DIP Package: Essential for Robust Electronics

The DIP package, short for Dual Inline Package, is a crucial component in the realm of electronic engineering. It serves as a standardized housing for integrated circuits (ICs) and other electronic devices, facilitating their assembly onto circuit boards. Originating in the mid-20th century, DIP packaging revolutionized the electronics industry by enabling mass production and interchangeability of components. Over time, DIP packages evolved to accommodate advancements in technology and miniaturization demands, leading to the introduction of various subtypes tailored to specific applications. From its inception to the present day, the DIP package remains an essential cornerstone of electronic design, embodying reliability, versatility, and compatibility across diverse electronic systems. Understanding the history and development of DIP packaging provides valuable insights into the evolution of electronic devices and the enduring significance of standardized component packaging.

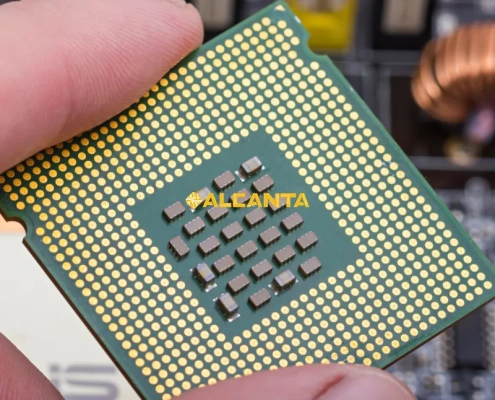

Characteristics of DIP Package

The DIP package boasts a distinctive appearance and robust structure, making it a popular choice in electronic design. Typically, a DIP package features a rectangular body with two parallel rows of leads or pins extending from the sides. These pins are evenly spaced along the edges, facilitating easy insertion into a circuit board. The body of the DIP package is often molded from a durable plastic material, providing protection for the enclosed electronic components.

DIP packages come in various dimensions to accommodate different types of integrated circuits and other devices. Commonly used sizes include 300 mil, 400 mil, and 600 mil widths, with the number of pins ranging from as few as 8 to as many as 64 or more. The dimensions and pin counts of DIP packages are standardized, allowing for easy integration into circuit board layouts and designs.

The structure of a DIP package includes the substrate, which serves as the foundation for mounting the electronic components. The substrate is typically made of a high-quality material such as ceramic or fiberglass, providing excellent thermal conductivity and electrical insulation. This ensures reliable performance and longevity, even in demanding operating conditions.

The appearance, dimensions, and structure of DIP packages contribute to their widespread use in electronic applications. Their standardized design and robust construction make them a versatile and reliable choice for integrating electronic components into circuit boards.

Applications of DIP Package

Comparison with Other Packaging Types

Advantages and Disadvantages of DIP Package

DIP packaging offers several distinct advantages, making it a preferred choice for certain applications. One of its primary strengths lies in its versatility and compatibility with through-hole mounting techniques, facilitating easy assembly and soldering onto circuit boards. Additionally, DIP packages typically feature robust construction, especially in ceramic variants, providing excellent mechanical stability and durability, which is crucial for harsh operating environments. Furthermore, DIP packages offer a wide range of pin counts and configurations, accommodating various circuit designs and integration requirements. Moreover, DIP packages often exhibit superior thermal performance compared to surface-mount alternatives, thanks to their larger surface area for heat dissipation.

However, DIP packaging also has some limitations that need to be considered. One significant drawback is its relatively larger size compared to surface-mount packages, which can restrict space on densely populated circuit boards and limit miniaturization efforts. Additionally, the through-hole mounting process used with DIP packages can be more time-consuming and labor-intensive compared to surface-mount assembly methods, potentially increasing manufacturing costs and complexity. Furthermore, DIP packages may exhibit higher parasitic capacitance and inductance due to longer lead lengths, which can affect high-frequency performance in certain applications.

When selecting DIP packaging for specific scenarios, several considerations come into play. For applications where reliability and mechanical robustness are paramount, such as industrial or automotive electronics, ceramic DIP packages may be preferred due to their superior durability. Conversely, for space-constrained applications or those requiring high-speed operation, surface-mount alternatives like SOIC or QFN packages might be more suitable. Additionally, cost considerations and manufacturing requirements should be taken into account when choosing between ceramic and plastic DIP packages, as each offers different trade-offs in terms of performance, cost, and assembly complexity. Ultimately, the selection of DIP packaging depends on a thorough assessment of the application’s requirements, including electrical performance, mechanical stability, thermal management, and cost constraints.

Trends in DIP Package Development

FAQs About DIP Package

What does DIP package stand for?

DIP stands for Dual Inline Package.

What is the difference between DIP and SOIC package?

The main difference between DIP (Dual Inline Package) and SOIC (Small Outline Integrated Circuit) packages lies in their form factors and mounting techniques. DIP packages typically feature a dual-row configuration with pins extending from the sides, designed for through-hole mounting on circuit boards. SOIC packages, on the other hand, are smaller and slimmer, with surface-mounted leads underneath the package body. SOIC packages offer higher pin densities and improved thermal performance compared to DIP packages, making them suitable for compact and high-density circuit designs.

What is the difference between PDIP and DIP package?

PDIP (Plastic Dual Inline Package) and DIP (Dual Inline Package) packages differ primarily in their material composition and construction. PDIP packages utilize plastic materials for the housing, offering cost-effectiveness and enhanced durability compared to traditional ceramic DIP packages. Additionally, PDIP packages often feature surface-mount leads, further reducing assembly complexity and enabling higher-speed operation. However, ceramic DIP packages maintain advantages in terms of superior thermal conductivity and mechanical stability, making them preferred for high-reliability applications where performance and longevity are crucial.

What is DIP and SOP?