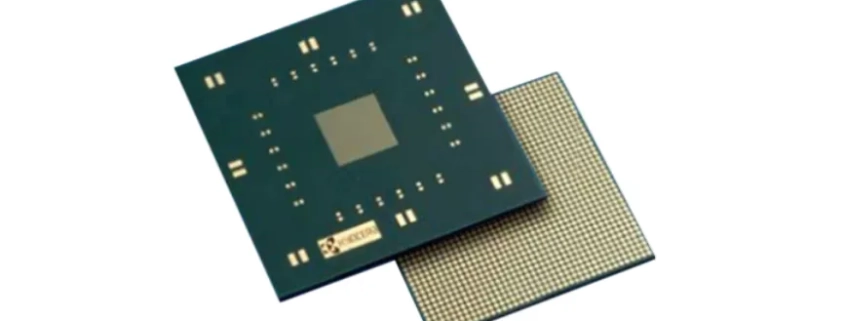

Integrated circuit packaging plays a crucial role in safeguarding delicate electronic components and ensuring their optimal performance in various applications. Among the myriad packaging options, the Plastic Quad Flat Package (PQFP) stands out for its versatility and wide-ranging applications.

Originating in the late 1980s, PQFP packaging revolutionized the semiconductor industry by offering a compact yet robust solution for housing integrated circuits. Initially used in consumer electronics, such as early personal computers and gaming consoles, PQFP quickly found its way into telecommunications, automotive, industrial, and aerospace sectors. Its adaptability to high-density designs and excellent thermal properties have cemented its status as a go-to choice for modern electronic devices.

In this blog post, we delve deeper into the features, differences, and applications of PQFP packaging, shedding light on its significance in contemporary electronics.

阅读更多