Miniature Marvels: Surface Mount Diode Innovations

In the realm of electronic components, showcasing performance is paramount. Surface mount diode packages play a pivotal role in ensuring optimal functionality and efficiency in various electronic devices. This blog aims to delve into the intricacies of surface mount diode packages, shedding light on their diverse types, advantages, and applications. By understanding the nuances of these components, readers can grasp their significance in modern electronics and appreciate how they contribute to the seamless operation of devices we rely on daily. From exploring common package types to highlighting their unique features, this overview sets the stage for an insightful exploration into the world of surface mount diode packages.

Introduction to Surface Mount Diodes (SMD Diodes)

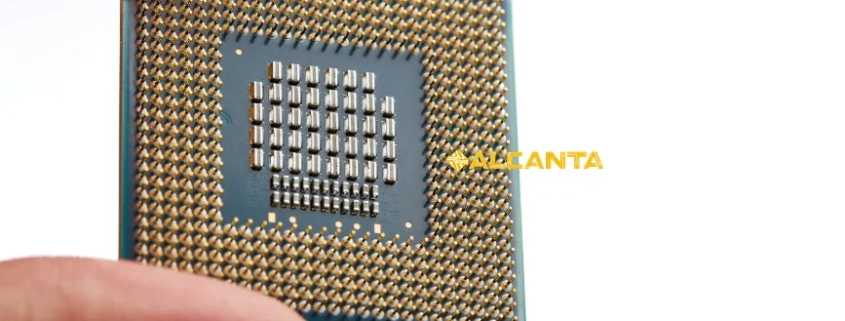

Definition and Role of IC Substrate in Semiconductor Devices

In the realm of semiconductor devices, the IC substrate plays a pivotal role as the foundation upon which intricate electronic components are built. Essentially, the IC substrate serves as a platform for mounting and interconnecting various semiconductor elements, including surface mount diodes (SMD diodes). It provides the necessary structural support and electrical pathways essential for the functionality of these components within electronic circuits.

Importance of Substrate in Ensuring Electrical Connectivity and Mechanical Support

The substrate’s significance lies in its ability to ensure robust electrical connectivity and mechanical support for the integrated circuit (IC) components. It serves as a medium through which electrical signals travel between different parts of the circuit, facilitating the transmission of data and power. Moreover, the substrate’s mechanical properties, such as rigidity and thermal conductivity, contribute to the overall reliability and performance of the semiconductor device.

Materials Commonly Used in IC Substrate Manufacturing

Various materials are utilized in the manufacturing of IC substrates, each chosen for its specific electrical, mechanical, and thermal properties. Common materials include ceramic substrates, such as alumina (Al2O3) and aluminum nitride (AlN), which offer excellent thermal conductivity and reliability. Additionally, organic substrates, like FR-4 (flame retardant 4), are widely used for their cost-effectiveness and versatility in applications where lower thermal performance is acceptable. The choice of substrate material depends on factors such as the intended application, performance requirements, and cost considerations.

Common Surface Mount Diode Package Types

Surface mount diodes (SMD diodes) are available in various package types, each designed to meet specific application requirements. Below are some of the most common types:

SOD (Small Outline Diode) Packages

SOD packages are characterized by their small size and low profile, making them suitable for space-constrained applications. They typically have two terminals and are available in various sizes, such as SOD-323 and SOD-523. SOD diodes find applications in consumer electronics, such as smartphones, tablets, and digital cameras.

SOT (Small Outline Transistor) Packages

SOT packages are similar in size to SOD packages but often have three terminals, allowing for additional functionality beyond simple diode applications. Examples include SOT-23 and SOT-89 packages. These diodes are commonly used in voltage regulation, signal conditioning, and power management circuits in automotive electronics and portable devices.

SMA (Surface Mount Axial) Packages

SMA packages resemble traditional through-hole diodes but are designed for surface mount applications. They have two terminals and are often used in high-frequency applications, such as RF communication systems, due to their low parasitic capacitance and inductance.

SMC (Surface Mount Diode MELF) Packages

SMC packages, also known as MELF (Metal Electrode Leadless Face), feature a cylindrical shape with metal ends. They offer improved thermal performance and are suitable for high-power applications. SMC diodes are commonly used in automotive electronics, power supplies, and industrial equipment.

5. SOD-123 Packages

SOD-123 packages are similar to SOD packages but slightly larger, offering higher power handling capabilities. They are commonly used in rectification and voltage clamping applications in power supplies, LED lighting, and telecommunications equipment.

Conclusion

Each type of surface mount diode package offers unique characteristics suited to specific application requirements, ranging from compact size and low profile to high-power handling capabilities. Understanding the differences between these packages enables designers to select the most suitable diode for their electronic circuits.

Advantages of Surface Mount Diode Packages

Surface mount diode packages offer several advantages over traditional through-hole diodes, contributing to their widespread adoption in modern electronic designs.

Smaller Size

Surface mount diode packages are significantly smaller than through-hole diodes, allowing for greater miniaturization of electronic devices. This reduction in size enables the design of compact and lightweight products, which is particularly advantageous in portable electronics such as smartphones, wearables, and IoT devices.

Lighter Weight

Due to their compact size and absence of bulky leads, surface mount diode packages are lighter in weight compared to through-hole diodes. This weight reduction is beneficial in applications where weight is a critical factor, such as aerospace, automotive, and medical devices, contributing to overall system efficiency and performance.

Lower Power Consumption

Surface mount diode packages typically exhibit lower parasitic capacitance and inductance compared to through-hole diodes. As a result, they offer improved high-frequency performance and reduced power losses, leading to lower power consumption in electronic circuits. This advantage is particularly significant in battery-powered devices and energy-efficient systems where minimizing power consumption is essential for extending battery life and reducing operating costs.

Enhanced Thermal Performance

Surface mount diode packages often feature improved thermal characteristics, allowing for efficient heat dissipation and thermal management in electronic assemblies. This enhanced thermal performance enables higher power handling capabilities and ensures the reliability and longevity of electronic devices, especially in high-power applications and harsh operating environments.

Conclusion

The advantages of surface mount diode packages, including smaller size, lighter weight, lower power consumption, and enhanced thermal performance, make them the preferred choice for modern electronic designs. By leveraging these benefits, designers can create innovative and efficient products that meet the demands of today’s technology-driven world.

Applications of Surface Mount Diodes in the Electronics Industry

Surface mount diodes (SMD diodes) play a crucial role in various electronic products across different industries, enabling compact designs, improved performance, and enhanced functionality.

Smartphones and Tablets

In smartphones and tablets, surface mount diodes are used in a wide range of applications, including power management, signal conditioning, and LED backlighting. They help regulate voltage levels, filter electromagnetic interference, and provide efficient lighting solutions for displays and cameras, contributing to the overall performance and user experience of these devices.

Televisions and Display Panels

Surface mount diodes are extensively used in televisions and display panels for tasks such as rectification, voltage regulation, and signal processing. They ensure stable power supply to the display components, facilitate smooth signal transmission, and enable precise control of brightness levels, resulting in vibrant and high-quality visuals for consumers.

Automotive Electronics

In the automotive industry, surface mount diodes are employed in various electronic systems, including engine control units (ECUs), infotainment systems, lighting systems, and driver assistance systems. They help manage power distribution, control lighting functions, and protect sensitive electronic components from voltage spikes and electromagnetic interference, ensuring safe and reliable operation of vehicles.

Industrial Equipment

Surface mount diodes find widespread use in industrial equipment and machinery for tasks such as power conversion, motor control, and sensor interfacing. They enable efficient energy conversion, precise control of motor speeds and directions, and accurate measurement of physical parameters, contributing to the productivity and reliability of industrial processes.

Consumer Electronics

Surface mount diodes are integral components in various consumer electronics products, including digital cameras, audio devices, gaming consoles, and wearable devices. They help regulate power consumption, process audio and video signals, and provide connectivity options, enhancing the functionality and user experience of these devices.

Conclusion

The widespread use of surface mount diodes across diverse industries underscores their importance in modern electronic designs. From smartphones and tablets to televisions, automotive electronics, and industrial equipment, these versatile components play a critical role in enabling the functionality and performance of a wide range of electronic products.

FAQs about surface mount diode packages

The most common SMD diode package is the SOD-123 package, which is widely used in various electronic applications due to its balance of size, power handling capability, and ease of handling during assembly.

Different diode package styles include SOD (Small Outline Diode), SOT (Small Outline Transistor), SMA (Surface Mount Axial), SMC (Surface Mount Diode MELF), and SOD-123 packages, among others. Each style offers unique characteristics suited to specific application requirements.

The smallest SMD diode package currently available on the market is the SOD-883 package, which measures approximately 0.6mm x 0.3mm x 0.35mm (L x W x H). Despite its tiny size, it offers reliable performance and is commonly used in applications where space is extremely limited.

Surface mount diodes (SMD diodes) are electronic components that are soldered directly onto the surface of a printed circuit board (PCB) without the need for leads or holes. They offer advantages such as smaller size, lighter weight, lower power consumption, and enhanced thermal performance compared to traditional through-hole diodes.