Substrate Manufacturing Process Explained Step by Step

In the world of advanced semiconductor packaging, the substrate serves as the physical and electrical interface between the silicon die and the printed circuit board (PCB). The substrate manufacturing process refers to the highly specialized sequence of steps used to build these intricate interposers, which must meet strict mechanical, electrical, and thermal performance requirements. As chip designs grow more complex and input/output (I/O) counts rise, the demands on substrate performance and precision continue to intensify. This blog will provide a detailed, technical look at each step involved in the substrate manufacturing process.

Materials Used in the Substrate Manufacturing Process

Substrate manufacturing begins with selecting the right base materials. The choice of material directly affects the final product’s reliability, signal integrity, and thermal stability.

| Material Type | Description | Common Applications | Key Properties |

|---|---|---|---|

| BT Resin | Bismaleimide Triazine resin with low CTE and good dimensional stability | Wire-bond substrates | Good heat resistance, electrical insulation |

| ABF | Ajinomoto Build-up Film for high-density interconnects | Flip-chip substrates | Thin dielectric layers, high wiring density |

| Glass Substrate | Ultra-flat glass with high dimensional accuracy | High-frequency, RF, AI packaging | Low CTE, high rigidity, excellent flatness |

| Polyimide Films | Flexible insulating film used in certain substrate layers | Flexible & semi-flex applications | High thermal resistance, flexibility |

| Copper Foil | Conductive layers formed during metallization | All substrate types | Excellent electrical conductivity |

Material selection is based on application-specific requirements such as heat resistance, electrical performance, layer count, and cost.

Get a Quotation For Substrate Manufacturing Process Now

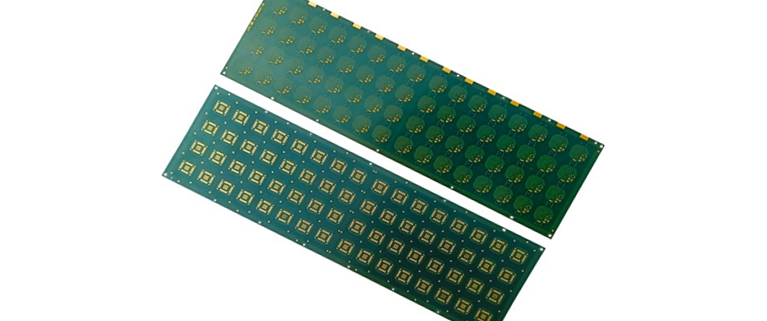

Substrate Manufacturing Process Flow Overview

The substrate manufacturing process flow can be broadly divided into three core stages:

-

Core Layer Preparation

-

Metallization and Circuit Patterning

-

Build-Up Layer Formation and Surface Finish

Each of these stages involves multiple sub-steps, with tight process controls and cleanroom environments maintained throughout. A simplified flow chart would include:

-

Lamination

-

Drilling (mechanical or laser)

-

Copper plating

-

Imaging and etching

-

Build-up layer addition

-

Surface finishing and cutting

Get a Quotation For Substrate Manufacturing Process Now

Detailed Substrate Manufacturing Process Steps

Core Layer Preparation

The process begins with laminating base materials under high pressure and temperature. This core substrate acts as the foundation for further build-up.

-

Lamination: Copper foil and resin-coated film are laminated to form the core.

-

Drilling: Through-holes or blind vias are created using mechanical or CO2/UV lasers.

-

Desmear & PTH: Hole walls are cleaned (desmear) and plated through-hole (PTH) process adds conductive paths.

Metallization and Circuit Patterning

This stage forms the copper interconnects on each layer.

-

Electroless & Electrolytic Copper Plating: Thin seed layer followed by bulk copper plating.

-

Dry Film Lamination: Photosensitive film applied on the surface.

-

Photolithography: UV exposure through a mask defines the circuit pattern.

-

Etching: Removes unexposed copper to reveal the desired circuit.

Build-up Layer Formation

To support multi-layer substrates, build-up technology is used.

-

Sequential Lamination: Alternating layers of resin and copper foil added.

-

Laser Drilling: Microvias (typically <100µm) formed for vertical interconnection.

-

Repeat Imaging & Etching: Similar process as in core layers, repeated per build-up layer.

Surface Treatment & Finalization

Final steps focus on protection, solderability, and yield.

-

Solder Mask Coating: Insulating layer applied to protect circuitry.

-

Surface Finish: ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), or others.

-

Profiling and Inspection: Dicing, electrical testing, and AOI to ensure quality.

Process Control and Cleanroom Requirements

The substrate manufacturing process is carried out in controlled environments:

-

Cleanroom Class 1000–10000 to avoid particle contamination

-

AOI (Automated Optical Inspection) and X-ray used for layer alignment and via integrity

-

Critical Dimension (CD) Monitoring ensures fine features (down to 5µm line/space) are maintained

-

SEM, impedance testing, and reliability analysis form part of inline and offline QA

Future Trends in Substrate Manufacturing Process

As devices shrink and integrate more functionality, the substrate must follow:

-

Higher Layer Counts: Moving from 4-8 layers to 10+ in advanced packages

-

Glass Substrate Adoption: Promising better flatness, tighter L/S, and low-loss performance

-

SAP (Semi-Additive Process): Enables finer lines with improved resolution

-

Additive Manufacturing: Inkjet or laser direct structuring for next-gen high-density substrates

Why the Substrate Manufacturing Process Matters

The substrate manufacturing process is not just a back-end support role—it is a precision-driven, material-sensitive, and innovation-heavy pillar of modern electronics. Mastering this process ensures better electrical performance, reliability, and cost efficiency in today’s high-performance semiconductor packages. As we push toward chiplet, 2.5D/3D, and heterogeneous integration, the importance of substrate technologies will only grow.

Contact Us Now

FAQs About substrate manufacturing process

What is substrate manufacturing?

Substrate manufacturing refers to the process of creating multilayer interposer structures that provide electrical, thermal, and mechanical connections between a semiconductor die and the next-level packaging, such as a PCB. It involves material preparation, lamination, microvia drilling, copper metallization, circuit patterning, and surface finishing. These substrates are essential in enabling high I/O density and signal integrity in advanced packaging.

What is the process of IC substrate manufacturing?

The IC substrate manufacturing process includes the following key steps:

-

Core material lamination (e.g., BT or ABF)

-

Via formation (mechanical or laser drilling)

-

Electroless and electrolytic copper plating

-

Photolithography for circuit patterning

-

Etching and stripping

-

Build-up layer stacking with microvias

-

Solder mask coating and surface finish

-

Dicing and final inspection

What is the manufacturing process of flip chip substrate?

The flip chip substrate manufacturing process is a high-density version of IC substrate production, optimized for direct die attach via solder bumps. It typically uses ABF build-up film and SAP (Semi-Additive Process) to achieve fine line/space below 10μm. Key steps include:

-

High-precision laser drilling of microvias

-

Thin dielectric layering for signal integrity

-

Fine-line copper patterning via SAP

-

ENIG or other surface finishes for bump compatibility

What is substrate in additive manufacturing?

In additive manufacturing, the term substrate refers to the base platform or initial layer on which materials are deposited layer by layer. It acts as a mechanical support during the build process, and its properties (material, roughness, temperature tolerance) significantly affect adhesion and print quality. This is different from semiconductor substrates, though the concept of building on a base layer is similar in both contexts.