Rogers 5880 Substrate Specifications: A Comprehensive Guide

Rogers 5880 substrate, known as Rogers RT/duroid 5880, is a high-frequency laminate material designed for advanced electronic applications. This substrate is composed of PTFE (polytetrafluoroethylene) with glass microfibers, providing exceptional electrical and mechanical properties. Its low dielectric constant and minimal loss tangent make it an ideal choice for RF (radio frequency) and microwave circuits, where signal integrity and performance are critical.

The importance of Rogers 5880 in various applications cannot be overstated. In RF and microwave circuits, the material’s consistent electrical performance ensures minimal signal loss and distortion, which is essential for communication systems, radar, and high-frequency electronics. Additionally, its stable dielectric properties across a wide range of frequencies make it suitable for aerospace, defense, and telecommunications industries. By offering reliable performance in demanding environments, Rogers 5880 substrate stands out as a preferred material for engineers and designers aiming to achieve high-precision and efficient electronic solutions.

What is Rogers RT/duroid 5880 Material?

Rogers RT/duroid 5880 is a high-frequency laminate known for its outstanding electrical and mechanical properties, making it a favored choice in advanced electronic applications. The material is primarily composed of PTFE (polytetrafluoroethylene), which is infused with glass microfibers. This unique composition gives Rogers 5880 its distinctive characteristics, including a low dielectric constant of approximately 2.2 and an extremely low loss tangent of around 0.0009 at 10 GHz. These properties are crucial for maintaining signal integrity and minimizing signal loss in high-frequency circuits.

Additionally, Rogers RT/duroid 5880 exhibits excellent thermal stability and chemical resistance, which allows it to perform reliably in harsh environments. The substrate’s mechanical stability is another significant advantage, providing robust support for intricate circuit designs without compromising performance. The material’s low moisture absorption further ensures consistent electrical properties, even in humid conditions.

Common Uses and Applications

Rogers RT/duroid 5880 is widely used in applications where high-frequency performance is essential. One of its primary uses is in RF (radio frequency) and microwave circuits, where the substrate’s low dielectric constant and loss tangent are critical for maintaining signal clarity and efficiency. This makes it a preferred material for designing communication systems, including satellite and cellular communications, radar systems, and GPS devices.

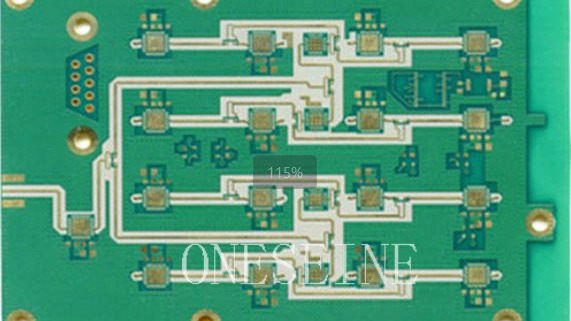

In the aerospace and defense industries, Rogers 5880 is employed in advanced radar and communication systems, where reliability and performance in extreme conditions are paramount. The material is also used in high-frequency PCBs (printed circuit boards) for test and measurement equipment, ensuring accurate signal transmission and minimal interference.

Furthermore, the telecommunications industry relies on Rogers 5880 for base stations, antennas, and other high-frequency components, benefiting from its consistent performance and durability. The material’s versatility extends to medical devices, where precision and reliability are critical, and in automotive electronics, where it supports advanced driver-assistance systems (ADAS) and other high-frequency applications.

In summary, Rogers RT/duroid 5880 is a highly specialized material offering exceptional electrical and mechanical properties, making it indispensable in various high-frequency and high-performance applications.

Specifications of Rogers RT/duroid 5880

Detailed Specifications

Rogers RT/duroid 5880 is a premium high-frequency laminate known for its superior electrical and mechanical properties. Here are its detailed specifications:

- Dielectric Constant (Dk): Approximately 2.20 at 10 GHz, ensuring minimal signal distortion.

- Dissipation Factor (Df): 0.0009 at 10 GHz, indicative of very low signal loss.

- Thermal Coefficient of Dielectric Constant: -125 ppm/°C, providing stable performance over a wide temperature range.

- Volume Resistivity: >10^7 MΩ·cm, ensuring excellent insulation and minimal electrical leakage.

- Surface Resistivity: >10^6 MΩ, contributing to high surface insulation resistance.

- Thermal Conductivity: 0.20 W/m·K, which aids in managing heat dissipation in high-power applications.

- Operating Temperature Range: -50°C to +150°C, suitable for extreme environmental conditions.

- Water Absorption: <0.02%, ensuring consistent electrical properties even in humid environments.

- Peel Strength: ≥7 lb/in (1.23 N/mm), ensuring robust adhesion of copper layers.

Comparison with Other Similar Materials

When compared to other high-frequency laminates, Rogers RT/duroid 5880 stands out due to its combination of low dielectric constant and low dissipation factor. Here’s how it compares to other materials:

- Rogers RO4350B: This laminate has a dielectric constant of 3.48 and a dissipation factor of 0.0037 at 10 GHz. While RO4350B is more cost-effective and easier to process, RT/duroid 5880 offers superior electrical performance with lower dielectric constant and loss tangent.

- Isola Astra MT77: With a dielectric constant of 3.00 and a dissipation factor of 0.0017 at 10 GHz, Astra MT77 is another high-frequency material. However, RT/duroid 5880’s lower dielectric constant makes it more suitable for applications requiring minimal signal delay.

- Taconic TLY-5: This material has a dielectric constant of 2.20, similar to RT/duroid 5880, but with a slightly higher dissipation factor of 0.0018 at 10 GHz. While both materials offer low Dk, RT/duroid 5880 provides a lower loss tangent, making it preferable for applications demanding the highest signal integrity.

- Arlon AD255C: With a dielectric constant of 2.55 and a dissipation factor of 0.0015 at 10 GHz, Arlon AD255C is another competitor. However, RT/duroid 5880’s lower dielectric constant and dissipation factor offer better performance in high-frequency applications.

Rogers RT/duroid 5880 is distinguished by its exceptionally low dielectric constant and dissipation factor, which are critical for high-frequency and high-performance applications. While other materials may offer advantages in cost or ease of processing, RT/duroid 5880’s superior electrical properties make it the material of choice for demanding RF and microwave applications.

Rogers RT/duroid 5880 Substrate Price

Factors Influencing the Price

Several factors influence the price of Rogers RT/duroid 5880 substrates:

- Material Composition: The high-quality PTFE and glass microfiber composition contribute to its superior performance and higher cost.

- Thickness and Size: Prices vary based on the thickness and size of the substrate sheets. Thicker and larger sheets typically cost more due to the increased material usage.

- Quantity Purchased: Bulk purchases often come with volume discounts, reducing the price per unit compared to smaller orders.

- Supplier and Distributor Pricing: Different suppliers and distributors may offer varying prices based on their procurement costs, inventory levels, and market demand.

- Market Demand and Supply: Fluctuations in demand, influenced by the tech industry and specific project requirements, can impact pricing. Limited supply or high demand periods can drive prices up.

- Customization and Processing Requirements: Custom orders requiring specific processing, such as additional surface treatments or pre-cut sizes, can increase the overall cost.

Average Cost and Pricing Trends

The average cost of Rogers RT/duroid 5880 substrates can vary widely based on the aforementioned factors. Generally, the price ranges from $200 to $500 per sheet, depending on thickness and size. For instance, a standard 18″ x 24″ sheet with a thickness of 0.060″ might cost around $300.

Pricing trends indicate that the cost of high-frequency laminates like Rogers 5880 has been relatively stable, with minor fluctuations driven by raw material costs and demand from the electronics and telecommunications sectors. Recently, there has been a slight upward trend in prices due to increased demand for advanced communication systems and the limited availability of high-quality materials.

Where to Buy (Suppliers and Distributors)

Rogers RT/duroid 5880 substrates can be purchased from various suppliers and distributors. Here are some notable options:

- Rogers Corporation: The manufacturer offers direct sales through their website and sales representatives. This is often the best option for ensuring authenticity and access to the latest product lines.

- Digi-Key Electronics: A leading distributor of electronic components, Digi-Key provides a wide range of Rogers materials, including RT/duroid 5880, with options for different sizes and thicknesses.

- Mouser Electronics: Another major distributor, Mouser, offers Rogers 5880 substrates with detailed product specifications and competitive pricing.

- RFMW, Ltd.: Specializing in RF and microwave components, RFMW provides access to Rogers materials with a focus on supporting high-frequency applications.

- TME (Transfer Multisort Elektronik): This distributor offers a broad selection of electronic materials and components, including Rogers 5880, catering to global customers.

The price of Rogers RT/duroid 5880 substrates is influenced by material composition, size, quantity, supplier pricing, market demand, and customization needs. The average cost ranges from $200 to $500 per sheet, with slight price increases observed due to rising demand in high-frequency applications. Reliable suppliers and distributors like Rogers Corporation, Digi-Key Electronics, Mouser Electronics, RFMW, Ltd., and TME offer a variety of purchasing options to meet diverse customer needs.

Thickness Options for Rogers RT/duroid 5880

Available Thicknesses

Rogers RT/duroid 5880 substrates are available in a range of thicknesses to cater to diverse application requirements. Commonly available thickness options include:

- 0.005″ (0.127 mm)

- 0.010″ (0.254 mm)

- 0.020″ (0.508 mm)

- 0.031″ (0.787 mm)

- 0.060″ (1.524 mm)

- 0.125″ (3.175 mm)

These thicknesses allow designers and engineers to choose the most appropriate substrate for their specific application needs, balancing factors like mechanical stability, signal performance, and space constraints.

How Thickness Affects Performance

The thickness of the Rogers RT/duroid 5880 substrate significantly impacts its performance in various ways:

- Signal Integrity:

- Thinner Substrates: Thinner substrates, such as 0.005″ and 0.010″, are ideal for high-frequency applications where minimal signal distortion and low insertion loss are critical. These thinner materials help maintain signal integrity by reducing the distance the signal travels through the dielectric material, minimizing phase delay.

- Thicker Substrates: Thicker substrates, such as 0.060″ and 0.125″, provide greater mechanical support and are suitable for applications where structural integrity is essential. However, thicker substrates can introduce more signal delay due to the increased distance the signal must travel.

- Thermal Management:

- Thinner Substrates: Thinner materials have less mass and can dissipate heat more rapidly, which is beneficial in applications where efficient thermal management is required to prevent overheating of components.

- Thicker Substrates: While thicker substrates have a greater ability to absorb and spread heat, they may not dissipate it as efficiently as thinner substrates. This can be a consideration in high-power applications where heat buildup needs to be managed.

- Mechanical Stability:

- Thicker Substrates: Thicker materials provide enhanced mechanical stability, making them suitable for applications involving larger or more complex circuit designs that require robust support to prevent bending or warping.

- Thinner Substrates: Thinner substrates are more flexible and can be used in applications where flexibility is required, such as in flexible circuits or in situations where the substrate needs to conform to a specific shape.

- Fabrication Considerations:

- Thicker Substrates: Thicker substrates may present more challenges during the fabrication process, such as difficulties in drilling and plating through holes. The increased thickness can also affect the alignment and registration of layers in multilayer PCBs.

- Thinner Substrates: Thinner substrates are easier to process and are less likely to encounter issues related to drilling and plating. They also offer better layer alignment in multilayer constructions, enhancing overall fabrication accuracy.

- Electrical Performance:

- Thicker Substrates: Thicker materials may introduce slight variations in the dielectric constant across the substrate’s thickness, potentially affecting the uniformity of electrical performance. However, for many applications, these variations are minimal and do not significantly impact performance.

- Thinner Substrates: Thinner substrates tend to have more uniform dielectric properties across their thickness, leading to more consistent electrical performance, which is crucial for high-frequency and high-precision applications.

The choice of substrate thickness in Rogers RT/duroid 5880 materials is a critical design decision that affects signal integrity, thermal management, mechanical stability, fabrication processes, and overall electrical performance. By selecting the appropriate thickness, engineers can optimize the substrate’s performance to meet the specific demands of their application.

Dielectric Constant of Rogers 5880

Importance of Dielectric Constant in Applications

The dielectric constant (Dk) of a substrate material is a critical parameter in the design and performance of high-frequency circuits. It measures the material’s ability to store electrical energy in an electric field and affects various aspects of circuit performance:

- Signal Speed and Propagation: The dielectric constant influences the speed at which signals propagate through the substrate. A lower Dk results in faster signal transmission, which is essential for high-speed and high-frequency applications.

- Impedance Control: Accurate control of impedance is crucial in RF and microwave circuits to ensure signal integrity and minimize reflection losses. The dielectric constant directly impacts the impedance of transmission lines, necessitating precise material selection for desired impedance values.

- Circuit Size: The dielectric constant affects the wavelength of signals within the substrate. A lower Dk allows for smaller circuit elements and more compact designs, which is beneficial in miniaturized and densely packed electronic systems.

- Losses and Efficiency: A stable and low dielectric constant reduces dielectric losses, enhancing the overall efficiency of the circuit and ensuring reliable performance in critical applications.

Value of the Dielectric Constant for Rogers 5880

Rogers RT/duroid 5880 has a dielectric constant of approximately 2.20 at 10 GHz. This low Dk value is one of the key features that make it highly suitable for high-frequency and high-performance applications. The consistent and low dielectric constant of Rogers 5880 provides several advantages:

- Enhanced Signal Integrity: The low Dk minimizes signal distortion and delays, ensuring clear and accurate signal transmission.

- Improved Efficiency: The material’s low dielectric losses contribute to higher circuit efficiency, making it ideal for power-sensitive applications.

- Precision in High-Frequency Applications: The stable dielectric constant across a wide frequency range ensures predictable and reliable performance, which is critical for advanced communication systems and high-frequency electronics.

Comparison with Other Materials

When comparing Rogers RT/duroid 5880 with other materials, its low dielectric constant stands out as a significant advantage. Here are some comparisons:

- Rogers RO4350B: This material has a dielectric constant of 3.48 at 10 GHz. While RO4350B is more economical and easier to process, its higher Dk makes it less suitable for applications requiring minimal signal delay and high-speed transmission compared to Rogers 5880.

- Isola Astra MT77: With a dielectric constant of 3.00 at 10 GHz, Astra MT77 offers good performance for high-frequency applications but still falls short of the lower Dk value provided by Rogers 5880.

- Taconic TLY-5: This material has a dielectric constant of 2.20, similar to Rogers 5880, making it a close competitor. However, the choice between the two often depends on other factors such as dissipation factor, mechanical properties, and specific application requirements.

- Arlon AD255C: With a dielectric constant of 2.55 at 10 GHz, Arlon AD255C offers a low Dk but is still higher than that of Rogers 5880. This makes AD255C less optimal for applications where the lowest possible dielectric constant is crucial.

The dielectric constant is a pivotal factor in determining the suitability of a substrate material for high-frequency and high-performance applications. Rogers RT/duroid 5880, with its low dielectric constant of approximately 2.20, offers significant advantages in terms of signal integrity, efficiency, and miniaturization. Its superior performance compared to other materials makes it an ideal choice for advanced RF and microwave circuits, ensuring reliable and high-speed signal transmission.

Loss Tangent of RT/duroid 5880

Definition and Significance of Loss Tangent

The loss tangent, also known as the dissipation factor or tan δ, is a measure of a dielectric material’s inherent energy loss when subjected to an alternating electric field. It quantifies the inefficiency with which the material stores and releases electrical energy and is expressed as the ratio of the imaginary part of the permittivity (energy loss) to the real part of the permittivity (energy storage). The lower the loss tangent, the lower the dielectric losses, leading to more efficient signal transmission.

The significance of the loss tangent in high-frequency applications is profound:

- Signal Integrity: A low loss tangent minimizes signal attenuation, preserving signal strength and integrity over long distances. This is critical in high-frequency circuits where signal degradation can impact performance.

- Efficiency: Materials with a low loss tangent ensure higher efficiency by reducing energy dissipation as heat. This is particularly important in power-sensitive applications and for maintaining the performance of sensitive electronic components.

- Thermal Management: Reduced energy loss translates to lower heat generation, which aids in thermal management and enhances the longevity and reliability of electronic devices.

Value for Rogers 5880 and Its Implications

Rogers RT/duroid 5880 is renowned for its exceptionally low loss tangent of approximately 0.0009 at 10 GHz. This low value has significant implications for its performance in high-frequency and high-performance applications:

- Enhanced Signal Clarity: The low loss tangent ensures minimal signal loss, maintaining high signal clarity and strength. This is essential for applications such as RF and microwave circuits, where signal quality is paramount.

- Higher Efficiency: The minimal energy dissipation translates to higher circuit efficiency, making Rogers 5880 an excellent choice for applications where power efficiency is critical, such as in satellite communication systems and portable electronic devices.

- Improved Thermal Performance: With lower dielectric losses, the substrate generates less heat during operation. This reduces the need for extensive thermal management solutions and enhances the overall reliability and lifespan of the electronic components.

- Suitability for High-Frequency Applications: The low loss tangent of Rogers 5880 makes it particularly well-suited for high-frequency applications, including radar systems, communication systems, and high-speed digital circuits. The material’s ability to maintain performance at high frequencies ensures that designs can meet stringent requirements for signal integrity and efficiency.

The loss tangent is a crucial parameter that impacts signal integrity, efficiency, and thermal performance in high-frequency applications. Rogers RT/duroid 5880’s exceptionally low loss tangent of approximately 0.0009 at 10 GHz positions it as a superior material for applications demanding minimal signal loss and high efficiency. This characteristic, combined with its low dielectric constant, makes Rogers 5880 an ideal choice for advanced RF and microwave circuits, ensuring reliable and high-performance operation across a wide range of applications.

General Overview of Rogers Substrates

Types of Substrates Offered by Rogers Corporation

Rogers Corporation is a leading provider of high-performance substrates and laminates used in various advanced electronic applications. The company offers a diverse range of substrate materials, each tailored to meet specific performance requirements. Key types of substrates include:

- RT/duroid® Series:

- RT/duroid® 5880: Known for its low dielectric constant and low loss tangent, ideal for high-frequency applications.

- RT/duroid® 5870: Similar to 5880 but with a slightly different composition for specific performance needs.

- RT/duroid® 6000 Series: Offers a range of dielectric constants and is used in microwave and millimeter-wave applications.

- RO4000® Series:

- RO4350B™ and RO4003C™: High-frequency circuit materials with low dielectric loss and stable dielectric constants, suitable for RF and microwave applications.

- TMM® Thermoset Microwave Materials:

- These materials offer a range of dielectric constants with low loss and excellent thermal stability, making them suitable for microwave and high-power applications.

- RO3000® Series:

- RO3003™ and RO3035™: Engineered for demanding RF and microwave circuits, offering low loss and excellent dimensional stability.

- RO4700™ LoPro® Series:

- Designed for high-speed digital and high-frequency analog applications, offering low insertion loss and excellent signal integrity.

- CLTE-XT™ Laminates:

- These materials provide stable dielectric properties over a wide frequency range and temperature variations, ideal for microwave and RF multilayer circuits.

- AD Series® Laminates:

- AD255C™ and AD300C™: Offer low Dk and low loss, optimized for antenna designs and other RF applications.

Key Features and Advantages

Rogers Corporation’s substrates are renowned for their exceptional performance characteristics, catering to a wide range of advanced electronic applications. Here are some key features and advantages:

- Low Dielectric Constant (Dk):

- Many Rogers substrates, like RT/duroid® 5880, have low dielectric constants, which enable faster signal transmission and reduced signal distortion. This is crucial for high-frequency and high-speed applications.

- Low Loss Tangent:

- Substrates such as RT/duroid® 5880 exhibit low loss tangent values, ensuring minimal signal loss and high efficiency. This feature is vital for maintaining signal integrity in RF and microwave circuits.

- Thermal Stability:

- Materials like the TMM® series and RO4000® series offer excellent thermal stability, ensuring consistent performance over a wide range of temperatures. This is essential for applications subjected to harsh environmental conditions.

- Mechanical Stability:

- Rogers substrates provide robust mechanical support, maintaining structural integrity and dimensional stability, which is important for complex circuit designs and multilayer boards.

- Chemical Resistance:

- Substrates such as RT/duroid® 5880 are chemically resistant, allowing them to perform reliably in corrosive environments and in applications where exposure to chemicals is common.

- Wide Range of Dielectric Constants:

- Rogers offers a broad spectrum of dielectric constants across its product lines, providing designers with the flexibility to choose materials that best suit their specific performance requirements.

- Customization and Versatility:

- The availability of various thicknesses and the ability to customize materials for specific applications make Rogers substrates highly versatile, catering to diverse industry needs.

- High Frequency Performance:

- Many Rogers materials are optimized for high-frequency applications, ensuring reliable performance in RF, microwave, and millimeter-wave frequencies, which is critical for modern communication systems and radar technologies.

- Proven Reliability:

- Rogers Corporation’s substrates are widely recognized for their reliability and performance, making them a trusted choice for critical applications in aerospace, defense, telecommunications, and medical industries.

Rogers Corporation offers a comprehensive range of high-performance substrates tailored to meet the demands of advanced electronic applications. The key features of these materials, such as low dielectric constant, low loss tangent, thermal and mechanical stability, and chemical resistance, make them ideal for high-frequency, high-speed, and high-reliability applications across various industries.

Applications of Rogers 5880 Substrate

Specific Examples in RF and Microwave Engineering

Rogers RT/duroid 5880 substrates are widely recognized for their exceptional performance in RF and microwave engineering. Here are some specific examples:

- Antenna Design:

- Phased Array Antennas: RT/duroid 5880 is used in phased array antennas for radar systems, where its low dielectric constant and low loss tangent ensure high efficiency and precise signal propagation.

- Patch Antennas: The material’s low dielectric constant allows for smaller, more compact patch antennas with excellent performance in communication systems, including satellite and terrestrial applications.

- High-Frequency Circuits:

- Power Amplifiers: The substrate’s low loss tangent helps minimize energy dissipation, making it ideal for high-power RF amplifiers used in broadcasting and telecommunications.

- Low Noise Amplifiers (LNAs): LNAs benefit from the low loss and stable dielectric properties of RT/duroid 5880, which help maintain signal clarity and reduce noise in sensitive applications like radio astronomy and deep-space communication.

- Filters and Couplers:

- Microwave Filters: The substrate’s consistent dielectric constant ensures reliable performance in microwave filters, which are critical for separating different frequency bands in communication systems.

- Directional Couplers: Used in various RF applications, directional couplers made with RT/duroid 5880 benefit from low insertion loss and stable performance, ensuring efficient signal routing.

- Phase Shifters:

- Radar Systems: Phase shifters in radar systems use RT/duroid 5880 for its stable dielectric properties, which are essential for precise phase control and accurate target detection and tracking.

- Transmission Lines:

- Microstrip Lines: The substrate is ideal for microstrip line designs, offering low signal loss and stable impedance characteristics, which are crucial for high-frequency signal transmission.

- Stripline Circuits: RT/duroid 5880 is also used in stripline circuits where its low dielectric constant helps achieve controlled impedance and minimal signal distortion.

Other Potential Applications

Beyond RF and microwave engineering, Rogers RT/duroid 5880 substrates find use in a variety of other advanced applications:

- Aerospace and Defense:

- Avionics Systems: The material’s excellent thermal stability and low loss make it suitable for high-frequency communication and navigation systems in aircraft.

- Electronic Warfare: RT/duroid 5880 is used in electronic warfare systems where reliable high-frequency performance is essential for signal jamming and interception technologies.

- Medical Devices:

- Imaging Systems: The substrate’s low dielectric loss is beneficial in medical imaging equipment like MRI and ultrasound devices, where it helps improve image resolution and clarity.

- Implantable Devices: The biocompatibility and stable performance of RT/duroid 5880 make it a suitable choice for implantable medical devices that require high-frequency signal transmission.

- Automotive:

- Radar Sensors: In advanced driver-assistance systems (ADAS), the material is used in radar sensors for collision avoidance and adaptive cruise control, where its low dielectric constant ensures accurate signal transmission and reception.

- Vehicle-to-Everything (V2X) Communication: RT/duroid 5880 supports high-frequency communication systems that enable vehicles to communicate with each other and with infrastructure, enhancing safety and traffic management.

- Telecommunications:

- Base Stations: The substrate is used in base station antennas and amplifiers for cellular networks, providing reliable performance and efficient signal processing at high frequencies.

- 5G Technology: RT/duroid 5880’s properties are well-suited for 5G applications, where low loss and high efficiency are critical for high-speed data transmission and low-latency communication.

- Satellite Communication:

- Transceivers: The material is used in satellite transceivers for its low loss and stable dielectric properties, which are essential for maintaining signal integrity over long distances.

- High-Frequency Modules: RT/duroid 5880 is ideal for high-frequency modules in satellite communication systems, ensuring efficient and reliable operation in space environments.

Rogers RT/duroid 5880 substrates are indispensable in a wide range of high-frequency and high-performance applications. Their exceptional dielectric properties, low loss tangent, and thermal stability make them ideal for RF and microwave engineering, as well as aerospace, medical, automotive, telecommunications, and satellite communication systems. These substrates enable precise signal transmission, high efficiency, and reliable performance across diverse and demanding applications.

FAQs About rogers 5880 substrate

Rogers RT/duroid 5880 is a high-performance substrate material used in advanced electronic applications. It is a type of PTFE (polytetrafluoroethylene) composite with a glass microfiber reinforcement. This material is designed to offer low dielectric constant and low loss tangent, making it ideal for high-frequency and high-speed applications. Its unique composition provides excellent thermal stability, low signal loss, and high mechanical strength, which are crucial for RF (radio frequency) and microwave circuits.

Rogers substrates are a family of high-performance circuit board materials produced by Rogers Corporation. They are used in a variety of advanced electronic applications, including RF, microwave, and high-speed digital circuits. Rogers substrates are known for their superior electrical properties, including low dielectric constant (Dk), low loss tangent, and excellent thermal stability. They are commonly used in high-frequency applications such as telecommunications, aerospace, and defense systems due to their ability to maintain signal integrity and efficiency in challenging environments.

Rogers RT/duroid 5880 has a dielectric constant of approximately 2.20 at 10 GHz. This low dielectric constant helps in achieving faster signal propagation and minimized signal distortion, which is essential for high-speed and high-frequency electronic applications. The material’s stable dielectric constant ensures reliable performance in demanding RF and microwave circuits.

Rogers RT/duroid 5880 is available in various thicknesses to meet different design requirements. Common thickness options include:

0.005″ (0.127 mm)

0.010″ (0.254 mm)

0.020″ (0.508 mm)

0.031″ (0.787 mm)

0.060″ (1.524 mm)

0.125″ (3.175 mm)

The choice of thickness depends on the specific application needs, such as mechanical support, signal integrity, and thermal management.