PCB Substrates: Key Factors and Application Insights

PCB Substrate serves as the foundation of a printed circuit board (PCB), providing mechanical support and electrical connectivity for electronic components. Its significance lies in ensuring the structural integrity of the PCB while facilitating the transmission of signals between components. Functionally, Substrate PCB acts as a dielectric material between copper traces, preventing short circuits and facilitating the flow of electrical signals across the board. Moreover, it influences the PCB’s thermal and electrical performance, affecting factors like signal integrity and reliability. Understanding the role of Substrate PCB is crucial in optimizing circuit board design for various applications, ensuring robust performance and longevity of electronic devices.

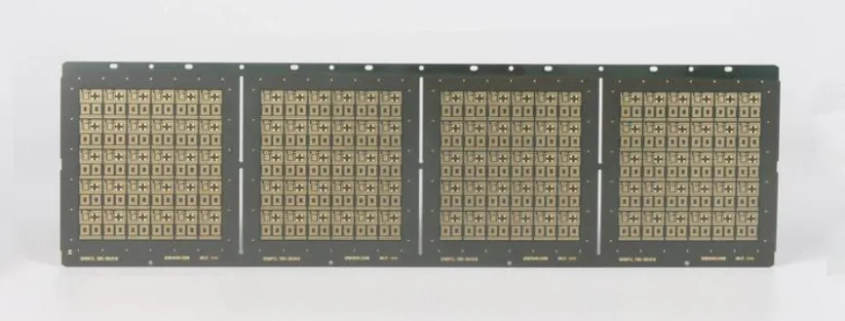

Analyzing Common Types of PCB Substrate

R4 Substrate

FR4 is the most widely used substrate material in PCB manufacturing due to its affordability and versatility. It is composed of woven fiberglass cloth impregnated with an epoxy resin binder. FR4 offers good mechanical strength, thermal stability, and flame resistance. However, its drawbacks include relatively high CTE and dielectric constant compared to other substrates.

Polyimide (PI) Substrate

Polyimide substrates, often referred to as Kapton, are known for their excellent thermal stability and chemical resistance. They are commonly used in flexible and high-temperature applications where traditional FR4 substrates may not suffice. Polyimide substrates exhibit low CTE and a moderate dielectric constant, making them suitable for demanding environments.

Polyamide (PA) Substrate

Polyamide substrates, such as DuPont’s Pyralux, are similar to polyimide substrates but offer enhanced flexibility and improved mechanical properties. They are frequently employed in flexible PCBs for applications requiring bendability and reliability. Polyamide substrates typically feature low CTE and a moderate dielectric constant, making them suitable for a wide range of applications.

Metal Substrates

Metal substrates, such as aluminum or copper, are used in specialized PCBs requiring superior thermal conductivity and heat dissipation capabilities. These substrates are often utilized in high-power LED lighting, automotive electronics, and power electronic applications. Metal substrates exhibit low CTE and high thermal conductivity, enabling efficient heat transfer away from sensitive components.

Comparing Characteristics of Various PCB Substrates

When comparing different PCB substrates, key characteristics to consider include:

– Coefficient of Thermal Expansion (CTE): Indicates the material’s tendency to expand or contract with changes in temperature. Lower CTE values are desirable for minimizing thermal stresses on components.

– Dielectric Constant: Determines the substrate’s ability to store electrical energy and affects signal propagation speed. Lower dielectric constants result in reduced signal attenuation and better high-frequency performance.

– Mechanical Strength: Reflects the substrate’s ability to withstand mechanical stress, bending, and impact without deformation or failure.

– Thermal Stability: Indicates the substrate’s ability to maintain its properties over a wide temperature range without significant degradation.

By evaluating these characteristics, designers can select the most appropriate substrate for their specific application requirements, balancing factors such as cost, performance, and environmental conditions.

Guide to Choosing PCB Substrate

Selecting the Most Suitable PCB Substrate for Project Requirements

Choosing the right PCB substrate is crucial for the success of any electronic project. Here’s a detailed guide on how to make the best selection:

1. Define Project Requirements: Begin by clearly understanding the project’s technical specifications, environmental conditions, and performance expectations. Consider factors such as operating temperature, humidity, mechanical stress, and electrical requirements.

2. Evaluate Material Properties: Research and compare the properties of different PCB substrates available in the market. Pay close attention to characteristics like thermal conductivity, dielectric constant, CTE, mechanical strength, and flame resistance.

3. Consider Application-Specific Needs: Different applications may require specific substrate properties. For example, high-frequency applications may prioritize substrates with low dielectric constants, while automotive electronics may require substrates with high thermal conductivity and reliability.

4. Assess Cost and Availability: Factor in the cost and availability of the chosen substrate material. While high-performance substrates may offer superior properties, they can also be more expensive. Ensure that the chosen substrate aligns with the project’s budget constraints and is readily available from reliable suppliers.

5. Evaluate Manufacturing Compatibility: Consider the compatibility of the chosen substrate with the PCB manufacturing process. Ensure that the substrate material can be easily processed, laminated, drilled, and soldered without compromising quality or reliability.

Key Factors in Choosing PCB Substrate Based on Specific Circuit Board Requirements

When selecting a PCB substrate, several key factors must be considered to meet specific circuit board requirements:

1. Thermal Management: If the project involves components that generate significant heat, prioritize substrates with high thermal conductivity and low CTE to ensure efficient heat dissipation and minimize thermal stresses.

2. Signal Integrity: For high-speed and high-frequency applications, opt for substrates with low dielectric constants and low loss tangents to maintain signal integrity, minimize signal attenuation, and reduce electromagnetic interference (EMI).

3. Mechanical Durability: Choose substrates with adequate mechanical strength and dimensional stability to withstand mechanical stress, vibration, and shock without compromising the structural integrity of the PCB.

4. Environmental Compatibility: Consider the operating environment and exposure to factors like moisture, chemicals, and UV radiation. Select substrates with suitable resistance to environmental conditions to ensure long-term reliability and performance.

5. Regulatory Compliance: Ensure that the chosen substrate complies with relevant industry standards and regulations, such as RoHS (Restriction of Hazardous Substances) directives, to meet legal and environmental requirements.

By carefully evaluating these factors and considering the specific requirements of the project, designers can confidently select the most suitable PCB substrate to optimize performance, reliability, and cost-effectiveness.

Contrasting PCB Substrate and IC Substrate

PCB Substrate:

1. Definition: PCB substrate refers to the base material upon which electronic components are mounted and interconnected to form a printed circuit board (PCB).

2. Functionality: PCB substrate provides mechanical support, electrical connectivity, and insulation between conductive traces on the PCB. It serves as a foundation for mounting components and routing electrical signals.

3. Material: PCB substrates can be made from various materials such as FR4, polyimide, polyamide, or metal substrates, each offering different properties and performance characteristics.

4. Importance: PCB substrate plays a critical role in circuit board design by influencing factors like thermal management, signal integrity, mechanical durability, and overall reliability of the PCB.

IC Substrate:

1. Definition: IC substrate, also known as package substrate or chip carrier, is a specialized substrate used to mount and interconnect integrated circuits (ICs) or semiconductor chips within a package.

2. Functionality: IC substrate provides electrical connections between the IC chip and the package leads or pins. It serves as a medium for transmitting signals and power between the IC chip and the external circuitry.

3. Material: IC substrates are typically made from materials such as ceramic, organic substrates (e.g., FR4), or metal substrates, depending on the specific requirements of the IC package and application.

4. Importance: While IC substrates are essential for packaging and interconnecting semiconductor chips, their role is primarily focused on providing electrical connections and mechanical support for the IC package. They play a crucial role in protecting the IC chip and facilitating its integration into electronic devices.

Emphasizing the Importance of PCB Substrate in Circuit Board Design

1. Foundation of Circuit Design: PCB substrate forms the foundation of circuit board design, providing the structural support and electrical connectivity necessary for integrating electronic components into functional systems.

2. Influence on Performance: The choice of PCB substrate significantly impacts the performance and reliability of the entire circuit board. Factors such as thermal conductivity, dielectric constant, and mechanical strength of the substrate can affect signal integrity, thermal management, and overall system functionality.

3. Customization and Optimization: Designers can customize and optimize PCB substrates to meet specific project requirements, such as high-speed signal transmission, thermal dissipation, or compact form factors. This flexibility allows for the creation of tailored solutions for diverse applications.

4. Long-Term Reliability: A well-selected PCB substrate ensures long-term reliability and durability of electronic devices by minimizing the risk of electrical failures, signal degradation, and mechanical damage over time.

In summary, while both PCB substrate and IC substrate play essential roles in electronic design and packaging, the PCB substrate holds greater importance in circuit board design due to its influence on overall performance, reliability, and functionality of electronic systems.

Exploring the Best PCB Substrate

Most Suitable PCB Substrate for Different Application Scenarios

1. High-Frequency Applications: For high-frequency applications such as telecommunications, radar systems, and RF devices, substrates with low dielectric constants like Rogers materials or polytetrafluoroethylene (PTFE) are preferred. These substrates minimize signal loss and maintain signal integrity at higher frequencies.

2. High-Temperature Environments: In applications exposed to high temperatures, such as automotive electronics, industrial controls, and aerospace systems, substrates with excellent thermal stability like polyimide (PI) or ceramic substrates are ideal. These substrates can withstand elevated temperatures without compromising performance.

3. Flexibility and Bendability: Flexible PCB substrates, such as polyimide (PI) or polyamide (PA) materials, are suitable for applications requiring flexibility and bendability, such as wearable devices, medical implants, and flexible displays. These substrates offer excellent mechanical flexibility while maintaining electrical performance.

4. High-Power and LED Lighting: Metal core PCB substrates, typically aluminum or copper-based, are preferred for high-power applications like LED lighting, power electronics, and automotive lighting systems. These substrates offer superior thermal conductivity, allowing efficient heat dissipation and improved reliability.

Analysis of Pros and Cons of Various PCB Substrates

1. FR4 Substrate:

– Pros: Cost-effective, readily available, good mechanical strength, and flame resistance.

– Cons: Relatively high dielectric constant and coefficient of thermal expansion (CTE), limited suitability for high-frequency applications.

2. Polyimide (PI) Substrate:

– Pros: Excellent thermal stability, chemical resistance, and flexibility.

– Cons: Higher cost compared to FR4, limited mechanical strength, may require specialized processing techniques.

3. Metal Core Substrate:

– Pros: Superior thermal conductivity, excellent heat dissipation, and mechanical stability.

– Cons: Higher cost, limited flexibility compared to organic substrates, may require additional thermal management solutions.

4. Ceramic Substrate:

– Pros: Exceptional thermal conductivity, stability at high temperatures, and low dielectric loss.

– Cons: High cost, brittleness, limited availability of large-size substrates.

5. Rogers Materials (High-Frequency Substrates):

– Pros: Low dielectric loss, excellent high-frequency performance, and reliability.

– Cons: Higher cost compared to standard FR4 substrates, limited availability of specific formulations.

Application in Real-World Projects

– Telecommunications Infrastructure: Rogers materials are commonly used in base station antennas and communication equipment to ensure reliable signal transmission.

– Automotive Electronics: Metal core PCB substrates are preferred in automotive applications for their ability to withstand high temperatures and provide efficient thermal management in engine control units (ECUs) and LED lighting systems.

– Consumer Electronics: FR4 substrates remain widely used in consumer electronics like smartphones, tablets, and laptops due to their cost-effectiveness and adequate performance for standard applications.

– Aerospace and Defense: Ceramic substrates are utilized in aerospace and defense applications where reliability, thermal stability, and performance under harsh environmental conditions are critical requirements.

By carefully evaluating the pros and cons of various PCB substrates and matching them with specific application requirements, designers can select the most suitable substrate to ensure optimal performance, reliability, and longevity of electronic systems.

FAQs about substrate pcb

A substrate in PCB (Printed Circuit Board) refers to the base material upon which electronic components are mounted and interconnected to form a functional circuit. It provides mechanical support and electrical insulation between the conductive traces on the PCB.

The best substrate for PCB depends on various factors such as the specific application requirements, operating conditions, and performance criteria. Commonly used substrates include FR4, polyimide (PI), polyamide (PA), metal substrates, and ceramic substrates. Each substrate has its own set of advantages and disadvantages, making the choice dependent on the specific needs of the project.

The main difference between PCB and package substrate lies in their respective roles within an electronic system. PCB substrate forms the foundation of the printed circuit board, providing mechanical support and electrical connectivity for components. Package substrate, on the other hand, is a specialized substrate used to mount and interconnect integrated circuits (ICs) within a package. While PCB substrate focuses on the overall circuit board design, package substrate is specifically tailored for the IC packaging process.

FR4 substrate for PCB is one of the most commonly used materials in the manufacturing of printed circuit boards. FR4 stands for Flame Retardant 4, indicating its flame retardant properties. It is composed of woven fiberglass cloth impregnated with an epoxy resin binder. FR4 offers good mechanical strength, thermal stability, and flame resistance, making it suitable for a wide range of applications.