Flexible substrates refer to materials that possess the ability to bend, fold, or conform to various shapes without breaking. These substrates play a crucial role across diverse industries due to their unique properties of flexibility, lightweight nature, and durability. They are integral in applications ranging from electronics to packaging and healthcare sectors. In electronics, flexible substrates enable the development of bendable displays and printed electronics, revolutionizing device design and functionality. In packaging, they offer innovative solutions for flexible packaging, enhancing convenience and sustainability. Similarly, in healthcare, flexible substrates are used in medical devices and wearable sensors, contributing to advancements in personalized healthcare and monitoring technologies. The versatility and adaptability of flexible substrates continue to drive their adoption and innovation across global markets.

What is a Flexible Substrate?

Definition and Characteristics

Flexible substrates are materials that exhibit pliability and can be bent or shaped without damage. They are typically thin and lightweight, allowing them to conform to curved surfaces or be rolled up. These substrates maintain their structural integrity while being flexible, making them suitable for applications where traditional rigid materials would be impractical or limiting.

Example Materials: Polymers, Thin Films, etc.

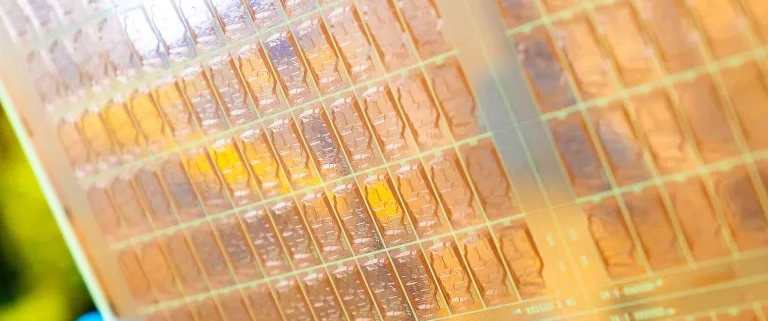

Flexible substrates encompass a variety of materials, with polymers being one of the most common. Polymers like polyethylene terephthalate (PET) and polyimide (PI) are widely used due to their flexibility, durability, and thermal stability. Thin films of metals or ceramics deposited onto flexible polymer substrates are also utilized, providing additional functionalities such as conductivity or barrier properties. Other materials include paper-based substrates and hybrid materials tailored for specific applications like flexible displays, electronic circuits, and flexible solar cells.

Applications of Flexible Substrates

Electronics Industry: Flexible Displays, Printed Electronics

Flexible substrates are pivotal in the electronics industry, enabling the development of flexible displays and printed electronics. Flexible OLED (organic light-emitting diode) displays utilize flexible substrates to create thin, lightweight screens that can be bent or curved without sacrificing performance. Printed electronics, such as flexible circuits and sensors, leverage the flexibility of substrates to integrate electronic functionalities into unconventional shapes and surfaces, expanding the possibilities for smart devices and IoT (Internet of Things) applications.

Packaging Industry: Flexible Packaging Solutions

In the packaging sector, flexible substrates play a crucial role in the development of flexible packaging solutions. Flexible packaging offers benefits such as lightweight, portability, and extended shelf life for products. Materials like flexible films and laminates provide barrier properties against moisture, oxygen, and light, preserving the freshness and quality of food and consumer goods. Flexible packaging also reduces material usage and transportation costs compared to rigid packaging, contributing to sustainability efforts in the packaging industry.

Healthcare Sector: Medical Devices, Wearable Sensors

Flexible substrates are increasingly employed in the healthcare sector for various applications, including medical devices and wearable sensors. Flexible substrates enable the development of wearable medical devices that conform comfortably to the body, allowing continuous monitoring of vital signs and health parameters. They facilitate the integration of sensors and electronics into wearable formats, supporting advancements in remote patient monitoring, health diagnostics, and personalized medicine. Flexible substrates also contribute to the development of implantable medical devices that require flexibility and biocompatibility to ensure patient safety and comfort.

Advantages of Flexible Substrates

Lightweight and Portable Nature

Flexible substrates are inherently lightweight and portable, making them ideal for applications where weight and space are critical factors. They enable the development of portable electronics, lightweight wearable devices, and compact packaging solutions that reduce shipping costs and storage space requirements.

Ability to Conform to Different Shapes

One of the key advantages of flexible substrates is their ability to conform to different shapes and surfaces. This flexibility allows for the creation of curved displays, conformable sensors, and packaging that molds around the product shape. It opens up new design possibilities in electronics, packaging, and healthcare, enabling innovative product designs and improving user experience.

Cost-effectiveness and Sustainability Benefits

Flexible substrates often contribute to cost savings in manufacturing due to their efficient use of materials and streamlined production processes. In packaging, they reduce material waste compared to rigid alternatives and offer energy savings in transportation due to lighter weight. Moreover, flexible substrates are often recyclable and contribute to sustainability goals by reducing overall environmental impact throughout their lifecycle.

Materials Used in Flexible Substrates

Detailed Look at Common Materials (e.g., PET, PI, Paper)

Flexible substrates utilize various materials tailored to specific applications:

– Polyethylene Terephthalate (PET): PET is widely used for its excellent mechanical properties, transparency, and resistance to moisture and chemicals. It is commonly used in flexible packaging, labels, and as a substrate for flexible electronics.

– Polyimide (PI): PI offers high thermal stability, flexibility, and excellent electrical insulation properties. It is suitable for applications requiring high temperature resistance, such as flexible circuits, aerospace components, and medical devices.

– Paper-based Substrates: Paper substrates are lightweight, biodegradable, and offer good printability. They are used in packaging, including food packaging, as well as in electronics for applications where cost-effectiveness and environmental considerations are paramount.

Properties and Suitability for Different Applications

– Electronics: Flexible substrates like PET and PI provide the necessary flexibility and durability for flexible displays, printed electronics, and flexible solar cells. They offer excellent substrate properties to support electronic components and maintain performance under bending and stretching conditions.

– Packaging: PET and other flexible films provide barrier properties that protect packaged goods from moisture, oxygen, and light. They are essential for extending shelf life and preserving product freshness, contributing to sustainability by reducing packaging weight and material waste.

– Healthcare: Polyimide substrates are used in medical devices and wearable sensors due to their biocompatibility, flexibility, and resistance to sterilization processes. They enable comfortable and reliable integration of electronics for continuous health monitoring and therapeutic applications.

This section delves into the materials commonly used as flexible substrates, highlighting their specific properties and suitability for diverse applications in electronics, packaging, and healthcare industries.

FAQs about flexible substrates market

An example of a flexible substrate is polyethylene terephthalate (PET). PET is a lightweight and flexible polymer commonly used in applications such as flexible packaging, flexible electronics (like flexible displays), and as a substrate for various printed electronics.

A flexible market refers to a market that can easily adapt to changes in supply and demand conditions, consumer preferences, and technological advancements. It typically describes industries or sectors where products or services can be rapidly adjusted or diversified to meet changing market dynamics and customer needs.

The global flexible packaging market was valued at approximately USD 117 billion in 2021. It is expected to grow at a compound annual growth rate (CAGR) of around 3.5% from 2022 to 2028. Flexible packaging includes materials like films, pouches, and bags that offer advantages such as lightweight, cost-effectiveness, and sustainability compared to traditional rigid packaging.

Flexible substrates can be made from various materials, including polymers like PET and polyimide (PI), thin films of metals or ceramics deposited on flexible polymer bases, and even paper-based materials. These substrates are chosen for their ability to bend, fold, or stretch without losing structural integrity, making them suitable for applications in electronics, packaging, healthcare, and more.