal attenuation.

- For instance, materials with lower loss tangents, such as Rogers 4350B, exhibit reduced attenuation, allowing signals to maintain integrity over longer distances. This characteristic is particularly important in applications like telecommunications, where signal fidelity is critical.

Implications for Design Choices in High-Frequency Applications

- Material Selection:

- Designers must carefully select PCB materials based on their dielectric constants and associated performance characteristics. Materials with lower dielectric constants and lower loss tangents, like Rogers 4003 and 4350B, are preferred for high-frequency applications to ensure faster signal propagation and minimal loss.

2. Circuit Layout and Design:

- The choice of dielectric constant affects not only material selection but also the design of the circuit itself. For instance, the spacing between traces, the width of transmission lines, and the overall layout must be optimized to accommodate the chosen material’s dielectric properties.

- Designers often use simulation tools to model how different dielectric constants will impact the performance of their circuits, allowing for adjustments that maximize efficiency and reliability.

3. Impact on Performance Metrics:

- The dielectric constant also influences key performance metrics such as rise time, signal integrity, and bandwidth. Higher-speed applications demand careful consideration of these factors, as even minor losses can have significant consequences on overall system performance.

The dielectric constant is a vital parameter that directly impacts signal propagation speed and attenuation in PCB materials. Understanding these effects enables designers to make informed choices regarding material selection and circuit design, ensuring optimal performance in high-frequency applications. As technology continues to advance, the importance of selecting the right dielectric properties becomes increasingly critical in achieving the desired functionality and reliability in electronic devices.

Practical Considerations for PCB Designers

When designing PCBs, especially for high-frequency applications, understanding and selecting materials based on their dielectric constant is crucial for ensuring optimal performance. Here are some practical considerations for PCB designers:

Tips for Selecting Materials Based on Dielectric Constant

- Assess Application Requirements:

- Determine the specific requirements of your application, including frequency ranges, signal integrity needs, and environmental conditions. High-frequency applications often necessitate materials with lower dielectric constants and loss tangents to minimize signal degradation and improve performance.

2. Consider Frequency Response:

- Select materials that offer suitable dielectric constants for the operating frequency. For example, Rogers materials like RO4003 and RO4350B, with dielectric constants around 3.48, are ideal for RF applications, while Rogers 5880, with a lower dielectric constant of approximately 2.94, may be preferred for ultra-high-speed digital applications.

3. Evaluate Thermal Properties:

- Consider the thermal stability of the material in addition to the dielectric constant. Materials that maintain their dielectric properties at elevated temperatures, such as Rogers PCB materials, can help ensure consistent performance under varying thermal conditions.

4. Look for Low Loss Characteristics:

- Focus on materials with low loss tangents to minimize signal loss. Materials like Rogers 4350B, with a low loss tangent, provide better performance in high-frequency circuits by reducing attenuation.

5. Account for Fabrication Processes:

- Different materials may have varying compatibility with fabrication processes. Ensure that the selected material can be processed with your chosen PCB manufacturing techniques without compromising performance or integrity.

Importance of Referring to Manufacturer Datasheets for Accurate Values

- Access to Detailed Specifications:

- Manufacturer datasheets provide crucial information about the dielectric constant, loss tangent, thermal properties, and other relevant characteristics of PCB materials. These specifications are essential for making informed design decisions.

2. Understand Variability:

- The dielectric constant can vary based on the material’s thickness, frequency of operation, and environmental factors. Datasheets typically offer a range of values and conditions, allowing designers to understand the material’s performance under different scenarios.

3. Ensure Compliance with Standards:

- Many applications require adherence to specific industry standards. Manufacturer datasheets provide compliance information that can help designers ensure their materials meet necessary regulatory and performance criteria.

4. Guidance on Application and Usage:

- Datasheets often include recommendations for the best applications and usage scenarios for each material. This guidance can help designers select the most appropriate material for their specific needs.

Selecting the right PCB materials based on dielectric constant involves careful consideration of application requirements, frequency response, thermal stability, and loss characteristics. Referring to manufacturer datasheets is essential for obtaining accurate values and ensuring that the chosen materials meet the performance demands of high-frequency applications. By following these practical tips, PCB designers can optimize their designs for reliability and efficiency, ultimately leading to better-performing electronic devices.

FQAs Abut Rogers PCB Material Dielectric Constant

The dielectric constant of PCB materials varies widely depending on the specific type. Common materials like FR-4 typically have a dielectric constant ranging from 4.2 to 4.5, while specialized materials like Rogers 4003 and 4350B have dielectric constants around 3.48.

FR-4 has a dielectric constant of approximately 4.2 to 4.5, while Rogers materials, such as RO4003 and RO4350B, have lower dielectric constants of about 3.48. The lower dielectric constant in Rogers materials allows for better signal integrity and reduced losses in high-frequency applications.

The dielectric constant of Rogers 4003 is approximately 3.48. This low value is beneficial for high-frequency circuit applications, helping to minimize signal degradation.

The dielectric constant of Rogers 4350B is also around 3.48. Like Rogers 4003, this low dielectric constant contributes to improved performance in high-speed and high-frequency applications.