Military PCB Standards & Manufacturers | MIL-PRF-31032 Guide

In electronics, PCB stands for Printed Circuit Board. It is the structural and electrical backbone of virtually every electronic system, from smartphones to satellites. In the military context, however, a PCB is far more than a signal routing platform—it is a mission-critical component that must operate reliably under extreme environmental conditions.

In defense applications, PCBs form the foundation of systems such as radar, communication units, navigation equipment, missile guidance systems, and avionics. Unlike commercial-grade boards, military PCBs are engineered for maximum durability, long-term stability, and absolute reliability. A single failure could compromise a mission or even risk lives.

Military PCB Standards

To ensure uniform quality and reliability, military electronics must comply with specific standards—often referred to as MIL-SPEC.

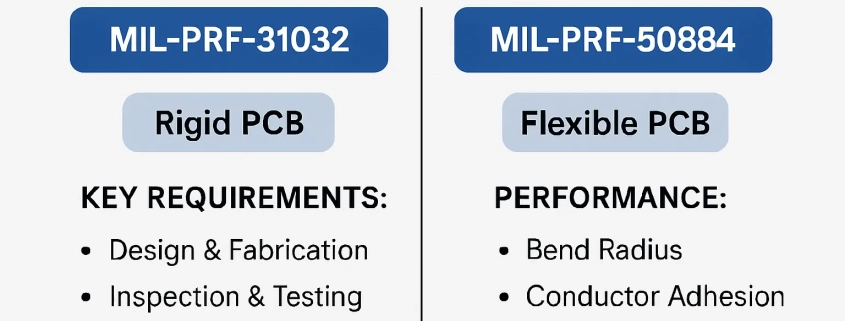

MIL-PRF-31032

-

Definition: A U.S. Department of Defense performance specification for the design, fabrication, and inspection of rigid PCBs for military applications.

-

Scope: Covers everything from raw materials and layer stack-up to hole plating and testing methods.

-

Key Requirements:

-

Full process control documentation.

-

Lot-by-lot and periodic qualification testing.

-

Environmental stress testing for temperature, humidity, and vibration.

-

-

Reference: The official document (MIL-PRF-31032 PDF) outlines the complete performance requirements and can be downloaded from the DoD ASSIST database.

MIL-PRF-50884

-

Definition: Similar to MIL-PRF-31032 but specific to flexible and rigid-flex PCBs used in military systems.

-

Key Focus: Bend radius, conductor adhesion, and performance under repeated flexing.

-

Applications: Aircraft wiring harnesses, foldable avionics modules, and compact battlefield electronics.

Other related military PCB standards include:

-

MIL-STD-275 (now largely replaced but historically significant for PCB design rules).

-

IPC-6012DS (defense and space addendum for rigid PCBs).

Characteristics of Military-Grade PCBs

Military PCBs differ from consumer-grade boards in both materials and design philosophy:

-

Temperature Resistance: Operation from -55°C to +125°C (or higher for aerospace systems).

-

Shock & Vibration Tolerance: Survive intense mechanical stress without microcracks or solder joint failures.

-

Moisture & Corrosion Resistance: Conformal coatings and sealed enclosures protect against salt fog, humidity, and chemicals.

-

EMI/EMC Protection: Enhanced grounding, shielding layers, and filter circuits.

-

Material Selection:

-

High-Tg FR-4 for standard rigid designs.

-

Polyimide for high-temperature and high-reliability builds.

-

PTFE (Rogers) for high-frequency radar and communication systems.

-

-

Surface Finishes:

-

ENIG (Electroless Nickel Immersion Gold) for corrosion resistance and fine-pitch components.

-

HASL or immersion silver for cost-effective builds.

-

-

Complex Layer Structures: Multilayer and HDI (High-Density Interconnect) to support miniaturized, high-performance systems.

Military PCB Manufacturing Process (PCB Fab)

Producing a MIL-SPEC PCB requires strict process control:

-

Design & DFM (Design for Manufacturability)

-

CAD layout with controlled impedance, EMI shielding, and thermal management.

-

Stack-up design to meet MIL-PRF requirements.

-

-

Material Procurement

-

Sourcing certified laminates and copper foils with full traceability.

-

-

Lamination & Drilling

-

Sequential lamination for multilayer structures.

-

Precision drilling for plated through holes (PTH) and microvias.

-

-

Plating, Imaging & Etching

-

Heavy copper plating for power circuits.

-

Photolithographic imaging for fine-line patterns.

-

-

Solder Mask & Surface Finish

-

Military-grade solder mask with high dielectric strength.

-

Surface finish applied per component and environment requirements.

-

-

Assembly

-

SMT (Surface-Mount Technology) and THT (Through-Hole Technology).

-

Leaded solder may still be used for high-reliability defense projects.

-

-

Inspection & Testing

-

AOI (Automated Optical Inspection), X-ray for hidden joints.

-

Electrical testing (flying probe, in-circuit).

-

Environmental Stress Screening (ESS) and thermal cycling.

-

Certification & Compliance

Manufacturers seeking to produce military PCBs must undergo a rigorous MIL-PRF-31032 or MIL-PRF-50884 qualification process. This includes:

-

Process audits by the Defense Logistics Agency (DLA).

-

Documentation of every production step.

-

Ongoing lot acceptance testing.

-

Traceability from raw material to finished product.

Compliance ensures that boards meet the demanding reliability requirements of military missions.

Leading Military PCB Manufacturers

The best military PCB suppliers share common traits:

-

MIL-SPEC certifications (MIL-PRF-31032, MIL-PRF-50884).

-

In-house environmental and electrical testing.

-

Ability to handle quick-turn PCB Express orders without sacrificing compliance.

Selecting a supplier should be based on:

-

Proven track record in defense contracts.

-

Capacity to deliver consistent quality at scale.

-

Secure data handling to protect classified designs.

FAQs About Military PCB

1. What does PCB stand for?

PCB stands for Printed Circuit Board, a platform that mechanically supports and electrically connects components using conductive tracks and pads.

2. What is a PCB in the army?

In military applications, a PCB is the backbone of mission-critical systems such as communication equipment, navigation units, radar modules, and weapons control systems. These boards are designed to survive extreme temperatures, vibration, and electromagnetic interference.

3. What is the military standard PCB?

A military standard PCB is a circuit board built to meet specific U.S. Department of Defense performance specifications, such as MIL-PRF-31032 for rigid boards and MIL-PRF-50884 for flexible and rigid-flex boards. These standards define material quality, manufacturing processes, and testing requirements.

4. What is MIL-PRF-31032?

MIL-PRF-31032 is a performance specification for the fabrication and inspection of rigid military PCBs. It outlines requirements for material selection, layer stack-up, plating quality, and environmental testing.

5. What is MIL-PRF-50884?

MIL-PRF-50884 is the corresponding performance specification for flexible and rigid-flex military PCBs, focusing on durability under bending and dynamic use.

6. Who are the best military PCB manufacturers?

The best military PCB manufacturers hold active MIL-PRF-31032 or MIL-PRF-50884 certifications, offer in-house environmental testing, and have a proven track record in defense electronics production. Factors like quick-turn capabilities, supply chain security, and strict quality control are essential.