In today’s rapidly advancing tech landscape, printed circuit boards (PCBs) serve as the foundation for virtually all electronic devices. From smartphones to aerospace systems, PCBs enable complex electrical connections within compact spaces. However, as modern devices become increasingly smaller and more powerful, traditional PCB designs often fall short. This is where high-density interconnect hdi pcb technology comes in. Designed to support miniaturization and higher performance requirements, HDI PCBs allow for finer lines, smaller vias, and more compact components—all while maintaining signal integrity and reliability. In this article, we’ll take a deep dive into the world of high-density interconnect hdi pcb. You’ll learn what it is, how it differs from standard PCBs, the various types and structures, and key design considerations. We’ll also explore the advantages of HDI, manufacturing processes, and cost factors, giving you a comprehensive guide to this crucial technology in modern electronics.

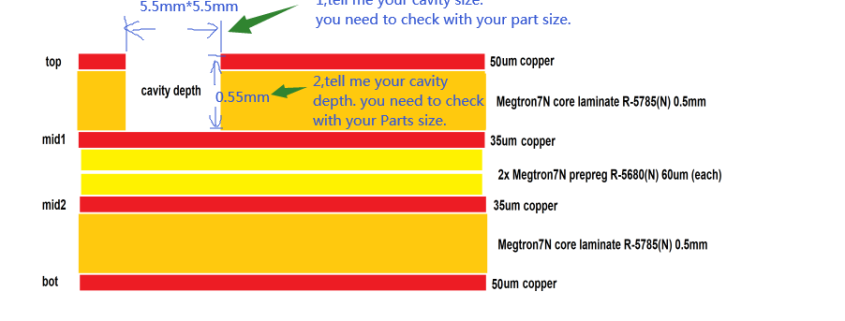

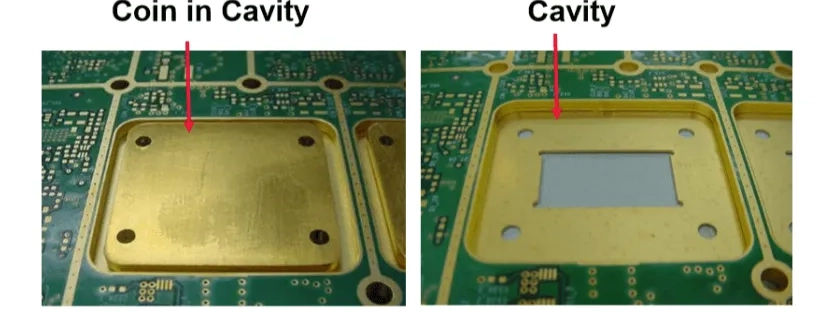

PCB cavities are recessed areas within circuit boards that allow components to be embedded at different depths, optimizing space and performance. What is PCB Cavity? It is a key design feature that enhances electrical functionality by reducing signal interference and improving thermal management.

As modern electronics demand thinner and more compact designs, PCB cavities have become essential in high-frequency and high-power applications. They enable better heat dissipation, minimize signal loss, and support the integration of advanced components. Widely used in RF modules, automotive electronics, and miniaturized devices, PCB cavities help achieve high-density layouts without compromising reliability. Their role in optimizing circuit board performance continues to grow as technology advances.

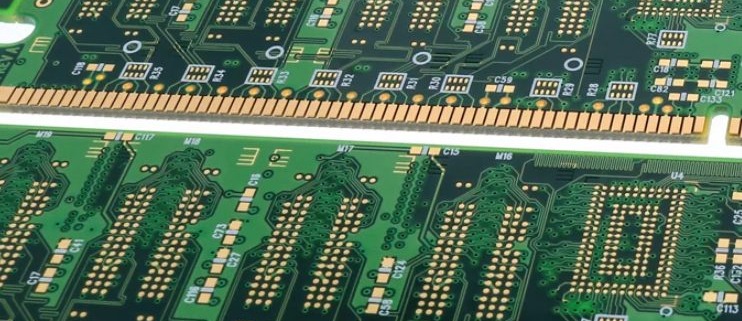

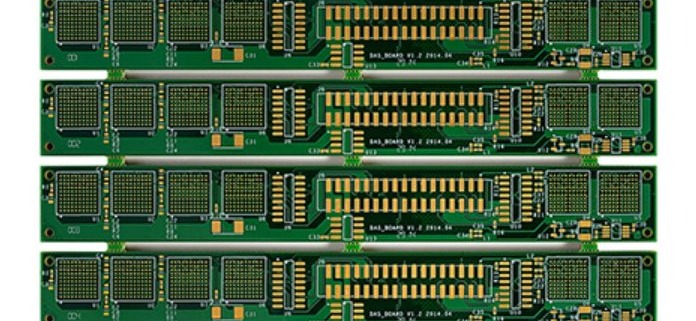

HDI PCB technology, or High-Density Interconnect PCB technology, refers to a type of printed circuit board with a higher wiring density per unit area compared to conventional PCBs. It utilizes advanced design features such as laser-drilled microvias, blind and buried vias, and high-performance thin materials to achieve superior electrical performance and space efficiency.

The importance of high-density interconnect technology in modern electronics is significant, as it enables the development of compact, lightweight, and high-performance devices. This technology is widely used in smartphones, tablets, medical devices, aerospace systems, and automotive electronics, where miniaturization and reliability are crucial. By reducing signal loss and improving power distribution, it enhances device efficiency and functionality. As the demand for smaller and more powerful electronic products grows, this technology continues to be a key enabler of innovation in the electronics industry.

HDI PCB (High-Density Interconnect PCB) is a cutting-edge printed circuit board technology that enhances circuit density by utilizing microvias, fine lines, and advanced lamination techniques. HDI PCB fabrication enables the design of compact, lightweight, and high-performance electronic devices, making it essential in modern technology.

The importance of HDI PCB fabrication lies in its widespread applications across industries such as consumer electronics, telecommunications, automotive, aerospace, and medical devices. Smartphones, tablets, wearables, and high-speed communication systems all rely on HDI PCBs to achieve miniaturization and improved signal integrity.

Compared to traditional PCBs, HDI PCBs offer several advantages, including higher electrical performance, reduced signal loss, and enhanced thermal management. The use of stacked and staggered vias improves reliability and increases layer interconnect density. Additionally, HDI PCB fabrication reduces the overall footprint of electronic products, making it a preferred choice for manufacturers aiming to optimize space and performance in modern circuit designs.

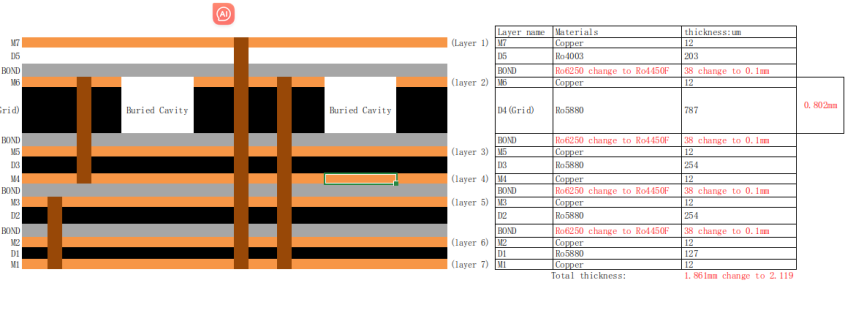

Embedded Cavity PCB Manufacturing is an advanced process that integrates components within recessed cavities in the PCB structure, enabling reduced board thickness, improved electrical performance, and better thermal management. As electronic devices continue to shrink while requiring higher functionality, embedded cavity PCBs have become a key solution in modern electronics.

We have produced Embedded Cavity PCB boards using cutting-edge technology, ensuring precise depth control and high-accuracy cavity sizes. Our capabilities range from 4-layer to 30-layer designs, meeting diverse application needs. By embedding components directly into the PCB, this technology enhances miniaturization, reliability, and performance, making it ideal for high-frequency, high-power, and mission-critical applications. Embedded Cavity PCB Manufacturing offers superior electromagnetic shielding, shorter interconnects, and improved mechanical stability.

HDI PCB Design (High-Density Interconnect PCB) refers to advanced printed circuit boards with higher wiring density per unit area compared to traditional PCBs. High-density interconnect PCBs incorporate microvias, blind vias, and buried vias, allowing more compact circuit layouts and reducing the number of PCB layers. This technology supports miniaturization while enhancing signal integrity and performance. Compared to traditional boards, this design offers a significant advantage in terms of space optimization and lightweight construction, making it ideal for high-speed and high-frequency applications. Modern electronic devices such as smartphones, medical devices, and automotive systems heavily rely on this advanced design to achieve smaller form factors, faster signal transmission, and improved reliability. As demand for compact and efficient electronics rises, this technology continues to play a pivotal role in advancing innovation and meeting industry needs. 阅读更多

There are two main types of cavity PCB designs: open cavities and buried cavities. Open cavities involve creating single or multiple voids directly on the board’s surface. In contrast, buried cavities are positioned between inner layers, nestled within the PCB stackup. Both designs are feasible across a wide range of layer counts, from 4 layers up to 50 layers.

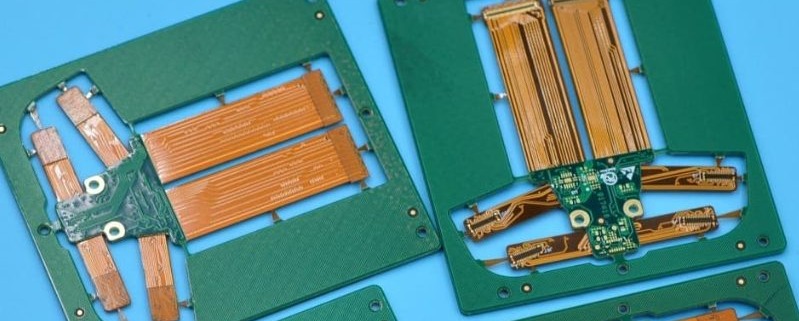

HDI Flex PCBs (High-Density Interconnector Flexible Printed Circuit Boards) are advanced circuit boards that combine high-density interconnection (HDI) technology with the flexibility of traditional flexible PCBs. HDI technology enables the creation of circuits with finer traces, microvias, and stacked vias, which are essential for compact, high-performance designs. The flexibility of these PCBs makes them ideal for applications that require space and weight savings. In the modern electronics industry, HDI Flex PCB are crucial for the miniaturization and functionality of devices. They are widely used in industries such as medical devices, where compact and reliable designs are necessary; automotive, where space-saving and durable circuits are needed for advanced control systems; consumer electronics, especially in smartphones and wearables; and aerospace, where performance and flexibility under extreme conditions are vital. HDI Flex PCBs are a key technology enabling innovation across these sectors.

High-Density Interconnect (HDI) PCBs are advanced circuit boards that feature finer lines, smaller vias, and higher wiring density, enabling more complex and compact designs. As a critical component in modern electronics, HDI PCBs enhance signal integrity and reduce electromagnetic interference, making them ideal for high-performance applications such as smartphones, automotive systems, and medical devices. Compared to traditional PCBs, HDI PCBs employ microvias, blind and buried vias, and laser drilling technology, which significantly increases layer density and aspect ratio capabilities. While standard PCBs rely on through-hole vias and thicker traces, HDI PCBs achieve superior electrical performance through reduced signal loss and improved impedance control. As demand for miniaturization and high-speed applications continues to grow, selecting the right hdi pcb manufacturer becomes essential for ensuring quality and reliability in advanced electronics. 阅读更多

Printed Circuit Board (PCB) technology has evolved significantly over the years, transitioning from basic single-layer boards to complex multi-layer designs capable of supporting high-speed applications. Among these advancements, the HDI PCB board (High-Density Interconnect PCB) has emerged as a critical innovation, enabling the miniaturization of modern electronic devices. An HDI PCB board utilizes microvias, blind vias, and buried vias to achieve higher wiring density and reduce the overall footprint of the PCB. This allows for more compact designs while maintaining superior electrical performance. In today’s advanced electronics, such as smartphones, wearables, and automotive systems, the HDI PCB board plays a vital role by enhancing signal integrity, reducing electromagnetic interference (EMI), and supporting higher-frequency signals. Its ability to increase circuit density and optimize electrical characteristics makes the HDI PCB board indispensable for high-performance, space-constrained applications across various industries. 阅读更多

CONTACT US

4th Floor, A3 Building, HuaFeng Industrial Park, GuanTian Village, BeiHuan Road, ShiYan Street, Bao An District, Shenzhen City, Guangdong Province, China

Tel:086 (0)755-8524-1496

WhatsApp: 8615014077679

Skype: Henrychinasz

📧 pcb@alcantapcb.com

CONTACT US

SHIPPING

![]()

CERTIFCATION

![]()

recent articles

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午

Copper Core PCB vs Aluminium Core PCB Explained2025-09-18 - 7:13 上午 Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午

Microwave PCB Manufacturers | RF Design and Fabrication2025-09-16 - 7:58 上午 Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午

Flex PCB Manufacturing Process: Step-by-Step Guide2025-09-10 - 6:59 上午 PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午

PCB Lamination Process & Sequential Lamination2025-09-04 - 8:10 上午