ABF Substrates Manufacturer: Driving Industry Growth

ABF substrates, short for “Ajinomoto Build-up Film,” are integral components in electronic manufacturing, facilitating the interconnection of semiconductor devices on printed circuit boards (PCBs). Their significance lies in their exceptional electrical properties, thermal stability, and reliability, making them ideal for high-performance electronic devices. However, the electronics industry is currently grappling with a shortage of ABF substrates, disrupting supply chains and affecting sectors ranging from consumer electronics to automotive and telecommunications. This scarcity underscores the critical role ABF substrates play in modern technology, prompting a closer examination of manufacturing processes, market dynamics, and potential solutions to alleviate the shortage. Understanding the complexities surrounding ABF substrates and the challenges faced by manufacturers is paramount in navigating this unprecedented situation.

Exploring ABF Substrate Manufacturers

The ABF substrate manufacturing industry boasts several key players, each contributing uniquely to the market. Among the prominent ABF substrates suppliers are Ajinomoto Co., Inc., Unimicron Technology Corporation, and Shinko Electric Industries Co., Ltd. Ajinomoto Co., Inc., renowned for its pioneering ABF technology, holds a significant market share owing to its high-quality products and extensive research and development efforts. Unimicron Technology Corporation is another major player, known for its diverse portfolio of ABF substrates catering to various electronic applications. Shinko Electric Industries Co., Ltd. also commands a notable presence in the industry with its innovative solutions and commitment to technological advancements.

These manufacturers play a crucial role in driving innovation within the ABF substrate manufacturing sector. Recent trends include advancements in material science to enhance substrate performance, such as improved thermal conductivity and mechanical properties. Innovations in manufacturing processes, such as laser drilling and precision etching techniques, have also emerged to meet the growing demand for smaller and more complex electronic devices. Additionally, efforts towards sustainable and eco-friendly manufacturing practices are gaining traction, reflecting a broader industry shift towards environmental consciousness.

Overall, the ABF substrate manufacturing industry continues to evolve rapidly, driven by technological advancements and market demands. Collaboration among manufacturers, research institutions, and end-users remains essential to foster innovation and address emerging challenges in the field. As the industry navigates through the current shortage of ABF substrates, these key players are poised to lead the way in shaping the future landscape of electronic manufacturing.

Understanding ABF Substrates: What Sets Them Apart

Exploring the Unique Features of ABF Substrates

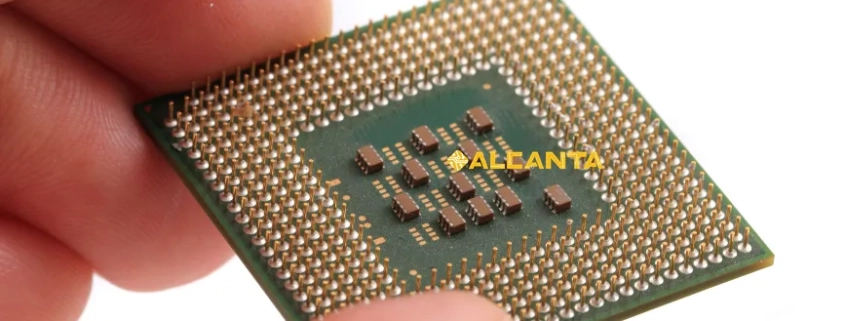

ABF substrates, manufactured by leading ABF substrates suppliers, are specialized materials used in electronic packaging and interconnect applications. These substrates consist of multiple layers of polymer films, reinforced with glass fiber, and feature a thin copper foil for conductivity. Their unique composition offers several distinguishing characteristics that set them apart from alternative materials such as BT (Bismaleimide Triazine).

Comparison with BT Substrates

While both ABF and BT substrates serve similar purposes in electronic manufacturing, they differ significantly in their composition and performance attributes. ABF substrates exhibit superior thermal stability and excellent electrical properties, making them ideal for high-frequency applications. In contrast, BT substrates may offer better mechanical strength but lack the same level of electrical performance and thermal conductivity.

Advantages of ABF Substrates

- Performance: ABF substrates demonstrate exceptional signal integrity and impedance control, crucial for high-speed data transmission in modern electronic devices. Their low dielectric constant and loss tangent ensure minimal signal distortion, enhancing overall system performance.

- Reliability: ABF substrates are highly reliable even under harsh operating conditions, thanks to their excellent thermal management capabilities. They dissipate heat efficiently, minimizing the risk of thermal-induced failures and ensuring long-term device reliability.

- Cost-effectiveness: Despite their advanced performance characteristics, ABF substrates remain cost-effective compared to alternative materials. Their ease of manufacturing and compatibility with standard PCB fabrication processes contribute to lower production costs, making them an attractive choice for manufacturers seeking to balance performance and affordability.

ABF substrates manufactured by reputable ABF substrates suppliers offer a compelling combination of performance, reliability, and cost-effectiveness, making them a preferred choice for a wide range of electronic applications. As the demand for high-speed and high-frequency devices continues to grow, ABF substrates are poised to play a pivotal role in shaping the future of electronic packaging and interconnect technologies.

Delving into ABF Material and PCBs

Understanding ABF Material Composition

ABF material, crafted by reputable ABF substrates manufacturers, is a critical component in modern electronic manufacturing. It typically comprises several layers of thermosetting polymer films, reinforced with glass fiber for enhanced mechanical strength and dimensional stability. A thin layer of copper foil is incorporated into the ABF material to facilitate electrical conductivity, enabling the interconnection of semiconductor devices on printed circuit boards (PCBs).

Exploring ABF PCBs and Their Applications

ABF PCBs, utilizing the advanced properties of ABF material, find extensive applications across various electronic devices, ranging from smartphones and tablets to automotive systems and aerospace technology. These PCBs offer several advantages over traditional substrates, including superior electrical performance, excellent thermal management, and reduced signal distortion. Their versatility allows for the creation of intricate and compact circuit designs, essential for miniaturized electronic devices.

Examples of ABF PCBs in Real-World Products

- Mobile Devices: ABF PCBs are commonly used in smartphones and tablets to support high-speed data transmission and signal integrity. Their compact size and reliability make them ideal for portable electronic devices where space is at a premium.

- Automotive Systems: ABF PCBs play a crucial role in automotive applications, providing reliable interconnect solutions for advanced driver assistance systems (ADAS), infotainment systems, and engine control units (ECUs). Their robust construction and thermal stability ensure optimal performance even in challenging environments.

- Aerospace Technology: In aerospace applications, where reliability and performance are paramount, ABF PCBs are preferred for avionics systems, communication equipment, and navigation instruments. Their ability to withstand extreme temperatures and vibration makes them well-suited for aerospace environments.

The integration of ABF PCBs into real-world products has led to significant improvements in performance, reliability, and overall functionality. As technology continues to advance, ABF substrates suppliers will play a crucial role in driving innovation and meeting the evolving demands of the electronics industry.

Market Dynamics and Industry Insights

Examining the Current Market Scenario for ABF Substrates

The market for ABF substrates, led by prominent ABF substrates manufacturers, is experiencing significant growth driven by the increasing demand for high-performance electronic devices. However, the industry is currently facing challenges due to supply-demand dynamics, leading to a shortage of ABF substrates. This imbalance has disrupted supply chains and impacted various sectors reliant on ABF substrates, including consumer electronics, automotive, and telecommunications.

Factors Contributing to the Shortage of ABF Substrates

Several factors contribute to the shortage of ABF substrates, including:

- Increased Demand: The proliferation of 5G technology, IoT devices, and emerging applications such as artificial intelligence (AI) and autonomous vehicles has fueled the demand for high-speed and high-frequency electronic devices, driving up the need for ABF substrates.

- Supply Chain Disruptions: The global semiconductor shortage, compounded by logistical challenges and raw material shortages, has disrupted the supply chain for ABF substrates, leading to production delays and allocation issues.

- Capacity Constraints: ABF substrates manufacturers are facing capacity constraints due to limited production facilities and equipment availability. Expanding production capacity requires significant investments and time, further exacerbating the shortage.

Potential Solutions

To address the shortage of ABF substrates, ABF substrates suppliers are exploring various strategies, including:

- Investment in Capacity Expansion: Manufacturers are investing in expanding production capacity and upgrading manufacturing facilities to meet the growing demand for ABF substrates.

- Diversification of Suppliers: Electronics companies are diversifying their supplier base to mitigate risks associated with supply chain disruptions. This includes collaborating with multiple ABF substrates manufacturers to ensure a stable supply of materials.

- Technology Innovation: Continuous innovation in material science and manufacturing processes is essential to improve production efficiency and meet the evolving performance requirements of electronic devices.

Analysis of Industry Trends

Emerging trends in the ABF substrates industry include:

- Advanced Packaging Technologies: The adoption of advanced packaging technologies, such as fan-out wafer-level packaging (FOWLP) and system-in-package (SiP), is driving demand for ABF substrates with enhanced performance and reliability.

- Sustainable Manufacturing Practices: Manufacturers are increasingly focused on implementing sustainable and eco-friendly manufacturing practices to reduce environmental impact and meet regulatory requirements.

- Integration of AI and Machine Learning: The integration of AI and machine learning technologies in electronic devices is driving demand for ABF substrates capable of supporting complex computing tasks with high efficiency.

Overall, while the shortage of ABF substrates presents challenges for the electronics industry, it also underscores the importance of collaboration, innovation, and strategic planning among ABF substrates manufacturers, suppliers, and end-users to address current challenges and drive future growth.

Case Studies and Use Cases

Examining Successful Implementations of ABF Substrates

Case Study 1: Smartphone Manufacturing

An ABF substrates manufacturer collaborated with a leading smartphone maker to implement ABF substrates in their flagship devices. By utilizing ABF substrates, the smartphone manufacturer achieved significant improvements in signal integrity and thermal management, resulting in enhanced performance and reliability. The adoption of ABF substrates enabled the smartphone maker to deliver high-speed data transmission and superior connectivity, distinguishing their products in a competitive market.

Case Study 2: Automotive Electronics

A major automotive manufacturer integrated ABF substrates into their advanced driver assistance systems (ADAS) and infotainment systems. ABF substrates offered the necessary reliability and thermal stability required for automotive applications, ensuring seamless operation in varying environmental conditions. The use of ABF substrates improved the overall performance and longevity of the automotive electronics, contributing to enhanced safety and user experience for drivers and passengers alike.

Demonstrating Versatility and Applicability Across Industries

Use Case 1: Aerospace Technology

ABF substrates find extensive applications in aerospace technology, where reliability and performance are paramount. Aerospace manufacturers utilize ABF substrates in avionics systems, communication equipment, and navigation instruments, benefiting from their exceptional thermal management and signal integrity capabilities. ABF substrates enable aerospace companies to deliver robust and reliable electronic solutions, crucial for the safety and efficiency of aircraft operations.

Use Case 2: Healthcare Devices

In the healthcare industry, ABF substrates are utilized in medical devices such as diagnostic equipment and patient monitoring systems. These devices require high levels of accuracy, reliability, and signal integrity, all of which are provided by ABF substrates. Whether in MRI machines or wearable health trackers, ABF substrates play a vital role in ensuring the seamless operation of healthcare devices, contributing to improved patient care and outcomes.

These case studies and use cases illustrate the versatility and applicability of ABF substrates across various industries, showcasing their ability to enhance performance, reliability, and functionality in electronic devices. As technology continues to evolve, ABF substrates manufacturers will play a crucial role in driving innovation and meeting the diverse needs of industries worldwide.

FAQs About ABF Substrates Manufacturer

What are the differences between ABF substrates and prepreg?

ABF substrates and prepreg serve different purposes in electronic manufacturing. ABF substrates are used as the core material in printed circuit boards (PCBs), providing the structural foundation for circuitry and interconnections. In contrast, prepreg, short for pre-impregnated, is a resin-based material used in the lamination process to bond layers of copper foil and substrate material together. While both are essential components of PCB fabrication, ABF substrates offer superior electrical performance and thermal stability compared to prepreg.

Are ABF substrates compatible with different manufacturing processes?

Yes, ABF substrates are compatible with various manufacturing processes commonly used in PCB fabrication, including etching, drilling, plating, and solder mask application. Their versatility and adaptability make them suitable for both conventional and advanced manufacturing techniques, such as laser drilling and sequential build-up processes. ABF substrates suppliers typically provide detailed technical specifications and guidelines to ensure compatibility with specific manufacturing processes.

How do ABF substrates contribute to the performance of electronic devices?

ABF substrates play a crucial role in enhancing the performance of electronic devices by providing excellent signal integrity, thermal management, and reliability. Their low dielectric constant and loss tangent minimize signal distortion, enabling high-speed data transmission and reducing electromagnetic interference. Additionally, ABF substrates dissipate heat efficiently, ensuring stable operation even under demanding conditions. These performance attributes contribute to the overall functionality and longevity of electronic devices.

What considerations should be made when selecting an ABF substrates manufacturer?

When choosing an ABF substrates manufacturer, several factors should be considered, including product quality, technical support, manufacturing capabilities, and reliability of supply. It is essential to partner with a reputable ABF substrates supplier with a proven track record of delivering high-quality products and exceptional customer service. Additionally, evaluating the manufacturer’s production capacity, technological expertise, and commitment to innovation can help ensure a successful partnership and reliable supply chain.

Why is there a shortage of ABF substrate?

The shortage of ABF substrate is primarily due to increased demand driven by emerging technologies such as 5G, IoT, and AI, coupled with supply chain disruptions and capacity constraints among manufacturers.

What is the difference between BT and ABF substrate?

The main difference between BT (Bismaleimide Triazine) and ABF substrate lies in their composition and performance characteristics. ABF substrates typically consist of multiple layers of polymer films reinforced with glass fiber, offering superior electrical properties and thermal stability compared to BT substrates. While BT substrates may offer better mechanical strength, they generally lack the same level of electrical performance and thermal conductivity as ABF substrates.

What is ABF material?

ABF material, short for Ajinomoto Build-up Film, is a specialized material used in electronic packaging and interconnect applications. It typically comprises several layers of thermosetting polymer films reinforced with glass fiber, along with a thin layer of copper foil for conductivity. ABF material is known for its exceptional electrical properties, thermal stability, and reliability, making it ideal for high-performance electronic devices.

What is ABF PCB?

ABF PCB (Printed Circuit Board) refers to a PCB that utilizes ABF material as its substrate. ABF PCBs are widely used in various electronic devices due to their superior performance, reliability, and thermal management capabilities. These PCBs enable high-speed data transmission, minimize signal distortion, and ensure stable operation even under harsh environmental conditions.

发表评论

Want to join the discussion?Feel free to contribute!