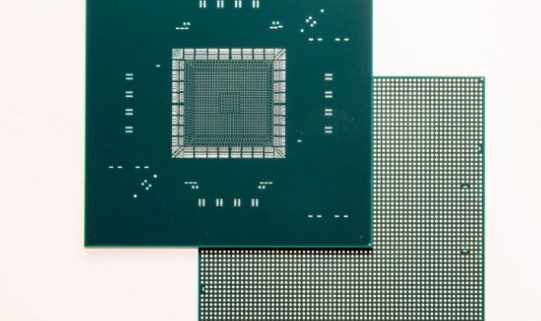

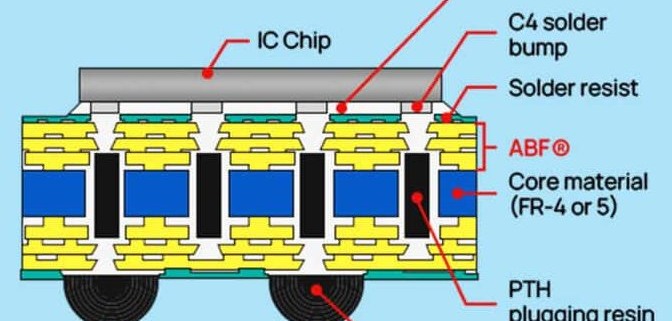

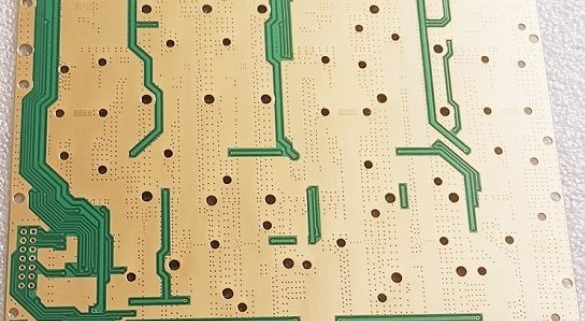

In the world of electronics, substrates play a crucial role as the foundational layer that supports and connects various components within a device. A substrate serves not only as a physical support but also as a medium for electrical connections, ensuring the functionality and reliability of the final product. Among the different types of substrates, BGA/IC Substrate has emerged as an essential technology in the development of modern devices.

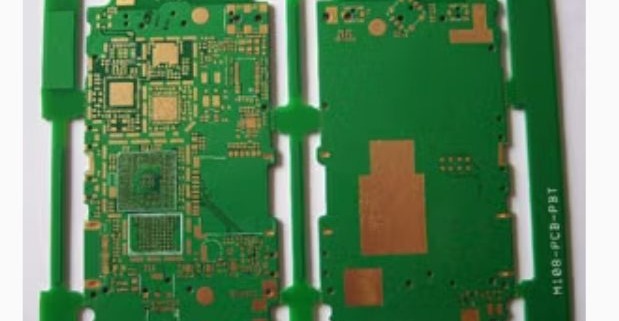

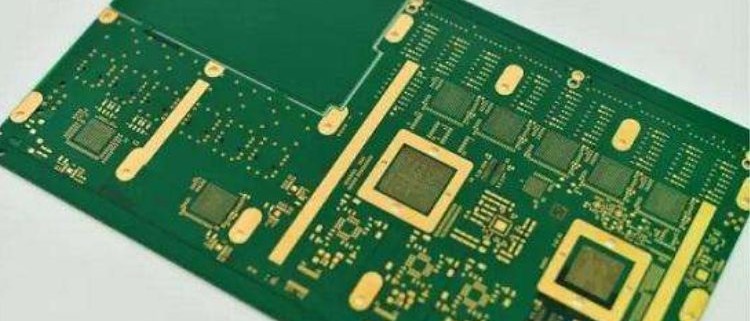

The BGA (Ball Grid Array) and IC (Integrated Circuit) substrates are integral in high-performance applications, such as smartphones, computers, and automotive systems. These substrates provide superior signal integrity, heat dissipation, and miniaturization, addressing the increasing demand for faster and more compact electronic products.

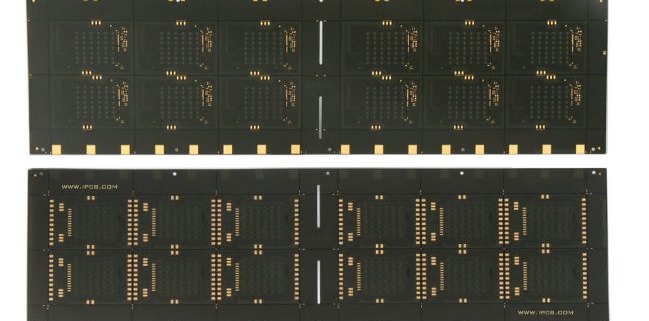

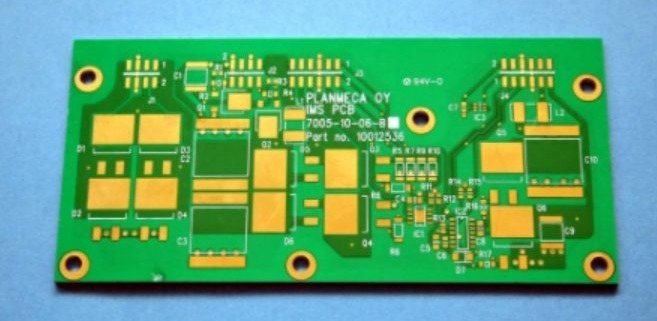

In the PCB (Printed Circuit Board) industry, BGA/IC substrates represent a critical evolution in packaging and interconnection technologies, facilitating the development of next-generation electronics with enhanced efficiency and reduced size. Their importance continues to grow as electronic devices become increasingly complex and powerful.