Top Applications of High Frequency PCB in Modern Electronics

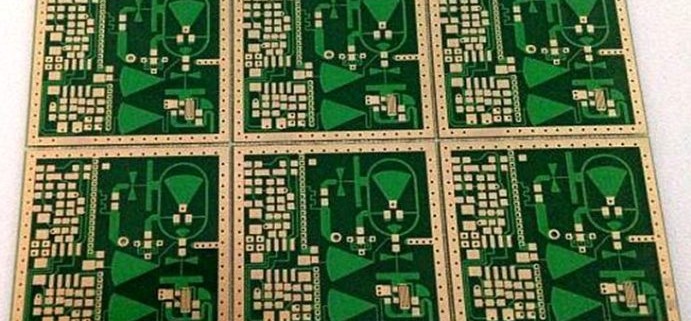

A High-Frequency PCB refers to a type of printed circuit board specifically designed to handle high-frequency signals, typically above 1 GHz. These PCBs are crucial for applications involving radio frequency (RF) signals, including wireless communication, radar systems, and advanced medical devices.

What makes a PCB “high-frequency” is its ability to efficiently transmit high-speed signals with minimal signal loss and distortion. Unlike standard PCBs, high-frequency PCBs are built using specialized materials, such as low-loss dielectrics, which minimize attenuation and ensure signal integrity at elevated frequencies. Key characteristics that differentiate high-frequency PCBs from standard ones include their material composition, precise trace designs, and careful attention to factors like impedance control, dielectric constant, and thermal management. These factors are critical for maintaining performance in environments with high-frequency RF signals, where even the smallest variations can lead to significant signal degradation.

Understanding High-Frequency PCB

What is a High-Frequency PCB?

A High-Frequency PCB is a printed circuit board specifically designed to handle high-frequency signals, typically in the range of 1 GHz to several gigahertz (GHz). These PCBs are tailored for applications that require the efficient transmission of radio frequency (RF) signals, which are commonly used in a variety of modern electronics. The primary function of a high-frequency PCB is to ensure minimal signal degradation and loss, ensuring that high-speed signals remain clear and intact over long distances or through complex circuits.

In modern electronics, high-frequency PCBs are indispensable in numerous advanced systems. Their primary role is to provide a stable platform for RF circuits, where signal integrity is crucial. They are used in systems like telecommunications, where signals are transmitted over vast distances, radar systems that require precise signal reflection and detection, and in medical devices like MRI machines, which rely on high-frequency electromagnetic waves for imaging.

Common Uses in RF Devices, Communication Systems, Radar, etc.

High-frequency PCBs are widely used in RF devices, communication systems, and radar applications. In RF devices, these PCBs serve as the foundation for circuits involved in the transmission and reception of high-frequency signals, such as antennas, transceivers, and amplifiers. Communication systems like 5G networks, satellite communications, and Wi-Fi routers rely on high-frequency PCBs to maintain fast and reliable data transmission. Radar systems, which detect objects by bouncing high-frequency radio waves off surfaces, also depend on these PCBs for accurate signal processing and reflection.

What is the Maximum Frequency of a PCB?

The maximum frequency that a PCB can handle depends on various factors, including the materials used, the design of the traces, and the quality of the components. High-frequency PCBs are generally designed to operate efficiently in the GHz range. However, as frequency increases, challenges such as signal loss, impedance mismatch, and dielectric losses become more pronounced.

Factors That Limit Frequency Range

Several factors limit the frequency range of a PCB. Material properties play a critical role, as materials with higher dielectric constants or greater loss tangents can cause signal attenuation, limiting the effective operating frequency. High-frequency PCBs are typically constructed using low-loss materials like PTFE (Teflon) or ceramics to minimize signal loss. Impedance control is another factor—if the PCB traces are not designed with proper impedance matching, signal reflections can occur, leading to signal degradation. Lastly, signal loss due to heat dissipation and trace design (such as trace width and spacing) can also restrict the maximum frequency a PCB can handle effectively.

Typical Frequency Range for High-Frequency PCBs

High-frequency PCBs are generally used in applications that operate within a frequency range from 1 GHz to several GHz, depending on the application. For example, RF communications can operate at frequencies between 1 GHz and 30 GHz, while specialized radar and satellite systems may push beyond 40 GHz. As the frequency increases, the design and material selection become even more critical, requiring advanced techniques to ensure signal quality and integrity.

High-Frequency PCB Materials

Types of Materials Used in High-Frequency PCBs

The materials used in high-frequency PCBs play a crucial role in the performance of the circuit board. Since these PCBs are designed to handle high-speed RF signals, selecting the right materials is essential to minimize signal loss, reduce attenuation, and maintain signal integrity. Unlike standard PCBs that use general-purpose materials, high-frequency PCBs utilize specialized materials that can handle the electrical and thermal demands of high-frequency signals.

The primary materials used in high-frequency PCBs include low-loss dielectrics, which help minimize signal degradation over long distances or in complex circuits. Common materials used in these PCBs are PTFE (Teflon), ceramics, and other engineered composites, each offering specific benefits depending on the application.

Low Loss Dielectrics

Low-loss dielectrics are essential for high-frequency PCBs, as they help maintain signal quality by reducing losses due to resistance and dielectric dissipation. These materials have a low loss tangent, which is a measure of how much power is lost when a signal passes through them. Materials such as PTFE (Polytetrafluoroethylene), ceramics, and certain other engineered materials are preferred due to their low dielectric constants and low dissipation factors, which significantly reduce signal loss at higher frequencies. PTFE is particularly known for its excellent electrical properties and ability to operate at very high frequencies, making it ideal for high-speed and high-frequency applications like telecommunications, aerospace, and defense.

Ceramics, on the other hand, offer extremely stable dielectric properties and low signal attenuation, which is why they are often used in more demanding RF applications where performance is critical, such as satellite communications or radar systems.

High-Speed PCB Materials vs. High-Frequency Materials

While both high-speed and high-frequency PCBs aim to transmit signals efficiently, the materials required for each type are different. High-speed PCBs typically deal with high-frequency digital signals, often in the range of hundreds of MHz to a few GHz. The primary concern in high-speed PCB materials is minimizing signal interference, reflections, and crosstalk between traces.

High-frequency PCBs deal with analog RF signals that operate at much higher frequencies—typically in the GHz range. These PCBs require materials that not only handle high-speed transmission but also provide low dielectric loss and minimal signal attenuation over longer distances. The materials used in high-frequency PCBs are specifically chosen to minimize the effects of skin effect, signal distortion, and power loss at very high frequencies. As such, high-frequency PCBs demand superior materials like PTFE, ceramics, and specialty composites, which are optimized for high-frequency performance rather than the primarily digital concerns of high-speed PCBs.

High-Frequency PCB Materials

Several materials are commonly used in high-frequency PCBs, each offering different advantages depending on the application. Here’s an overview of the most popular options:

-

FR4 (for lower frequencies)

Although FR4 is the most common material used for standard PCBs, it’s not suitable for high-frequency applications due to its higher dielectric loss and poor performance at frequencies above 1 GHz. However, for lower-frequency RF applications (up to a few GHz), FR4 can still be used effectively, offering a balance of cost and performance. -

Rogers Materials

Rogers materials, such as Rogers 4003 and Rogers 5880, are widely used in high-frequency PCBs. These materials are specially designed for RF and microwave applications and offer excellent electrical properties with low loss tangents, stable dielectric constants, and high thermal conductivity. Rogers materials are popular for high-performance RF devices like antennas, amplifiers, and satellite communications equipment. -

Teflon (PTFE)

Teflon is a well-known material for high-frequency PCBs due to its low dielectric constant and low dissipation factor. PTFE-based materials, like Rogers 4003C and others, are widely used in high-frequency PCBs for applications that require high performance and minimal signal loss, such as aerospace, defense, and high-speed communication systems. -

Other High-Frequency Materials

In addition to the above, materials like ceramics and specialized composites such as Isola’s I-Tera and Taconic’s TLY are also used in high-frequency PCBs. These materials offer low signal loss, thermal stability, and high-frequency performance, making them ideal for specific applications like radar, wireless communication, and medical equipment.

The Role of Aluminum-Backed PCBs in High-Frequency Designs

Aluminum-backed PCBs are commonly used in high-frequency PCBs where heat dissipation is a concern. These PCBs feature an aluminum substrate that acts as a heat sink, efficiently dissipating the heat generated by high-power RF signals or high-speed components. This is especially important in applications like power amplifiers, radar systems, and communication devices, where maintaining low temperatures is essential for optimal performance and longevity of the components. The aluminum substrate not only helps with thermal management but also provides additional mechanical strength to the PCB, making it more durable in demanding environments.

High-Frequency Fabrics and Clothing

In addition to high-frequency PCBs, high-frequency materials are also being incorporated into fabrics and clothing for shielding and health protection. These specialized fabrics, made from materials like silver-coated fibers, are used to create garments that protect the wearer from harmful electromagnetic fields (EMF) generated by RF devices. High-frequency fabrics are particularly useful in areas with high RF exposure, such as near wireless communication towers, or for individuals sensitive to EMF. These fabrics can be used in protective clothing, bed linens, and other everyday items, offering a unique application of high-frequency materials beyond electronics.

This section provides a detailed overview of the materials used in high-frequency PCBs, emphasizing the importance of selecting the right materials to ensure high performance in demanding RF applications. The comparison between high-speed and high-frequency PCB materials also highlights the unique requirements for designing efficient and reliable high-frequency PCBs.

High-Frequency PCB Design

Challenges in Designing High-Frequency PCBs

Designing a high-frequency PCB presents several unique challenges compared to standard PCBs. The primary concern in high-frequency PCB design is maintaining signal integrity, which becomes increasingly difficult as the frequency of the signal rises. High-frequency signals are more prone to various issues like signal attenuation, electromagnetic interference (EMI), and crosstalk, all of which can degrade performance and cause circuit failure.

-

Signal Integrity: At high frequencies, even small imperfections in the PCB, such as improper trace routing or material inconsistencies, can cause significant signal degradation. Ensuring the signals remain strong and clear as they traverse the PCB is critical for optimal performance.

-

Electromagnetic Interference (EMI): High-frequency signals emit electromagnetic radiation, which can interfere with nearby circuits and external devices. Proper shielding and grounding techniques must be employed to prevent EMI and ensure the PCB functions as intended.

-

Crosstalk: In high-frequency PCBs, crosstalk between adjacent traces can occur due to the coupling of signals at high speeds. This unwanted interaction can lead to false signals or data corruption, making it vital to carefully design trace spacing and layer configurations to minimize these effects.

To overcome these challenges, designers of high-frequency PCBs use a variety of advanced techniques, including specialized materials, precise layout strategies, and simulation tools that model signal behavior at high frequencies.

Techniques for Minimizing Signal Loss and Ensuring Signal Integrity

Minimizing signal loss and maintaining signal integrity are crucial goals in the design of high-frequency PCBs. Several techniques are employed to achieve these goals:

-

Material Selection: Choosing low-loss dielectric materials like PTFE, ceramics, and Rogers composites helps reduce signal attenuation. These materials are specifically chosen for their ability to maintain signal clarity over long distances or when traveling through multiple layers of the PCB.

-

Controlled Impedance: Maintaining a consistent impedance throughout the PCB is critical in high-frequency PCB design. Any impedance mismatch can cause signal reflections, leading to data errors or complete signal loss. Impedance-controlled traces, often achieved through careful trace width design and controlled materials, ensure that signals are transmitted efficiently with minimal reflection.

-

Via Optimization: Vias are often used in high-frequency PCBs to connect different layers. However, vias introduce inductance and resistance, which can degrade signal quality. Optimizing via design by minimizing via length, using back-drilled vias, and ensuring proper via plating can reduce these losses.

Design Tips and Best Practices

When designing high-frequency PCBs, the following best practices and tips can help ensure optimal performance:

-

Grounding and Shielding: Proper grounding is crucial for the performance of high-frequency PCBs. A solid ground plane helps maintain signal integrity and reduces EMI. Shielding, whether in the form of metal enclosures or specialized ground layers, also helps to prevent external interference from affecting the circuit. In addition, ensuring a low-impedance path to ground minimizes the impact of unwanted noise.

-

Layer Stack-up Recommendations: The PCB layer stack-up is another critical factor in high-frequency PCB design. A common strategy is to use a multilayer PCB where signal traces are sandwiched between ground and power planes. This configuration provides a stable reference for signal routing and minimizes signal loss. The layer stack-up should be optimized to ensure that the signal traces are as close to the ground plane as possible, providing better impedance control and reducing noise susceptibility.

-

Trace Width and Spacing: The width and spacing of the traces are crucial for controlling impedance in high-frequency PCBs. Too wide or too narrow a trace can cause impedance mismatch, resulting in signal reflections or power loss. Calculating the correct trace width and spacing based on the PCB material’s dielectric constant and the desired impedance is essential for maintaining signal integrity.

-

Minimizing Signal Reflection and Transmission Line Losses: To reduce signal reflections and transmission line losses, high-frequency PCBs often employ techniques such as controlled impedance traces, minimizing via inductance, and using proper termination resistors. In addition, careful attention to trace routing and avoiding sharp bends can prevent the signal from being disrupted.

High-Speed PCB Design vs. High-Frequency PCB Design

Although both high-speed PCB design and high-frequency PCB design aim to transmit signals as efficiently as possible, the requirements for each are different, especially regarding the type of signals involved.

-

High-Speed PCB Design: Typically, high-speed PCB design deals with digital circuits that operate at high clock speeds. The primary challenges are dealing with signal integrity, reducing noise, and minimizing crosstalk between closely spaced traces. The signals are usually transmitted in the form of digital pulses, and the focus is on timing and minimizing delay or jitter.

-

High-Frequency PCB Design: On the other hand, high-frequency PCB design deals with analog RF signals, which require more precise control over impedance, signal reflection, and loss. The signals in high-frequency PCBs operate at much higher frequencies (often in the GHz range), which means that the effects of parasitics (such as capacitance, inductance, and resistance) are more pronounced. Designing for high-frequency PCBs involves more careful consideration of materials, trace layouts, and minimizing signal degradation.

While high-speed PCB design focuses on digital performance and timing, high-frequency PCB design requires greater attention to material properties, signal integrity, and physical trace characteristics to ensure that high-frequency RF signals remain clean and reliable.

Applications of High-Frequency PCB

Industries Using High-Frequency PCBs

High-frequency PCBs play a crucial role in a wide range of industries where high-speed signal transmission and minimal signal degradation are vital. As technologies continue to advance, the demand for high-frequency PCBs is growing in several key sectors, including telecommunications, aerospace, defense, and medical devices. Below, we explore how high-frequency PCBs are used in these industries and their significant applications.

Telecommunications

Telecommunications is one of the largest sectors relying on high-frequency PCBs for critical systems like cellular networks, satellite communications, and broadband services. As the demand for faster and more reliable communication systems grows, especially with the rise of 5G and beyond, the role of high-frequency PCBs becomes more significant.

-

Cellular Networks: In modern cellular networks, high-frequency PCBs are used in base stations, transmitters, and receivers. These circuits handle high-speed RF signals that ensure seamless communication, especially as mobile devices move towards higher data rates and lower latency. The design of high-frequency PCBs in this context must be able to handle complex signal routing, interference, and minimal loss to ensure optimal performance.

-

Satellite Communications: High-frequency PCBs are critical in satellite communication systems, where RF signals are transmitted over vast distances. These systems rely on high-frequency PCBs to maintain signal integrity, reduce noise, and ensure reliable data transmission between ground stations and satellites orbiting the Earth.

Aerospace and Defense

In aerospace and defense, high-frequency PCBs are integral to mission-critical systems, including radar, avionics, and military communications. These sectors demand high-frequency PCBs that can operate reliably in extreme environments, often under harsh conditions like high radiation, temperature variations, and vibration.

-

Radar Systems: High-frequency PCBs are used in radar systems to process and transmit RF signals that are crucial for detecting objects at long distances. These systems must be highly sensitive, and the high-frequency PCBs must maintain signal clarity and accuracy despite interference from the environment.

-

Avionics: The aviation industry relies on high-frequency PCBs for avionics systems, such as navigation, flight control, and communication systems. These systems require high-frequency PCBs to handle the high-speed RF signals used in satellite navigation, weather radar, and in-flight communications.

-

Military Communications: In military applications, high-frequency PCBs are used in communication devices, electronic warfare systems, and other advanced technologies. The ability to maintain secure and reliable communications is vital in defense, making high-frequency PCBs essential for secure, high-performance systems.

Medical

The medical industry has also seen significant advancements with the use of high-frequency PCBs in devices like MRI machines, high-precision medical imaging devices, and diagnostic equipment. These applications demand high-frequency PCBs that can handle RF signals accurately and consistently, with minimal interference or degradation, to produce high-quality imaging or diagnostic results.

-

MRI Systems: Magnetic Resonance Imaging (MRI) machines rely on high-frequency PCBs to process and generate the RF signals required for imaging. These systems use high-frequency PCBs to transmit and receive electromagnetic waves that create detailed images of the body’s internal structures. The signal integrity and precision of high-frequency PCBs are critical for accurate medical diagnoses.

-

High-Precision Medical Imaging Devices: Other medical devices, such as ultrasound machines and X-ray systems, also rely on high-frequency PCBs to transmit and process high-frequency signals for imaging purposes. These devices require high-frequency PCBs to maintain signal clarity and minimize noise, ensuring precise, high-resolution images for diagnosis and treatment planning.

Future Trends in High-Frequency PCB Applications

As technology continues to evolve, the applications for high-frequency PCBs are expanding into several emerging fields. New advancements in telecommunications, autonomous vehicles, and sensor systems are driving the demand for more advanced high-frequency PCBs with higher performance capabilities.

-

5G and Beyond: One of the most significant trends in high-frequency PCB applications is the widespread adoption of 5G networks. These next-generation communication systems rely on high-frequency PCBs to handle the high-speed RF signals required for ultra-fast data transfer and low-latency communication. As 5G technology matures and 6G begins to emerge, high-frequency PCBs will play a crucial role in supporting higher frequency bands and greater signal capacity.

-

Autonomous Vehicles: Autonomous vehicles require complex sensor systems to navigate and interact with their environment. These systems, such as radar, LiDAR, and cameras, rely heavily on high-frequency PCBs to process the high-speed signals that detect objects, measure distances, and enable real-time decision-making. As autonomous vehicles become more widespread, the demand for high-frequency PCBs that can operate in challenging automotive environments will continue to grow.

-

Advanced Sensor Systems: The Internet of Things (IoT) and the growing use of smart devices in homes, factories, and cities are driving the development of advanced sensor systems. These sensors, which collect and transmit data in real-time, require high-frequency PCBs to process high-speed signals with minimal interference. Applications like smart grids, environmental monitoring, and industrial automation will rely on high-frequency PCBs to support the vast amounts of data generated by these systems.

High-frequency PCBs are already essential in several key industries, including telecommunications, aerospace, defense, and medical devices, and are set to play a critical role in emerging technologies like 5G, autonomous vehicles, and advanced sensor systems. As these technologies continue to evolve, high-frequency PCBs will be at the heart of innovations that enable faster, more reliable, and more efficient systems across various sectors.

Recommended PCBs for High-Frequency RF Devices

Best PCB Materials for RF Applications

When it comes to high-frequency PCBs, selecting the right material is critical for ensuring optimal signal integrity, minimal loss, and reliable performance, particularly in RF (radio frequency) applications. Certain materials are specially engineered to meet the demands of high-frequency signals, providing low loss, stable dielectric properties, and excellent thermal conductivity. Here are some of the best materials used in high-frequency PCBs for RF applications:

-

Rogers 4003: One of the most popular materials for high-frequency PCBs, Rogers 4003 offers excellent electrical performance with a low dielectric constant and low dissipation factor. This makes it ideal for RF applications that require low signal loss and high precision. It is commonly used in telecommunications, radar systems, and other RF devices operating at frequencies up to 6 GHz.

-

Rogers 5880: Rogers 5880 is another high-performance material widely used for high-frequency PCBs. Known for its stability at high frequencies, it offers superior signal integrity and low dielectric loss. It is often used in applications that require higher frequencies, such as microwave and millimeter-wave systems, and is capable of operating at frequencies up to 20 GHz. Rogers 5880 is particularly well-suited for military, aerospace, and satellite communication applications.

-

Rogers 4350B: Another material from Rogers, 4350B is designed for even higher frequency applications, offering a low loss tangent and consistent dielectric properties across a wide range of frequencies. It is frequently used in complex RF devices, including communication systems, where performance and durability are crucial.

-

Taconic TLY: This is a high-performance laminate designed specifically for high-frequency PCBs. Taconic TLY offers low dielectric loss and is excellent at handling high-power RF signals, which makes it a go-to choice for demanding applications such as satellite communications and radar systems.

How to Select the Right PCB Material Based on Frequency Requirements

Choosing the right material for a high-frequency PCB is essential to maintaining signal integrity and ensuring that the board can handle the required frequencies with minimal loss. When selecting a PCB material for RF applications, the following factors must be considered:

-

Frequency Range: The operating frequency of the device is the first consideration. For devices that operate below 1 GHz, standard materials like FR4 might suffice, but for higher frequencies (typically above 1 GHz), materials like Rogers 4003 or Rogers 5880 are better suited because they offer lower dielectric loss and greater stability.

-

Dielectric Constant (Dk): The dielectric constant affects signal velocity and impedance. Materials with stable dielectric constants, such as Rogers and Taconic products, help maintain consistent impedance and ensure signal integrity at high frequencies.

-

Loss Tangent (Df): The loss tangent is a measure of how much energy is lost as heat when a signal passes through a material. High-frequency PCBs require materials with a low loss tangent to minimize signal attenuation and ensure the signal maintains its strength and clarity over distance. Materials like Rogers 4003 and Rogers 5880 offer excellent low-loss performance, making them suitable for high-frequency RF applications.

-

Thermal Stability: RF devices often generate heat, and the PCB material must be able to handle temperature fluctuations without compromising performance. Materials like Rogers and Taconic are designed to withstand high temperatures, ensuring long-term stability and performance.

-

Mechanical Properties: The PCB material must be durable enough to handle the mechanical stresses and environmental conditions that it will face during operation. Materials like ceramics and aluminum-backed PCBs are often selected for their mechanical strength in high-frequency applications.

Choosing the Right PCB Manufacturer for High-Frequency PCBs

When selecting a PCB manufacturer for high-frequency PCBs, it’s essential to choose one with experience in RF and high-frequency circuit design. The right manufacturer will have the expertise and resources necessary to produce PCBs that meet the stringent requirements of high-frequency applications. Here are some key factors to consider:

-

Experience with RF and High-Frequency Design: Not all PCB manufacturers have the knowledge or capabilities to produce high-frequency PCBs. It’s crucial to select a manufacturer that specializes in RF design and has a deep understanding of the challenges involved in high-frequency signal transmission. Look for manufacturers with a proven track record of producing high-frequency PCBs for industries like telecommunications, aerospace, and medical applications.

-

Material Selection: The manufacturer should be able to offer a range of high-quality materials, such as Rogers, Taconic, and other specialized laminates that are essential for high-frequency PCBs. They should also be capable of advising you on the best materials based on your specific frequency and performance requirements.

-

Testing and Simulation Capabilities: A good manufacturer will provide comprehensive testing and simulation services to ensure the high-frequency PCB performs as expected. This may include signal integrity analysis, thermal simulation, impedance testing, and EMI testing to verify that the PCB meets all required specifications. Be sure to ask about their testing procedures and whether they offer pre-production prototypes for testing before finalizing the design.

-

Quality Assurance and Certification: Ensure the manufacturer adheres to stringent quality control processes and holds relevant certifications, such as ISO 9001 or IPC-A-600, which indicate a commitment to producing high-quality PCBs. The manufacturer should also provide thorough inspection and testing reports to ensure the high-frequency PCB meets all performance standards.

-

Lead Time and Cost: While quality is the priority, lead time and cost are also important factors. Look for a manufacturer who can deliver high-frequency PCBs within your project timeline without compromising quality. It’s important to strike a balance between cost, speed, and performance, especially for complex high-frequency designs.

-

Customer Support: A reliable PCB manufacturer will offer strong customer support throughout the design and production process, assisting with design challenges, material selection, and troubleshooting. Choose a manufacturer that is responsive and willing to collaborate with your engineering team to ensure the success of the high-frequency PCB.

Selecting the right materials and manufacturer for high-frequency PCBs is crucial for ensuring the optimal performance of RF devices. By considering factors like frequency requirements, dielectric properties, and testing capabilities, you can ensure that your high-frequency PCB meets the stringent demands of modern RF applications. Whether you’re working on telecommunications equipment, aerospace systems, or medical devices, the right combination of materials and manufacturing expertise will ensure your high-frequency designs perform reliably and efficiently.

FQAs Abut High Frequency PCB

What are high frequency PCBs?

High frequency PCBs are printed circuit boards specifically designed to handle signals at high frequencies, typically above 1 GHz. These PCBs are optimized for minimal signal loss, stable dielectric properties, and high performance in applications like telecommunications, radar, and RF (radio frequency) systems. The materials used in these PCBs are selected for their low dielectric constant and low loss tangent, ensuring efficient signal transmission with minimal attenuation.

What is the maximum frequency of a PCB?

The maximum frequency a PCB can handle depends on the materials used and the design of the board. Standard PCBs, like those made from FR4, are generally used up to 1 GHz, while high-frequency PCBs made from specialized materials such as Rogers or Taconic can operate effectively in the GHz range, with some designs capable of handling frequencies up to 20 GHz or higher. For extremely high-frequency applications, such as in satellite communications or microwave systems, high-frequency PCBs can even operate at frequencies beyond 40 GHz.

What is the difference between high speed and high frequency PCB?

The main difference between high speed and high frequency PCBs lies in the type of signals they handle and the design challenges involved. High speed PCBs are designed to handle rapid digital signals and are typically focused on ensuring fast data transmission with minimal signal degradation. They are used in applications like computers, networking equipment, and digital devices. In contrast, high frequency PCBs handle RF signals, which are analog in nature and require specialized materials to minimize signal loss, noise, and interference. High frequency PCBs are used in applications like wireless communications, radar, and satellite systems.

Which PCBs should be recommended for high frequency RF devices?

For high frequency RF devices, materials like Rogers 4003, Rogers 5880, and Taconic TLY are commonly recommended. These materials have low dielectric constants and loss tangents, which are essential for maintaining signal integrity at high frequencies. Additionally, ceramic-based PCBs and aluminum-backed PCBs are also excellent choices, providing both mechanical strength and good thermal management. When selecting a PCB for an RF device, it’s important to consider the frequency range, signal integrity requirements, and the operating environment of the device.