Enhancing Automotive Safety: Transparent PCB Substrate Solutions

In the realm of modern electronics, transparent PCB substrates hold a pivotal role, offering not just functionality but also aesthetic appeal. As technology advances, there’s a growing demand for sleek, transparent designs in various electronic devices, from smartphones to automotive displays. The substrate material, often overlooked, plays a critical role in ensuring the performance and reliability of PCBs. It serves as the foundation upon which components are mounted and interconnected, influencing electrical properties, thermal management, and overall durability. Understanding the significance of transparent PCB substrates and selecting the appropriate material is paramount in achieving desired transparency while maintaining functionality and reliability in electronic designs.

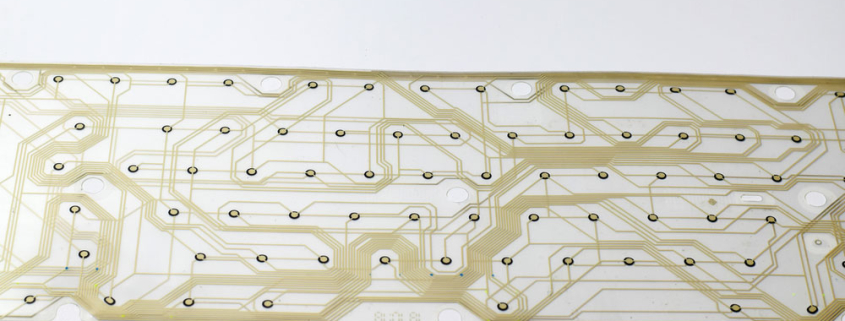

Understanding Transparent PCB Substrates

Definition and significance of transparent PCB substrates

Transparent PCB substrates, unlike traditional opaque ones, allow light to pass through, making them ideal for applications where visibility or aesthetics are crucial. They are typically made from materials like polycarbonate, PET, or transparent FR4. The significance of transparent PCB substrates lies in their ability to blend seamlessly into designs where visibility or aesthetics are paramount, such as in consumer electronics, automotive displays, and medical devices.

Comparison with traditional PCB substrates

When compared to traditional substrates, transparent variants offer a distinct advantage in terms of aesthetics and design flexibility. Traditional PCB substrates are opaque, limiting their use in applications where transparency is desired. Transparent substrates enable innovative designs, allowing engineers to create sleek, modern devices with visible internal components or integrated lighting systems.

Importance of transparency in certain applications

Transparency in certain applications is vital for functionality and aesthetics. For example, in consumer electronics, transparent PCB substrates can be used in devices like smartphones and tablets to create a visually appealing design while ensuring reliable performance. In automotive applications, transparent substrates enable the integration of heads-up displays (HUDs) and transparent displays in dashboards, providing drivers with vital information without obstructing their view of the road. In medical devices, transparent substrates facilitate the development of diagnostic equipment with visible internal components, enhancing usability and aesthetics.

Materials Used in Transparent PCB Substrates

Overview of Materials Transparent PCB substrates are crafted from various materials, each offering unique properties and suitability for different applications. Common materials include polycarbonate, PET (Polyethylene Terephthalate), transparent FR4, and emerging alternatives.

Polycarbonate Polycarbonate, renowned for its optical clarity and impact resistance, is a popular choice for transparent PCB substrates. Its high strength-to-weight ratio makes it ideal for applications requiring durability. Additionally, polycarbonate offers excellent thermal stability and can withstand a wide temperature range. However, its relatively high cost and susceptibility to scratches are notable limitations.

PET (Polyethylene Terephthalate) PET is valued for its exceptional transparency, flexibility, and low moisture absorption. It is commonly used in applications where flexibility is essential, such as flexible PCBs or curved displays. PET’s affordability and ease of processing make it a preferred choice for mass-produced electronic devices. However, its relatively lower thermal resistance compared to other materials may limit its use in high-temperature applications.

Transparent FR4 Transparent FR4, a variant of traditional FR4 substrate, is engineered to provide transparency without compromising on performance. Its composition typically includes fiberglass reinforced epoxy resin, offering good electrical insulation properties. Transparent FR4 is suitable for various applications, including automotive displays, LED lighting, and consumer electronics. Its compatibility with standard PCB manufacturing processes makes it a versatile choice.

Other Emerging Materials Innovations in material science continue to introduce novel materials for transparent PCB substrates. These include transparent conductive films, graphene-based substrates, and nanocomposites. While still in the experimental or early adoption phase, these materials hold promise for applications requiring enhanced conductivity, flexibility, or thermal properties. Further research and development are underway to unlock their full potential in transparent electronics.

The Best Substrate for PCB: Factors to Consider

Electrical Properties of Transparent PCB Substrate Transparent PCB substrates must possess specific electrical properties to ensure optimal performance. Key factors include the dielectric constant, which affects signal propagation speed, and the loss tangent, which influences signal integrity by determining the amount of energy lost as heat. Additionally, high insulation resistance is crucial to prevent leakage currents and maintain reliability in electronic circuits.

Thermal Conductivity and its Impact Efficient heat dissipation is essential for maintaining component reliability and prolonging the lifespan of electronic devices. The thermal conductivity of the substrate material directly affects its ability to dissipate heat generated during operation. Transparent PCB substrates with high thermal conductivity help in efficiently transferring heat away from critical components, thus enhancing overall performance and reliability.

Mechanical Properties for Durability Mechanical properties play a vital role in ensuring the durability and reliability of transparent PCB substrates. Flexibility is essential for applications requiring bendable or flexible PCBs, such as wearable electronics or automotive interiors. Conversely, rigidity is necessary for applications where the substrate must support heavy components or withstand mechanical stress. Additionally, transparency should not compromise the substrate’s mechanical strength, ensuring it can withstand handling and assembly processes without damage.

Cost Considerations and Performance Balancing performance requirements with cost considerations is crucial in selecting the best transparent PCB substrate. While high-performance materials may offer superior electrical and thermal properties, they often come at a higher cost. It’s essential to evaluate the specific requirements of the application and weigh the benefits of enhanced performance against the budget constraints. Opting for cost-effective materials that meet the necessary specifications without sacrificing reliability is key to achieving a balance between performance and affordability in transparent PCB substrate selection.

The Substrate Layer of a PCB Board: Its Role and Composition

Explanation of the Substrate Layer’s Function The substrate layer in a PCB serves as the foundation upon which electronic components are mounted and interconnected. It provides mechanical support, electrical insulation, and thermal management for the circuitry. Essentially, the substrate layer acts as a platform that holds all the components in place while facilitating electrical connections between them.

Composition and Interaction with Other PCB Components The substrate layer is typically composed of a non-conductive material, such as fiberglass reinforced epoxy resin (FR4), which provides a stable base for the circuitry. On top of the substrate layer, copper traces are etched to form the conductive pathways that connect various components. The substrate layer also interacts with other PCB components, such as the solder mask and silkscreen layers, which provide additional protection and labeling for the circuitry.

Importance of Substrate Material in Signal Integrity and Overall Performance The choice of substrate material significantly impacts the signal integrity and overall performance of the PCB. The dielectric constant and loss tangent of the substrate material influence the speed and quality of signal transmission, affecting the circuit’s functionality. Additionally, the thermal conductivity of the substrate material plays a crucial role in dissipating heat generated by the components, thereby preventing overheating and ensuring reliability.

Moreover, the mechanical properties of the substrate material, such as flexibility and rigidity, determine the PCB’s resilience to mechanical stress and environmental factors. A robust substrate material is essential for withstanding the rigors of assembly, handling, and operation without compromising performance.

The substrate layer is a critical component of a PCB, providing structural support, electrical insulation, and thermal management for the circuitry. The choice of substrate material is paramount in ensuring signal integrity, thermal stability, and overall performance of the PCB.

hoosing the Best Transparent PCB Substrate for Flexibility and Performance

When considering substrates for flexible PCBs, the selection of the right transparent PCB substrate is crucial to ensure both flexibility and performance. Among the various options available, transparent PCB substrates offer unique advantages in terms of flexibility and visibility, making them a preferred choice for certain applications.

Polyimide (PI): Properties, Flexibility, and Applications

Polyimide (PI) transparent PCB substrates are renowned for their exceptional flexibility, thermal stability, and chemical resistance. These properties make them well-suited for applications where flexibility is paramount, such as wearable technology, medical devices, and aerospace systems. The transparency of PI substrates further enhances their appeal, allowing for the creation of flexible electronic devices with see-through capabilities.

Liquid Crystal Polymer (LCP): Advantages and Limitations

Liquid Crystal Polymer (LCP) substrates offer outstanding mechanical strength, dimensional stability, and high-frequency performance. While LCP transparent PCB substrates may lack the same level of flexibility as PI, they excel in applications requiring high-speed and high-frequency operation. The transparent nature of LCP substrates adds versatility to their use in various electronic devices, although their flexibility may be more limited compared to other materials.

PET: Flexibility and Suitability for Certain Applications

Polyethylene Terephthalate (PET) transparent PCB substrates are valued for their flexibility, transparency, and affordability. PET substrates offer good mechanical flexibility, making them suitable for applications where bendable and lightweight electronic devices are desired. While PET may have lower thermal resistance compared to other materials, it remains a popular choice for consumer electronics and other applications where cost-effectiveness and flexibility are prioritized.

The selection of the best transparent PCB substrate for flexible PCBs depends on specific application requirements, including flexibility, thermal stability, and performance specifications. Transparent PCB substrates such as PI, LCP, and PET each offer unique advantages and limitations, allowing for flexibility and visibility in a wide range of electronic devices.

DIY Transparent PCB: Challenges and Considerations

Challenges in DIY Transparent PCB Fabrication

Creating transparent PCBs at home poses several challenges, primarily due to the limited availability of transparent substrate materials and the complexity of achieving transparency in the fabrication process. Here are some key considerations and challenges:

Sourcing Transparent PCB Substrate Materials

One of the primary challenges in DIY transparent PCB fabrication is sourcing suitable transparent substrate materials. While traditional opaque substrates like FR4 are widely available, transparent alternatives such as transparent PET or polycarbonate may be more challenging to find. Limited availability and high costs can pose barriers to DIY enthusiasts seeking to experiment with transparent PCBs.

DIY Approaches to Creating Transparent PCBs

Despite the challenges, DIY enthusiasts have developed various approaches to creating transparent PCBs. These methods often involve modifying existing opaque substrates or using alternative materials to achieve transparency. Some DIYers opt for techniques like sanding or polishing opaque substrates to enhance transparency, while others explore alternative materials such as transparent acrylic or glass.

Techniques for Achieving Transparency in PCB Fabrication

Achieving transparency in PCB fabrication requires careful consideration of materials and processes. Techniques such as using transparent solder mask and conductive inks, as well as opting for thinner substrate materials, can help enhance transparency. Additionally, choosing substrate materials with inherent transparency, such as transparent PET or polycarbonate, can simplify the fabrication process.

Considerations for DIYers

DIYers embarking on transparent PCB projects should be prepared to invest time and effort in sourcing suitable materials and experimenting with fabrication techniques. It’s essential to carefully consider the desired level of transparency, as well as the trade-offs in terms of cost, availability, and performance. Additionally, DIYers should be mindful of safety considerations when working with materials like glass or acrylic, as they can be brittle and pose risks of breakage or injury during fabrication.

While DIY transparent PCB fabrication presents challenges in material sourcing and fabrication techniques, enthusiasts can explore various approaches to achieve transparency in their projects. By experimenting with alternative materials and techniques, DIYers can unlock new possibilities in transparent electronics and expand their creative horizons.

Applications of Transparent PCBs

Transparent PCBs offer a wide range of applications across various industries, leveraging their unique properties to enhance functionality, aesthetics, and user experience.

Automotive: Transparent Displays, Lighting Systems, and Sensors In the automotive sector, transparent PCBs find applications in dashboard displays, heads-up displays (HUDs), and lighting systems. Transparent displays provide drivers with critical information without obstructing their view of the road, enhancing safety and convenience. Additionally, transparent PCBs are used in sensors for automotive safety systems, such as collision detection and parking assistance.

Consumer Electronics: Transparent Keyboards, Touch Panels, and Displays Transparent PCBs are increasingly utilized in consumer electronics, where aesthetics and design flexibility are paramount. They are incorporated into transparent keyboards, touch panels, and displays, creating sleek and modern devices with visible internal components. Transparent PCBs enable innovative designs in smartphones, tablets, and wearable technology, enhancing user interaction and visual appeal.

Aerospace and Military: HUDs, Cockpit Instruments, and Avionics In the aerospace and military sectors, transparent PCBs play a crucial role in heads-up displays (HUDs), cockpit instruments, and avionics systems. HUDs project vital information directly onto the aircraft’s windshield, providing pilots with real-time data without obstructing their view. Transparent PCBs enable lightweight and compact designs for avionics systems, contributing to improved aircraft performance and situational awareness.

Medical Devices: Transparent Sensors, Monitors, and Diagnostic Equipment Transparent PCBs are utilized in various medical devices, including sensors, monitors, and diagnostic equipment. Transparent sensors enable non-invasive monitoring of vital signs and physiological parameters, enhancing patient comfort and mobility. Transparent PCBs are also incorporated into medical imaging devices, such as X-ray machines and ultrasound scanners, facilitating accurate diagnosis and treatment planning.

Transparent PCBs find applications across diverse industries, ranging from automotive and consumer electronics to aerospace, military, and medical sectors. Their unique properties enable innovative designs and functionalities, driving advancements in technology and enhancing user experience in various applications.

FAQs About Transparent PCB substrate

Common materials used in transparent PCBs include polycarbonate, PET (Polyethylene Terephthalate), and transparent FR4. These materials offer optical clarity while maintaining electrical and mechanical properties necessary for PCB applications.

The best substrate for a PCB depends on the specific requirements of the application. However, FR4 (Flame Retardant 4) is one of the most widely used substrates due to its excellent electrical insulation properties, mechanical strength, and cost-effectiveness. Other factors like thermal conductivity, flexibility, and transparency may influence substrate selection for specialized applications.

The substrate layer of a PCB board is the foundational layer upon which the circuit components are mounted and interconnected. It typically consists of a non-conductive material like fiberglass reinforced epoxy resin (FR4). The substrate provides mechanical support, electrical insulation, and thermal management for the circuitry.

Flexible PCBs require substrates that offer both flexibility and electrical insulation. Common materials used for flexible PCB substrates include Polyimide (PI), Liquid Crystal Polymer (LCP), and Polyethylene Terephthalate (PET). These materials can withstand bending and flexing while maintaining electrical integrity, making them suitable for applications like wearable devices and automotive electronics.

发表评论

Want to join the discussion?Feel free to contribute!