Elevating RF: Rogers TMM Products Overview

Established as a premier provider of high-performance material solutions, Rogers Corporation has consistently pushed the boundaries of innovation. With a rich history spanning decades, Rogers has earned global recognition for its commitment to excellence and pioneering advancements in various industries. Central to its portfolio is the Thermoset Microwave Materials (TMM) product series, renowned for its paramount importance in microwave and RF applications. Through meticulous research and development, Rogers TMM products have become synonymous with reliability, efficiency, and unmatched performance. As we delve into the intricacies of the Rogers TMM series, we uncover a world where cutting-edge technology meets the demands of modern telecommunications, aerospace, automotive, and beyond.

Overview of Rogers TMM Product Series

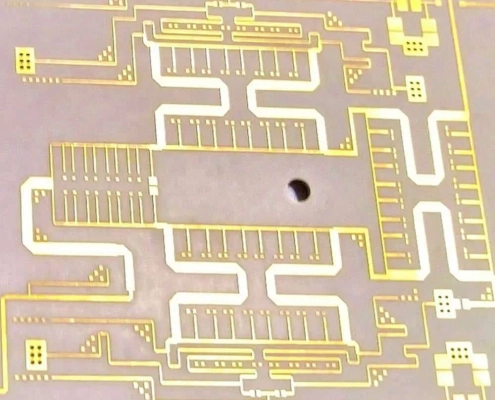

The Rogers TMM (Thermoset Microwave Materials) product series constitutes a comprehensive array of high-performance materials meticulously engineered to meet the stringent demands of microwave and RF (Radio Frequency) applications. Characterized by exceptional dielectric properties, thermal stability, and mechanical strength, the TMM series stands as a testament to Rogers Corporation’s dedication to technological excellence.

- Rogers TMM10:

- TMM10 embodies a high-performance material ideal for applications requiring exceptional electrical properties and mechanical stability.

- Its low dielectric constant and loss tangent make it suitable for high-frequency circuits, microstrip antennas, and radar systems.

- TMM10 offers excellent dimensional stability, ensuring consistent performance across a wide range of operating conditions.

- Rogers TMM3:

- TMM3 is renowned for its superior dielectric properties and thermal stability, making it a preferred choice for microwave circuit substrates.

- With a low dielectric constant and low loss tangent, TMM3 is well-suited for high-frequency communication systems, satellite communications, and phased array antennas.

- Its exceptional electrical performance enables enhanced signal integrity and reduced signal loss in RF applications.

- Rogers TMM6:

- TMM6 stands out for its versatility and reliability, catering to a diverse range of microwave and RF circuit designs.

- Offering a balance of electrical and mechanical properties, TMM6 finds applications in power amplifiers, base station antennas, and satellite communications.

- Its excellent thermal conductivity and dimensional stability ensure robust performance in demanding environments.

- Rogers 92ML:

- Rogers 92ML is characterized by its high dielectric constant and low loss, making it suitable for high-frequency, high-speed digital applications.

- Commonly used in millimeter-wave radar systems, automotive collision avoidance systems, and high-speed digital communication networks.

- Its exceptional signal integrity and reliability make it an indispensable choice for next-generation electronic devices.

- Rogers CT:

- CT (Ceramic Thermoset) materials offer exceptional thermal conductivity and mechanical strength, making them ideal for power electronics and thermal management applications.

- Widely utilized in power amplifiers, RF transmitters, and automotive electronic control units (ECUs) for efficient heat dissipation and thermal stability.

- Rogers CLTE:

- CLTE (Ceramic Laminated Thermoset) materials combine the benefits of high-frequency performance and thermal management capabilities.

- Suitable for demanding applications such as 5G base stations, aerospace radar systems, and medical imaging equipment where thermal stability and RF performance are critical.

- Rogers AES:

- AES (Advanced Engineered Solutions) materials offer advanced performance for demanding RF and microwave applications.

- Designed for automotive radar sensors, medical imaging devices, and aerospace communication systems, AES materials deliver exceptional electrical performance and reliability.

Each product within the Rogers TMM series is meticulously engineered to address specific challenges in microwave and RF applications, providing engineers and designers with unparalleled performance, reliability, and innovation.

Conclusion

FAQs About Rogers TMM

What is TMM10i material?

TMM10i is an advanced thermoset microwave material developed by Rogers Corporation. It is known for its exceptional electrical properties, including a low dielectric constant, making it suitable for high-frequency applications in microwave and RF circuits.

What is the dielectric constant of TMM4?

The dielectric constant of TMM4 is typically around 4.5 to 5.0, depending on specific formulations and manufacturing processes. TMM4 is commonly used in microwave circuit substrates and RF applications where moderate dielectric constants are desired.

What is the dielectric constant of tmm3?

TMM3, another material from Rogers Corporation’s TMM series, typically exhibits a dielectric constant ranging from approximately 3.0 to 3.4. This low dielectric constant makes TMM3 suitable for high-frequency communication systems, satellite communications, and phased array antennas, where signal integrity is crucial.

What is the dielectric constant of TMM10i?

The dielectric constant of TMM10i specifically depends on its formulation and manufacturing specifications. However, like other materials in the TMM series, TMM10i is engineered to have a low dielectric constant, ensuring excellent electrical performance in microwave and RF applications.