Navigating LCC Packages: Key Features and Applications

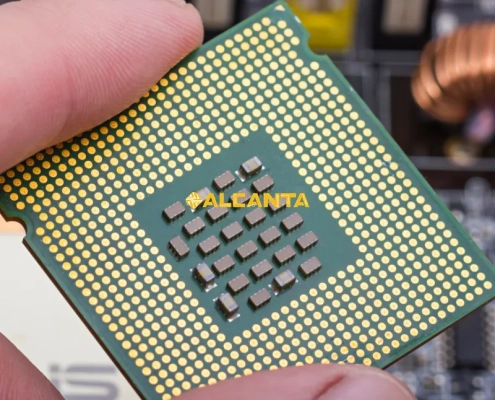

The Leadless Chip Carrier (LCC) package stands as a pivotal component in modern electronics manufacturing, embodying a rich history of evolution. Originally conceived as a solution for miniaturization, LCC technology has evolved to become integral in compact electronic designs. Its key features, including compact size, robustness, and efficient thermal management, make LCC packages highly sought-after in various industries. As electronics continue to advance, LCC packages remain at the forefront, driving innovation and enabling the creation of smaller, more powerful devices. Understanding the significance and evolution of LCC packages provides insight into the dynamic landscape of modern electronics manufacturing.

Understanding LCC vs PLCC Packages: A Comprehensive Comparison

Applications of LCC Packages: Versatility Across Industries

Technical Specifications and Standards: Ensuring Quality and Reliability

The successful integration of Leadless Chip Carrier (LCC) packages into electronic systems hinges upon adherence to stringent technical specifications and industry standards. Let’s delve into the key aspects governing LCC packages:

Overview of Technical Specifications

Technical specifications for LCC packages encompass various parameters, including dimensional tolerances, material properties, electrical characteristics, and thermal performance. These specifications dictate the design, manufacturing, and testing processes to ensure consistent quality and reliability.

Examination of Industry Standards

Industry standards play a crucial role in defining the requirements and guidelines for LCC packages. Standards organizations such as the International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE), and Joint Electron Device Engineering Council (JEDEC) establish standards related to package dimensions, materials, solderability, and environmental testing.

Compliance Requirements

Compliance with industry standards is essential to meet regulatory requirements and ensure interoperability and compatibility with other components and systems. Manufacturers must conduct thorough testing and certification processes to demonstrate compliance with applicable standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Importance of Adherence to Specifications

Adherence to technical specifications and industry standards is paramount for the reliability and performance of LCC packages. Strict compliance ensures that LCC packages meet specified criteria for mechanical robustness, electrical functionality, and thermal management, thereby reducing the risk of premature failure and ensuring long-term reliability in operation.

Case in Point

- LCC Package Substrate: The substrate material used in LCC packages plays a critical role in determining thermal conductivity, mechanical stability, and electrical performance. Adherence to specifications for substrate material composition, thickness, and dielectric properties is essential to meet the performance requirements of LCC packages in various applications.

In conclusion, a thorough understanding of technical specifications and adherence to industry standards are essential pillars in ensuring the quality, reliability, and performance of LCC packages. By complying with established criteria and best practices, manufacturers can deliver products that meet the demanding requirements of modern electronic systems while maintaining high levels of customer satisfaction and trust.

Full Form of PLCC Package: Unraveling Plastic Leaded Chip Carrier Technology

Advancements and Future Trends: Shaping the Landscape of LCC Package Technology

Recent advancements in Leadless Chip Carrier (LCC) package technology have propelled the field of electronic packaging forward, ushering in a new era of innovation and efficiency. Let’s explore the latest developments and future trends in LCC packages:

Recent Advancements in LCC Package Technology

- Miniaturization: Ongoing research and development efforts have led to the miniaturization of LCC packages, enabling the creation of smaller, more compact electronic devices without compromising performance.

- Enhanced Thermal Management: Novel materials and designs for LCC package substrates have improved thermal conductivity and heat dissipation, addressing the growing demand for efficient thermal management in high-power applications.

- High-Speed Connectivity: Advancements in LCC package design have facilitated the integration of high-speed connectivity features, such as high-frequency RF and microwave capabilities, catering to the needs of emerging technologies like 5G and IoT.

Predictions for Future Developments and Innovations

- Integration of Advanced Materials: Future LCC packages are expected to leverage advanced materials, such as thermally conductive polymers and nanocomposites, to further enhance thermal performance and reliability.

- Multi-Chip Integration: The trend towards multi-chip integration within LCC packages is anticipated to continue, enabling the consolidation of multiple functions into a single package for improved efficiency and cost savings.

- Enhanced Reliability Testing: Manufacturers are likely to invest in more rigorous reliability testing methodologies to ensure the long-term performance and durability of LCC packages in harsh operating environments.

Implications of LCC Advancements on the Electronics Industry

- Increased Productivity and Efficiency: The adoption of advanced LCC packages enables electronics manufacturers to streamline assembly processes, reduce component size, and improve overall productivity and efficiency.

- Accelerated Innovation Cycles: Faster development cycles facilitated by advancements in LCC technology allow for quicker time-to-market for new electronic products and technologies, driving innovation across industries.

- Expanded Application Possibilities: As LCC packages continue to evolve, their versatility and performance improvements open up new application possibilities in sectors such as healthcare, automotive, and aerospace, fueling further growth and expansion of the electronics industry.

The continuous evolution of LCC package technology holds immense promise for the future of electronic packaging. With ongoing advancements and innovations, LCC packages are poised to play a central role in shaping the next generation of electronic devices, driving efficiency, reliability, and performance to new heights.

FAQs About LCC Package

What is an LCC package?

An LCC (Leadless Chip Carrier) package is a type of electronic packaging used to mount and connect integrated circuits (ICs) onto printed circuit boards (PCBs). Unlike traditional packages with leads extending from the body, LCC packages feature terminal connections directly on the package substrate, enhancing thermal performance and miniaturization.

What is the difference between LCC and PLCC?

The main difference between LCC and PLCC (Plastic Leaded Chip Carrier) lies in their packaging design. LCC packages have no leads protruding from the body, whereas PLCC packages have leads extending from the sides. Additionally, LCC packages typically offer better thermal management due to their direct connection to the substrate, while PLCC packages are easier to handle and solder.

What does LCC stand for in electronics?

In electronics, LCC stands for Leadless Chip Carrier. It refers to a type of electronic package where the integrated circuit is mounted directly onto the substrate, without the use of leads extending from the package body.

What is the full form of PLCC package?