SOP Package: Shaping Tomorrow’s Electronics

The Small Outline Package (SOP Package) stands as a ubiquitous form of IC packaging within the electronics industry. Renowned for its compact design and versatility, SOP Package finds extensive utilization across various electronic devices, ranging from consumer electronics to industrial machinery. As a crucial component in modern electronic manufacturing, SOP Package accommodates the integration of complex circuitry while ensuring efficient thermal management. Its adaptability to diverse applications, coupled with its space-saving attributes, renders SOP Package indispensable in the design and production of electronic gadgets worldwide. In this blog, we delve into the intricate features and applications of SOP Package, shedding light on its significance within the realm of electronic engineering.

Features of SOP Package

Introducing the basic features of SOP Package

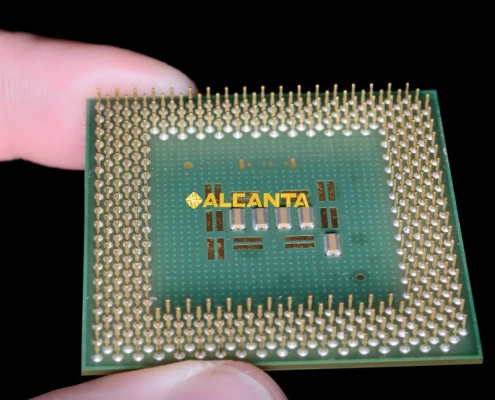

The Small Outline Package (SOP Package) boasts several distinctive features that contribute to its widespread adoption in the electronics industry. One of the key aspects of SOP Package is its compact dimensions, which allow for efficient space utilization on electronic circuit boards. Typically, SOP Packages come in various sizes, ranging from SOP8 to SOP28, accommodating different pin configurations and functionalities.

In addition to its compact size, SOP Package also offers a notable number of pins, facilitating the integration of complex circuitry within a limited space. These packages often feature a standardized pin layout, ensuring compatibility with industry-standard manufacturing processes and equipment.

Discussing the design advantages of SOP Package

SOP Package exhibits several design advantages that make it an attractive choice for electronic applications. Firstly, its small size enables manufacturers to design sleek and compact electronic devices without compromising on functionality. This is particularly advantageous in portable gadgets such as smartphones, tablets, and wearables, where space optimization is paramount.

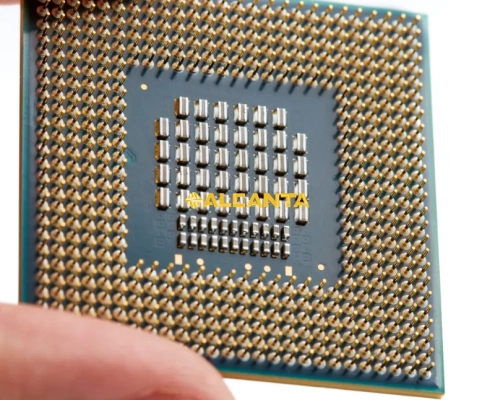

Furthermore, SOP Package excels in thermal dissipation, thanks to its efficient design and the materials used in its construction. The SOP Package substrate, typically made of materials like FR-4 or ceramic, aids in heat dissipation, preventing overheating and ensuring the reliable operation of electronic components even under demanding conditions.

Overall, the combination of compact dimensions, ample pin configurations, and excellent thermal management capabilities makes SOP Package a preferred choice for a wide range of electronic applications, including consumer electronics, automotive systems, industrial equipment, and more.

Differences Between SOP Package and Other Packaging Types

Examples of SOP Package Applications

Future Trends of SOP Package

As the electronics industry continues to evolve, the Small Outline Package (SOP Package) is expected to undergo significant advancements and innovations to meet the growing demands for smaller, more efficient electronic devices. Several key trends are likely to shape the future development of SOP Package:

1. Technological Improvements: Future SOP Packages are anticipated to incorporate advanced technologies to enhance their performance and functionality. This may include the integration of advanced semiconductor processes, such as silicon germanium (SiGe) and silicon carbide (SiC), to improve speed, power efficiency, and reliability. Additionally, innovations in design methodologies, such as 3D packaging and heterogeneous integration, may enable further miniaturization and integration of components within SOP Packages.

2. Innovations in Packaging Materials: Advancements in packaging materials are expected to play a significant role in the future development of SOP Package. New materials with enhanced thermal conductivity, such as advanced ceramics and metal-matrix composites, may be employed in SOP Package substrates to improve thermal management and reliability. Furthermore, the development of flexible and stretchable substrates may enable the creation of SOP Packages for wearable and flexible electronics applications.

3. Integration of Advanced Functionality: Future SOP Packages may integrate advanced functionalities, such as embedded sensors, wireless communication capabilities, and power management circuitry. This trend aligns with the growing demand for smart and connected devices in various industries, including consumer electronics, automotive, and healthcare. The integration of such functionalities within SOP Packages can streamline design complexity, reduce system footprint, and enhance overall performance.

4. Enhanced Reliability and Durability: Improvements in manufacturing processes and quality control measures are expected to enhance the reliability and durability of SOP Packages. This includes advancements in soldering techniques, hermetic sealing methods, and testing procedures to mitigate common failure mechanisms such as solder fatigue, moisture ingress, and thermal cycling-induced stress. Additionally, the adoption of advanced simulation and modeling techniques may enable more accurate prediction and prevention of reliability issues during the design phase.

5. Eco-Friendly Packaging Solutions: With increasing emphasis on environmental sustainability, future SOP Packages may incorporate eco-friendly packaging materials and manufacturing processes. This may include the use of recyclable or biodegradable substrates, lead-free soldering techniques, and energy-efficient manufacturing practices. By adopting environmentally friendly packaging solutions, manufacturers can reduce their environmental footprint and meet regulatory requirements while delivering high-performance electronic products.

Overall, the future development of SOP Package is poised to be driven by a combination of technological advancements, material innovations, integration of advanced functionalities, and a commitment to environmental sustainability. By embracing these trends, SOP Package manufacturers can continue to meet the evolving needs of the electronics industry and contribute to the advancement of next-generation electronic devices.

FAQs About SOP Package

What is a sop package?

A SOP (Small Outline Package) is a type of integrated circuit (IC) package characterized by its small size and surface-mount design. It is commonly used in electronics for its compact form factor and efficient thermal management.

What is the difference between SOP and SOIC package?

The main difference between SOP (Small Outline Package) and SOIC (Small Outline Integrated Circuit) package lies in their pin configurations. While both are surface-mount packages with small outlines, SOP packages typically have a gull-wing or J-lead configuration, whereas SOIC packages have a traditional dual in-line configuration.

What is an example of a SOIC package?

An example of a SOIC (Small Outline Integrated Circuit) package is the SOIC-8 package. This package has eight leads and is commonly used for a variety of integrated circuits, including operational amplifiers, voltage regulators, and microcontrollers.

What is the full form of SSOP package?

The full form of SSOP (Shrink Small Outline Package) is “Shrink Small Outline Package.” Similar to SOP packages, SSOP packages are characterized by their small size and surface-mount design but typically have a smaller outline and lead pitch, allowing for higher lead counts in smaller footprints.