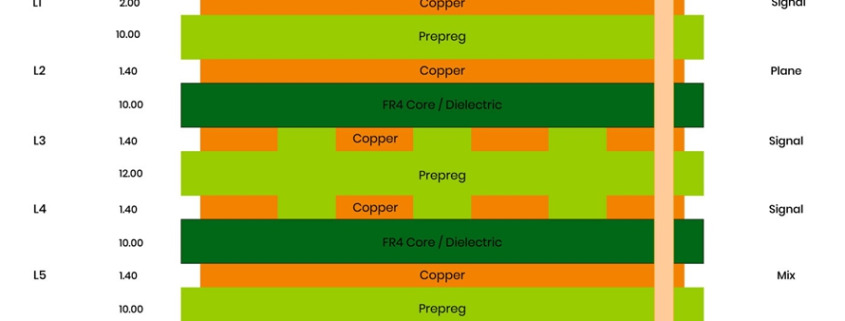

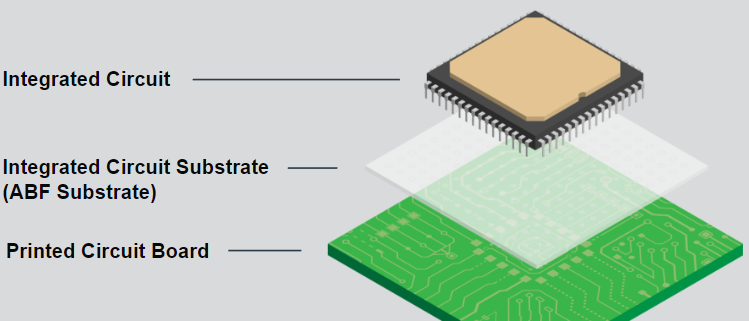

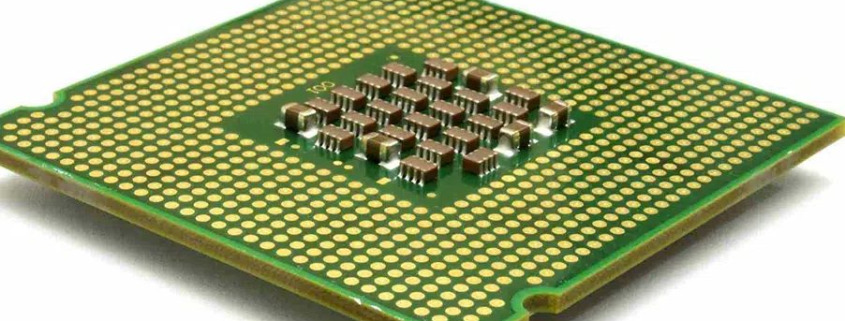

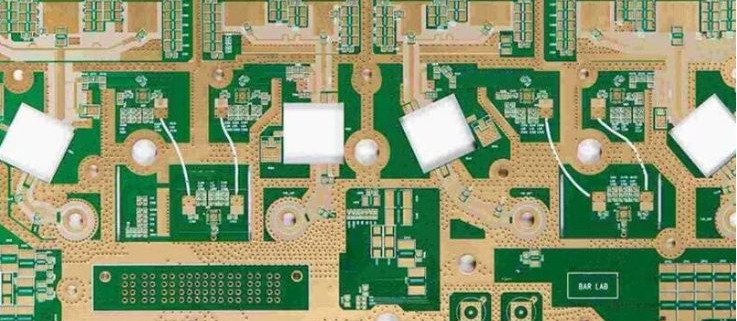

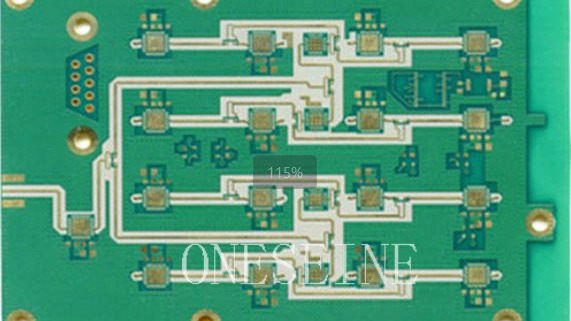

The thickness of FR4 substrate plays a critical role in printed circuit board (PCB) design, directly influencing the overall performance and reliability of electronic devices. FR4, a widely used material, is valued for its excellent insulation, flame resistance, and mechanical strength, making it the go-to choice for most PCB applications. Its thickness is not just a structural component; it also affects the electrical properties, such as signal integrity and impedance control, especially in high-frequency circuits.

Choosing the right thickness of FR4 substrate is essential, as it impacts thermal management, mechanical durability, and the ability to handle power demands. Thinner substrates are ideal for compact, lightweight designs with minimal space, while thicker substrates offer better mechanical support and heat dissipation for high-power applications. Understanding the balance between the thickness and the performance requirements of the PCB ensures the success of electronic designs in various industries.

阅读更多