CSP Package: Revolutionizing Electronics Packaging

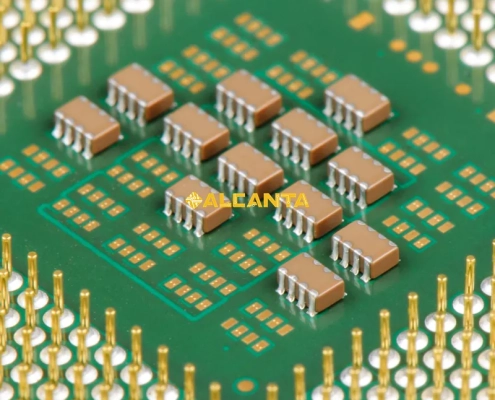

CSP Package stands at the forefront of modern electronics packaging, revolutionizing the industry with its compact size and versatile applications. Its significance lies in enabling smaller, lighter, and more efficient electronic devices, meeting the growing demand for portability and functionality across various sectors. In this blog, we delve into the diverse application areas where CSP Package excels, ranging from consumer electronics like smartphones and wearables to industrial equipment and automotive systems. Furthermore, we provide a comprehensive overview of the main topics, including the different types of CSP Packages, comparisons with other packaging technologies such as BGA, and insights into the future trends shaping the evolution of CSP Package technology.

Introduction to CSP Package

Types of CSP Packages

Comparison with Other Packaging Technologies

Comparison between CSP Package and BGA Package

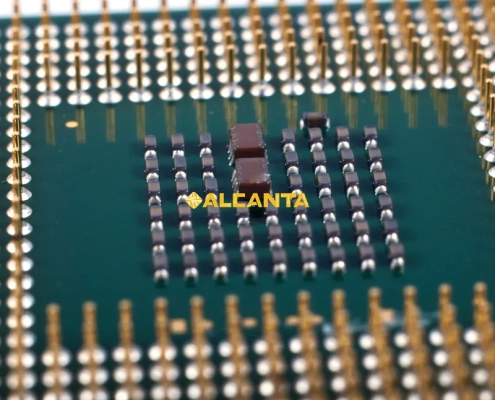

CSP (Chip Scale Package) and BGA (Ball Grid Array) are two popular packaging technologies in the electronics industry, each with its own unique features and advantages.

Differences

- Size: One of the primary differences between CSP and BGA is their size. CSP packages are designed to be almost the same size as the integrated circuit chip itself, while BGA packages typically have a larger footprint with solder balls arranged in a grid pattern beneath the package.

- Interconnection: In CSP packages, connections are typically located along the perimeter of the package, whereas in BGA packages, connections are located beneath the package in a grid array.

- Assembly Process: The assembly process for CSP packages may involve flip-chip bonding, where the chip is directly bonded to the substrate, while BGA packages often use wire bonding or solder ball attachment.

Advantages of CSP Package over BGA Package

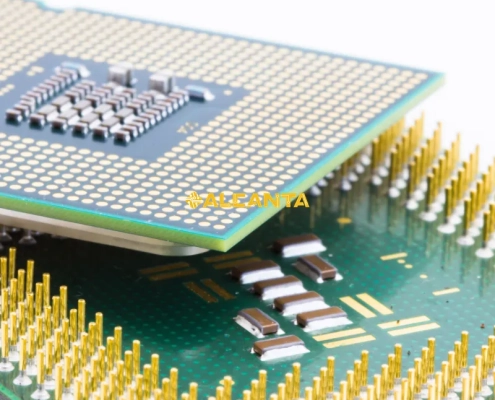

- Space Efficiency: CSP packages offer superior space efficiency compared to BGA packages due to their smaller footprint and reduced package size.

- Shorter Signal Paths: CSP packages typically have shorter signal paths, leading to improved electrical performance and reduced signal delay.

- Enhanced Thermal Performance: The smaller size of CSP packages allows for better heat dissipation, resulting in improved thermal performance compared to BGA packages.

Analysis of Differences and Similarities between CSP Package, QFN Package, BGA Package, and Other Packaging Technologies

CSP Package vs. QFN Package

- Both CSP and QFN (Quad Flat No-leads) packages offer space-efficient solutions with exposed pads on the bottom surface for soldering.

- CSP packages are typically smaller and offer higher interconnect density compared to QFN packages.

- QFN packages may offer better thermal performance due to the exposed thermal pad.

CSP Package vs. Other Packaging Technologies

- Compared to traditional leaded packages like Dual In-line Package (DIP) and Small Outline Integrated Circuit (SOIC), CSP packages offer significant space savings and improved electrical performance.

- CSP packages may have higher manufacturing costs and require specialized assembly equipment compared to some other packaging technologies.

- When compared to advanced packaging technologies like Wafer-Level Packaging (WLP) and System-in-Package (SiP), CSP packages offer a balance between cost-effectiveness and performance for many applications.

Size of CSP Package

Explanation of the Size Range and Considerations

CSP Packages come in a variety of sizes to meet the diverse needs of different applications. The size range typically varies from as small as 0.5mm x 0.5mm for ultra-miniature applications to larger sizes such as 10mm x 10mm for more complex integrated circuits. The choice of CSP Package size depends on several factors including:

- Application Requirements: Consider the space constraints and performance requirements of the application. Smaller CSP Packages are suitable for compact devices like wearables and IoT sensors, while larger packages may be required for high-performance computing applications.

- Thermal Considerations: Smaller CSP Packages may have limited thermal dissipation capabilities, which could impact their suitability for applications with high heat generation. Larger packages may offer better thermal management options.

- Assembly and Manufacturing Processes: The size of the CSP Package can influence assembly and manufacturing processes. Smaller packages may require specialized equipment and processes, which could affect production costs.

Presentation of Common Standards and Specifications

Below is a table presenting common standards and specifications for CSP Package sizes:

| Package Size (mm x mm) | Application | Common Standards |

| 0.5 x 0.5 | Wearables, IoT sensors | JEDEC JC-11, IPC-7095 |

| 2 x 2 | Mobile devices, Consumer electronics | JEDEC MO-220 |

| 5 x 5 | Automotive, Industrial electronics | JEDEC MO-211 |

| 10 x 10 | High-performance computing | JEDEC MO-307 |

These standards provide guidelines for package dimensions, pad layouts, and other specifications to ensure interoperability and compatibility across different manufacturers and applications. It’s essential for designers and manufacturers to adhere to these standards to facilitate seamless integration and interchangeability of CSP Packages in electronic systems.

Applications of CSP Package in Electronic Products

Future Trends of CSP Package

FAQs About CSP Package

What is a CSP package?

A CSP package, or Chip Scale Package, is a type of integrated circuit packaging that is designed to be nearly the same size as the chip it encapsulates. It eliminates excess packaging material, resulting in a compact package ideal for space-constrained applications.

What is the difference between BGA and CSP package?

The main difference between BGA (Ball Grid Array) and CSP (Chip Scale Package) is in their size and packaging approach. BGA packages typically have a larger footprint with solder balls arranged in a grid pattern beneath the package, while CSP packages are designed to be almost the same size as the chip, with connections typically located along the package perimeter.

What is the size of a CSP package?

The size of a CSP package varies depending on the specific application and manufacturer. CSP packages can range from as small as 0.5mm x 0.5mm for ultra-miniature applications to larger sizes such as 10mm x 10mm for more complex integrated circuits.

What does CSP stand for in electronics?

CSP stands for Chip Scale Package in electronics. It refers to a packaging technology where the package size is comparable to the size of the integrated circuit chip itself, enabling compact and space-efficient designs.