The Role of Silver/AU QNF Leadframe in Semiconductor Packaging

Leadframes are essential components in semiconductor packaging, providing the mechanical support for the integrated circuit (IC) and enabling electrical connections between the IC and the printed circuit board (PCB). Typically made from materials like copper, gold, or silver, leadframes are chosen for their excellent electrical conductivity and mechanical properties. They are particularly important in QFN (Quad Flat No-lead) packaging, which is favored in modern electronics due to its compact design and superior performance. This article will focus on Silver/AU QNF Leadframe, exploring the benefits of using silver and gold in QFN packages. By examining their excellent conductivity, corrosion resistance, and mechanical strength, we will highlight why these materials are preferred for high-performance applications in today’s electronic devices.

The Basics of QFN Packaging: Silver/AU QNF Leadframe

Overview of Silver/AU QNF Leadframe Package

The QFN (Quad Flat No-lead) package is a popular semiconductor packaging type that is recognized for its compact, flat design with leads positioned underneath the package. This unique structure eliminates the need for external leads around the perimeter, making it highly efficient in terms of space. QFN packages are used in a variety of electronic devices, offering a low-profile, lightweight solution that is ideal for applications requiring high-density packaging, such as smartphones, automotive electronics, and other compact devices. The Silver/AU QNF Leadframe is a key element of this packaging type, offering enhanced performance through its excellent electrical and thermal conductivity, especially in demanding high-frequency applications.

Benefits of Silver/AU QNF Leadframe: Low-profile, High Performance, and Suitability for High-density Applications

One of the primary benefits of the QFN package is its low-profile design, which reduces the overall height of the component, making it suitable for modern electronics that require minimal space. Additionally, the QFN package is known for its high-performance capabilities, particularly in terms of speed and power efficiency. The Silver/AU QNF Leadframe further enhances these qualities by offering superior conductivity, which helps in maintaining the integrity of high-speed signals and ensuring reliable electrical connections in dense, high-performance circuits. Its compactness and efficiency make QFN an ideal choice for applications like mobile devices, wearables, and automotive systems, where space and performance are crucial.

Why Silver/AU QNF Leadframe Are Important for QFN Packages

Leadframes are critical components in QFN packages, serving as the bridge between the semiconductor die and the printed circuit board (PCB). The leadframe connects the electrical leads of the chip to the PCB through bonding wires, ensuring a stable and reliable connection. For Silver/AU QNF Leadframe, the use of silver and gold materials improves the overall performance by reducing the resistance in the electrical pathways, leading to faster signal transmission and reduced power loss. Furthermore, QFN leadframes play a significant role in heat dissipation, helping to manage the thermal energy generated during operation. The excellent thermal properties of silver and gold in the Silver/AU QNF Leadframe allow for better heat distribution, preventing overheating and enhancing the overall reliability of the device in high-performance applications.

Materials for QFN Leadframes: Silver/AU QNF Leadframe

Common Leadframe Materials in Silver/AU QNF Leadframe

Leadframes for QFN (Quad Flat No-lead) packages are typically made from a variety of metal materials, including copper, gold, silver, and various alloys. Each material is selected based on its specific properties, such as electrical conductivity, corrosion resistance, thermal properties, and cost-effectiveness. Copper is one of the most commonly used materials due to its excellent electrical conductivity, but it may require surface treatments to prevent oxidation. Gold, on the other hand, is known for its superior corrosion resistance and conductivity but comes at a higher cost. Silver and gold leadframes are particularly chosen for applications where high performance and reliability are paramount.

For Silver/AU QNF Leadframe, silver is often preferred for its unmatched electrical conductivity, while gold provides excellent protection against oxidation and long-term durability. The choice between these materials often depends on balancing performance and manufacturing costs.

Overview of Material Selection Based on Conductivity, Corrosion Resistance, and Cost-Effectiveness for Silver/AU QNF Leadframe

When selecting materials for QFN leadframes, engineers consider several critical factors:

- Conductivity: Materials like copper, silver, and gold are chosen for their high electrical conductivity, ensuring efficient signal transmission and minimal loss.

- Corrosion Resistance: Leadframes must resist environmental factors like moisture and temperature fluctuations. Silver and gold are particularly beneficial in this regard, offering excellent corrosion resistance that ensures long-lasting performance.

- Cost-Effectiveness: Copper is the most cost-effective material, while silver and gold, though more expensive, provide superior performance. Manufacturers must weigh these factors based on the specific application and requirements of the end product.

The Silver/AU QNF Leadframe utilizes silver and gold for their unique balance of high conductivity and resistance to environmental degradation, making them ideal for high-performance, high-reliability applications.

Focus on Silver and Gold in Silver/AU QFN Leadframe

Silver Leadframes

Silver is an excellent choice for leadframes due to its very high electrical conductivity, which enhances the speed and efficiency of electronic devices. In Silver/AU QNF Leadframe applications, silver helps minimize signal degradation and power loss, making it ideal for high-speed circuits. Its thermal conductivity also aids in better heat dissipation, helping to manage the temperature of the device and improve overall reliability.

Gold Leadframes

Gold is widely used in semiconductor packaging because of its exceptional corrosion resistance and ability to maintain its properties over time. It is less prone to oxidation, making it ideal for applications that require long-term reliability in harsh environments. However, gold is significantly more expensive than silver, which can be a factor in material selection when cost is a concern.

Comparison of Silver and Gold Leadframes in Terms of Performance and Cost for Silver/AU QNF Leadframe

While both silver and gold leadframes offer excellent performance, they each have distinct advantages:

- Performance: Silver outperforms gold in terms of electrical conductivity, which is critical for high-speed, high-frequency applications. However, gold’s superior resistance to corrosion and oxidation makes it more suitable for long-term, harsh environments.

- Cost: Silver is generally more affordable than gold, making it a cost-effective alternative in most applications, especially when the ultimate focus is on electrical and thermal performance. Gold, while more expensive, provides added durability and is often chosen for high-end, mission-critical applications.

In Silver/AU QNF Leadframe packaging, silver is often preferred for applications where electrical performance is the highest priority, and gold is reserved for scenarios where long-term durability and resistance to environmental degradation are crucial.

Manufacturing Process of Silver/Gold Leadframes: Silver/AU QNF Leadframe

How Silver/AU QFN Leadframe Are Made

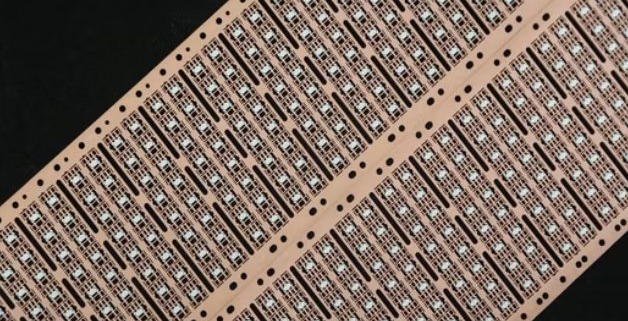

The production of Silver/AU QNF Leadframe involves a multi-step process that combines precision and advanced techniques to ensure high-quality, durable, and effective leadframes. The main steps include stamping, etching, and molding, which are used to create the desired shape and features of the leadframe. These processes start with a metal sheet, typically made of copper, silver, or gold alloys, which is then precisely shaped into a frame that will hold the semiconductor die in place.

- Stamping: The first step in leadframe fabrication is stamping, where a metal sheet is cut into the required shape. This is done using high-precision stamping machines that ensure accuracy in creating the frame’s layout, including the leads, which will later connect to the PCB (Printed Circuit Board).

- Etching: Once the basic shape is stamped out, etching is used to define smaller features and remove excess metal. Etching is particularly important for creating intricate patterns on the leadframe that will ensure proper electrical connections.

- Molding: After the etching, the leadframe undergoes molding, a process where the frame is encapsulated with a molding compound. This compound serves to protect the die and the leadframe, ensuring mechanical stability and insulation.

Surface Treatment and Finishes of Silver/AU QFN Leadframe

Surface treatments are crucial in the manufacturing of Silver/AU QNF Leadframe, particularly when using silver and gold. These metals are prone to oxidation and corrosion if not properly treated. Several surface finishing techniques are employed to improve performance and durability:

-

Electroplating: One of the most common methods for finishing silver and gold leadframes is electroplating. This involves the deposition of a thin layer of gold or silver onto the leadframe. The plating process not only enhances electrical conductivity but also provides a protective coating that resists corrosion. Silver leadframes may undergo a thin gold plating to further protect the material from oxidation while maintaining the superior conductivity of silver.

-

Coating: In some cases, leadframes are coated with an additional layer of protective material such as nickel or palladium. This coating serves as a barrier to environmental factors, ensuring longer-lasting performance in harsh conditions.

-

Adhesion Promoters: To improve the bonding between the leadframe and other components like the semiconductor die, adhesion promoters are often used. These chemicals enhance the surface properties, ensuring that the die remains securely attached during operation, even under stress and heat.

Challenges in Manufacturing Silver/AU QFN Leadframe

Manufacturing Silver/AU QNF Leadframe with silver and gold presents unique challenges, primarily due to the cost and complexity of working with these precious metals.

-

Cost and Complexity of Silver and Gold Plating: One of the significant challenges in producing silver and gold leadframes is the cost involved in plating these metals. Both silver and gold are expensive, and electroplating these metals requires precise control to ensure the right thickness and uniformity. The gold plating process, in particular, requires additional care to prevent material waste and ensure that the plating thickness is uniform across the leadframe’s surface.

-

Ensuring Uniformity and Durability of the Metal Layers: Achieving uniform plating is critical for the performance of Silver/AU QNF Leadframe. Variations in the thickness of silver or gold plating can affect the electrical conductivity and mechanical properties of the leadframe. Additionally, ensuring the durability of the metal layers is essential to prevent issues like peeling or wear over time, especially in high-stress applications. The manufacturing process must be carefully monitored to achieve consistent results and meet the stringent reliability standards required for high-performance electronics.

The fabrication of Silver/AU QNF Leadframe involves meticulous techniques to ensure the quality and longevity of the product. While the costs and complexities involved in working with silver and gold are higher compared to other materials, the resulting performance benefits, including superior conductivity and corrosion resistance, make these leadframes highly desirable in high-performance semiconductor applications.

Advantages of Silver and Gold Leadframes in QFN Packaging: Silver/AU QNF Leadframe

Superior Electrical Performance of Silver/AU QFN Leadframe

One of the primary advantages of using Silver/AU QNF Leadframe in semiconductor packaging is its superior electrical performance. Silver and gold are among the best materials for electrical conductivity, which is critical in ensuring the efficiency of high-speed and high-frequency circuits. Silver, in particular, has the highest electrical conductivity of all metals, allowing for faster signal transmission with minimal resistance. This makes Silver/AU QNF Leadframe ideal for applications where high-speed data transfer is crucial, such as telecommunications, high-frequency devices, and high-performance computing systems. The enhanced conductivity ensures that electrical signals travel efficiently through the leadframe, reducing the risk of power loss and ensuring reliable, high-performance operations.

Improved Thermal Conductivity of Silver/AU QFN Leadframe

Silver and gold are not only excellent conductors of electricity but also excel at conducting heat. This is a vital property in the design of Silver/AU QNF Leadframe, as managing heat dissipation is essential to maintaining the long-term reliability and performance of electronic devices. The semiconductor die generates heat during operation, and a leadframe’s ability to dissipate this heat can prevent overheating, which can lead to device failure. Silver, with its superior thermal conductivity, helps transfer heat away from the sensitive components, while gold’s thermal properties further enhance heat management. As a result, Silver/AU QNF Leadframe contributes to better overall thermal management in compact QFN packages, ensuring that the electronic devices function within their optimal temperature range.

Corrosion Resistance of Silver/AU QFN Leadframe

Corrosion resistance is another major advantage of Silver/AU QNF Leadframe. Silver and gold are both highly resistant to oxidation and corrosion, which is crucial for the longevity and reliability of semiconductor devices. Over time, exposure to moisture and environmental factors can cause corrosion, leading to poor electrical connections and ultimately device failure. The corrosion-resistant properties of silver and gold help maintain the integrity of the leadframe and prevent issues related to oxidation, making Silver/AU QNF Leadframe ideal for use in harsh environments or applications where long-term durability is required. By protecting the electrical connections from corrosion, these materials ensure the longevity of the device, even in high-temperature or high-humidity conditions.

Enhanced Mechanical Strength of Silver/AU QFN Leadframe

Silver and gold leadframes offer enhanced mechanical strength compared to other metals. The combination of high conductivity and robustness makes Silver/AU QNF Leadframe a reliable choice for applications that require both electrical performance and mechanical durability. Silver and gold’s natural strength ensures that the leadframe can withstand physical stress, vibration, and mechanical shock without losing its structural integrity. This is particularly important in applications such as automotive electronics, industrial systems, and mobile devices, where components are subject to constant movement and environmental challenges. The enhanced mechanical strength of Silver/AU QNF Leadframe contributes to stronger connections, better resistance to wear and tear, and a longer lifespan for the overall electronic device.

The use of Silver/AU QNF Leadframe in QFN packaging provides significant advantages in terms of electrical performance, thermal conductivity, corrosion resistance, and mechanical strength. These benefits make silver and gold leadframes ideal for high-performance, high-reliability applications, ensuring that semiconductor packages operate efficiently and last longer in demanding conditions.

Applications of Silver and Gold Leadframes: Silver/AU QNF Leadframe

Consumer Electronics and Silver/AU QFN Leadframe

Silver/AU QNF Leadframe plays a significant role in the manufacturing of consumer electronics, where space-saving, high-performance components are essential. Smartphones, tablets, and wearables benefit from the use of QFN packages, as these devices require compact, reliable, and efficient packaging solutions. The superior electrical and thermal conductivity of silver and gold leadframes ensures that the electronic components in these devices perform optimally. Silver/AU QNF Leadframe helps maintain fast signal processing speeds, essential for the performance of touch screens, processors, and wireless communication modules. Additionally, the corrosion resistance and mechanical strength of silver and gold leadframes make them ideal for consumer devices that are subjected to frequent use and potential exposure to environmental factors.

Automotive Electronics and Silver/AU QFN Leadframe

In the automotive industry, Silver/AU QNF Leadframe is increasingly being used in critical systems that require high durability and performance. Modern vehicles rely on a range of sophisticated electronic systems, from engine control units to advanced driver assistance systems (ADAS). These systems must withstand extreme temperatures, vibration, and long-term stress while maintaining high-performance levels. Silver and gold leadframes, with their excellent electrical conductivity and corrosion resistance, ensure that automotive electronics operate reliably in harsh conditions. The Silver/AU QNF Leadframe provides the necessary strength and heat dissipation required in automotive applications, making it a preferred choice for components in critical safety systems, infotainment, and communication systems within vehicles.

Industrial and Military Devices Using Silver/AU QFN Leadframe

Silver/AU QNF Leadframe is also crucial for industrial and military devices, which often operate in demanding environments where reliability and durability are paramount. Industrial equipment, such as power control systems, industrial sensors, and heavy machinery, require leadframes that can handle high temperatures, humidity, and exposure to corrosive substances. Similarly, military-grade devices need semiconductor packages that can endure extreme conditions like vibration, shock, and exposure to harsh chemicals. Silver and gold leadframes offer the mechanical strength and corrosion resistance necessary to maintain the integrity and longevity of these devices. The Silver/AU QNF Leadframe ensures that semiconductor packages in industrial and military applications deliver consistent performance, even in challenging environments.

High-Speed Communication Equipment and Silver/AU QFN Leadframe

In the realm of high-speed communication equipment, such as networking devices, telecommunications, and radio frequency (RF) applications, low impedance and minimal signal loss are critical for ensuring efficient data transfer and communication. Silver/AU QNF Leadframe is particularly well-suited for these applications due to its exceptional electrical conductivity. Silver leadframes, in particular, minimize signal degradation, enabling high-speed signal processing in devices like routers, base stations, and mobile communication systems. The high thermal conductivity of silver and gold also aids in dissipating heat generated by high-frequency signals, ensuring that the components remain within optimal temperature ranges. By providing excellent electrical and thermal performance, Silver/AU QNF Leadframe enhances the reliability and efficiency of high-speed communication systems, which are vital for modern networking and telecom infrastructure.

Silver/AU QNF Leadframe is widely used across various industries, from consumer electronics to automotive, industrial, military, and high-speed communication systems. The combination of superior electrical performance, thermal conductivity, corrosion resistance, and mechanical strength makes silver and gold leadframes ideal for applications that require both high reliability and performance in challenging environments.

Future Trends in Leadframe Technology: Silver/AU QNF Leadframe

Advancements in Materials and Coatings for Silver/AU QFN Leadframe

The future of Silver/AU QNF Leadframe technology is likely to see continued advancements in materials and coatings to improve performance and reduce costs. Researchers are exploring new alloys and composite materials that combine the best properties of silver and gold while addressing some of their limitations, such as cost and mechanical strength. These new materials aim to provide even better electrical conductivity, thermal dissipation, and corrosion resistance. Additionally, advanced coatings like nano-coatings and hybrid metal coatings are being developed to further enhance the durability and performance of leadframes. These materials and coatings will offer improved resistance to harsh environments, making Silver/AU QNF Leadframe even more suitable for high-end applications in automotive, industrial, and aerospace sectors, where reliability is critical.

Innovation in plating techniques may lead to more cost-effective ways of applying silver and gold coatings. Techniques such as atomic layer deposition (ALD) or electrochemical deposition are being explored for more efficient, uniform coatings. These advancements will not only reduce the overall cost of Silver/AU QNF Leadframe but also improve their performance in demanding applications like high-speed communication equipment and consumer electronics.

Miniaturization and Performance Enhancements of Silver/AU QFN Leadframe

As electronic devices continue to shrink in size while increasing in performance, the demand for smaller and more efficient leadframes is on the rise. Silver/AU QNF Leadframe technology plays a significant role in meeting this need. Miniaturization of leadframes is essential to accommodate the ever-decreasing space available in modern devices such as smartphones, wearables, and automotive systems. At the same time, these devices require enhanced performance, including faster processing speeds and higher power efficiency.

The future of Silver/AU QNF Leadframe technology will involve developing even more compact leadframe designs while retaining their electrical and thermal performance capabilities. This will likely involve advances in microelectronics, such as the adoption of fine-pitch leadframe designs and the integration of new materials that can operate effectively at smaller scales. Enhanced performance will also be a priority, with manufacturers focusing on improving the conductivity and heat management properties of silver and gold leadframes. These advancements will ensure that Silver/AU QNF Leadframe can continue to meet the rigorous demands of next-generation electronics, where both size and efficiency are crucial.

Green and Sustainable Manufacturing of Silver/AU QFN Leadframe

Sustainability is becoming an increasingly important consideration in leadframe production, and this trend is expected to continue in the future. The electronics industry, including Silver/AU QNF Leadframe manufacturing, is under pressure to reduce its environmental footprint. This has led to the development of eco-friendly materials and more sustainable manufacturing processes. Researchers are working on alternatives to traditional silver and gold materials that are both cost-effective and have a lower environmental impact. Some of these alternative materials are being tested for their potential to provide similar electrical and thermal performance, while being more eco-friendly.

In addition to the materials themselves, the processes used to produce Silver/AU QNF Leadframe are evolving to become greener. For example, more sustainable electroplating and coating methods are being developed to reduce waste and energy consumption during the production process. The use of recyclable and non-toxic chemicals, as well as cleaner energy sources in manufacturing, is becoming a key focus to ensure that leadframe production meets environmental standards. These changes will not only help reduce the carbon footprint of leadframe manufacturing but will also appeal to eco-conscious industries looking to meet sustainability goals.

The future of Silver/AU QNF Leadframe technology is poised for significant advancements. The development of new materials and coatings will enhance performance while reducing costs, miniaturization will drive more compact and efficient designs, and sustainable manufacturing practices will ensure that the technology meets environmental standards. These trends will continue to support the growth of high-performance, reliable, and eco-friendly electronic devices across various industries.