Advantages of Integrated Press Hole Rogers PCB in High-Speed

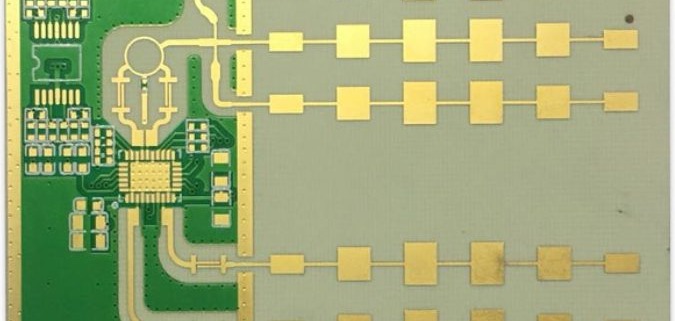

Printed Circuit Boards (PCBs) are essential in modern electronics, providing the physical structure to connect electronic components and ensuring reliable electrical signals in devices like smartphones, computers, and medical equipment. Among the various types, Rogers PCBs are renowned for their superior performance in high-frequency applications, offering low signal loss, excellent thermal stability, and high electrical reliability. These attributes make them ideal for demanding fields like RF communication, radar systems, and satellite technology. An advanced variation, the Integrated Press Hole Rogers PCB, combines traditional drilling with an integrated press hole process, enhancing both manufacturing efficiency and electrical performance. This technology is particularly valuable in specialized applications, such as 5G networks, high-speed communications, and automotive radar systems, where high-frequency signal integrity and thermal management are crucial.

What is Integrated Press Hole Rogers PCB?

An Integrated Press Hole Rogers PCB is a specialized type of printed circuit board designed to offer superior performance for high-frequency and high-speed applications. It utilizes advanced manufacturing techniques to improve upon traditional PCB designs, specifically by integrating press hole technology into the production process. This results in a PCB that not only supports high-frequency signals but also enhances overall electrical and thermal performance.

The term Integrated Press Hole refers to a process that combines traditional drilling methods with press hole technology. In typical PCB manufacturing, holes are drilled into the board to create vias for electrical connections. However, the Integrated Press Hole Rogers PCB takes this one step further by employing a press hole technique, which helps to reduce the mechanical stresses often caused by conventional drilling. This process is particularly useful when working with the advanced materials used in Rogers PCBs, which are designed to handle high-frequency signals.

By integrating the press hole method, this technology enhances the performance of Rogers PCBs in several ways. First, it improves the accuracy and reliability of the vias, ensuring better signal integrity in high-speed applications. The process also helps reduce the risk of defects such as micro-cracks or uneven hole walls that can negatively impact performance. Additionally, the Integrated Press Hole Rogers PCB manufacturing process is more efficient, reducing production time and costs while maintaining high-quality standards. This combination of advanced performance and manufacturing efficiency makes Integrated Press Hole Rogers PCBs the preferred choice for industries where precision and reliability are paramount.

Introduction to Rogers PCB and Integrated Press Hole Rogers PCB

Rogers PCBs are a specialized type of printed circuit board made from high-performance materials that offer unique advantages in demanding applications, particularly in high-frequency, high-speed, and RF (radio frequency) technologies. These PCBs are widely used in industries that require precise signal integrity and minimal interference, such as telecommunications, aerospace, automotive, and medical devices.

The key characteristics of Rogers PCBs include exceptional high-frequency properties, low signal loss, and high stability and reliability. Rogers materials are engineered to handle the electrical demands of modern electronics, particularly where traditional PCB materials may struggle. These boards exhibit superior performance in high-speed signal transmission, making them the go-to solution for applications like 5G networks, satellite communication, radar systems, and other RF technologies.

One of the most critical properties of Rogers PCBs is their low signal loss. This is essential for maintaining signal clarity, especially in high-frequency environments where even small losses can lead to significant performance degradation. The use of advanced materials such as RO4003, RO4350B, and RO5880 ensures that Rogers PCBs maintain low dielectric constants and low dissipation factors, both of which contribute to better performance in high-frequency applications.

Rogers PCBs offer high stability and reliability, even under extreme conditions. These boards are highly resistant to temperature fluctuations and environmental stress, making them suitable for mission-critical applications where failure is not an option. The combination of these properties—low signal loss, high stability, and reliability—makes Rogers PCBs ideal for use in high-frequency, RF, and high-speed signal transmission applications.

When enhanced by the Integrated Press Hole Rogers PCB technology, these performance attributes are further optimized. The press hole method reduces potential mechanical stress and improves the reliability of vias and connections, ensuring that high-frequency signals travel with minimal distortion. This makes the Integrated Press Hole Rogers PCB an even more robust choice for industries requiring the highest standards of performance.

Advantages of Integrated Press Hole Technology in Integrated Press Hole Rogers PCB

The Integrated Press Hole Rogers PCB technology combines traditional drilling methods with advanced press hole techniques, resulting in a more efficient and precise manufacturing process. This hybrid approach significantly enhances the performance and reliability of Rogers PCBs, especially in demanding high-frequency and high-speed applications.

Combining Traditional Drilling and Press Hole Methods

Traditional PCB manufacturing often involves drilling holes into the board for vias, which are used to create electrical connections between different layers. However, drilling can introduce certain limitations, such as the potential for inaccurate hole placements and mechanical stresses that can compromise the integrity of the PCB. The Integrated Press Hole Rogers PCB approach overcomes these challenges by integrating a press hole process, which helps to reduce the risks of inaccuracies and mechanical defects. This process combines the best aspects of both drilling and press hole technologies, leading to more reliable and precise vias.

Improving Hole Accuracy and Reducing Hole Wall Losses

One of the main advantages of Integrated Press Hole Rogers PCB technology is its ability to improve hole accuracy. Traditional drilling can sometimes result in uneven hole walls, which can affect the electrical performance of the PCB. The press hole method allows for smoother and more precise holes, reducing the risk of defects such as micro-cracks or inconsistent hole dimensions. This improvement ensures better signal integrity and fewer chances of signal degradation, which is especially crucial in high-speed and high-frequency applications.

The Integrated Press Hole Rogers PCB method significantly reduces hole wall losses. In high-frequency applications, the integrity of the vias is critical for maintaining signal clarity. By minimizing hole wall losses, this technology helps preserve the quality of the electrical signals passing through the PCB, ensuring better performance and higher efficiency.

Lower Manufacturing Costs and Increased Production Efficiency

The integration of press hole technology into the traditional drilling process also offers significant cost benefits. By improving the accuracy and reducing the likelihood of defects, Integrated Press Hole Rogers PCB manufacturing can streamline the production process. This results in fewer rejected boards and lower material waste, ultimately reducing manufacturing costs. Moreover, the use of advanced press hole technology increases production efficiency by allowing for faster and more precise hole formation, which speeds up the overall PCB fabrication process.

Enhancing Electrical Performance and Thermal Management

The combination of traditional drilling and press hole methods in Integrated Press Hole Rogers PCB technology not only improves hole accuracy but also enhances the overall electrical performance of the PCB. The high precision of the vias and the reduced losses in the signal transmission paths contribute to better electrical characteristics, such as lower signal loss and improved transmission speed. This is particularly valuable in high-frequency applications, where maintaining signal quality is essential.

The Integrated Press Hole Rogers PCB technology also improves thermal management. The press hole process allows for more uniform hole placement, which can improve the distribution of heat across the PCB, reducing the chances of overheating or thermal-related failure. This is especially beneficial for high-power applications or systems that generate significant heat during operation.

Improving Overall Reliability, Especially in High-Frequency and High-Speed Applications

Reliability is a key consideration in the design and manufacturing of PCBs, particularly in high-frequency and high-speed applications where even small defects can lead to system failure. The Integrated Press Hole Rogers PCB method ensures that the vias are more accurate and consistent, reducing the risk of mechanical failures, signal interference, or performance degradation. This enhanced reliability makes Integrated Press Hole Rogers PCBs an excellent choice for mission-critical applications, such as aerospace, telecommunications, and automotive electronics, where long-term performance and stability are essential.

The Integrated Press Hole Rogers PCB technology offers numerous advantages, including improved hole accuracy, reduced signal losses, lower manufacturing costs, and enhanced electrical and thermal performance. These benefits make it a superior choice for industries that require high-performance, reliable PCBs capable of handling high-frequency and high-speed signal transmission.

Applications of Integrated Press Hole Rogers PCB

The Integrated Press Hole Rogers PCB offers enhanced performance and reliability, making it ideal for a wide range of high-frequency and high-speed applications. Its advanced manufacturing technology ensures superior electrical performance and thermal management, making it well-suited for industries where precision and signal integrity are critical. Below are some key applications where Integrated Press Hole Rogers PCBs are widely used:

High-Speed Communication Applications with Integrated Press Hole Rogers PCB

One of the primary applications of Integrated Press Hole Rogers PCBs is in high-speed communication systems, such as 5G networks and satellite communications. These systems rely on fast, reliable signal transmission over long distances, often under challenging environmental conditions. Integrated Press Hole Rogers PCBs are particularly beneficial in these areas because they offer low signal loss, high-frequency stability, and reliable performance at extremely high speeds. By integrating press hole technology, these PCBs can handle the increased demand for higher frequencies and bandwidth, making them a perfect fit for next-generation communication technologies like 5G and advanced satellite systems.

Wireless Communication with Integrated Press Hole Rogers PCB

Integrated Press Hole Rogers PCBs are also commonly used in wireless communication devices, including Wi-Fi routers, Bluetooth modules, and other wireless systems. These devices require PCBs that can manage high-speed data transmission while maintaining signal clarity and minimal interference. The low signal loss and high stability of Integrated Press Hole Rogers PCBs ensure that wireless signals remain strong and clear, even in environments with multiple competing signals. This makes them ideal for applications where signal integrity is critical for maintaining connectivity, such as in consumer electronics, IoT (Internet of Things) devices, and wireless communication infrastructure.

High-Frequency Radar Systems with Integrated Press Hole Rogers PCB

Another critical application of Integrated Press Hole Rogers PCBs is in high-frequency radar systems, which are used in various industries, including defense, aerospace, and automotive. Radar systems rely on precise signal transmission and low-loss performance to detect and track objects at long ranges. Integrated Press Hole Rogers PCBs provide the necessary electrical properties to handle the high-frequency signals required in radar systems, while also ensuring that the system’s performance remains reliable in harsh environments. The enhanced reliability and low-loss capabilities of these PCBs make them an excellent choice for both military and civilian radar applications, such as air traffic control, weather monitoring, and autonomous vehicle radar.

Automotive Electronics and Radar with Integrated Press Hole Rogers PCB

The automotive industry, especially with the development of autonomous driving systems, increasingly relies on high-performance PCBs. Integrated Press Hole Rogers PCBs are essential in automotive radar and sensor systems, such as those used in LiDAR, radar sensors, and advanced driver assistance systems (ADAS). These systems need highly reliable and accurate signal transmission to process data from sensors and cameras in real-time. The high-frequency and low-loss properties of Integrated Press Hole Rogers PCBs ensure that the electronic systems in autonomous vehicles can process information rapidly and accurately, making them a crucial part of modern vehicle electronics. The press hole technology also helps improve the durability and robustness of these PCBs, which is vital in the automotive environment where reliability is non-negotiable.

Power Electronics and Energy Systems with Integrated Press Hole Rogers PCB

Integrated Press Hole Rogers PCBs are also used in power electronics and energy systems, where efficient power conversion, signal transmission, and thermal management are essential. These PCBs are ideal for applications such as solar inverters, electric vehicle (EV) charging stations, and power distribution systems, where high power and high-frequency signals must be managed efficiently. The low signal loss and superior thermal properties of Integrated Press Hole Rogers PCBs ensure that energy systems operate efficiently while maintaining safety and reliability. Additionally, these PCBs help prevent overheating, which is critical in power electronics where high heat generation is common.

The Integrated Press Hole Rogers PCB plays a crucial role in modern high-speed, high-frequency, and high-reliability applications across a variety of industries. From 5G communications to autonomous driving and power electronics, the enhanced electrical performance, signal integrity, and reliability offered by these PCBs make them indispensable for applications that require precision and durability.

Manufacturing Process of Integrated Press Hole Rogers PCB

The manufacturing process of Integrated Press Hole Rogers PCB involves a combination of advanced techniques designed to maximize the performance, reliability, and efficiency of the PCB. This process integrates traditional PCB manufacturing methods with innovative press hole technology to achieve high-precision vias and enhanced electrical performance, making it ideal for high-frequency and high-speed applications. Below is a detailed explanation of the manufacturing steps involved in producing Integrated Press Hole Rogers PCBs.

Material Selection

The first step in the production of Integrated Press Hole Rogers PCBs is the careful selection of materials. Rogers materials, such as RO4003, RO4350B, and RO5880, are chosen based on their excellent high-frequency properties, low signal loss, and thermal stability. These materials are known for their low dielectric constants and low dissipation factors, which are essential for maintaining signal integrity in high-speed applications. The material’s ability to handle high temperatures and mechanical stresses is also a critical factor in ensuring the durability and performance of the finished PCB.

Design Phase

Once the materials are selected, the next step is the design phase. During this stage, the PCB layout is created based on the specific requirements of the application. This includes the positioning of components, the routing of signal paths, and the design of the vias that will connect the different layers of the PCB. The Integrated Press Hole Rogers PCB design focuses on optimizing the placement of vias and minimizing signal path lengths to reduce signal loss and improve performance.

Advanced design software is used to simulate the PCB’s electrical characteristics and ensure that the design meets the required specifications. Special attention is given to the design of the press holes, ensuring they align correctly with the rest of the vias to achieve optimal performance.

Press Hole Process

The hallmark of Integrated Press Hole Rogers PCBs is the integration of the press hole process. This advanced method combines the traditional drilling technique with a press hole procedure, which is used to create high-precision vias. Unlike conventional drilling, which can cause mechanical stress and inaccuracies in the hole formation, the press hole technique allows for smoother, more uniform holes with better dimensional accuracy. The press hole method also helps reduce the risk of defects, such as micro-cracks or uneven hole walls, which can negatively impact the performance of the PCB.

In the Integrated Press Hole Rogers PCB manufacturing process, the press hole is created by pressing the material with high pressure to form the desired hole shape, which is then processed in the next steps. This improves hole integrity, making it especially beneficial for high-frequency applications where signal loss through imperfect vias can significantly degrade performance.

Drilling

Once the press holes are created, the next step is drilling. This step is required for forming additional vias and through-holes that are necessary for the electrical connections between different layers of the PCB. Traditional drilling methods are still used, but the integration with the press hole process ensures that the overall hole quality is significantly improved. The precision of the vias created through this hybrid process results in better electrical performance and signal integrity.

During the drilling process, care is taken to ensure the correct alignment of the holes, minimizing the risk of misalignment that could lead to connection failures. The drilling is performed using high-precision machines that can handle the hard Rogers material, ensuring that the vias are created with minimal mechanical stress and high accuracy.

Optimizing Production to Reduce Errors or Defects

To optimize the production process and reduce errors or defects in Integrated Press Hole Rogers PCBs, several quality control measures are implemented at each step. These include:

-

Automated Inspection Systems: Using advanced automated optical inspection (AOI) systems, manufacturers can detect any misalignments, defects in hole dimensions, or material inconsistencies early in the process. This ensures that any issues are identified and addressed before moving to the next stage, reducing the likelihood of defective boards.

-

Process Control: Throughout the manufacturing process, strict process control is maintained. Parameters such as temperature, pressure, and time during the press hole process are carefully monitored and controlled to ensure consistency and accuracy. Similarly, the drilling process is closely monitored to avoid any damage to the PCB or inaccurate hole formation.

-

Material Testing: Each batch of Rogers material is thoroughly tested for its dielectric properties, thermal stability, and mechanical strength before it is used in production. This helps ensure that only the highest quality materials are used in the manufacture of Integrated Press Hole Rogers PCBs, leading to a higher overall yield and fewer defects.

Ensuring PCB Reliability Under Extreme Conditions

The Integrated Press Hole Rogers PCB is specifically designed to perform reliably under extreme conditions, such as high temperatures, mechanical stress, and high-frequency environments. To ensure reliability:

-

Thermal Management: The design and manufacturing processes ensure that the PCB can efficiently dissipate heat generated during operation. The uniformity and accuracy of the vias and press holes help distribute heat evenly across the board, preventing localized overheating and ensuring long-term reliability.

-

Environmental Testing: Once the Integrated Press Hole Rogers PCB is manufactured, it undergoes a series of environmental tests to verify its performance under harsh conditions. These tests simulate real-world conditions such as extreme temperatures, humidity, and vibration, ensuring that the PCB can withstand the stresses of its intended application, whether it’s in an aerospace system, automotive electronics, or a 5G communication device.

-

Reliability Testing: The final PCBs are subjected to reliability tests, including thermal cycling and mechanical stress testing, to confirm that they will perform consistently over time. The high precision of the press holes and vias ensures that there are no weak points that could fail under stress, enhancing the overall reliability of the board.

The Integrated Press Hole Rogers PCB manufacturing process is designed to produce high-performance, reliable PCBs that meet the demands of high-frequency, high-speed applications. By combining traditional drilling with the press hole method, this process not only improves the accuracy and efficiency of PCB production but also ensures that the final product can reliably perform under extreme conditions. This makes Integrated Press Hole Rogers PCBs an excellent choice for industries where precision, performance, and reliability are critical.

Difference Between Integrated Press Hole Rogers PCB and Traditional Rogers PCB

While both Integrated Press Hole Rogers PCBs and traditional Rogers PCBs are known for their high-performance capabilities in high-frequency and high-speed applications, there are significant differences in their manufacturing processes, performance, and cost. These differences can make Integrated Press Hole Rogers PCBs a more suitable choice in certain applications where precision, signal integrity, and reliability are critical.

Comparison of Traditional Rogers PCBs vs. Integrated Press Hole PCBs

Traditional Rogers PCBs are made from high-quality Rogers materials such as RO4003, RO4350B, and RO5880, which are known for their excellent electrical properties, low signal loss, and high thermal stability. However, the manufacturing process for traditional Rogers PCBs typically relies on conventional drilling methods to create vias and through-holes. While this process is effective, it can lead to challenges in terms of hole accuracy and mechanical stress, particularly when working with high-frequency signals.

Integrated Press Hole Rogers PCBs incorporate an advanced manufacturing technique that combines traditional drilling with press hole technology. This hybrid approach helps create more accurate and precise vias, improving both the mechanical integrity and electrical performance of the board. The integration of press hole technology helps eliminate many of the imperfections that can arise from conventional drilling methods, making it particularly useful in applications that demand high reliability and performance.

Differences in Performance: Electrical Characteristics, Thermal Stability, Mechanical Strength

Electrical Characteristics:

-

Traditional Rogers PCBs offer good performance in terms of low signal loss and high-frequency stability, but they can still suffer from imperfections in the vias. These imperfections may result in signal degradation, especially in high-speed or high-frequency applications where precise signal integrity is paramount. Vias in traditional PCBs are drilled using mechanical methods that may lead to inconsistencies such as uneven hole walls or minor misalignments, which can negatively impact the performance of high-frequency circuits.

-

Integrated Press Hole Rogers PCBs, however, significantly improve electrical performance. The press hole process helps reduce hole wall losses, improves the precision of the vias, and minimizes the risk of signal interference. This results in better signal integrity, lower signal loss, and higher performance at extremely high frequencies, making Integrated Press Hole Rogers PCBs the preferred choice for demanding applications like 5G networks, satellite communications, and radar systems.

Thermal Stability:

-

Both Traditional Rogers PCBs and Integrated Press Hole Rogers PCBs are known for their excellent thermal stability, which is a key characteristic of Rogers materials. However, the Integrated Press Hole Rogers PCB process can offer enhanced thermal performance due to its improved via and hole integrity. Since the press hole technique helps evenly distribute heat across the PCB and reduces the risk of localized overheating, it can provide superior thermal management in high-power or high-frequency applications.

-

In contrast, Traditional Rogers PCBs may have less consistent thermal dissipation properties, especially if the vias are not uniformly drilled, potentially leading to uneven heat distribution. This can be a concern in certain applications where precise thermal management is crucial.

Mechanical Strength:

-

Traditional Rogers PCBs can experience mechanical stresses and deformations due to the drilling process. The drilling method can sometimes cause micro-cracks or inconsistencies in the hole walls, which may weaken the overall mechanical strength of the board. This can become a significant issue when the PCB is subjected to harsh conditions, such as vibrations, high mechanical stress, or extreme temperatures.

-

Integrated Press Hole Rogers PCBs are more mechanically robust. The press hole method improves the uniformity and strength of the vias, reducing the risk of defects and increasing the mechanical integrity of the PCB. This makes Integrated Press Hole Rogers PCBs more reliable in applications where durability and long-term performance are critical, such as in aerospace, automotive, and military applications.

Cost Comparison: Traditional Manufacturing Methods vs. Newer Technologies

The cost of manufacturing Traditional Rogers PCBs is generally lower compared to Integrated Press Hole Rogers PCBs, primarily due to the simpler manufacturing process. Traditional drilling techniques are well-established and require less specialized equipment, which keeps production costs relatively low. However, this cost savings comes with trade-offs in terms of performance, particularly in high-frequency or high-speed applications.

Integrated Press Hole Rogers PCBs involve more advanced and specialized manufacturing processes, which can increase production costs. The press hole technique requires additional equipment and more precise control over the drilling process, resulting in higher upfront costs. However, the benefits in terms of improved performance, reduced defects, and higher reliability often justify the increased cost, especially in applications where PCB performance is critical.

While the initial cost of Integrated Press Hole Rogers PCBs may be higher, the overall cost-effectiveness of these boards becomes evident over time. The enhanced performance and reduced risk of failure can lead to lower maintenance costs and fewer product defects, making Integrated Press Hole Rogers PCBs a more cost-effective solution in the long run, particularly for high-end, mission-critical applications.

Integrated Press Hole Rogers PCBs offer several advantages over Traditional Rogers PCBs, particularly in terms of electrical performance, thermal stability, and mechanical strength. The press hole technology significantly improves via accuracy and reduces signal loss, making these PCBs ideal for high-frequency and high-speed applications. While the manufacturing process for Integrated Press Hole Rogers PCBs may be more expensive, the increased reliability and enhanced performance often justify the additional cost, especially for industries where precision and long-term durability are paramount.

Key Considerations When Choosing Integrated Press Hole Rogers PCB

Selecting the right Integrated Press Hole Rogers PCB for your application involves careful consideration of several critical factors. These factors ensure that the PCB meets the specific demands of high-frequency, high-speed, and high-reliability applications. Below, we outline the key considerations that should guide the selection process of an Integrated Press Hole Rogers PCB.

Frequency and Signal Transmission Requirements

One of the most important factors to consider when choosing an Integrated Press Hole Rogers PCB is the frequency and signal transmission requirements of the application. Integrated Press Hole Rogers PCBs are particularly beneficial in high-frequency applications because they help minimize signal loss and maintain signal integrity, even at extremely high speeds. If your application involves 5G networks, satellite communications, or high-speed radar systems, ensuring that the PCB can handle the required frequency range without significant signal degradation is essential.

The press hole technology within Integrated Press Hole Rogers PCBs ensures that vias are formed with high precision, reducing imperfections that could impact signal transmission. Additionally, the improved hole accuracy helps maintain consistent signal quality, which is crucial in applications requiring fast and stable data transmission.

Electrical Performance and Thermal Management Needs

When selecting an Integrated Press Hole Rogers PCB, it is essential to consider the electrical performance and thermal management needs of your application. Integrated Press Hole Rogers PCBs excel in providing excellent electrical characteristics, such as low signal loss and high-frequency stability. The precise via formation enabled by press hole technology enhances signal integrity, reducing unwanted interference and improving overall performance.

In addition to electrical performance, thermal management is also a critical consideration. High-speed and high-frequency applications generate significant heat, which can affect the performance and reliability of the PCB. Integrated Press Hole Rogers PCBs offer improved thermal dissipation due to their uniform and precise via structures, helping to evenly distribute heat and prevent hot spots. If your application involves high-power or high-temperature environments, ensuring that the PCB can handle the thermal stress while maintaining optimal performance is vital.

Material Selection: Compatibility of Different Rogers Materials

Another key consideration when choosing an Integrated Press Hole Rogers PCB is the material selection. Rogers offers a variety of materials, each with specific properties suited for different applications. Some of the most common Rogers materials used in Integrated Press Hole Rogers PCBs include:

-

RO4003: Known for its low-loss dielectric properties, this material is often used in high-frequency applications such as communications and radar systems.

-

RO4350B: With its excellent thermal and electrical stability, RO4350B is commonly used in high-speed digital and RF applications.

-

RO5880: Ideal for applications that require high reliability, such as automotive or aerospace electronics, this material offers low dissipation factor and high thermal conductivity.

When choosing an Integrated Press Hole Rogers PCB, it is essential to select the right Rogers material that is compatible with the application’s frequency, power requirements, and environmental conditions. The right material ensures that the Integrated Press Hole Rogers PCB performs optimally, with minimal signal loss and high stability, even under extreme conditions.

Manufacturer and Supply Chain Considerations

The manufacturer and supply chain considerations play a significant role in the overall quality and cost of the Integrated Press Hole Rogers PCB. It is crucial to choose a reliable PCB manufacturer with expertise in producing high-quality Integrated Press Hole Rogers PCBs. A reputable manufacturer will have the necessary experience and technology to execute the press hole process with precision, ensuring that the vias are uniform and that the final product meets the required specifications.

In addition to manufacturing capabilities, it is important to consider the supply chain for materials and components. Given that Integrated Press Hole Rogers PCBs rely on specific Rogers materials, it is essential to ensure that the manufacturer has access to a consistent and reliable supply of these materials. Supply chain stability can affect lead times, production schedules, and ultimately, the timely delivery of your finished PCBs.

Communication and customer support are important factors when selecting a manufacturer. Ensure that the manufacturer offers clear communication throughout the production process and provides support for troubleshooting, design assistance, and post-production quality checks.

Choosing the right Integrated Press Hole Rogers PCB involves a careful evaluation of several factors, including frequency and signal transmission requirements, electrical and thermal performance needs, material compatibility, and the reliability of the manufacturer and supply chain. By addressing these key considerations, you can ensure that the Integrated Press Hole Rogers PCB will meet the demands of your specific application, offering high performance, reliability, and long-term durability. Whether you’re working with 5G, satellite communications, or high-power electronics, selecting the right Integrated Press Hole Rogers PCB will be crucial to achieving the best possible performance and efficiency for your application.

Common Issues and Solutions in Integrated Press Hole Rogers PCB

While Integrated Press Hole Rogers PCBs offer significant advantages in terms of performance, accuracy, and reliability, there are some common challenges associated with the application of this technology. These challenges typically arise during the manufacturing process, material selection, or the specific requirements of high-frequency applications. Understanding these challenges and the solutions available can help ensure the optimal performance of Integrated Press Hole Rogers PCBs.

Common Challenges in Applying Integrated Press Hole Technology

Hole Integrity and Precision

One of the primary challenges in producing Integrated Press Hole Rogers PCBs is maintaining the integrity and precision of the press holes. While the press hole method improves via accuracy compared to traditional drilling, imperfections in the press hole formation process can still occur. These imperfections may affect the PCB’s performance, especially in high-frequency and high-speed applications where even small errors can cause significant signal degradation.

Material Compatibility and Uniformity

The unique properties of Rogers materials, such as RO4003, RO4350B, and RO5880, are essential for high-performance Integrated Press Hole Rogers PCBs, but these materials can present challenges when it comes to ensuring consistent compatibility during the press hole process. Variations in material thickness, surface consistency, or even the chemical composition of different material batches can lead to inconsistencies in the hole formation, which can compromise the performance and reliability of the final PCB.

Manufacturing Complexity and Cost

The Integrated Press Hole Rogers PCB process is more complex than traditional PCB manufacturing, which can lead to higher costs and more intricate production processes. The need for specialized equipment and higher precision often results in longer production times and increased material costs, which may not always align with tight budget constraints, particularly for low-volume or cost-sensitive projects.

Thermal Management Challenges

Although Integrated Press Hole Rogers PCBs offer improved thermal performance compared to traditional PCBs, managing heat dissipation can still be a challenge in applications involving high power and high frequencies. If the thermal properties are not properly managed, the PCB may experience thermal stress, which could lead to signal degradation, component failure, or even physical warping.

Design Constraints and Layout Optimization

While Integrated Press Hole Rogers PCBs offer improved via and hole accuracy, designing an optimal layout for the press hole process can still be challenging. The location, size, and arrangement of the vias need to be carefully planned to ensure the press hole technology works effectively and that there is no negative impact on signal integrity or board reliability.

Solutions: How to Overcome Technical Challenges During Manufacturing or Application

Enhancing Press Hole Process Control

To address the challenge of hole integrity and precision, advanced process control is crucial. Manufacturers can implement tighter process controls, including precise monitoring of pressure, temperature, and time during the press hole formation. Additionally, automated optical inspection (AOI) and X-ray inspection technologies can be used to detect imperfections early in the process, ensuring that only high-quality press holes are produced. Implementing quality control measures at every stage of production will reduce the likelihood of defects and ensure the Integrated Press Hole Rogers PCB meets the required specifications.

Selecting Compatible Materials and Testing for Uniformity

To overcome material compatibility challenges, manufacturers should carefully select Rogers materials that are specifically suited for the Integrated Press Hole Rogers PCB process. It is essential to perform thorough testing and material inspections before production begins to ensure that all material batches meet uniformity standards. Using materials with well-defined characteristics can help reduce variations in hole formation and improve the overall consistency of the finished PCB. Collaboration between designers and material suppliers is critical to ensure material compatibility and avoid production delays.

Optimizing Production Efficiency to Control Costs

Given the increased complexity and cost of producing Integrated Press Hole Rogers PCBs, manufacturers can take several steps to optimize production efficiency. Streamlining the production process by improving yield rates, reducing material waste, and using advanced automation can help lower the overall cost. Additionally, selecting a manufacturer with experience in Integrated Press Hole Rogers PCBs ensures that the process is more efficient and cost-effective, especially when scaling production for high-volume projects.

Advanced Thermal Management Solutions

While Integrated Press Hole Rogers PCBs offer better thermal dissipation than traditional PCBs, additional thermal management strategies may still be required for high-power applications. Using thermal vias, heat sinks, and other passive cooling techniques can help further enhance the PCB’s ability to manage heat. Designers can also incorporate advanced materials or coatings to improve heat distribution across the board. Ensuring a robust thermal management design is critical for maintaining performance and reliability in high-power applications.

Layout Design Optimization

To overcome design constraints and ensure the best performance of Integrated Press Hole Rogers PCBs, careful consideration must be given to the layout and via placement. Engineers should utilize advanced PCB design tools that offer real-time simulation and optimization features, allowing them to evaluate the impact of the press hole design on signal integrity and overall PCB performance. By simulating electrical characteristics early in the design phase, potential issues related to via placement or signal routing can be identified and corrected before production begins.

Designers should consider factors such as the size, pitch, and alignment of vias, ensuring they are compatible with the press hole process. By optimizing the design for Integrated Press Hole Rogers PCBs, manufacturers can avoid performance issues and ensure that the board meets the application’s specific needs.

While there are some common challenges associated with Integrated Press Hole Rogers PCBs, these issues can be effectively addressed through careful planning, advanced manufacturing techniques, and optimization of materials and design. By enhancing process control, selecting compatible materials, optimizing production efficiency, managing thermal requirements, and fine-tuning PCB layouts, manufacturers and engineers can overcome these challenges and take full advantage of the superior performance and reliability these PCBs provide. With the right strategies in place, they can deliver exceptional results in high-frequency, high-speed applications where performance, durability, and precision are essential.

Future Trends in Integrated Press Hole Rogers PCB

The future of Integrated Press Hole Rogers PCB technology is promising, driven by continuous advancements in materials, manufacturing techniques, and the increasing demand for higher performance in electronic devices. As industries continue to evolve, Integrated Press Hole Rogers PCBs will play a crucial role in meeting the increasingly complex requirements of high-frequency, high-speed, and high-reliability applications. Below, we explore the future trends of Integrated Press Hole Rogers PCBs, focusing on how the technology will adapt to new challenges and integrate with emerging technologies.

Adapting to Higher Frequencies and More Demanding Performance Requirements

One of the most notable trends in Integrated Press Hole Rogers PCBs is their ability to adapt to the growing demands for higher frequencies and enhanced performance. As communication systems move toward 5G and beyond, and as radar and satellite technologies continue to advance, the need for Integrated Press Hole Rogers PCBs that can handle increasingly higher frequencies will only intensify. Integrated Press Hole Rogers PCBs are already known for their superior performance in high-frequency applications due to the advanced via technology and Rogers material properties. However, to keep up with future demands, manufacturers will need to refine their techniques to support frequencies in the millimeter-wave spectrum and beyond.

The technology’s ability to reduce signal loss and provide high stability even at extreme frequencies is crucial for applications in 5G, Wi-Fi 6, and future wireless technologies. Engineers and manufacturers will need to focus on refining press hole processes to further minimize signal loss, reduce thermal stress, and ensure that the PCB can maintain high integrity under extreme conditions. Integrated Press Hole Rogers PCBs will likely evolve with materials that are specifically designed to manage higher frequencies while maintaining low signal attenuation, making them ideal for cutting-edge applications in wireless communication and radar systems.

Integration with Other Advanced PCB Technologies

Another exciting trend is the integration of Integrated Press Hole Rogers PCBs with other advanced PCB technologies. As electronic systems continue to evolve, the demand for multi-functional, high-performance PCBs is rising. One significant area of development is the integration of Integrated Press Hole Rogers PCBs with millimeter-wave technology, which is critical for future communications systems and automotive radar applications. Integrated Press Hole Rogers PCBs can be enhanced to support the higher frequency ranges required for millimeter-wave systems, which are already being used in 5G communication, advanced radar systems, and autonomous vehicles.

In addition to millimeter-wave technology, Integrated Press Hole Rogers PCBs are expected to integrate with artificial intelligence (AI) and machine learning applications. These emerging technologies require PCBs that not only provide excellent high-speed signal transmission but also handle complex processing tasks with minimal latency. Integrated Press Hole Rogers PCBs will evolve to support AI-powered systems in fields such as automotive electronics (autonomous driving), industrial automation, and telecommunications infrastructure. The need for low-latency communication and high processing power will require continuous innovation in PCB manufacturing to ensure that Integrated Press Hole Rogers PCBs meet the needs of AI-driven devices.

The combination of advanced Integrated Press Hole Rogers PCBs with millimeter-wave and AI technologies will lead to the development of more compact, efficient, and high-performing electronic systems. This convergence will push Integrated Press Hole Rogers PCBs to new heights, enabling them to support next-generation technologies that demand both speed and reliability.

The future of Integrated Press Hole Rogers PCBs is filled with exciting possibilities, particularly as industries demand higher frequencies, more complex functionalities, and enhanced performance. As Integrated Press Hole Rogers PCBs evolve to meet these challenges, they will adapt to support the next wave of high-frequency applications and integrate seamlessly with cutting-edge technologies such as millimeter-wave and AI. Manufacturers will continue to refine materials and production techniques, ensuring that Integrated Press Hole Rogers PCBs remain at the forefront of the PCB industry, providing reliable, high-performance solutions for a wide range of demanding applications.